Device and method for cleaning fume exhauster

A technology for cleaning devices and range hoods, which is applied to cleaning methods and appliances, cleaning methods using liquids, and oil fume removal, etc., which can solve the problems of easy leakage of cleaning liquid from the bottom of the wind wheel 15, inability to wash the oil stains of the wind wheel 15, and limited cleaning area and other problems to achieve better cleaning effect, convenient control and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

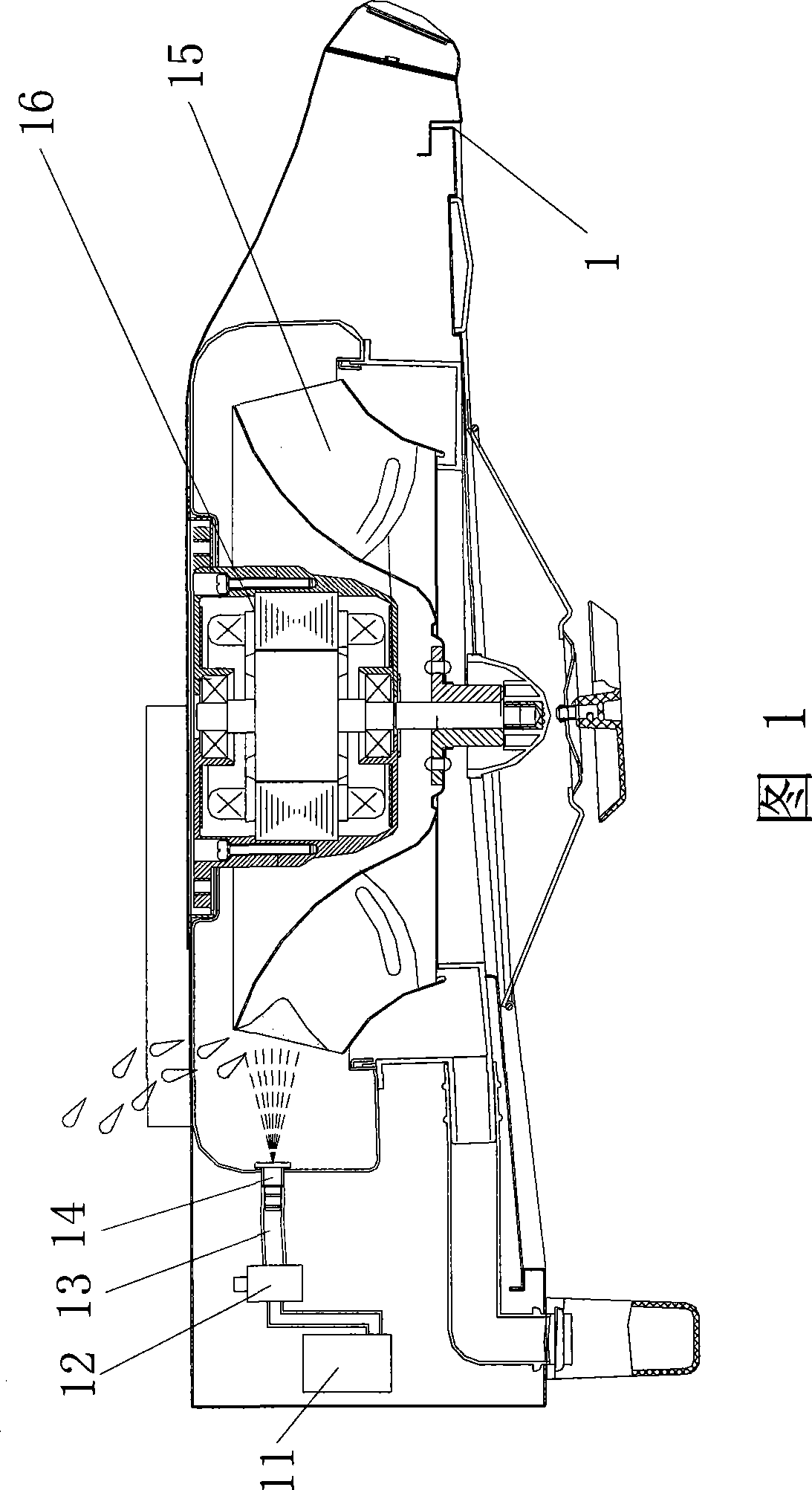

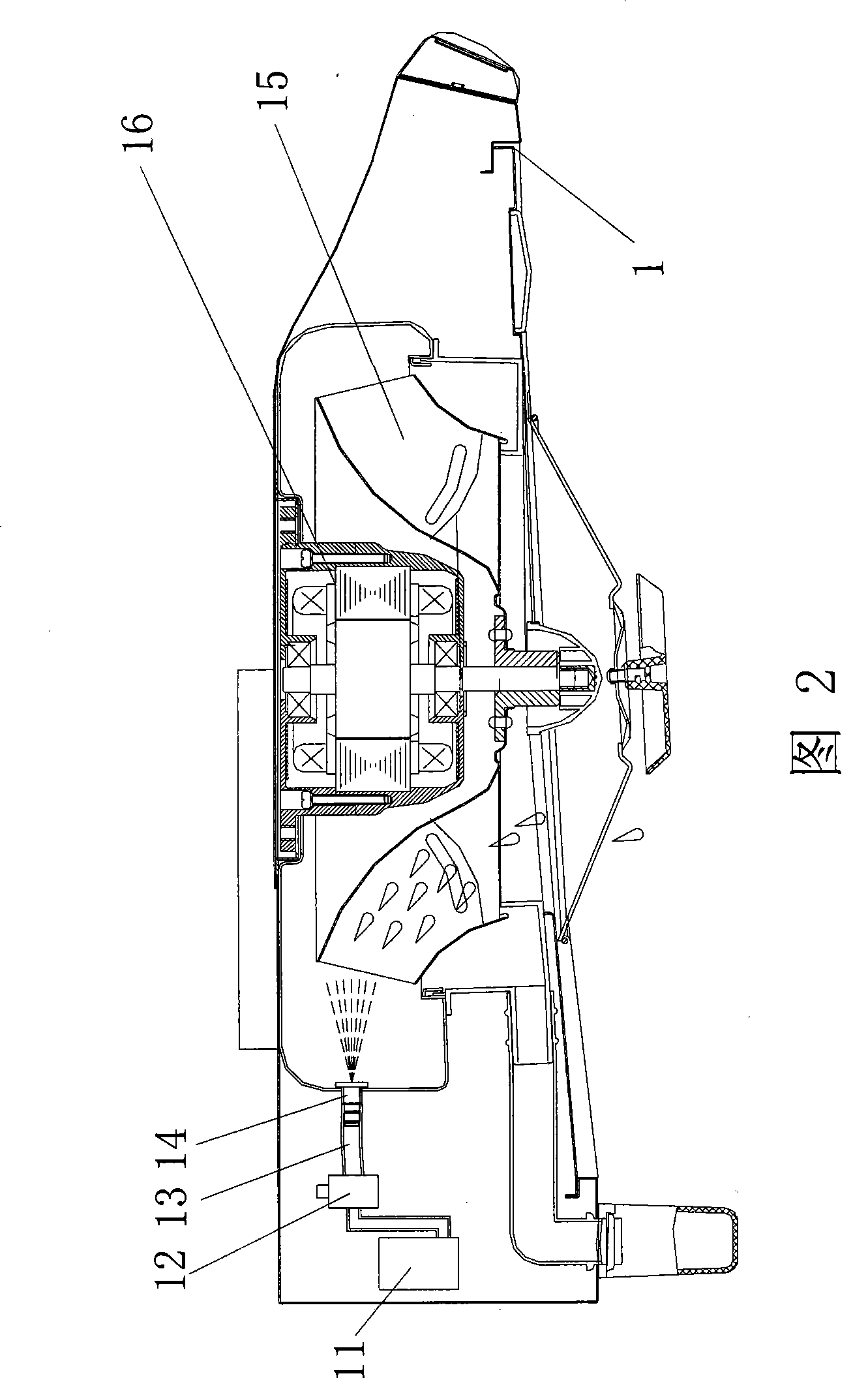

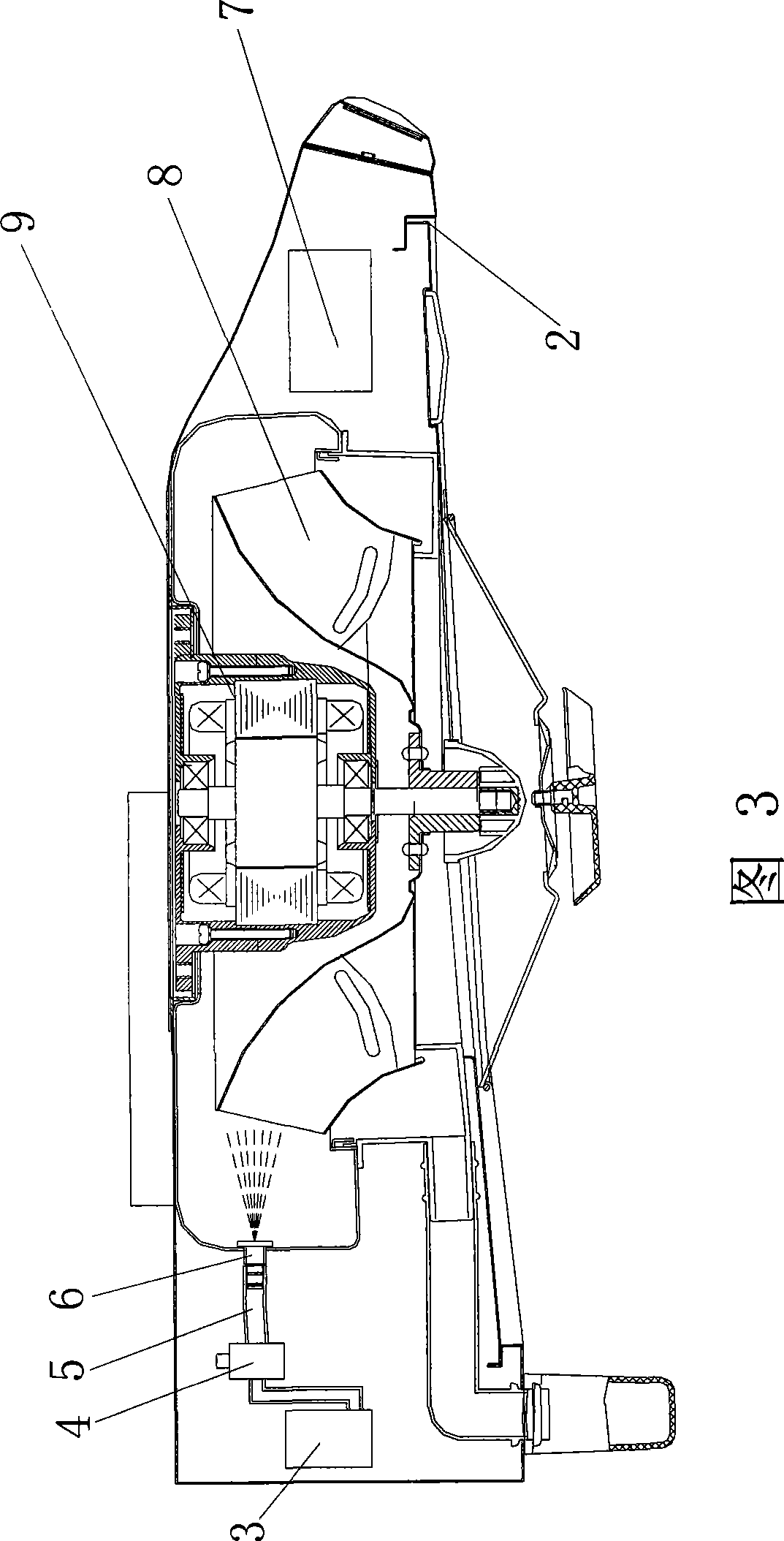

[0038] As shown in Figure 3, Figure 4 As shown, a range hood cleaning device includes a water tank 3 installed on the range hood 2, a water pump 4, a water supply pipe 5, a wind wheel 8, a motor 9 for driving the wind wheel 8, and a cleaning program controller 7, and the water tank 3 uses To contain cleaning liquid, the water inlet of the water pump 4 is connected to the water tank 3, the water outlet of the water pump 4 is connected to the water inlet of the water supply pipe 5, and the water outlet of the water supply pipe 5 is provided with a cleaning nozzle 6, and the cleaning nozzle 6 is located at the bottom of the range hood 2. On the wall of the outer edge of the wind chamber. When the water pump 4 is working, the cleaning solution in the water tank 3 is drawn out and sprayed out from the cleaning nozzle 6. The spraying direction of the cleaning nozzle 6 is aligned with the blade of the range hood 2 and the wind wheel 8, which is beneficial to apply the cleaning soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com