Dust removing and explosion preventing apparatus for wood dust explosion

A technology of dust explosion and explosion-proof device, applied in the field of wood processing, can solve the problems of large manpower and material resources, poor explosion-proof effect, short service life, etc., to achieve the effect of small footprint, avoid noise pollution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

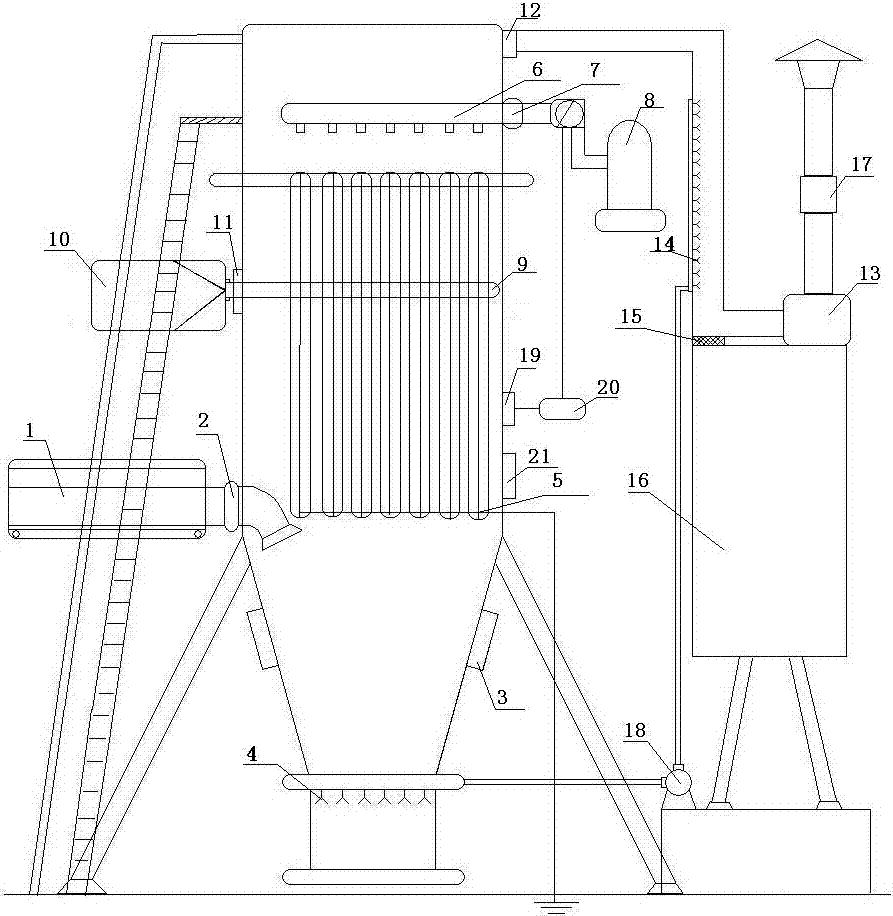

[0024] Such as figure 1 As shown, the dust removal and explosion-proof device for wood dust explosion includes a wood dust conveyor, a bag filter and an exhaust chimney, and is characterized in that: the wood dust conveyor is a closed belt conveyor 1, and the closed belt conveyor 1 and bag The dust collectors are connected through the explosion-proof valve 2, and the explosion-proof valve 2 controls the feeding of the bag filter inlet. The ash is clean and thorough, and the control is simple and accurate, especially with a long service life. It can be used in the environment of high temperature, high pressure and dusty media, eliminating the phenomenon of "blocking" and "tower arch" of the ash hopper. The top of the ash hopper unloader is set There is a sprinkler 4, which can spray bio-nanofilm agents or water to better prevent the discharge from detonating in the air. The filter bags of the bag filter contain metal wires 5, which are connected to the bag filter. The metal sh...

Embodiment 2

[0026] Such as figure 1 As shown, the dust removal and explosion-proof device for wood dust explosion includes a wood dust conveyor, a bag filter and an exhaust chimney, and is characterized in that: the wood dust conveyor is a closed belt conveyor 1, and the closed belt conveyor 1 There is an electromagnetic separator above the material flow to remove static electricity from the material and avoid explosion during transmission. A temperature measuring device is installed on the shaft of the belt conveyor to monitor the temperature in real time to avoid explosion accidents caused by excessive temperature. The closed belt type The conveyor 1 is connected to the bag filter through an explosion-proof valve 2, which controls the feeding of the bag filter inlet. A vibrator 3 is installed on the ash bucket wall of the bag filter to Strong force, clean and thorough dust removal, simple and accurate control, especially long service life, can be used in high temperature, high pressure,...

Embodiment 3

[0028] Such as figure 1 As shown, the dust removal and explosion-proof device for wood dust explosion includes a wood dust conveyor, a bag filter and an exhaust chimney, and is characterized in that: the wood dust conveyor is a closed belt conveyor 1, and the closed belt conveyor 1 There is an electromagnetic roller above the material flow to remove static electricity from the material and avoid explosions during transmission. A temperature measuring device is installed on the shaft of the belt conveyor to monitor the temperature in real time to avoid explosion accidents caused by excessive temperature. The closed belt type The conveyor 1 is connected to the bag filter through an explosion-proof valve 2, which controls the feeding of the bag filter inlet. A vibrator 3 is installed on the ash bucket wall of the bag filter to Strong force, clean and thorough dust removal, simple and accurate control, especially long service life, can be used in high temperature, high pressure, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com