Patents

Literature

290results about How to "Prevent deflagration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

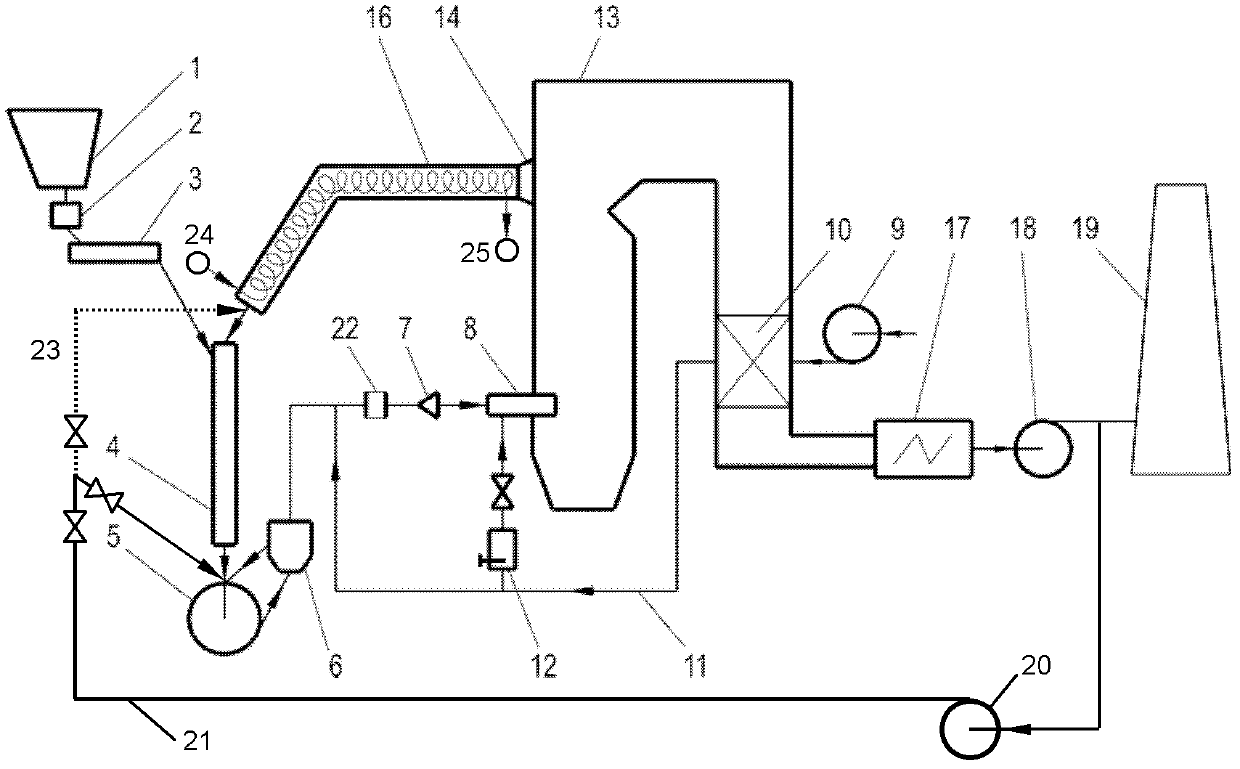

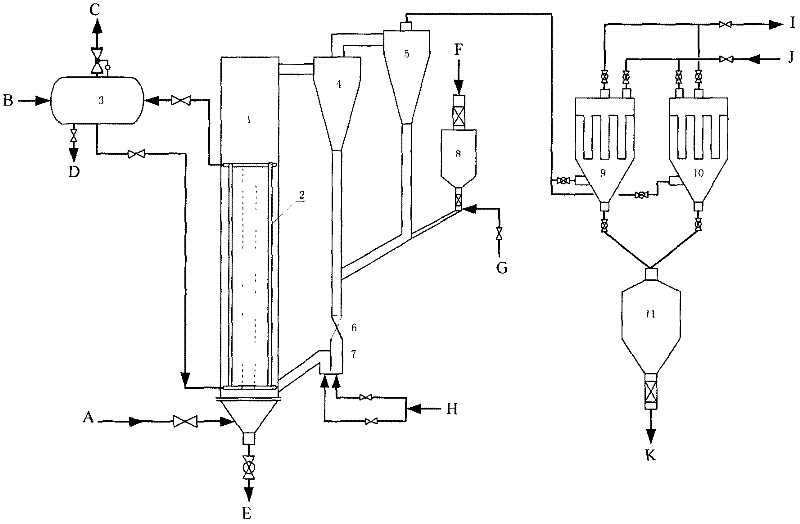

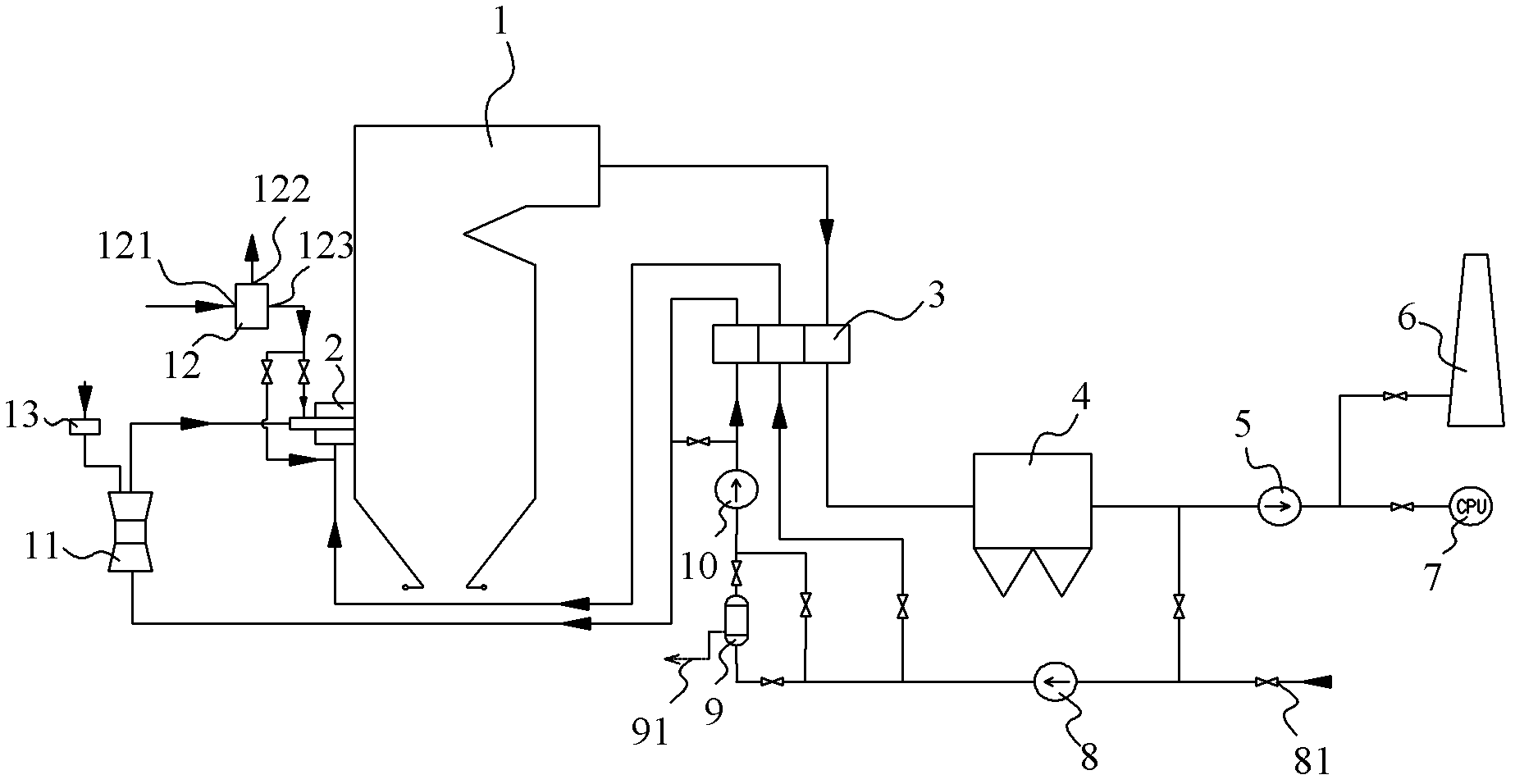

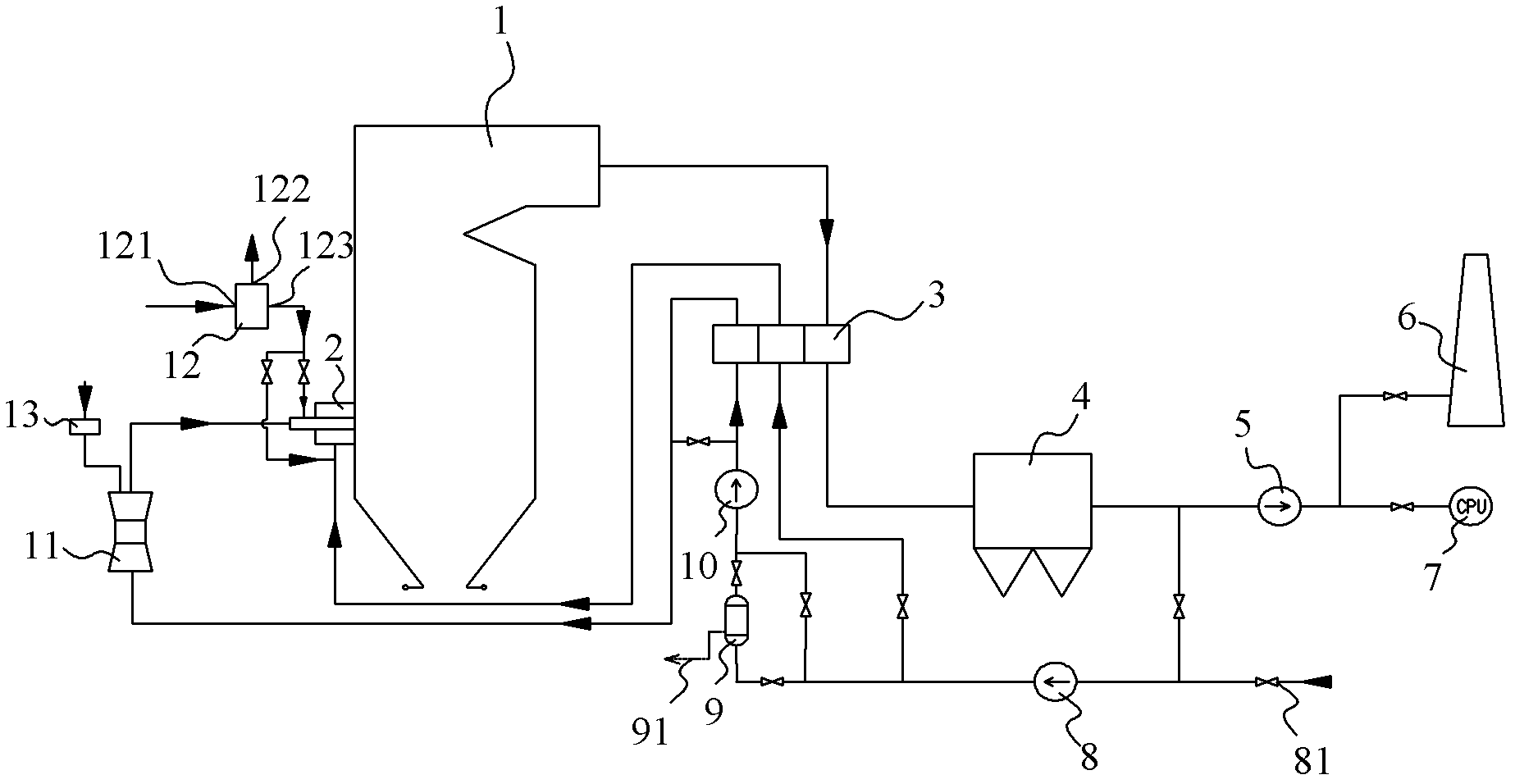

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

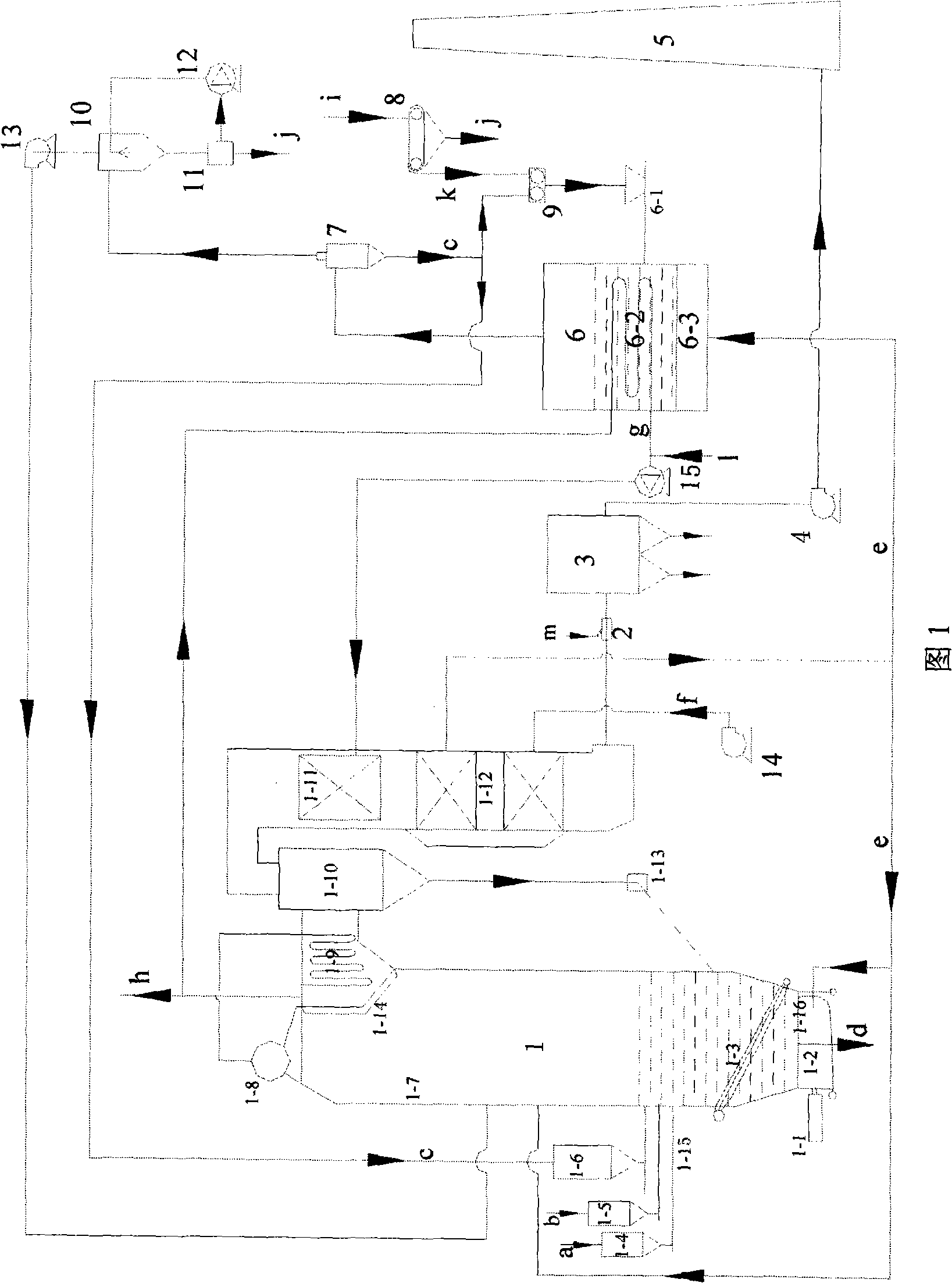

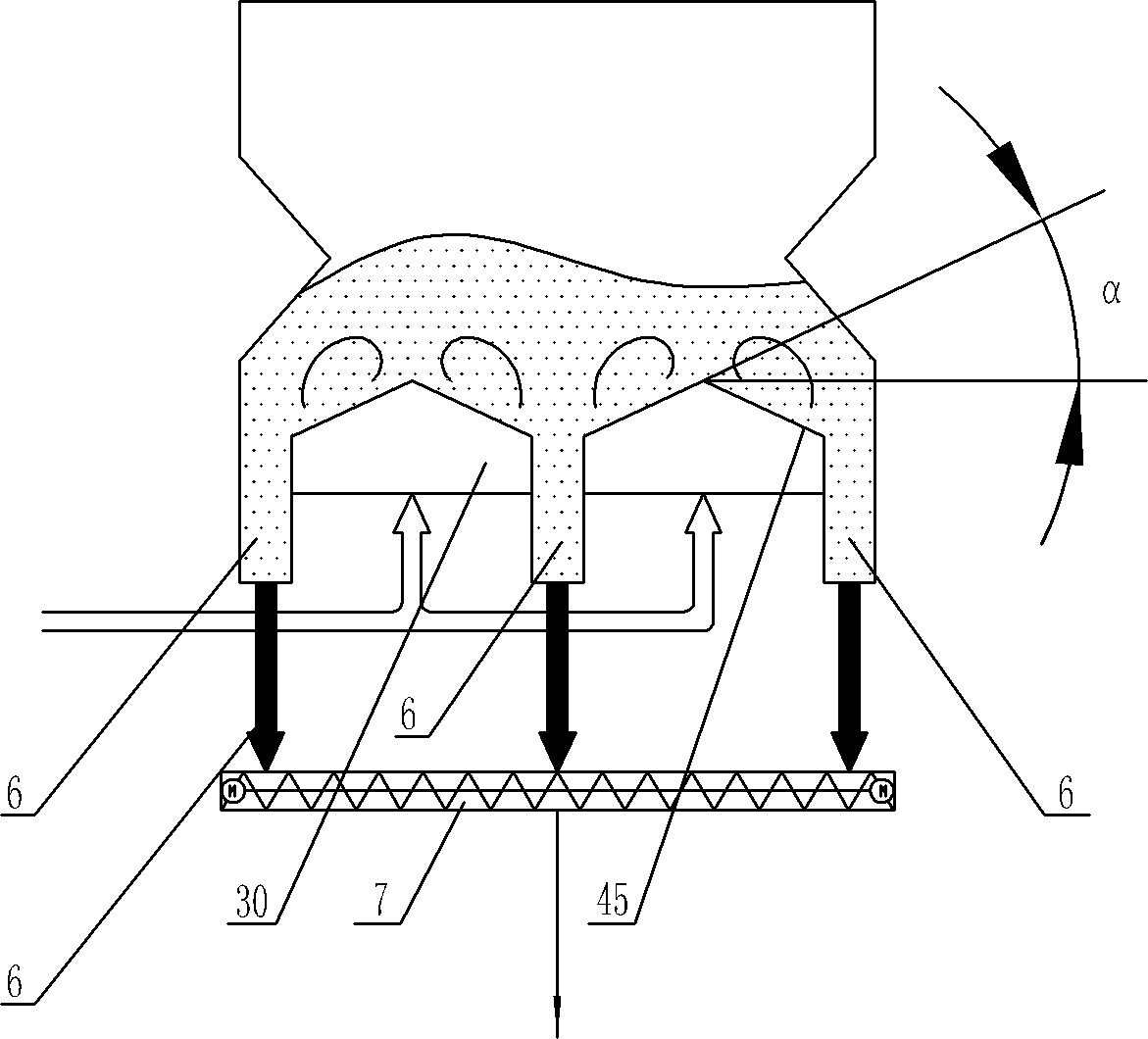

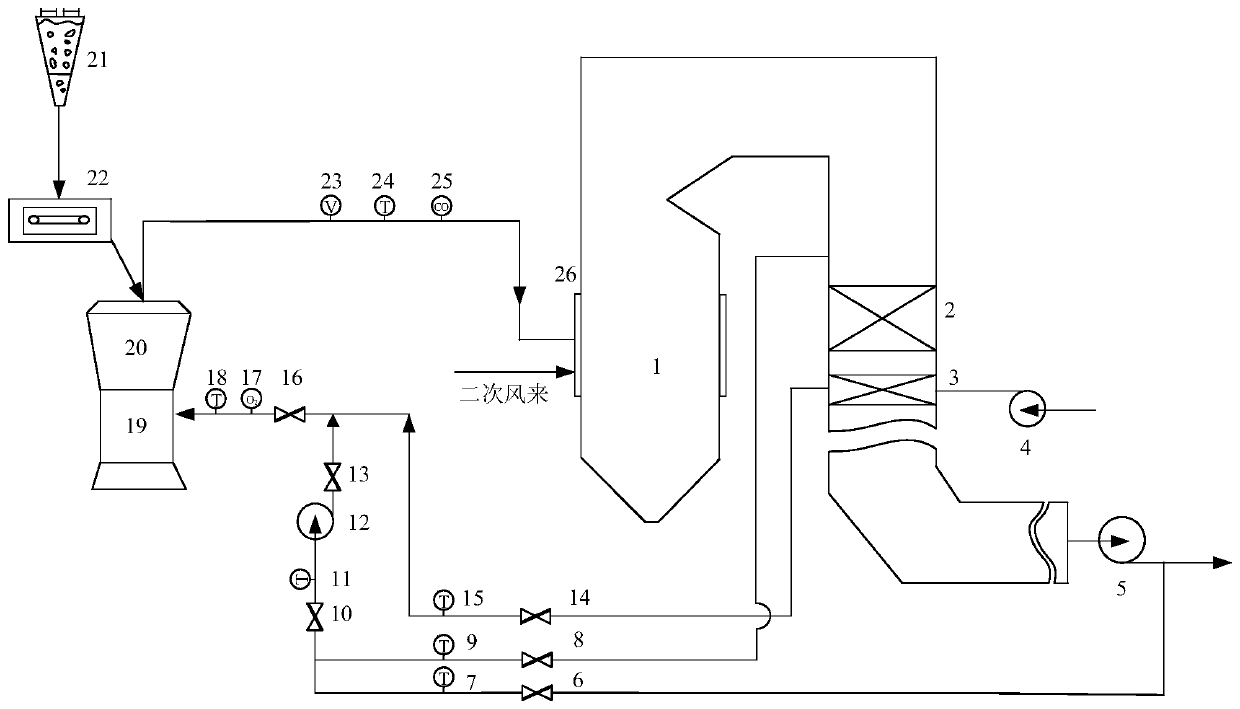

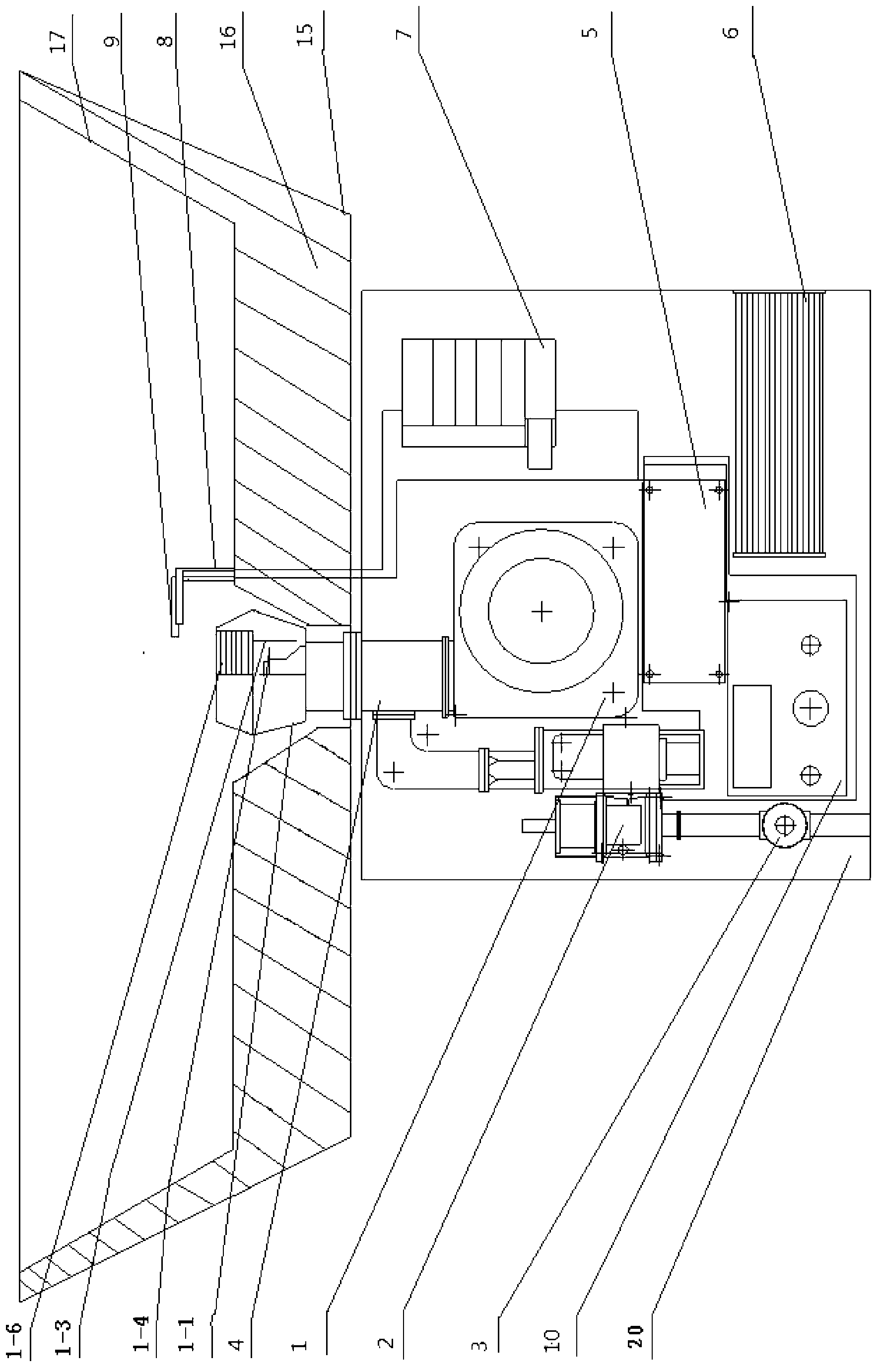

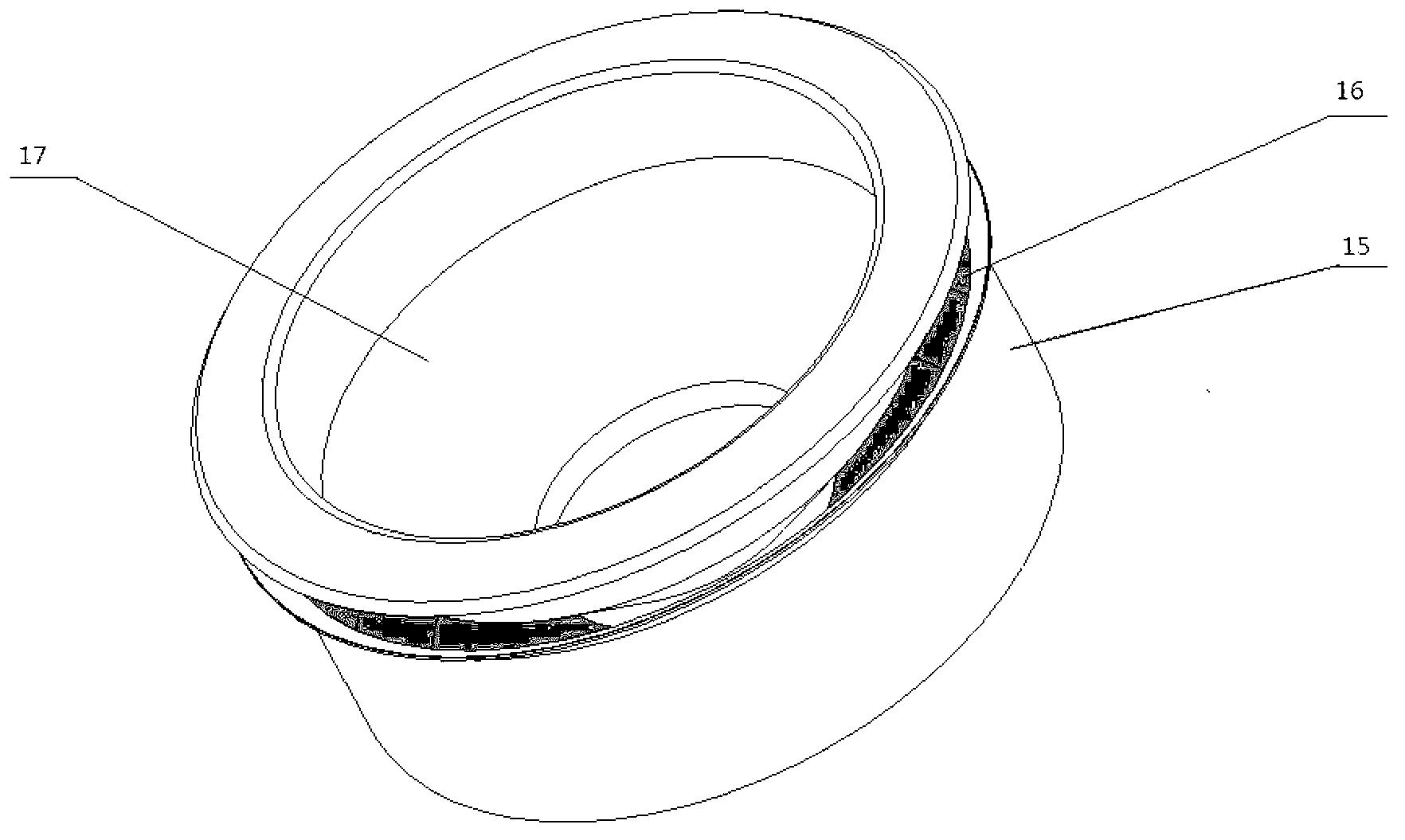

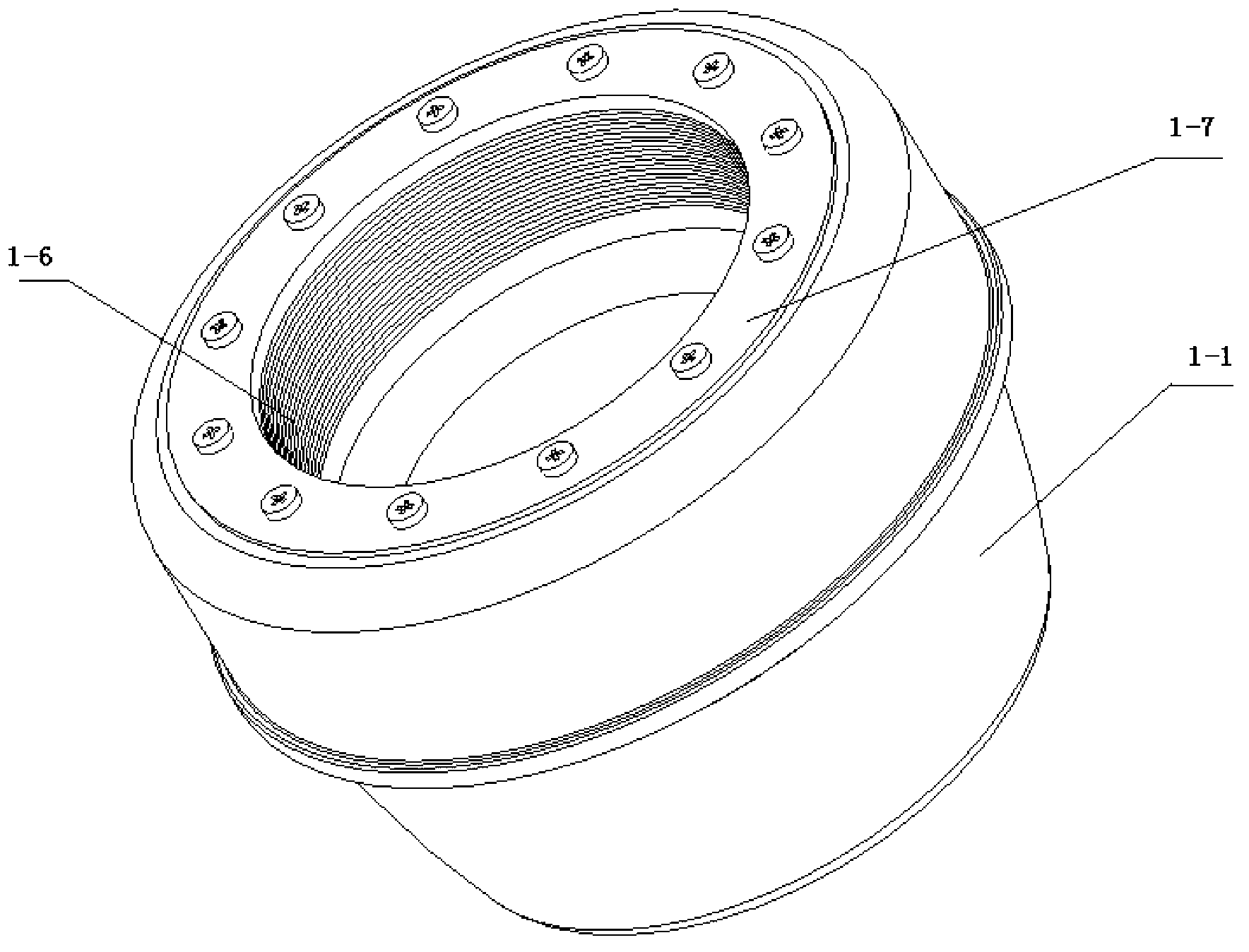

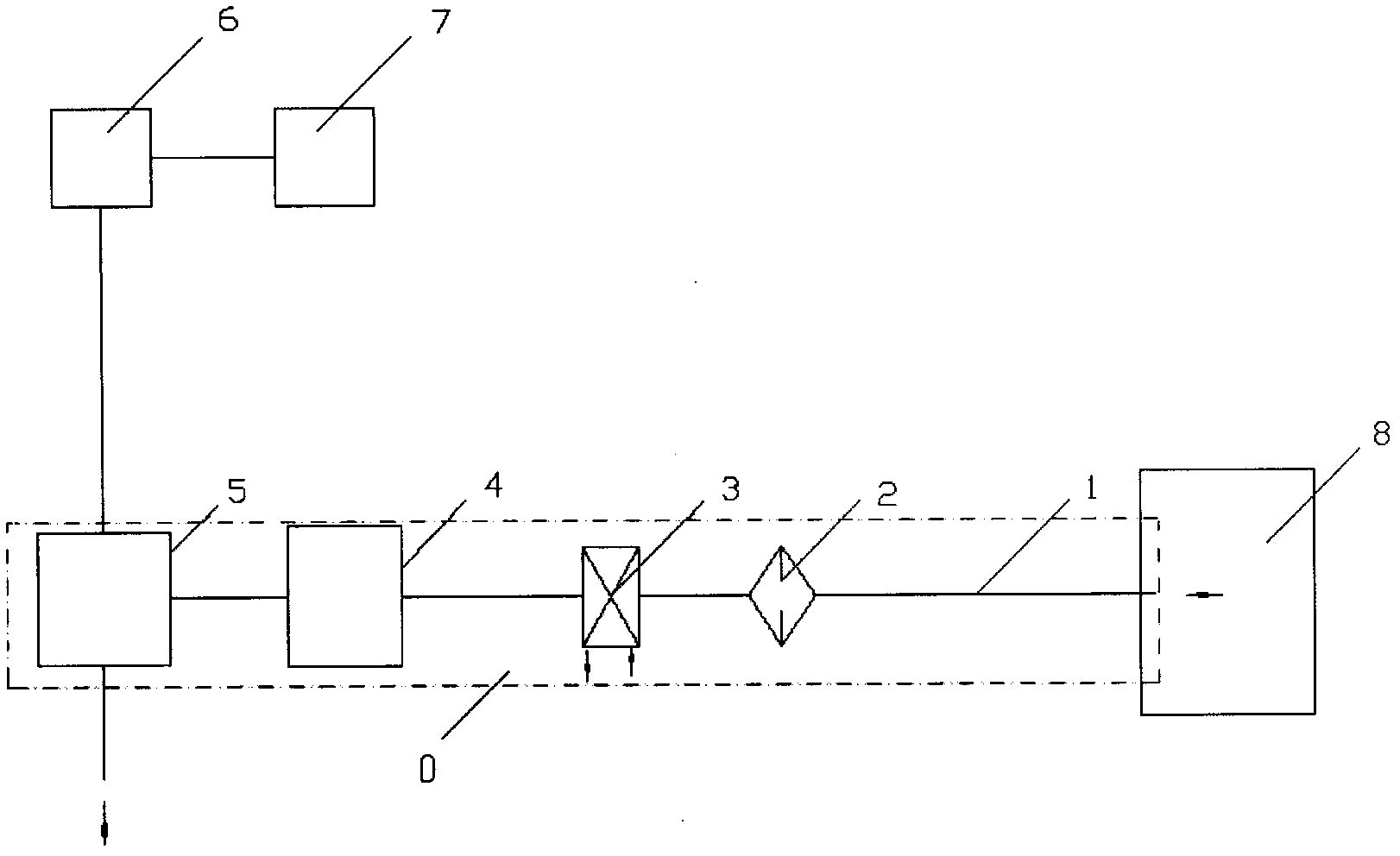

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

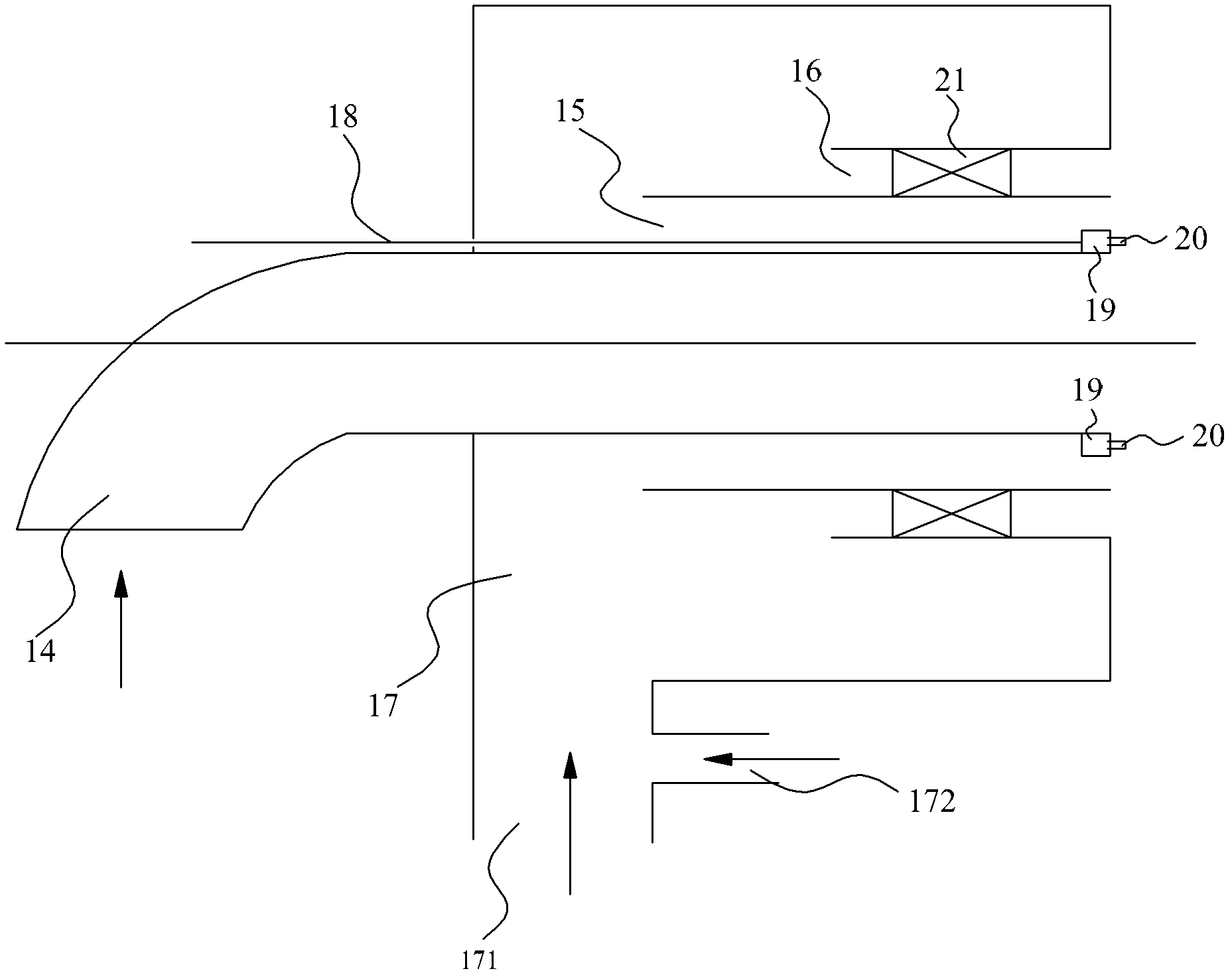

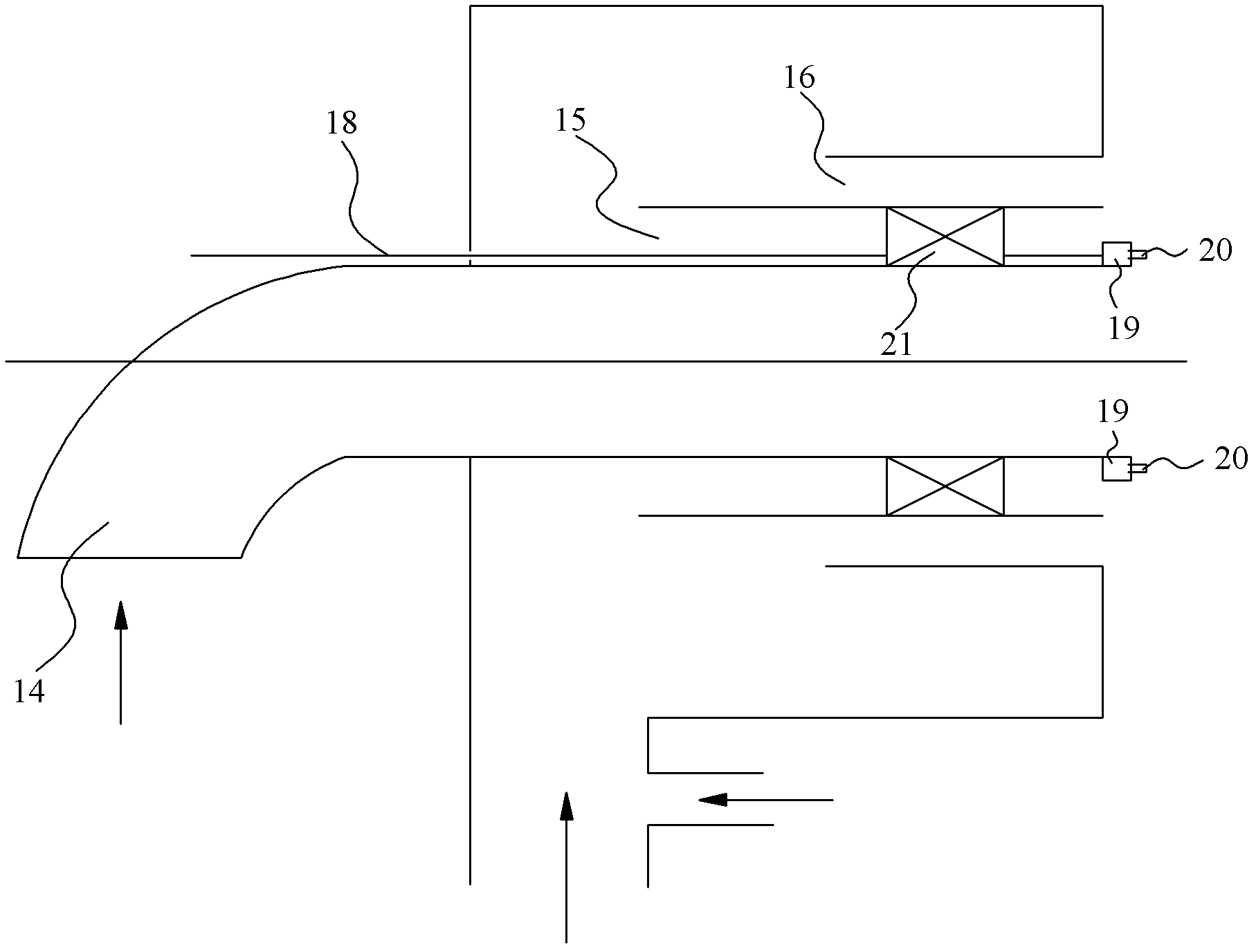

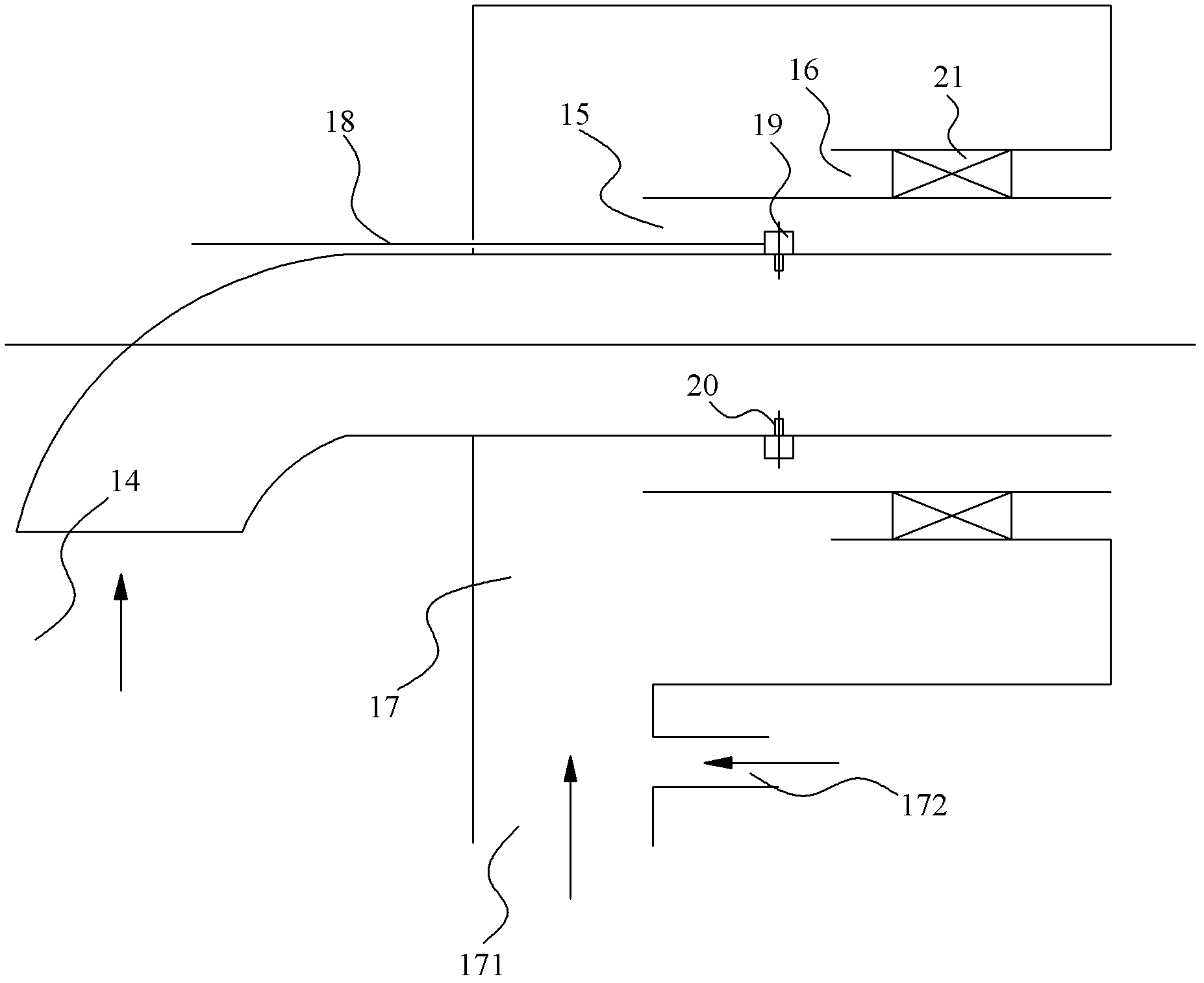

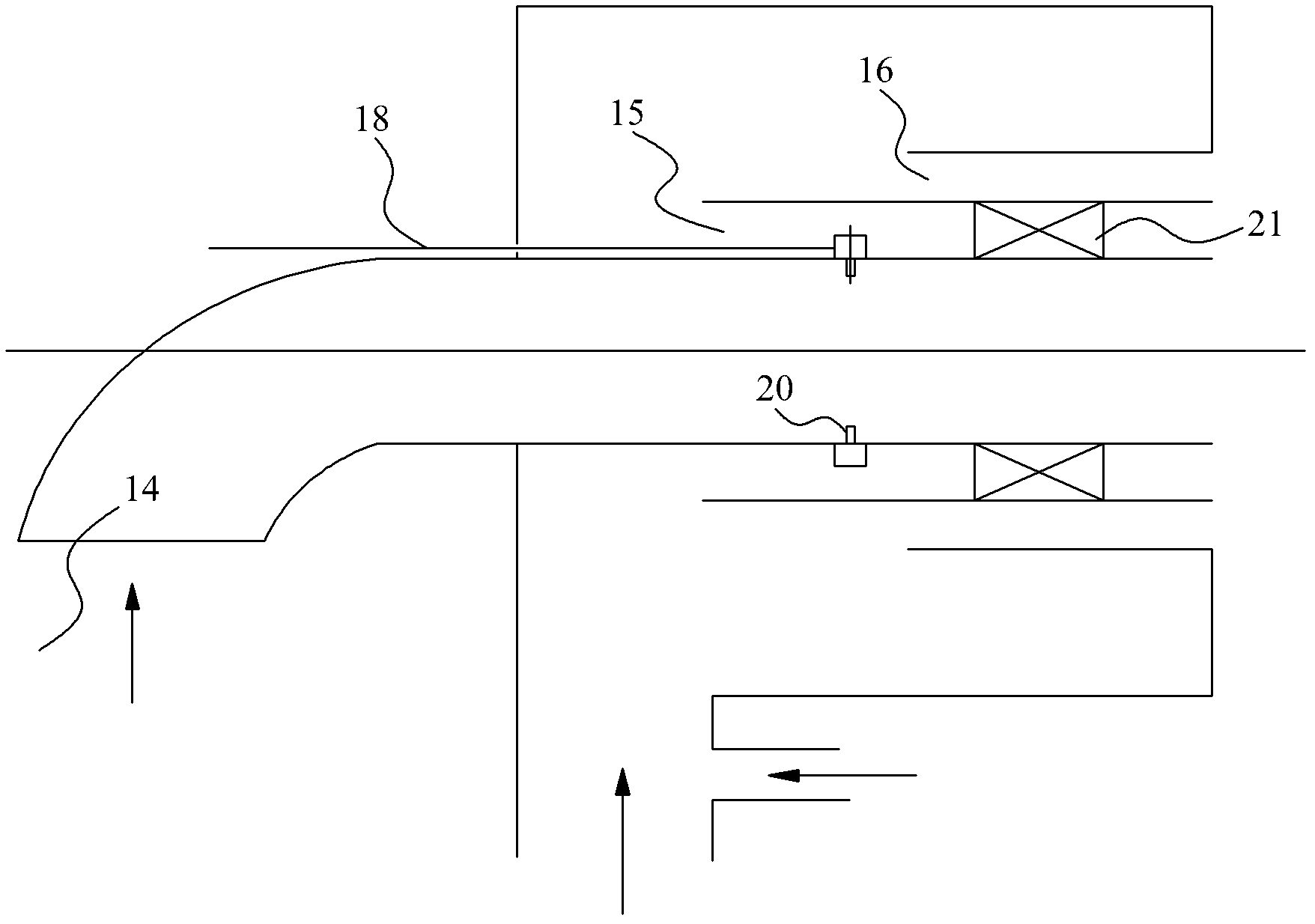

High-efficiency oil sludge pyrolysis oil making method and system

InactiveCN104261649AReduce moisture contentPrevent deflagrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAtmospheric airOil sludge

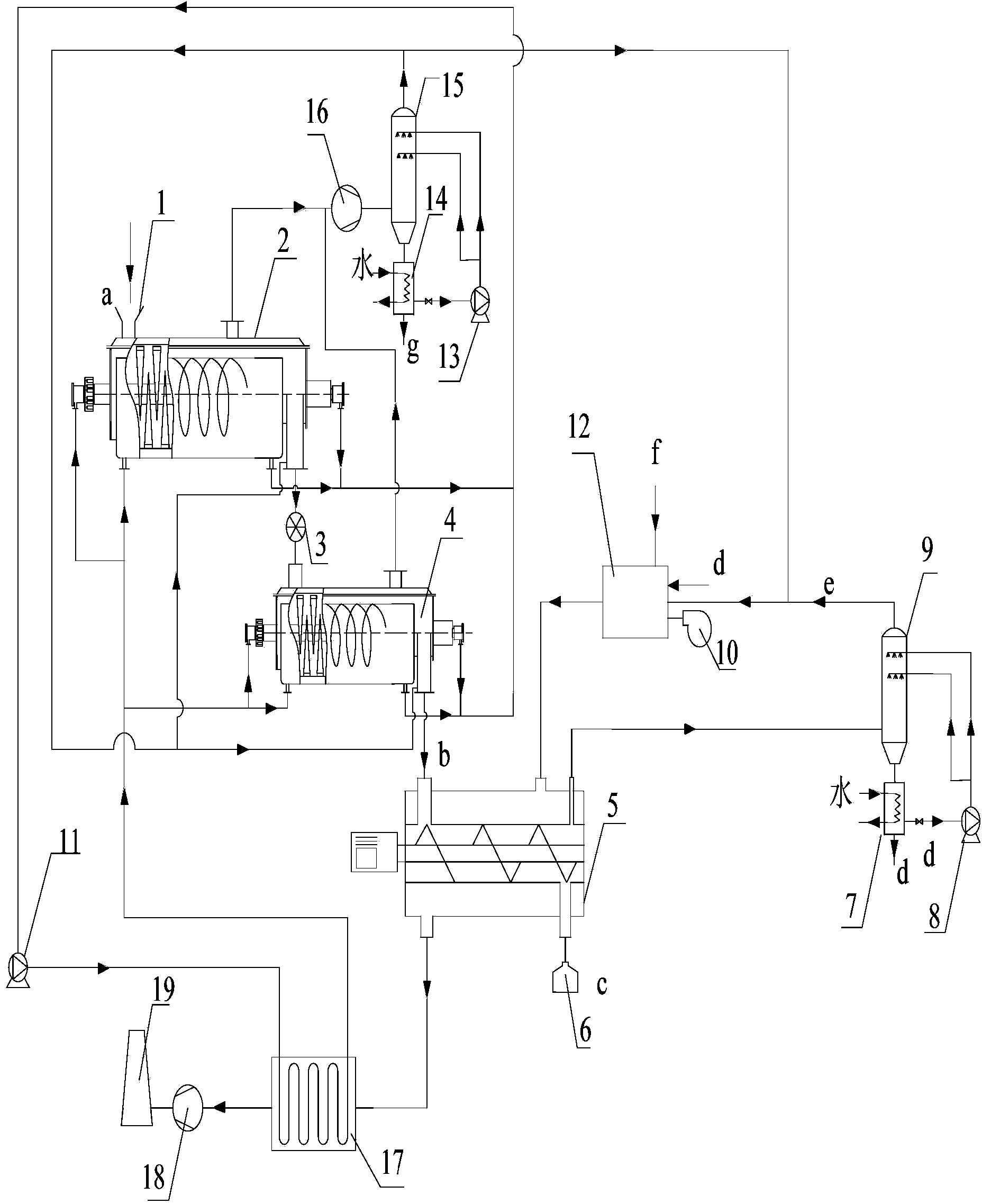

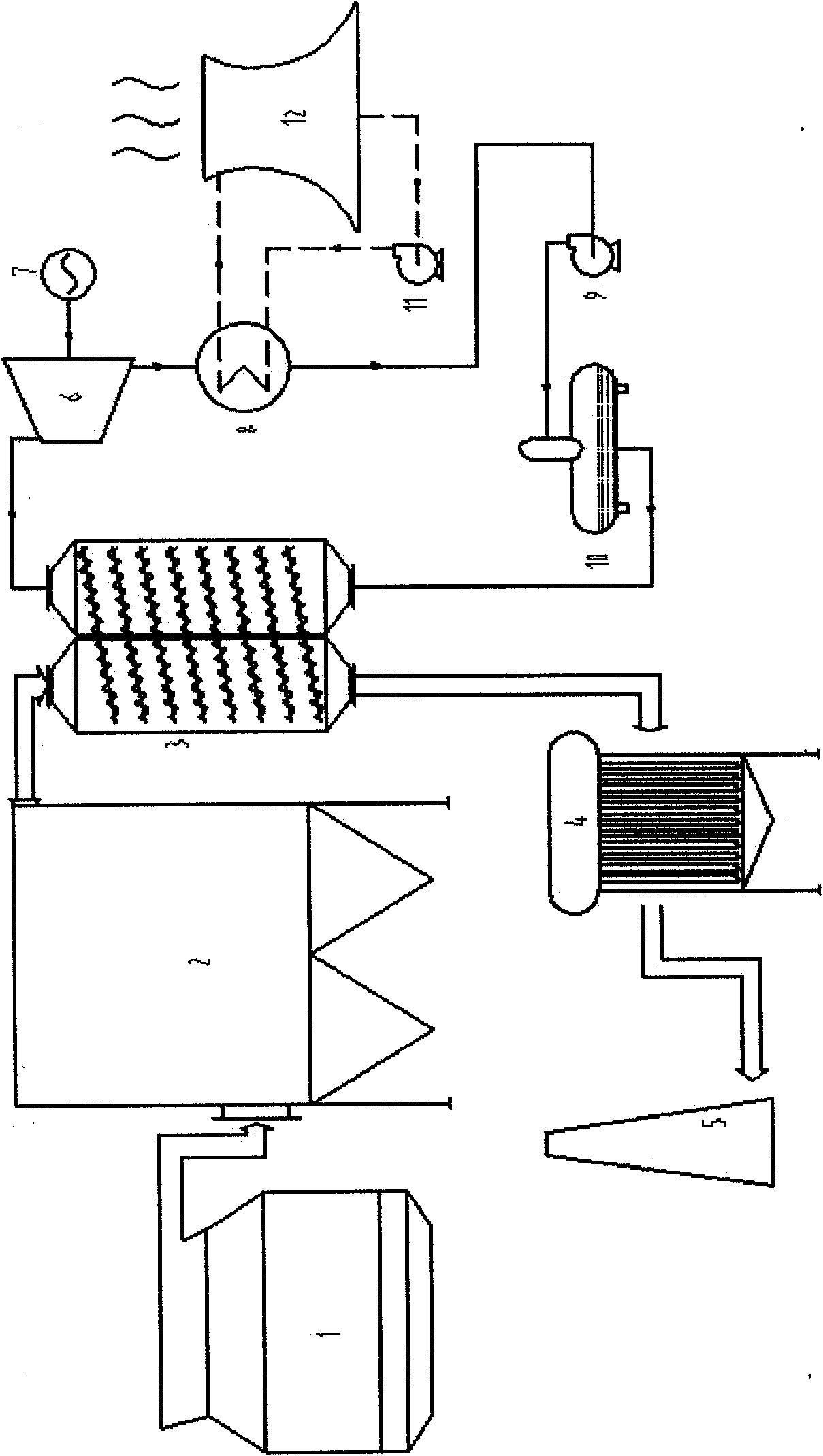

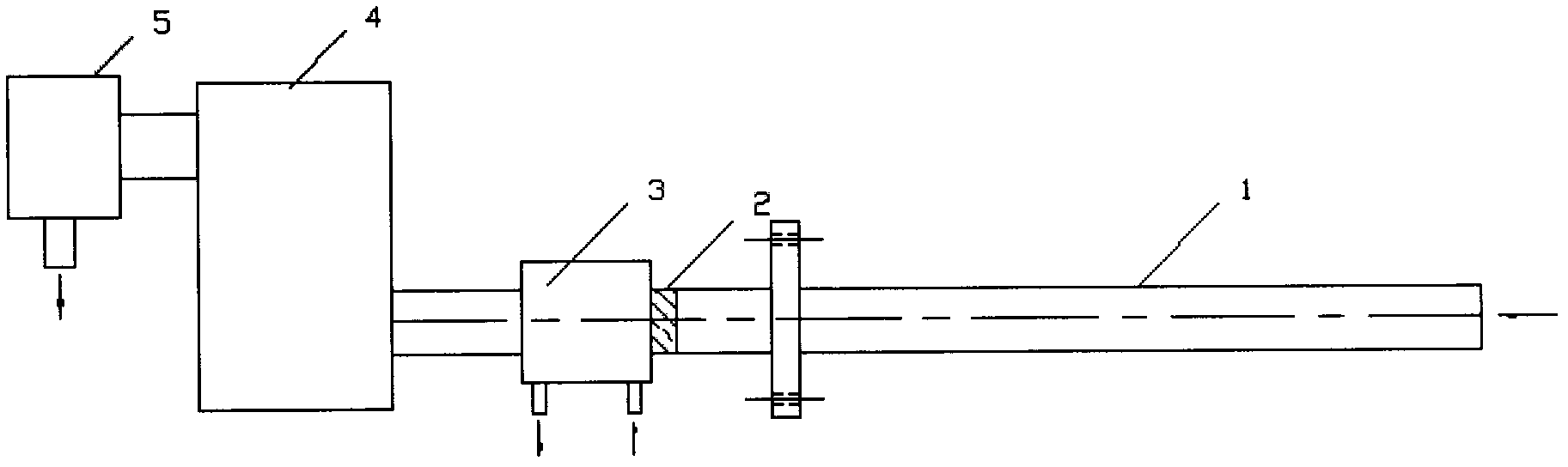

The invention discloses a high-efficiency oil sludge pyrolysis oil making method and system and belongs to the technical field of solid waste recycling and environment. Crude oil sludge is subjected to deep drying and breaking treatment by virtue of a two-stage blade-type dryer and then enters a spiral pyrolyzing furnace, and produced pyrolysis gas is subjected to spray cooling to obtain an oil product; noncondensing gas and part of pyrolysis oil which are produced in a drying and pyrolysis process are fed into a burning furnace to be burned, and high temperature smoke produced during burning is used for providing heat for a pyrolysis furnace; smoke at an outlet of a jacket of the pyrolysis furnace passes through a heat conduction oil heat exchanger to recycle waste heat and then is discharged into the air; and the heat conduction oil after being heated provides heat for the blade-type dryer. Therefore, the high-efficiency oil sludge pyrolysis oil making method and system are safe and reliable, drying pyrolysis efficiency is high, the oil product in the sludge can be recycled, gradient utilization of energy is realized, and oil sludge recycling and harmless treatment is realized.

Owner:SOUTHEAST UNIV

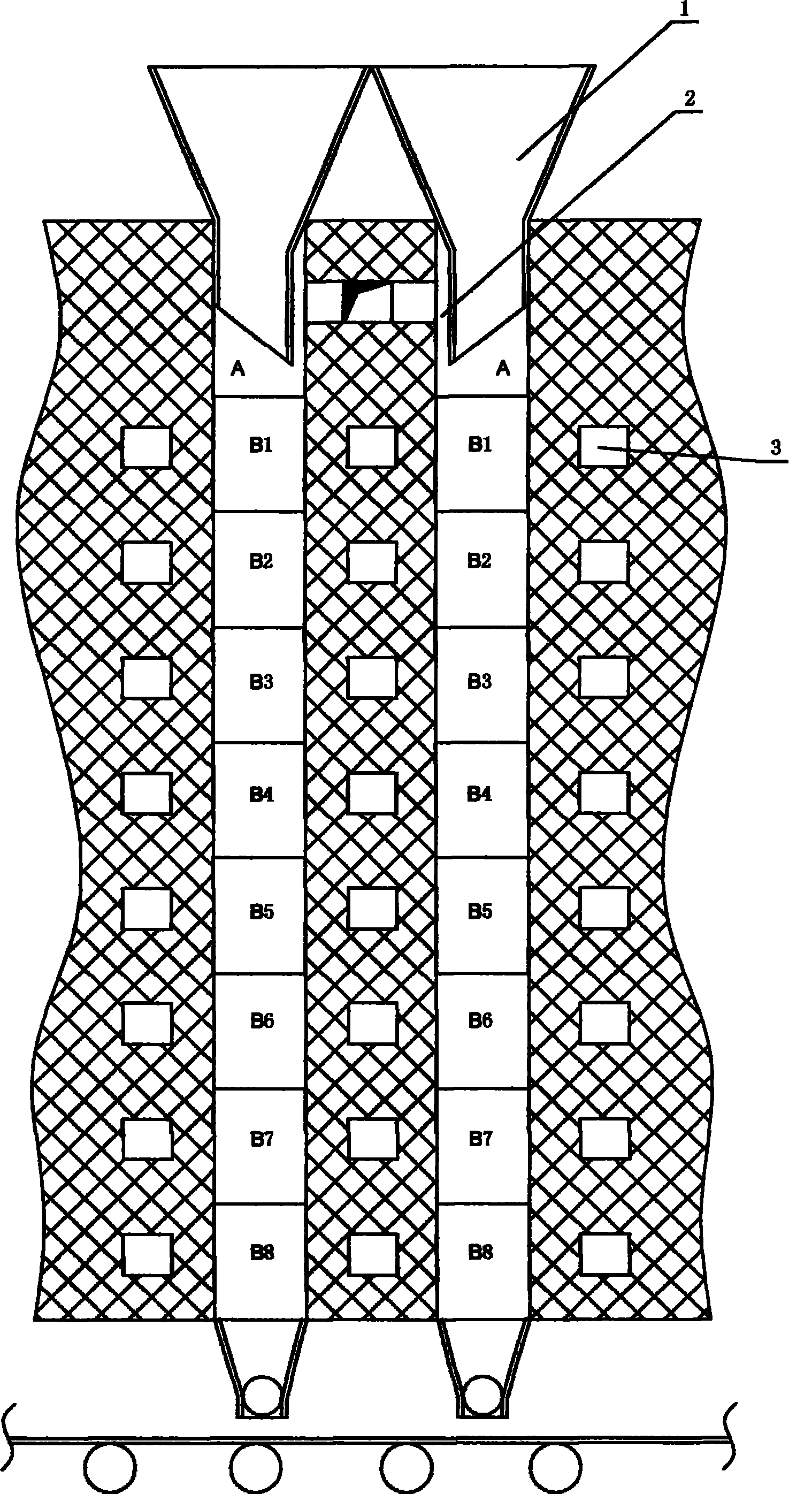

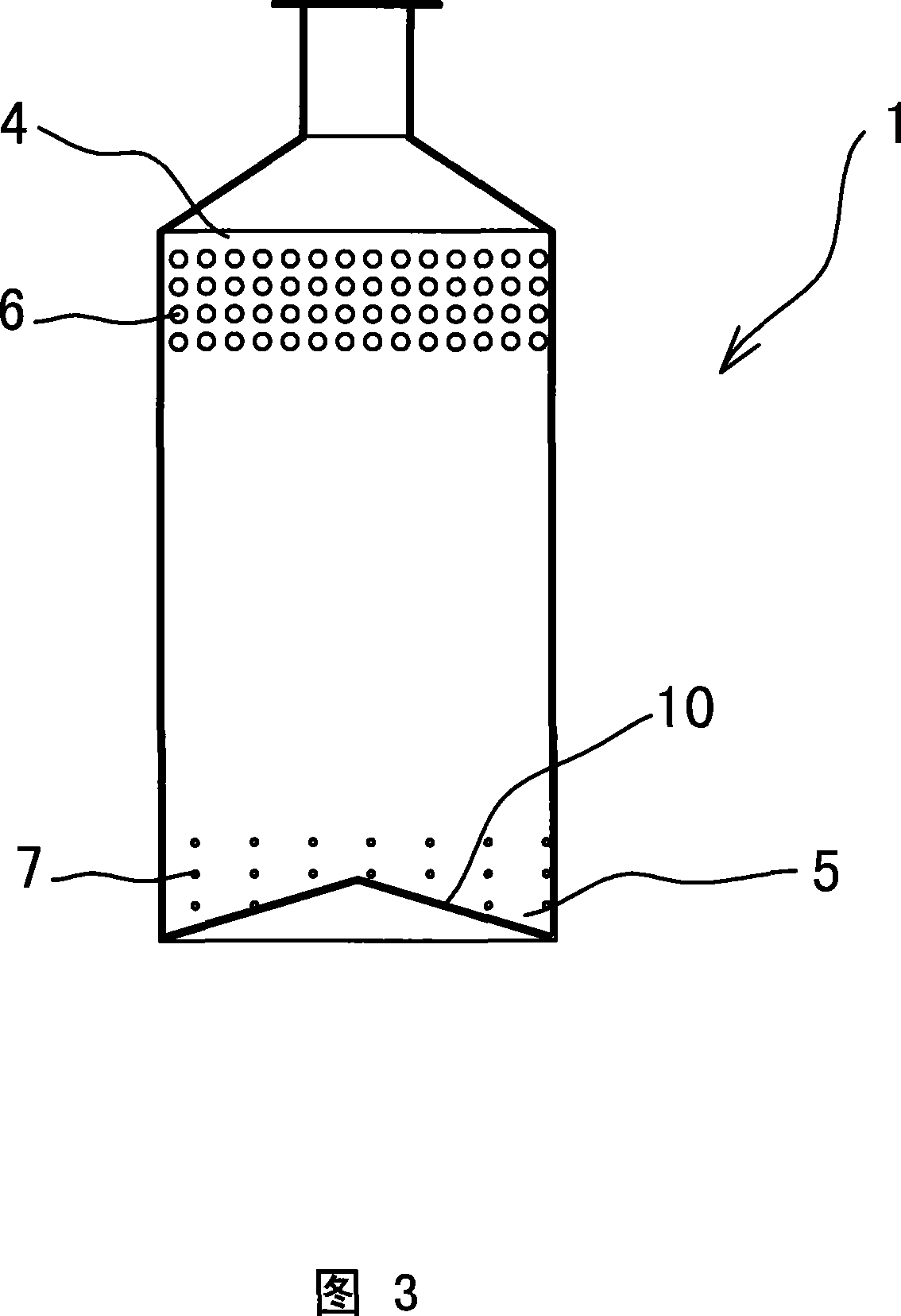

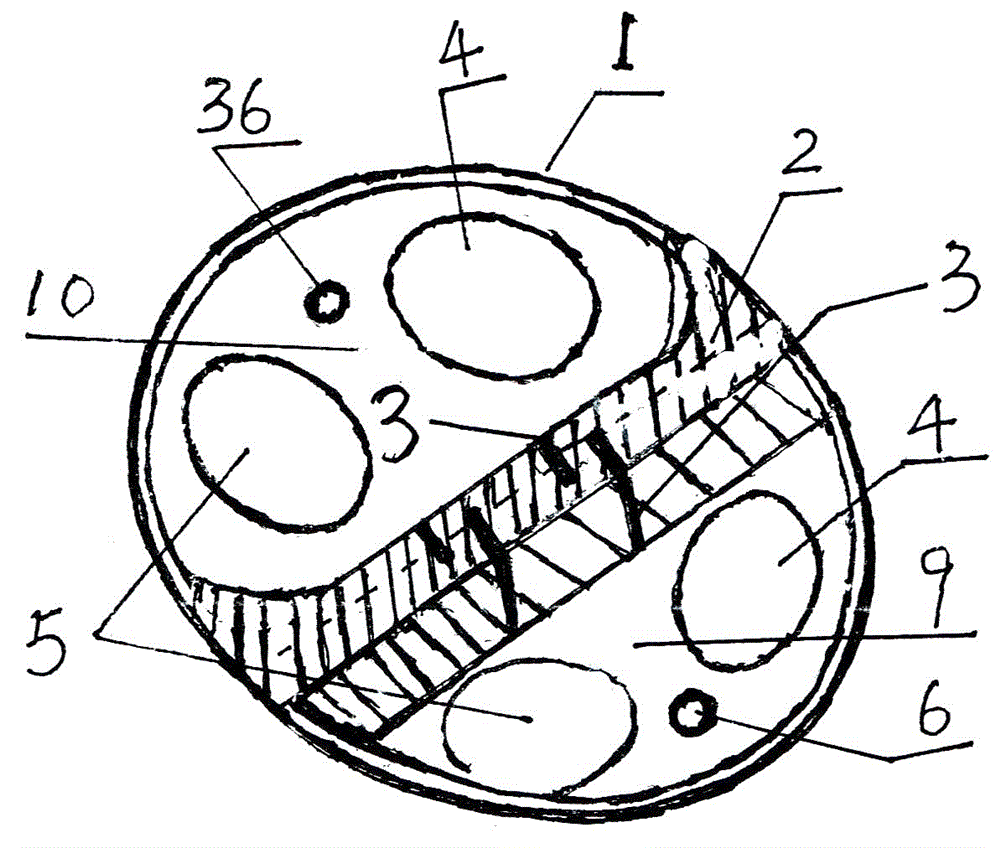

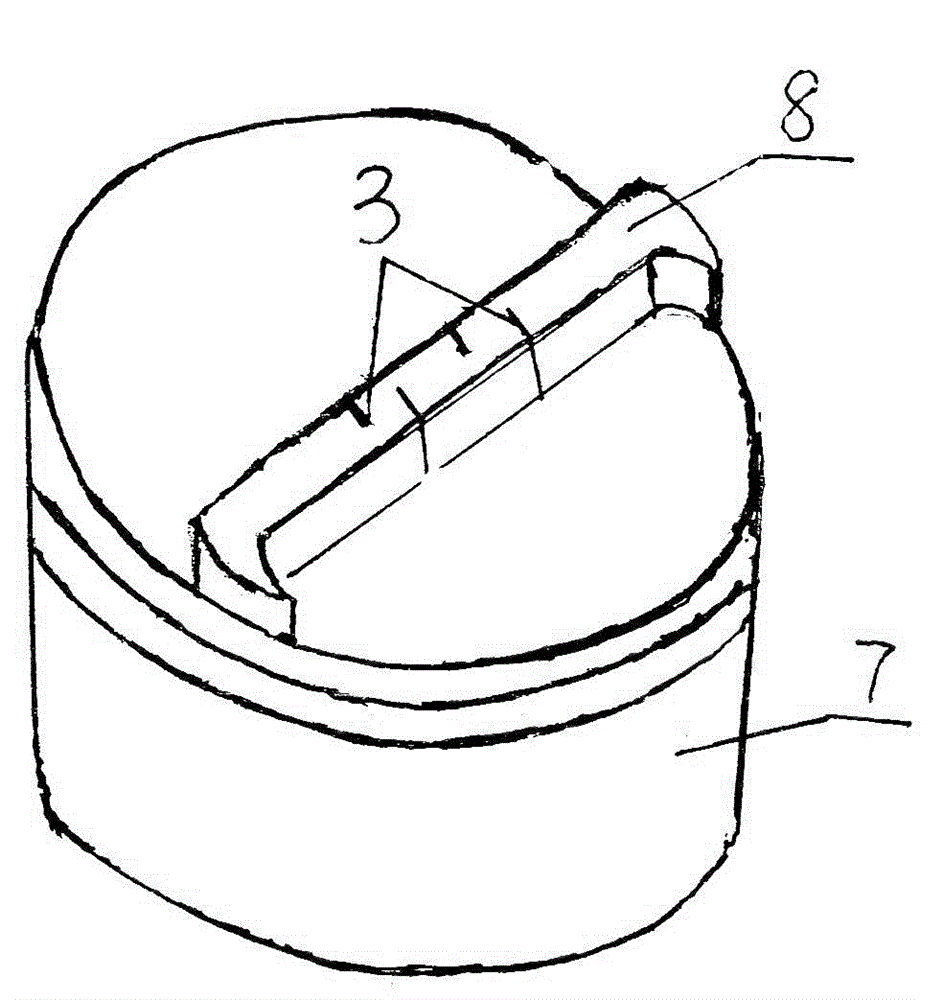

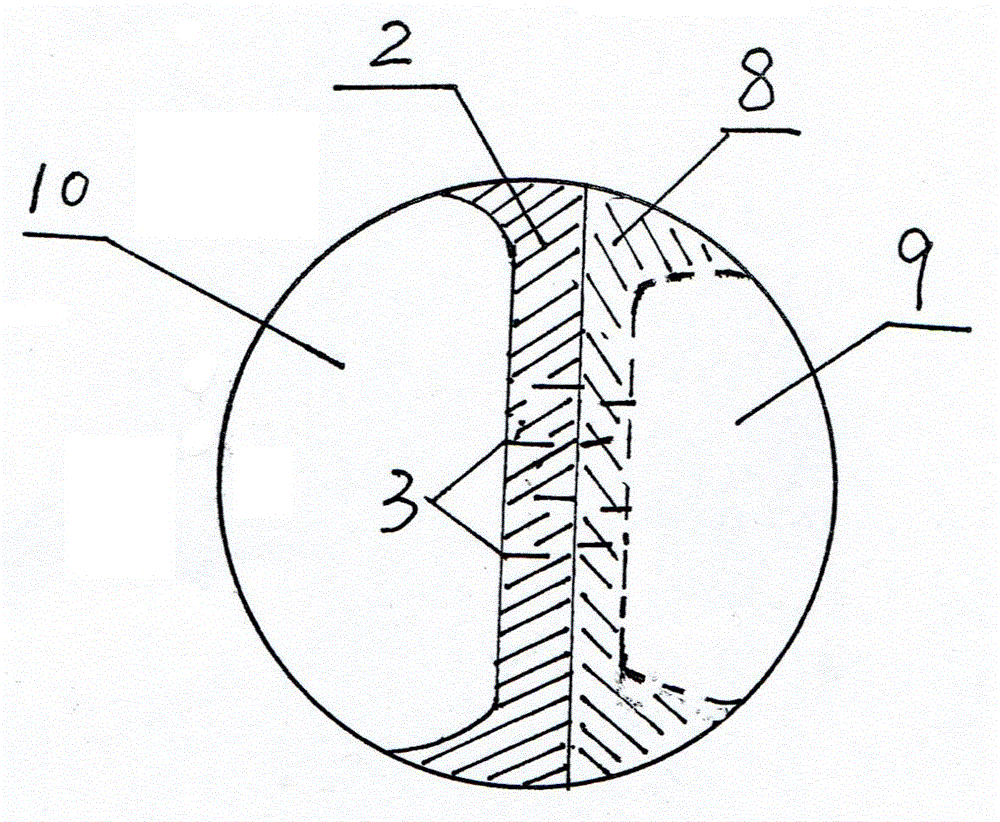

Circulating fluidized bed garbage incineration boiler and pollution control system with same

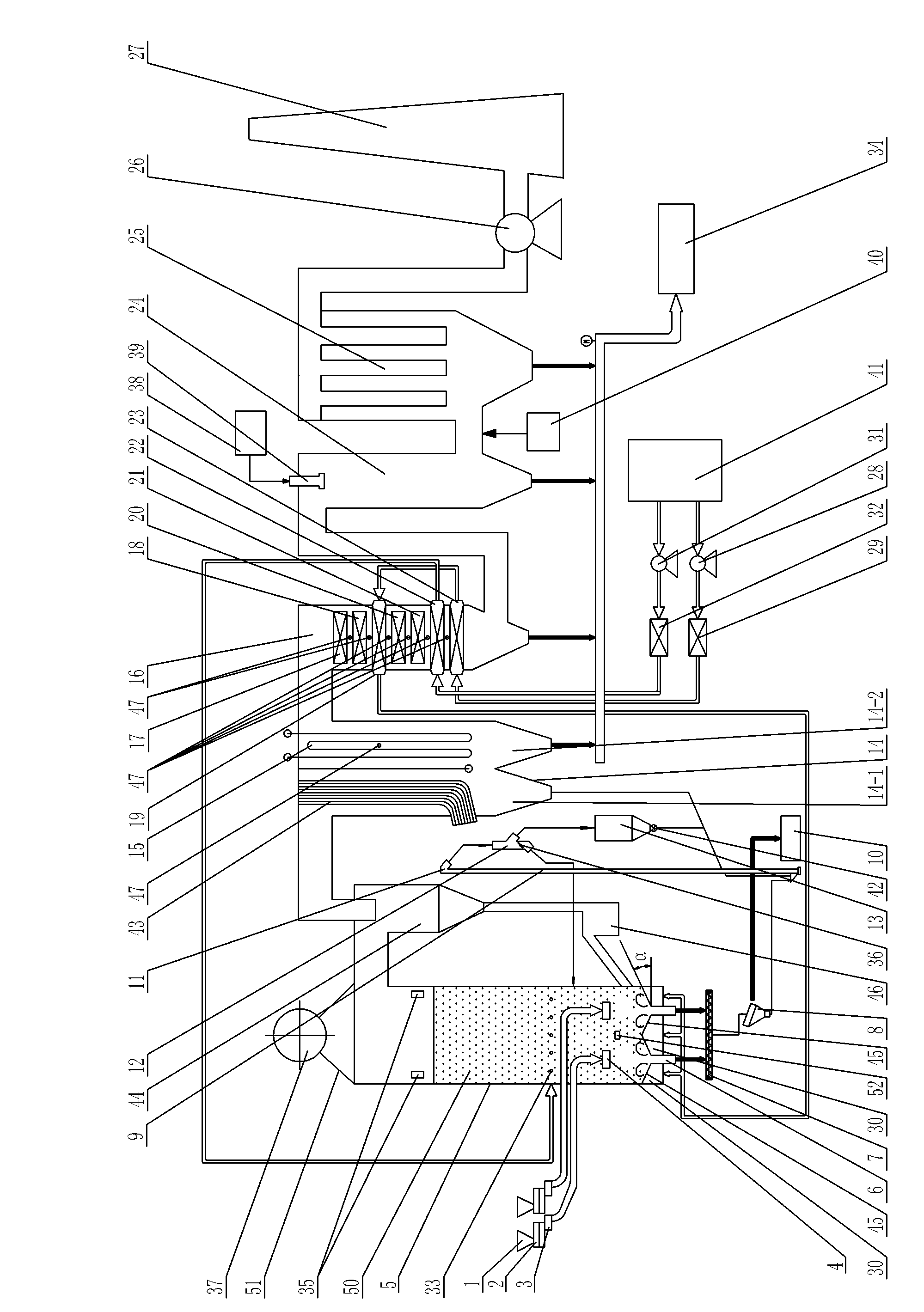

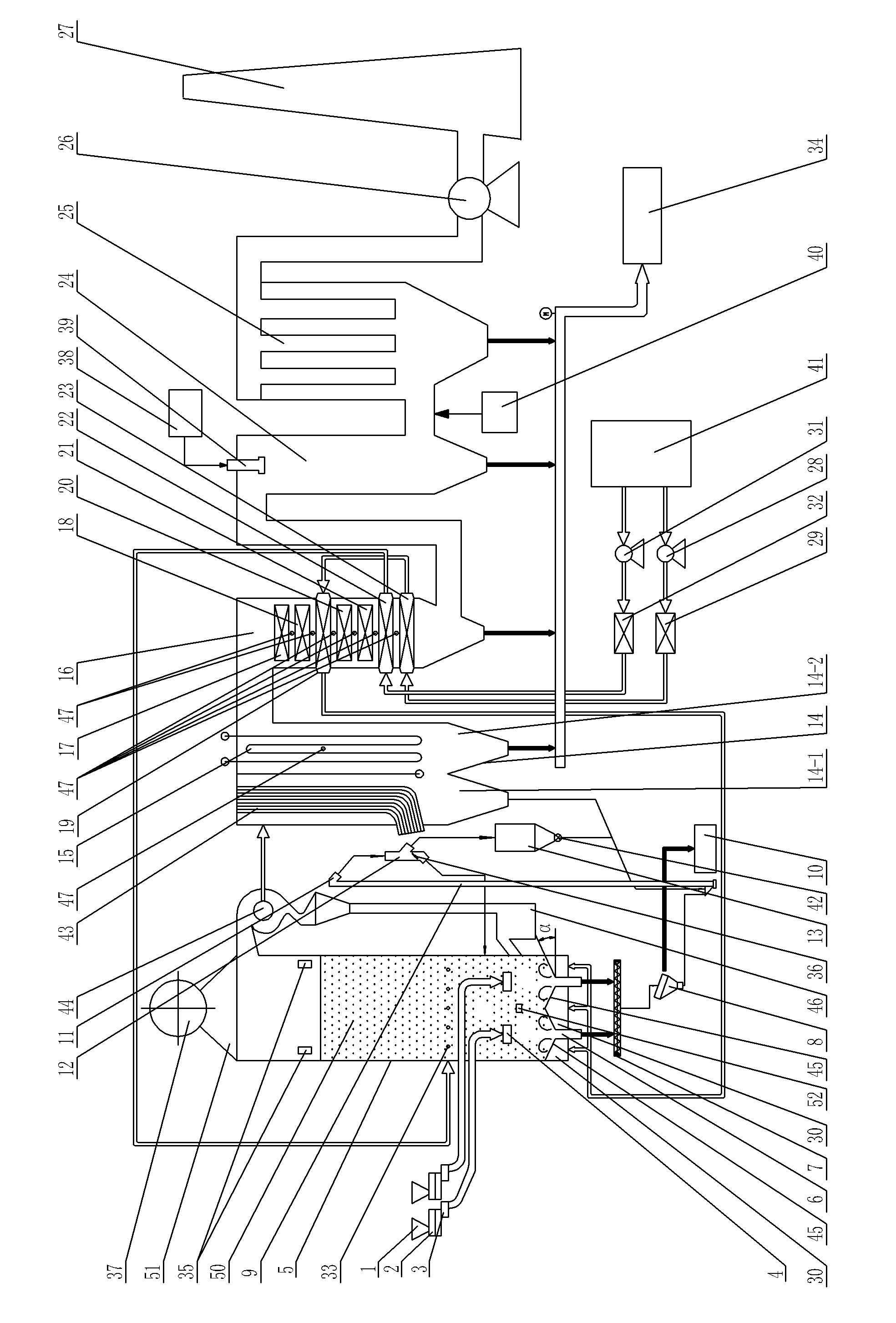

The invention discloses a circulating fluidized bed garbage incineration boiler and a pollution control system with the same, which relate to a garbage incineration boiler and a pollution control system with the same, and aim to solve the problems that the conventional circulating fluidized bed garbage incineration furnace difficultly discharges slag and is required to be stopped regularly to remove the slag and the economy of a garbage incineration plant is influenced. According to the scheme I, a circulating fluidized bed and double V-shaped wind distributing plates are arranged in a boiler body, the boiler body, a separator, a flue gas cooling chamber and a tail flue are communicated in sequence, an upper level low-temperature superheater, a lower level low-temperature superheater, a primary wind air preheater, a secondary wind air preheater, an upper level primary wind economizer, a lower level primary wind economizer, an upper level secondary wind economizer and a lower level secondary wind economizer are arranged in the tail flue, and the separator is communicated with the boiler body by a U-shaped valve; different from the scheme I, the scheme III is characterized in that: double inverted V-shaped wind distributing plates are adopted; different from the scheme III, the scheme V is characterized in that: an inverted V-shaped wind distributing plate is adopted; and according to the scheme II, the scheme IV and the scheme VI, a semidry reaction tower, a bag-type dust collector, an induced draft fan, a chimney, a fly ash cabin, a lime slurry preparation system, a rotary atomizer and an active carbon injecting device are added on the basis of the scheme I, the scheme III and the scheme V. The circulating fluidized bed garbage incineration boiler and the pollution control system with the same are used for incinerating garbage, and pollutant emission can be controlled.

Owner:无锡光核新能源建设有限公司

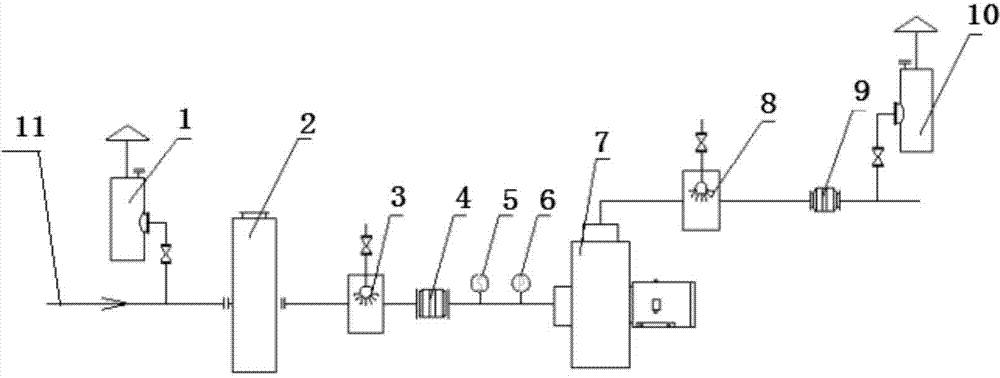

Integrated waste heat generating and heating system and process flow thereof

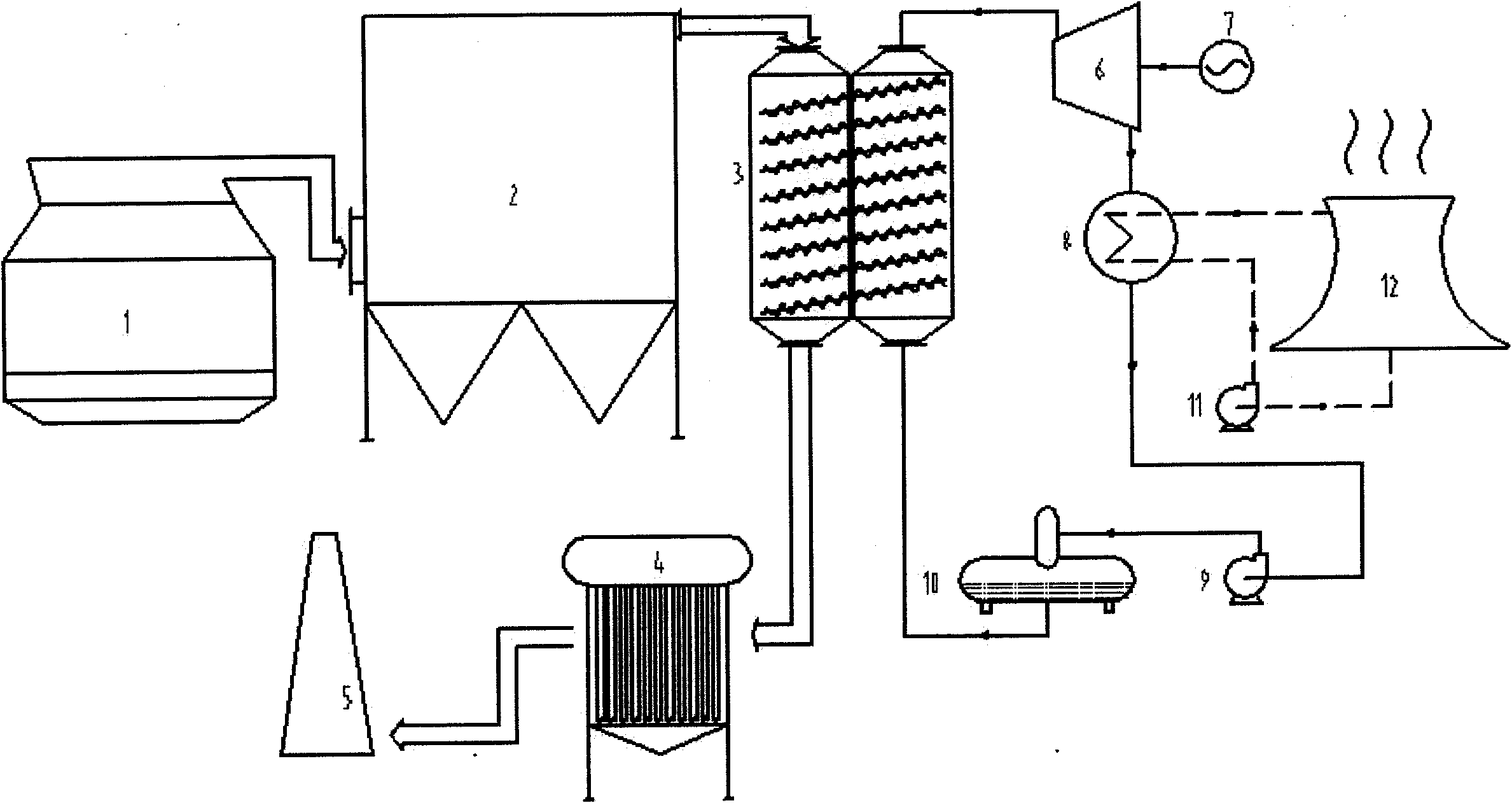

InactiveCN101852555AAvoid paralysisLow running costValve arrangementsDispersed particle filtrationFiberHeat conducting

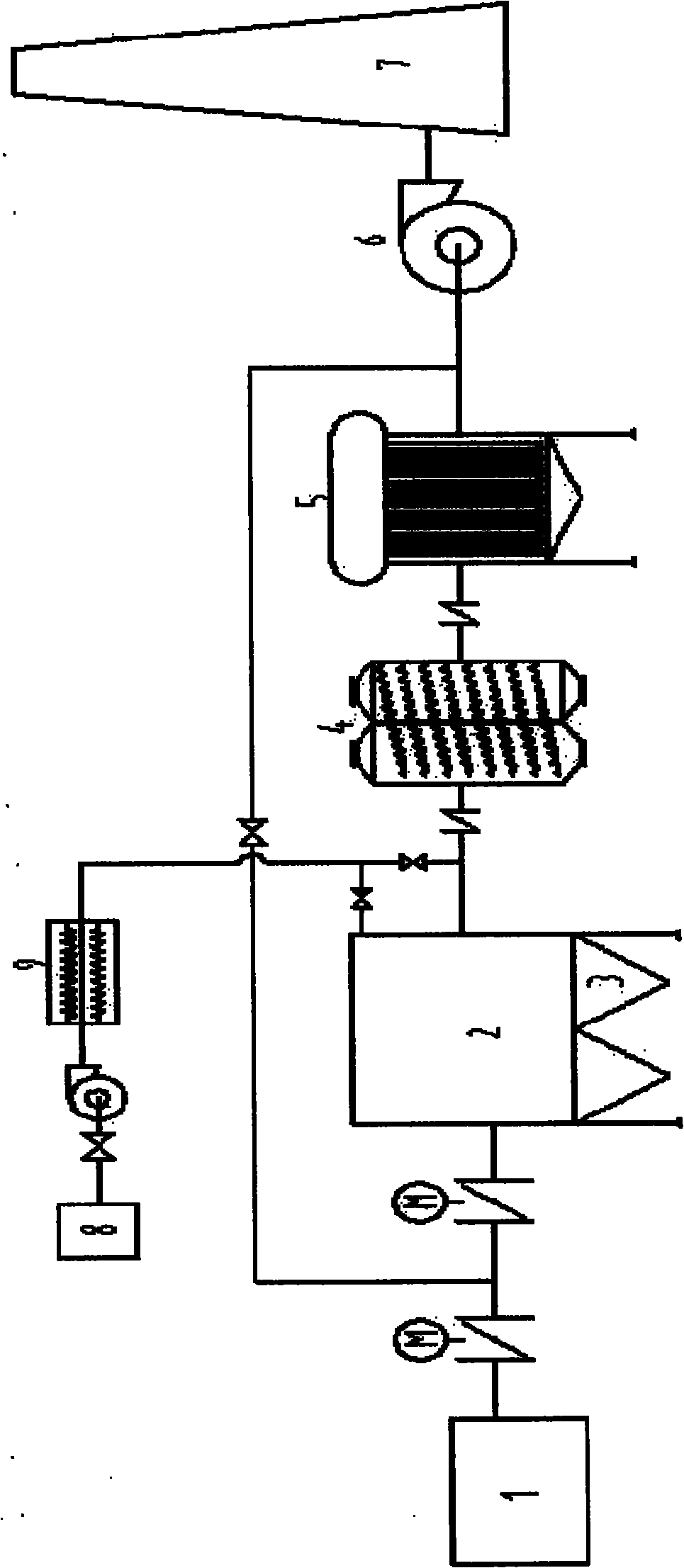

The invention discloses a waste heat generating equipment system and a waste heat generating process. The system comprises a ceramic fiber dust collector (2), a rapid heat conducting heat-pipe waste heat boiler (3), a rapid heat conducting heating device (4), a steam replenishing and condensing steam turbine (6), a condenser (8), a condensing water pump (9) and a vacuum deaerator (10), wherein ceramic fiber dust collector (2) is arranged at a waste heat outlet end; the rapid heat conducting heat-pipe waste heat boiler (3) bears a steam preparing device for power generation; the rapid heat conducting heating device (4) is arranged on the smoke inlet of a boiler; medium and high-pressure main steam generated by a rapid heat conducting heat-pipe waste heat boiler is mixed and enters the steam replenishing and condensing steam turbine (6) through a pipeline; low-pressure steam enters the steam replenishing and condensing steam turbine (6) through a steam replenishing pipeline; waste steam on the tail part of the steam turbine enters the condenser (8); condensed water enters the vacuum deaerator (10) through the condensing water pump (9) and a pipeline; water from which oxygen is removed in the deaerator enters the heat-pipe waste heat boiler (3) through a water supply pump of the boiler; and low-temperature smoke discharged from the back end of the boiler is delivered into the rapid heat conducting heating device (4). The waste heat utilization ratio of the integrated system is enhanced by over 60 percent on average, so unit energy consumption of an enterprise is greatly lowered, the problem of unstable running of the system due to dust blocking of the boiler and wearing of a heat exchange tube in a medium and low temperature waste heat generating system is solved and comprehensive generating efficiency is enhanced by over 30 percent.

Owner:童裳慧

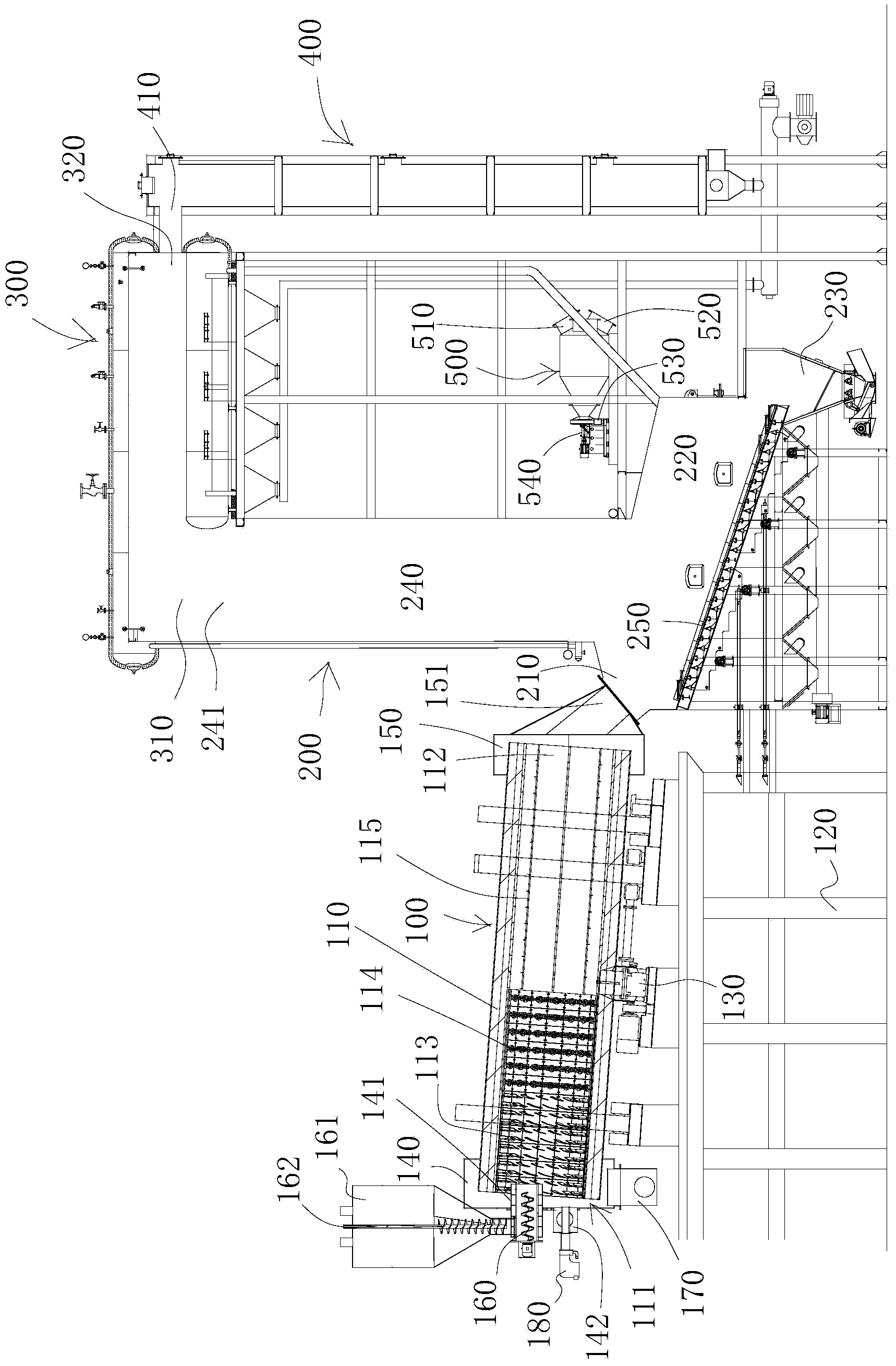

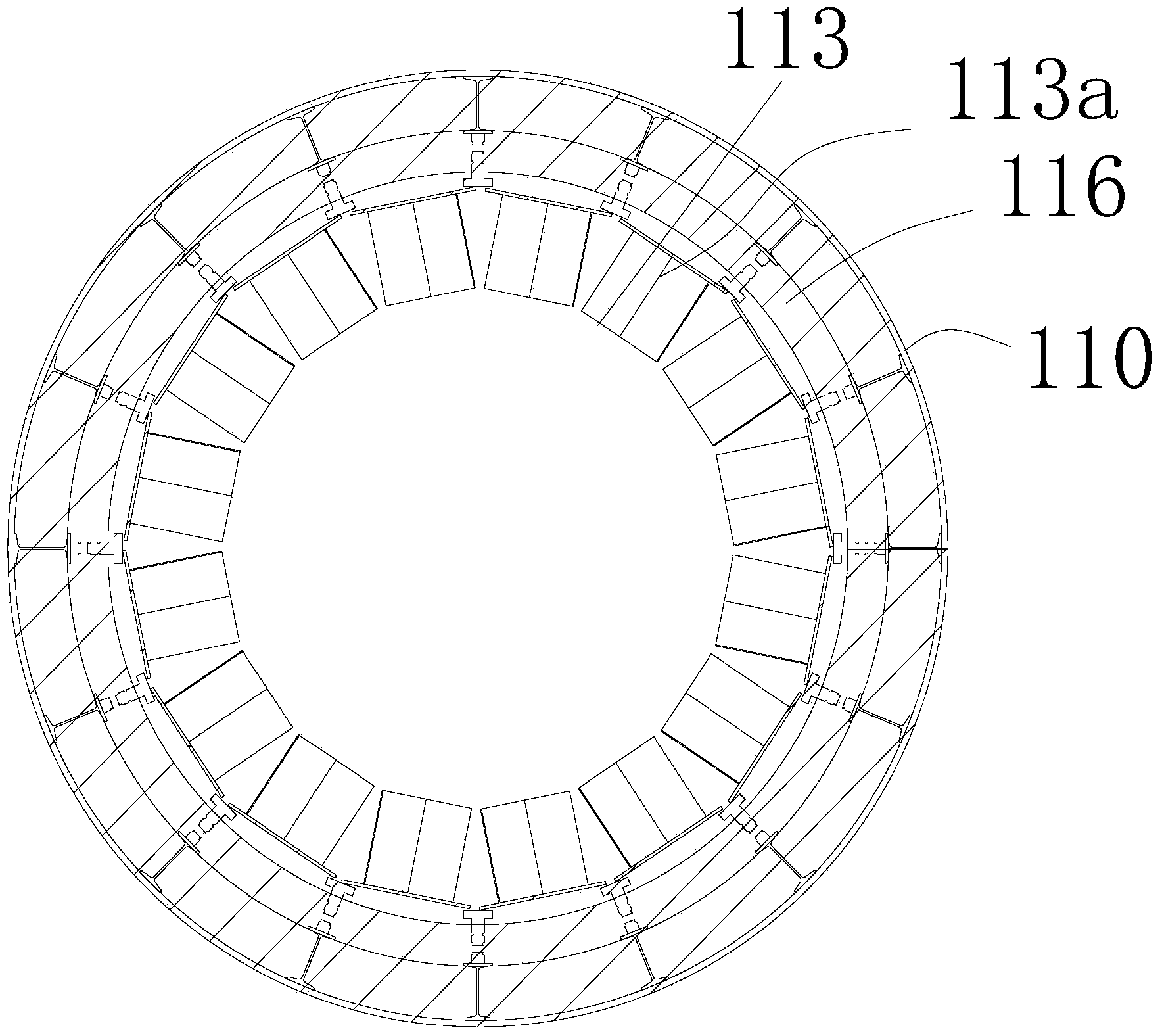

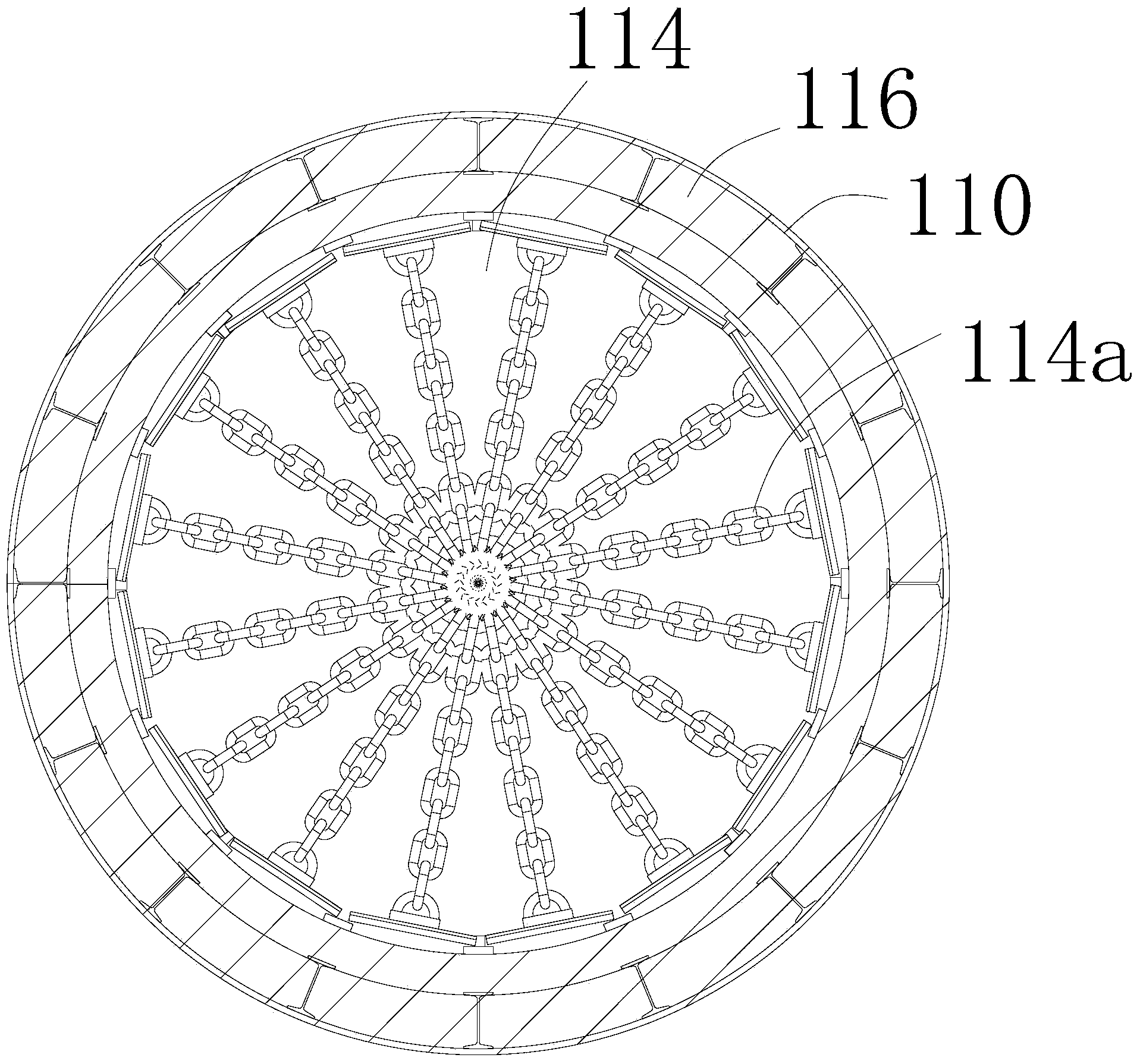

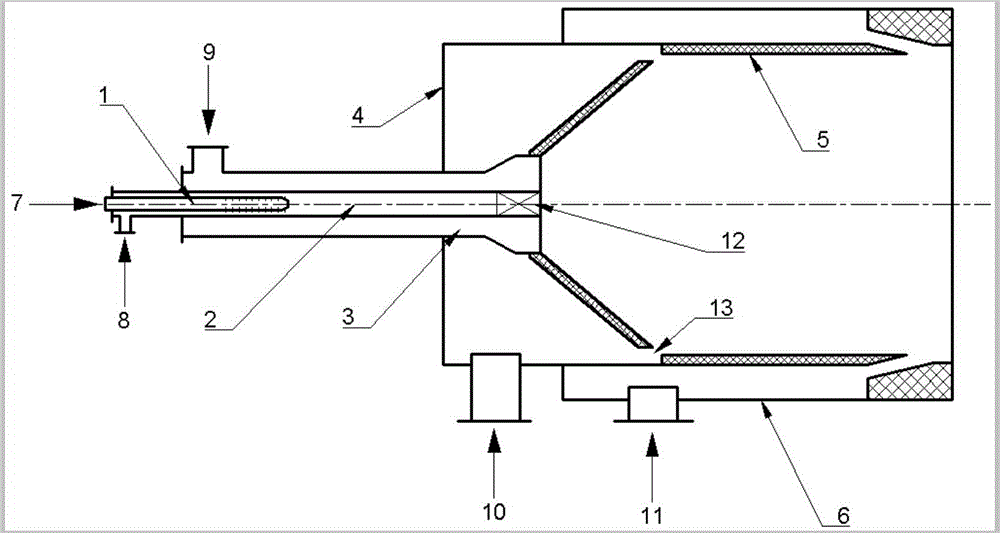

Smoke pyrolysis kiln-furnace-combined type sludge incinerator

ActiveCN103542415APrevent revert processingPrevent deflagrationIncinerator apparatusSteam generation using hot heat carriersAir preheaterCombustion chamber

The invention discloses a smoke pyrolysis kiln-furnace-combined type sludge incinerator. The smoke pyrolysis kiln-furnace-combined type sludge incinerator comprises a rotary pyrolysis device, an incineration furnace, a waste heat boiler, an air preheater and a smoke distribution device and integrates the advantages of a rotary kiln, a pyrolysis gasifier and a reciprocating grate furnace; a rotary pyrolysis gasifier is provided with the smoke distribution device and mixes and distributes smoke in a flow temperature and oxygen content adjustable mode to achieve stable pyrolysis gasification and anoxic combustion of in-furnace sludge, combustible gas generated during the pyrolysis process can enter two combustion chambers of the incineration furnace under the action of system negative pressure for high-temperature incineration; unburnt solid sludge during the anoxic combustion can directly drop on the reciprocating grate of the incineration furnace for continuous incineration. According to the smoke pyrolysis kiln-furnace-combined type sludge incinerator, sludge is pyrolyzed through waste heat inside system smoke, so that energy consumption can be reduced; meanwhile, the content of oxygen entering the rotary kiln is strictly controlled, detonation can be effectively avoided; the waste heat boiler can generate steam for heat supply and power generation.

Owner:上海煜工环保科技有限公司

Direct fired pulverizing system of smoke drying lignite coal fan mill

ActiveCN102889607AGuaranteed temperatureReduce ventilationDrying gas arrangementsLump/pulverulent fuel preparationBoiler furnaceProcess engineering

The invention discloses a direct fired pulverizing system of a smoke drying lignite coal fan mill, which comprises a high temperature furnace smoke pipe and a hot wind mixer, wherein the high temperature furnace smoke pipe is formed by arranging a cluster of circular pipes in parallel to form a flue; the circular pipes are located in a vapor-water circulating system of a power plant; an outlet of the high temperature furnace smoke pipe is communicated with a down drying tube; an inlet is communicated with a hot smoke pumping port of a boiler furnace; the hot wind mixer is connected between a classifier and a pulverized coal distributer; the other route of the hot wind device is connected to the hot wind mixer; and a coal inlet of the fan coal mill is further connected with a cool smoke pumping port of the boiler flue. The direct fired pulverizing system of the smoke drying lignite coal fan mill has the advantages of safety in operation, simple structure, low investment and being capable of effectively utilizing heat energy of high-quality smoke.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

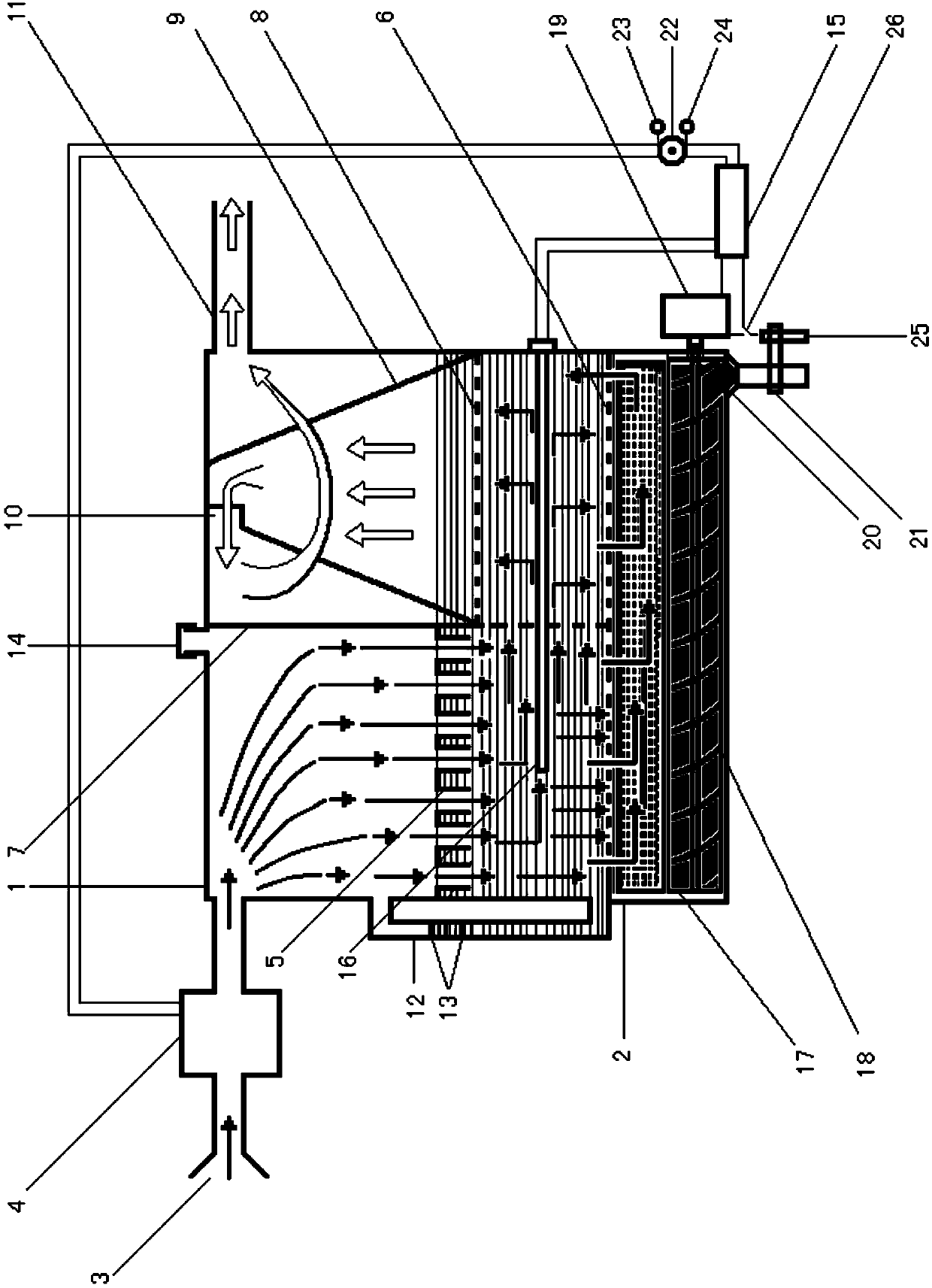

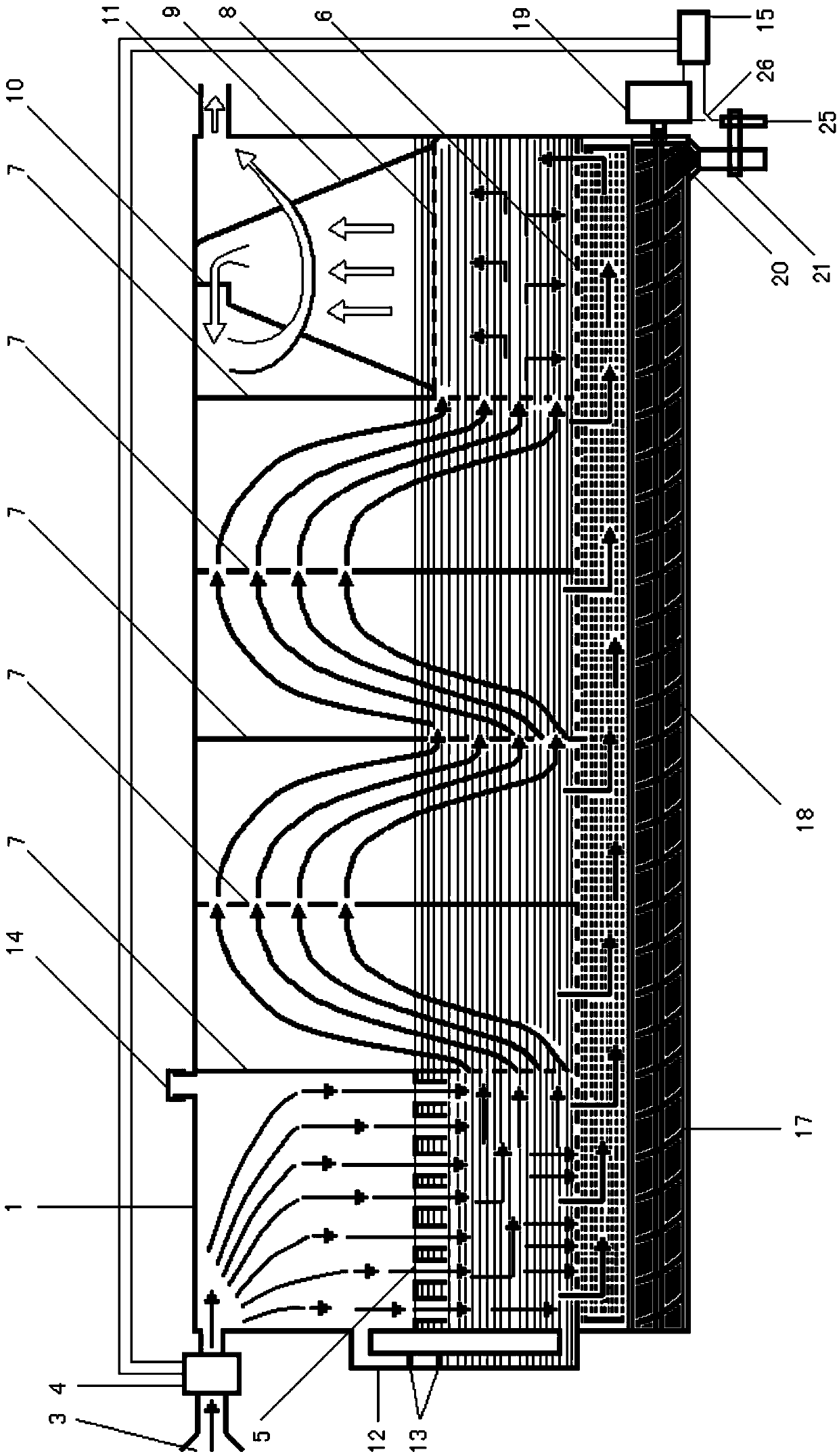

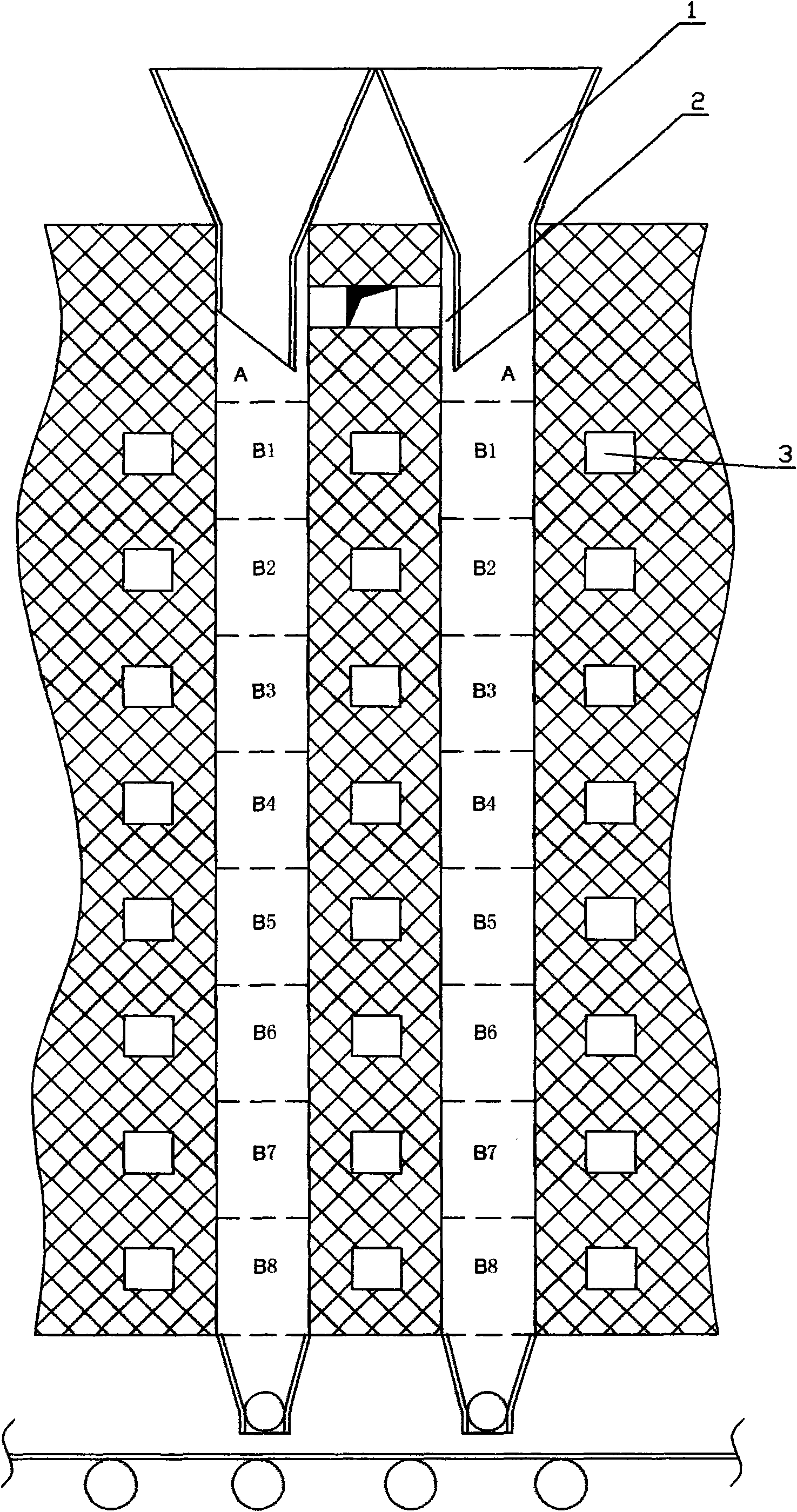

Air purification equipment using liquid reducing agent and working and applying method of air purification equipment

ActiveCN104174246AIncrease deflationPrevent deflagrationCombination devicesGas treatmentParticulatesEnvironmental engineering

The invention discloses air purification equipment using a liquid reducing agent. The air purification equipment is characterized by comprising a polluted gas suction opening, a polluted gas purification cavity and a clean gas discharging opening, wherein the polluted gas purification cavity is divided into a plurality of cavities by a plurality of half-surface multihole type pollution particle vertical baffles; pollution cleaning liquid is contained in the polluted gas purification cavity; one end of each half-surface multihole type pollution particle vertical baffle is closed, and the other end of each half-surface multihole type pollution particle vertical baffle is used for communicating two adjacent cavities through multiple holes; the polluted gas suction opening and the clean gas discharging opening are respectively formed in the two cavities at the head and the tail. The air purification equipment has the advantages that polluted air enters the pollution cleaning liquid, so that all particulate matters entering pollution cleaning equipment can be humidified to gain the weight and basically retained; by the adding of a feldspar aqueous solution component, carbon elements in carbon dioxide and other elements in the feldspar aqueous solution are combined to generate carbonate type substances, and sucked carbon dioxide components can be eliminated.

Owner:段洪池 +1

Process for calcining petroleum coke

The invention discloses a process for calcining petroleum coke. The calcination of the petroleum coke is carried out in a tank type calcining furnace, and the tank body of the tank type calcining furnace is provided with a preheating zone and 6-8 calcining zones sequentially from top to bottom, wherein the calcining temperature of the first calcining zone at the uppermost part is controlled in the maximum calcining temperature interval allowed by the petroleum coke; the calcining temperature of the second calcining zone in the downstream position of the first calcining zone is kept in the maximum calcining temperature interval and is not higher than the calcining temperature of the first calcining zone; starting from the third calcining zone, the calcining temperature of each calcining zone gradually reduces relative to the calcining temperature of the adjacent calcining zone in the upstream position; and in the undermost calcining zone, the calcining temperature is reduced to the discharging temperature. In the invention, when the petroleum coke is calcined, the high temperature zone is positioned at the top end of the calcining furnace, thereby relieving the high temperature deformation phenomenon of the furnace body, being more favorable for overflow of combustible gas in the petroleum coke, reducing the corrosion of the combustible gas on wall bricks, and being favorable for prolonging the service life of the tank type furnace.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

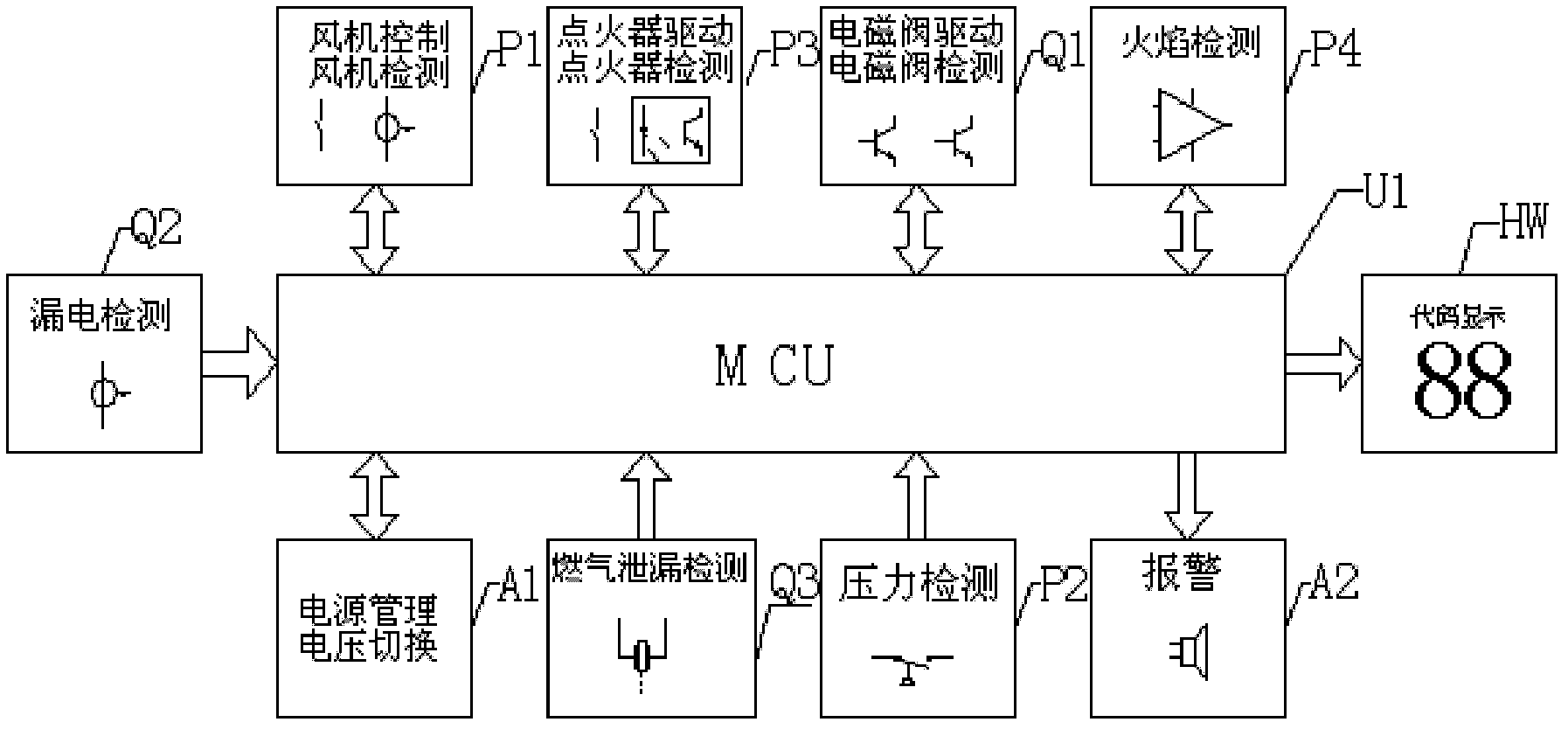

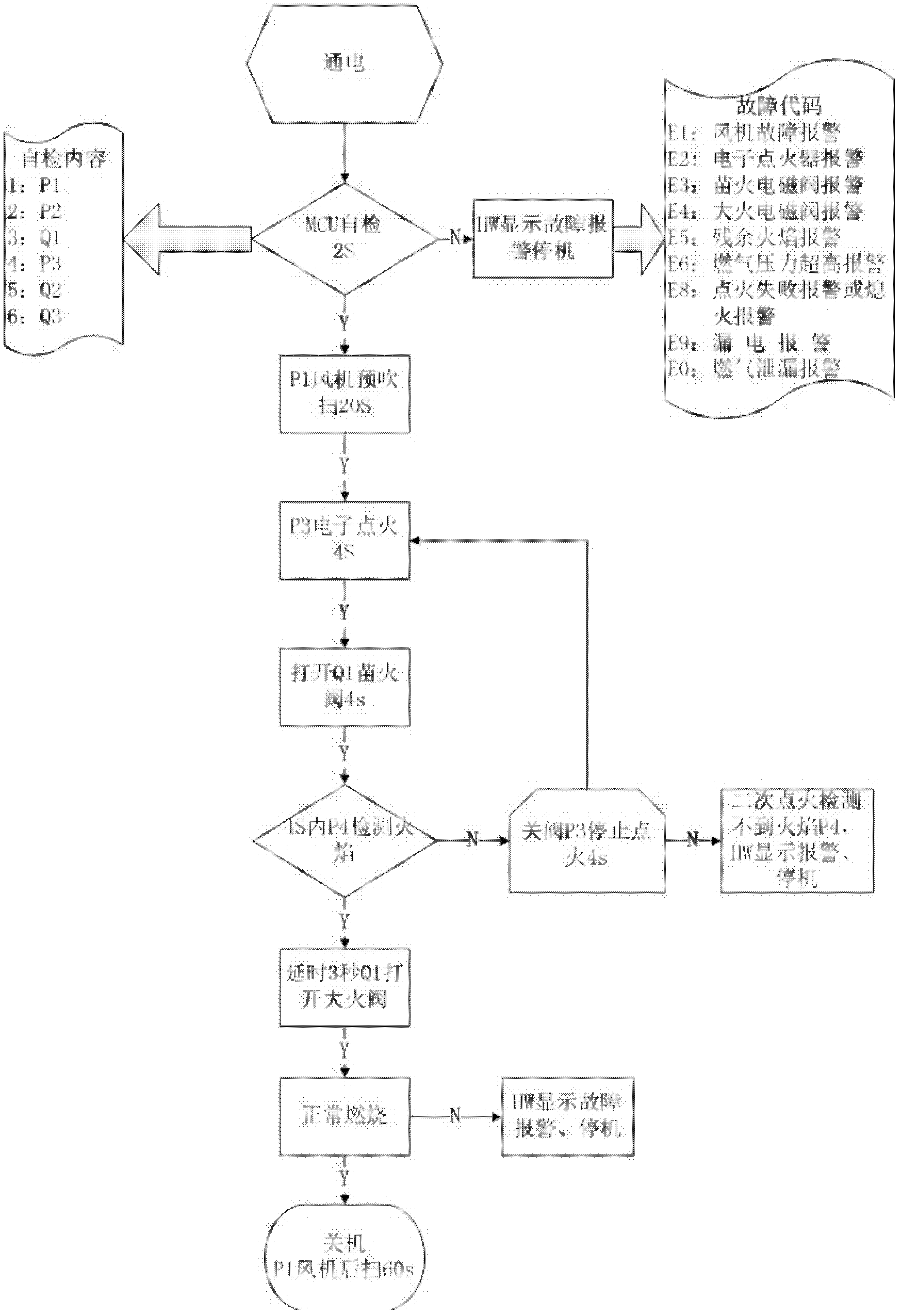

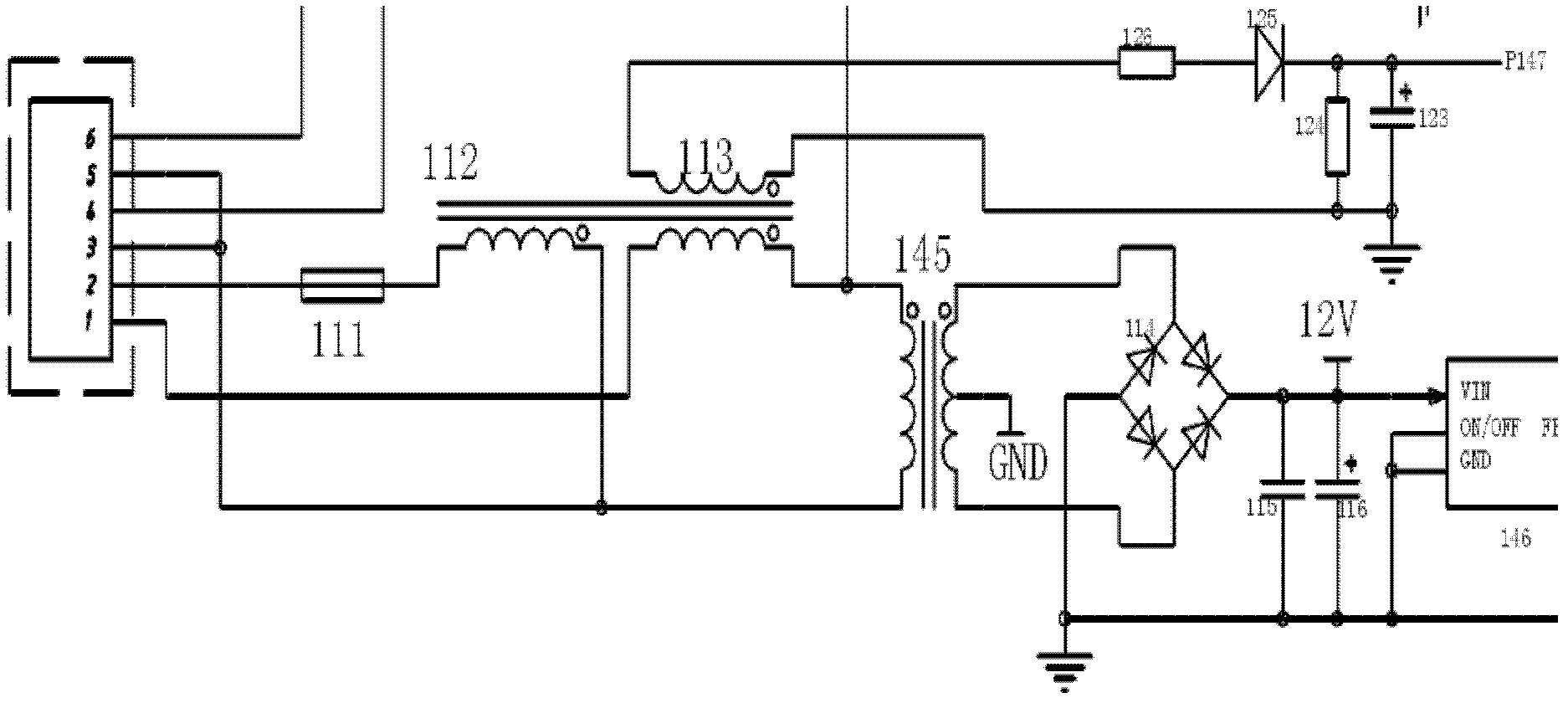

Control system for commercial gas cooker

InactiveCN102563722AImprove the safety of useEasy to maintainDomestic stoves or rangesLighting and heating apparatusCookerEngineering

The utility model discloses a control system for a commercial gas cooker. The commercial gas cooker comprises a blower for purging a hearth of the commercial gas cooker, and an igniter used for igniting. The control system for the commercial gas cooker is characterized by comprising an intense-fire solenoid valve, a weak-fire solenoid valve, a gas pressure switch, a gas leakage detector and a program controller, wherein the program controller is used for controlling all the components of the control system as well as the blower and the igniter according to the preset program and detecting the flame and all the components of the control system. The phenomenon of detonation in the closed hearth due to certain reasons is avoided; and whether the pressure of the gas source is controlled in the specified range or not and whether the gas cooker has the phenomenon of electric leakage or not are simultaneously monitored, so that the safety in use of the gas cooker is enhanced, the gas cooker is convenient to maintain, and when the system is abnormal, the gas source is cut off during the warning process, and meanwhile, the fault part is displayed.

Owner:上海集焰节能科技有限公司

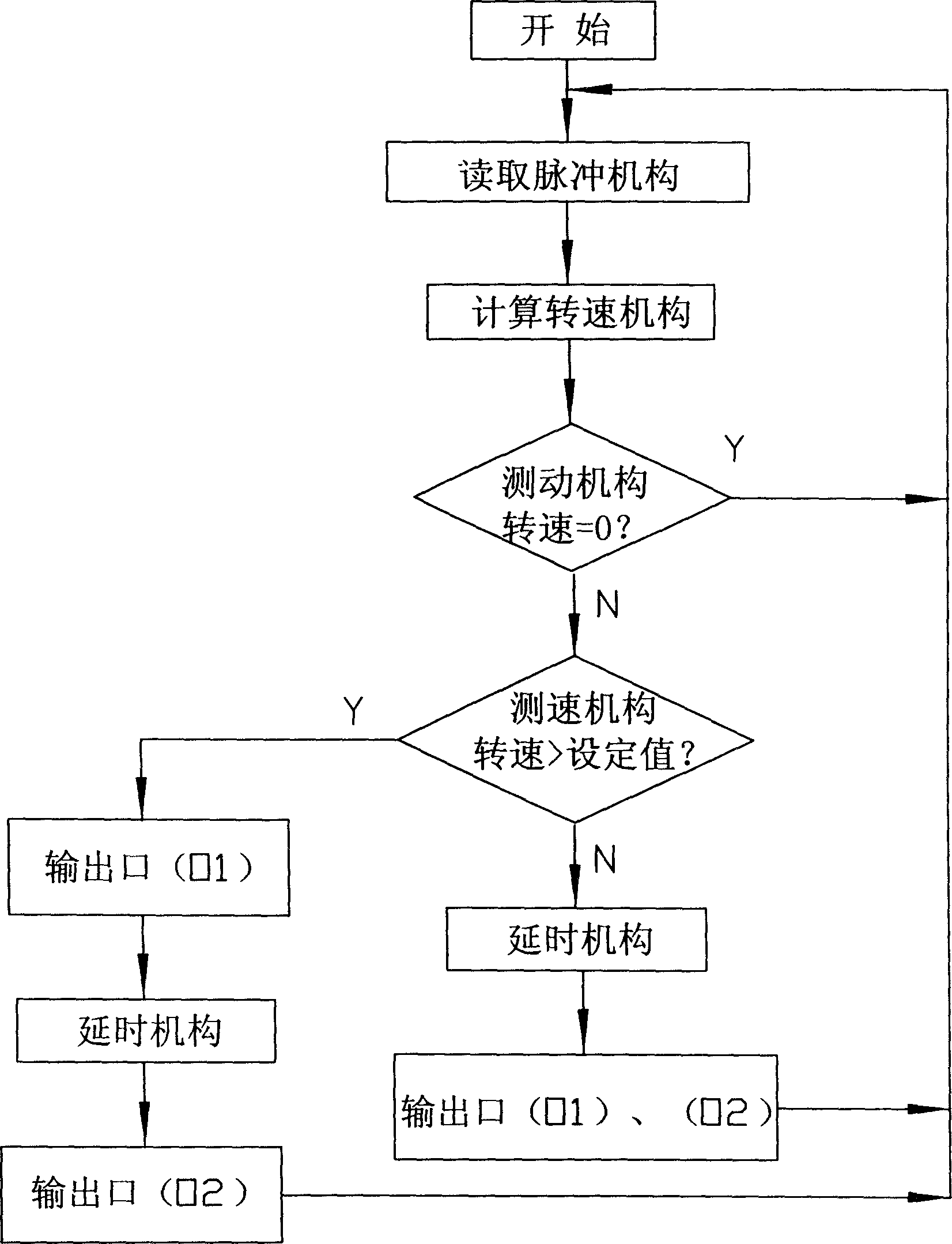

Gas burning system and igniting method thereof

InactiveCN104421959AAvoid enteringImprove securityFuel supply regulationCombustion systemCombustion chamber

The invention discloses a gas burning system. The gas burning system comprises a burning chamber, a gas main pipeline, a gas branch pipeline, an air main pipeline and a central control unit, wherein the gas main pipeline and the air main pipeline are respectively connected with the burning chamber, the gas main pipeline is sequentially provided with a first gas pressure sensor, a first cutting valve, a second cutting valve and a second gas pressure sensor along the flowing direction of gas, the gas main pipeline between the first cutting valve and the second cutting valve is communicated with one end of the gas branch pipeline, the other end of the gas branch pipeline is connected with the burning chamber, the gas branch pipeline is provided with a third cutting valve and a fourth cutting valve, and an igniting device and a fire detecting device are arranged inside the burning chamber. The burning system ignites in a fire-leading mode and can control the process before and during fire-leading and during working and burning. Accidents caused by the deflagration phenomenon and the gas leakage are prevented.

Owner:BEIJING NEW BUILDING MATERIALS PLC

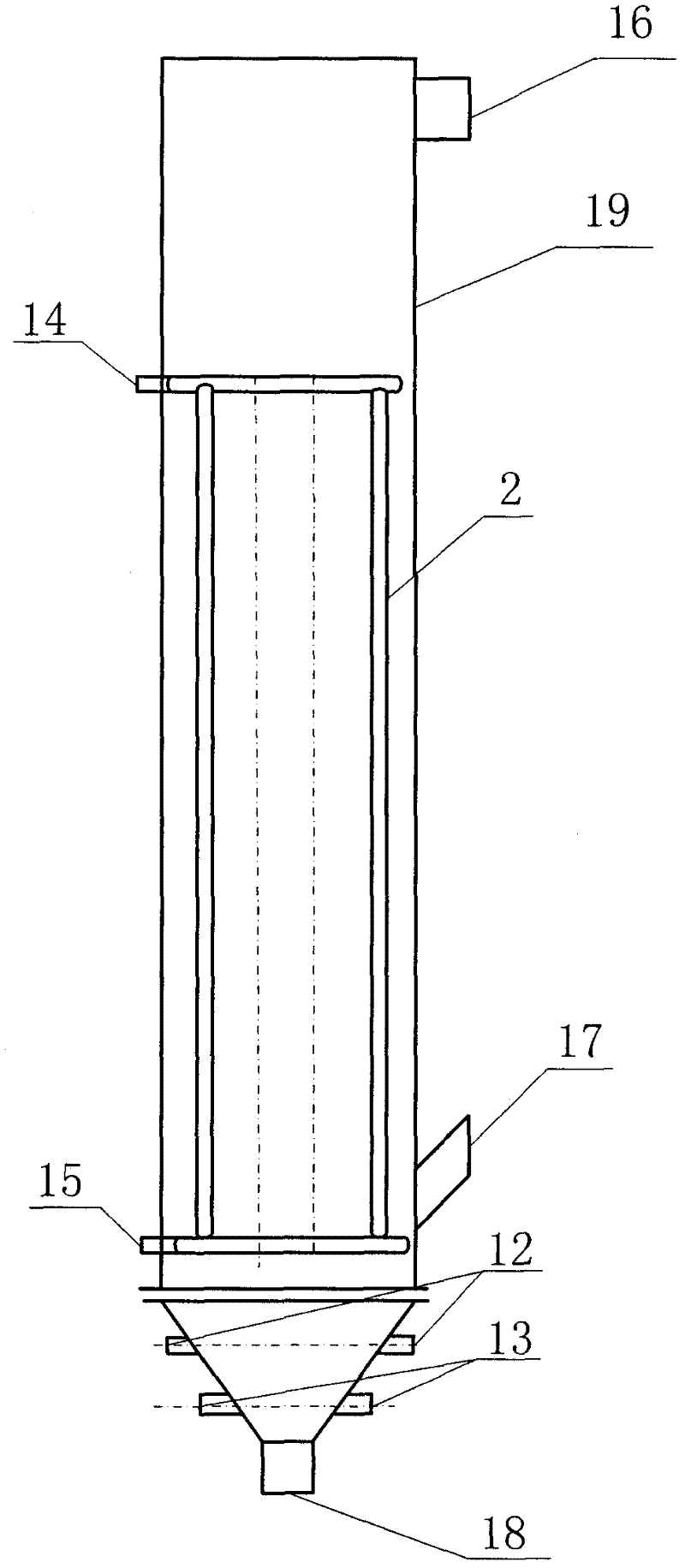

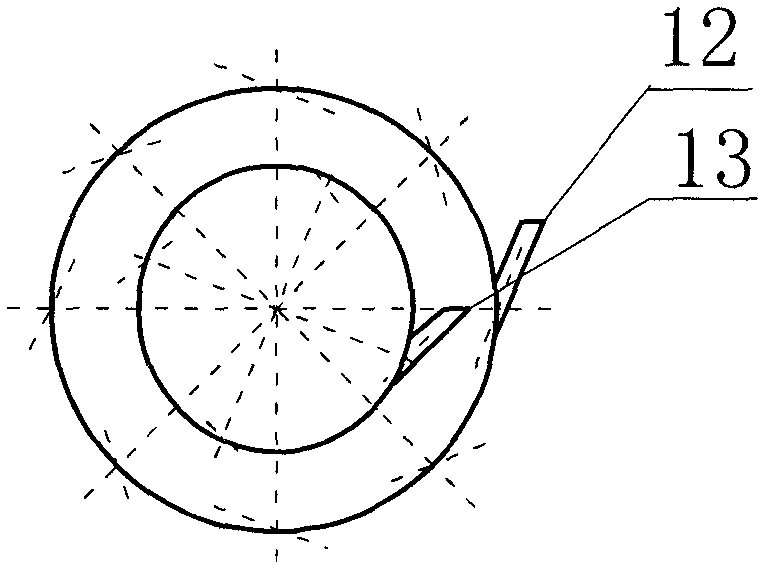

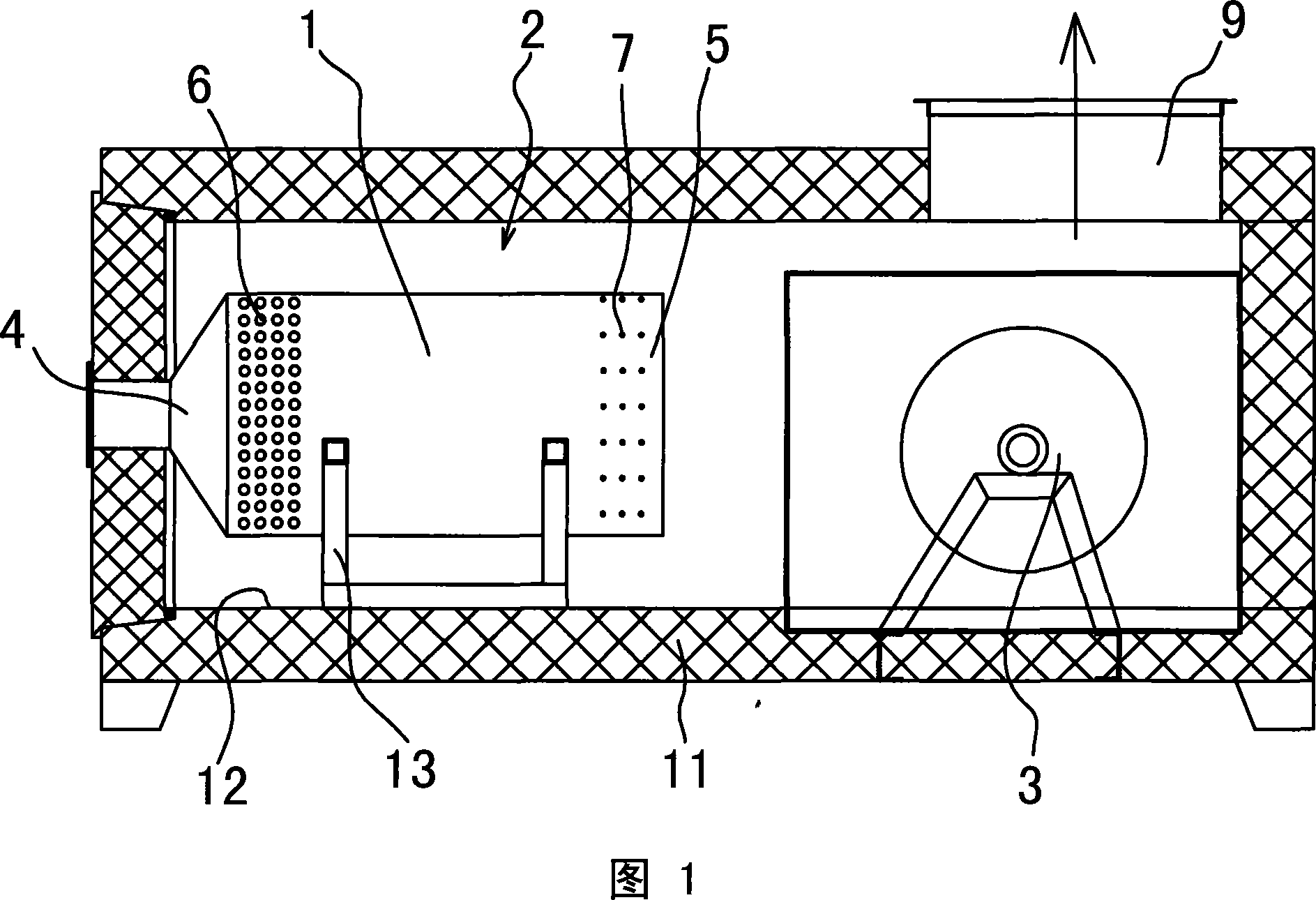

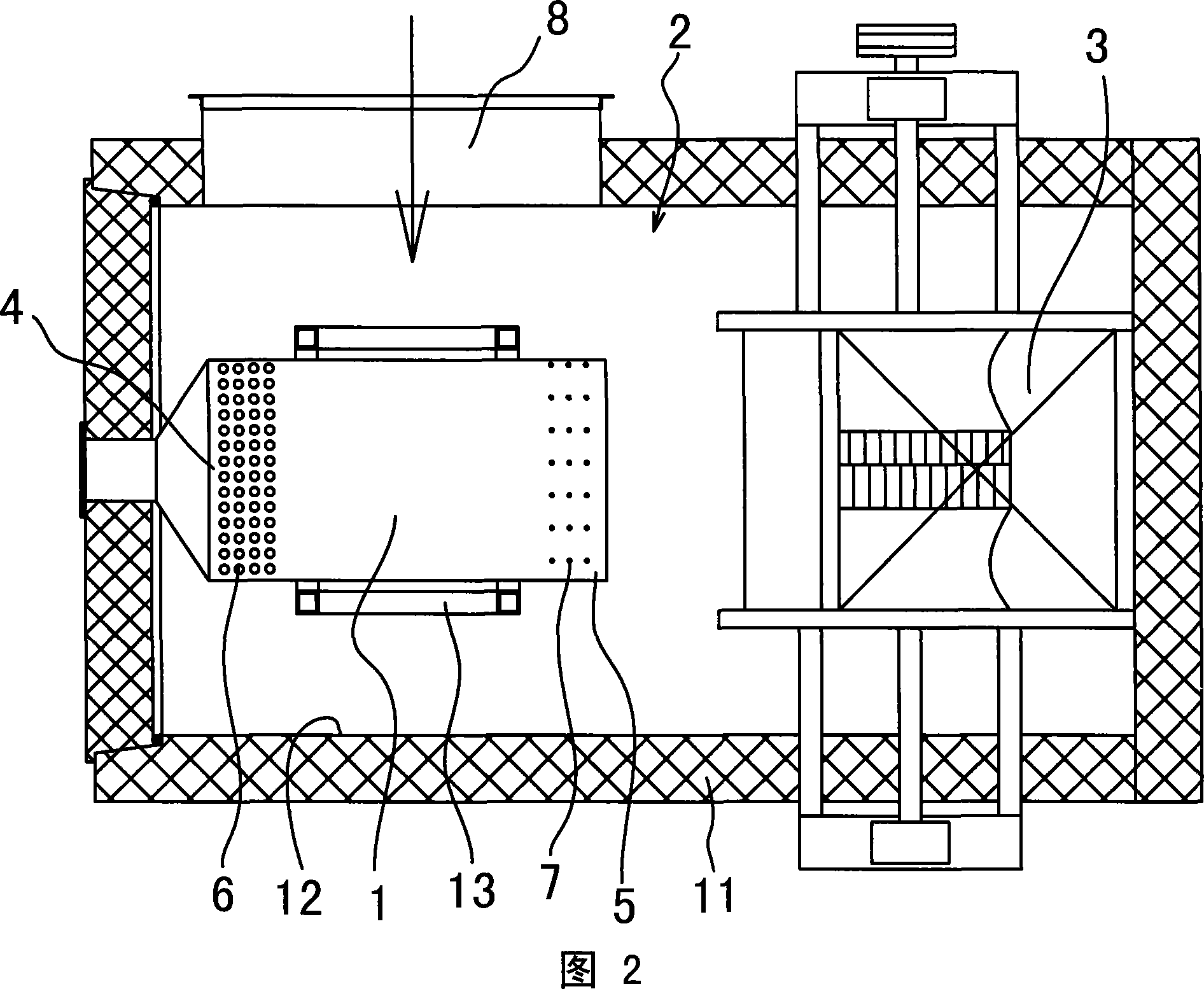

Fluidized bed catalytic deoxidation method and equipment for oxygen-containing coal bed gas

The invention relates to a fluidized bed catalytic deoxidation method for oxygen-containing coal bed gas. The fluidized bed catalytic deoxidation method comprises the following steps that: a fluidized bed deoxidation reactor is preheated to the temperature of 300-400 DEG C; the oxygen-containing coal bed gas is fed into the fluidized bed deoxidation reactor; deoxidation catalyst granules are loaded into a feed hopper and are added into the fluidized bed deoxidation reactor under the action of air blowing and supplying; methane and oxygen in the coal bed gas are subjected to low-temperature catalytic combustion reaction in the fluidized bed deoxidation reactor; the gas moves upwards with the carrying of part of solid catalyst granules and enters a one-stage cyclone separator and a two-stage cyclone separator from the top outlet of the fluidized bed deoxidation reactor, and the collected solid catalyst granules circularly enter the fluidized bed deoxidation reactor under the control of a feed back control valve and air blowing and supplying; and the deoxidated coal bed gas which is subjected to coarse dust removal by the cyclone separators is subjected to fine catalyst dust removal by a high-temperature filter, and then, is transferred to a follow-up system for use. The fluidized bed catalytic deoxidation method for the oxygen-containing coal bed gas has the advantages of good safety, low energy consumption, high deoxidation efficiency, long service life of catalyst and large processing capacity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

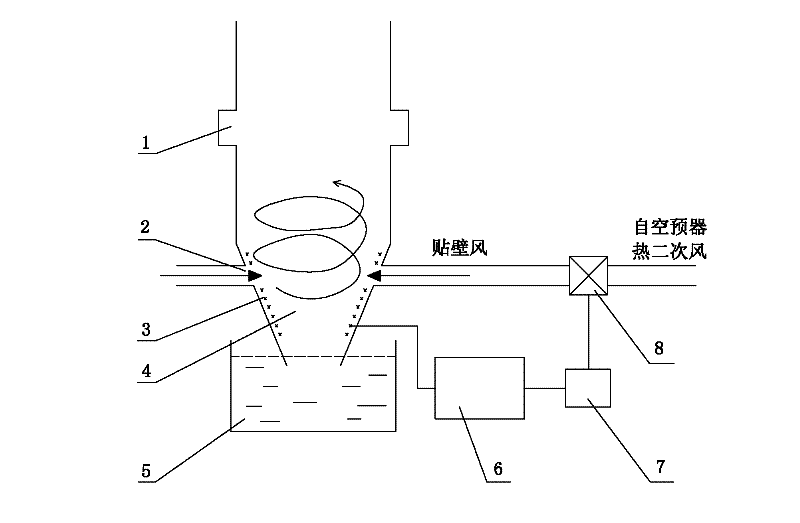

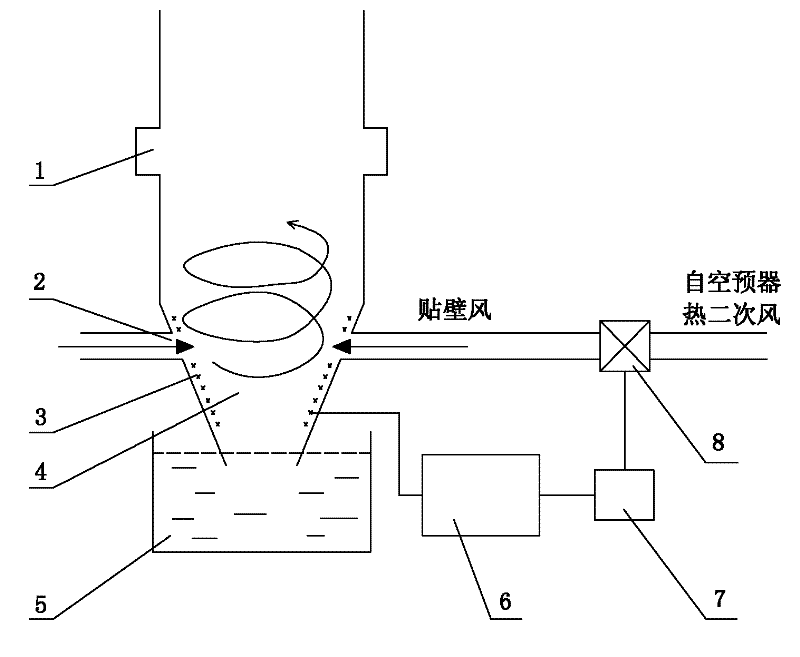

Early-warning adjustment system and early-warning adjustment method for preventing detonation of large-scale power station pulverized-fuel boiler furnace

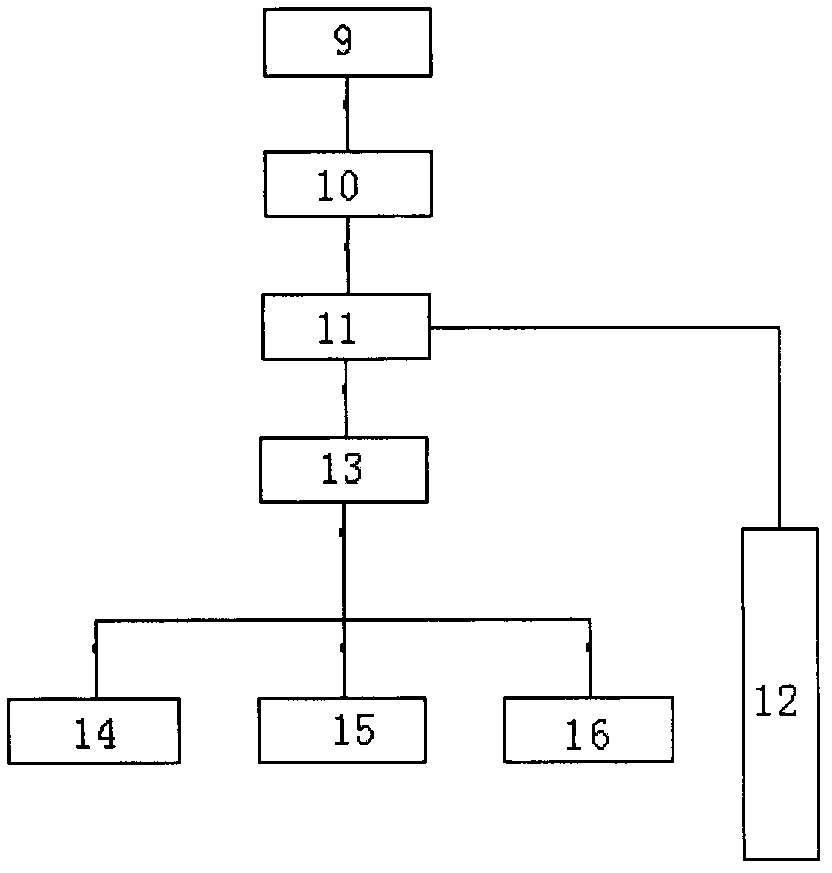

ActiveCN102563692ARealize online monitoringReduce concentrationIndirect carbon-dioxide mitigationCombustion regulationAir preheaterDetonation

The invention relates to an early-warning adjustment system and an early-warning adjustment method for preventing detonation of a large-scale power station pulverized-fuel boiler furnace. The purposes of early warning and eliminating detonation can be achieved by the following steps: arranging CO concentration detecting points on a wall surface of a cooled ash bucket and additionally arranging a near-wall air supply system; feeding CO signals back to a DCS (Distributed Control System); controlling a near-wall air adjusting valve by the DSC according to the feedback of the CO signals; and feeding secondary hot air from an air preheater to an area of the cooled ash bucket in a four-wall tangential way to reduce the concentration of the CO. The warning adjusting system provided by the invention has significance in safety of a large-scale power station pulverized-fuel boiler.

Owner:XI AN JIAOTONG UNIV

Oxygen-enriched combustion system

ActiveCN102563687APrevent deflagrationPrimary air temperature increasedPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustion systemEngineering

The invention discloses an oxygen-enriched combustion system. The oxygen-enriched combustion system comprises a boiler body, a cyclone combustor, a primary air circulating system, a secondary air circulating system and an oxygen supply system, wherein the boiler body comprises a smoke exhausting pipeline; the cyclone combustor comprises a primary air channel and a secondary air channel and is arranged on the boiler body; a ring-shaped oxygen chamber is arranged at a primary air channel outlet, and is communicated with a hearth of the boiler body by oxygen spraying pipes which are uniformly distributed; the primary air circulating system is connected with the smoke exhausting pipeline and the primary air channel of the cyclone combustor; the secondary air circulating system is connected with the smoke exhausting pipeline and the secondary air channel of the cyclone combustor; and the oxygen supply system is connected with the primary air channel and the secondary air channel and oxygen is input into the oxygen supply system. The oxygen-enriched combustion system has the advantages that the temperature of primary air of an outlet of a coal mill is improved, and the highest temperature is up to about 200 DEG C; the pure oxygen can be injected into the hearth quickly, so that the coal powder is sprayed into the boiler to be ignited and combusted quickly; the combustion efficiency is greatly improved; and the concentration of CO2 in smoke exhausted by the boiler is up to more than 80%, and the capture of CO2 is conveniently realized.

Owner:SHANGHAI BOILER WORKS

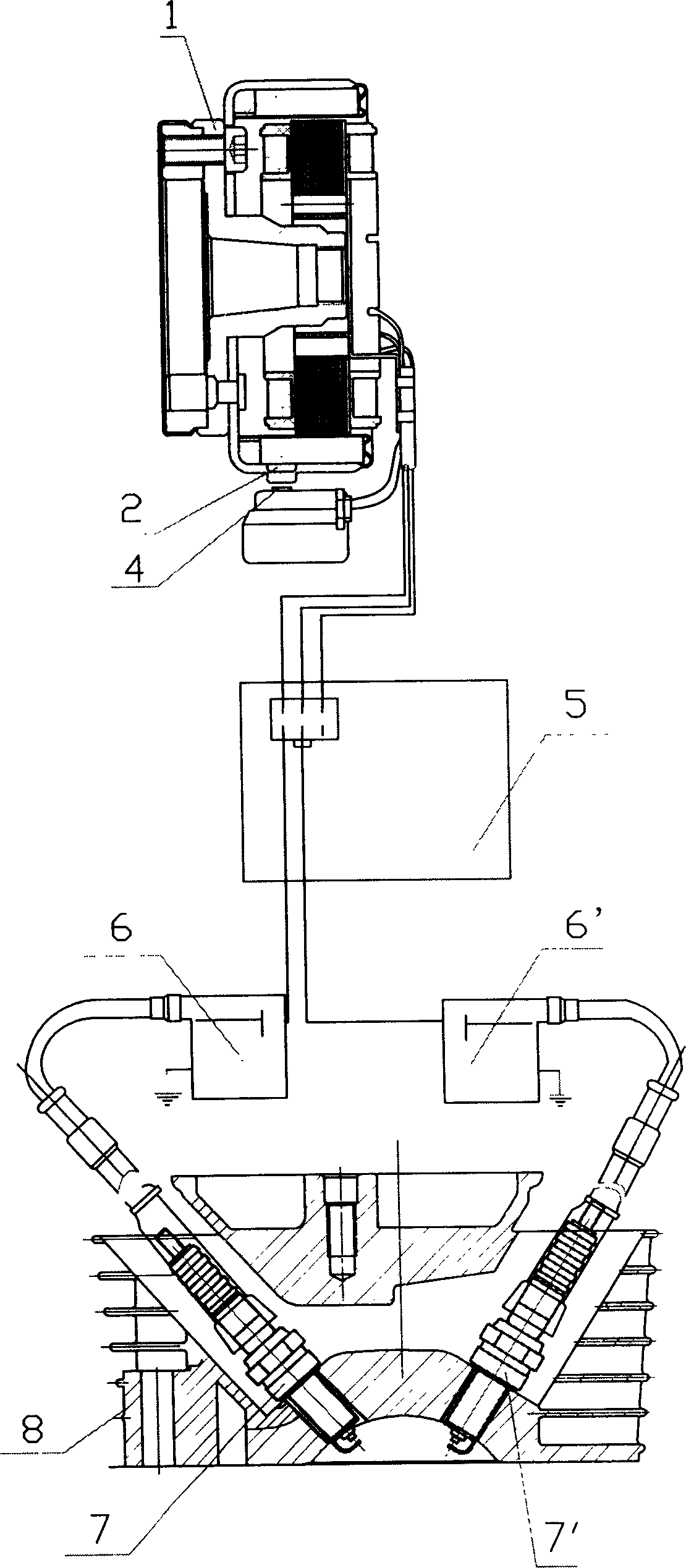

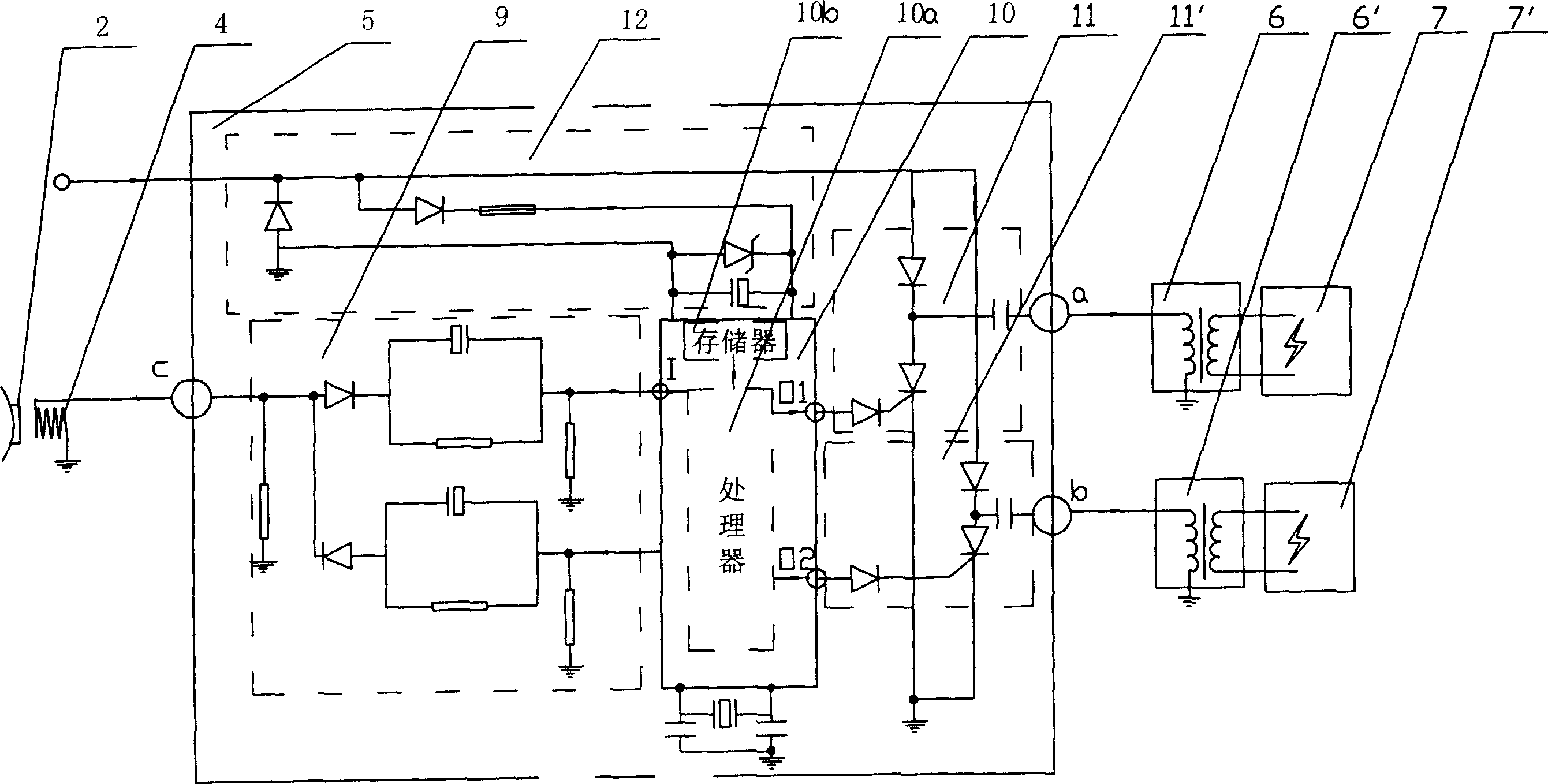

Asynchronous igniter for sparking plug of engine

ActiveCN1837601AGuaranteed separate controlWon't interfereIgnition automatic controlAutomatic controlHigh pressureLow frequency

The invention relates to a motor spark plug asynchronous igniter, which is formed by a magnetic motor rotor, a flywheel boss, an electromagnetic sensor, an electric igniter, a high-pressure boss and a spark plug. Wherein, the electric igniter receives the signal of electromagnetic sensor and sends ignition signal to the high-pressure boss to control the ignition of spark plug. The invention is characterized in that: there are morn than one high-pressure bosses, which are connected to the different outputs of electric igniter; the input of electric igniter is connected to the electromagnetic sensor to judge the speed of magnetic motor and set the ignition time sequence to send the low-frequency ignition signal or high-frequency ignition signal to several high-pressure bosses to control several spark plugs ignite synchronously or asynchronously. The invention has better anti-disturb ability and reliability.

Owner:CHONGQING ZONGSHEN ENGINE MFG

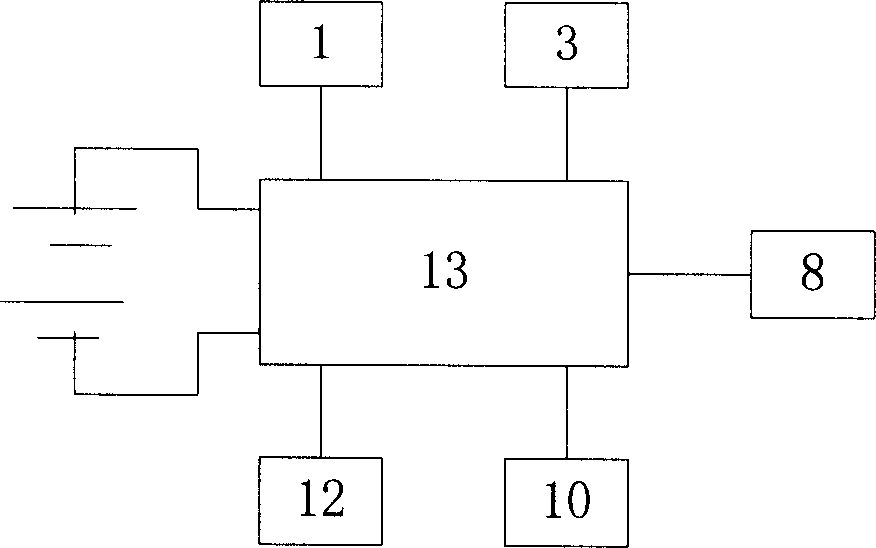

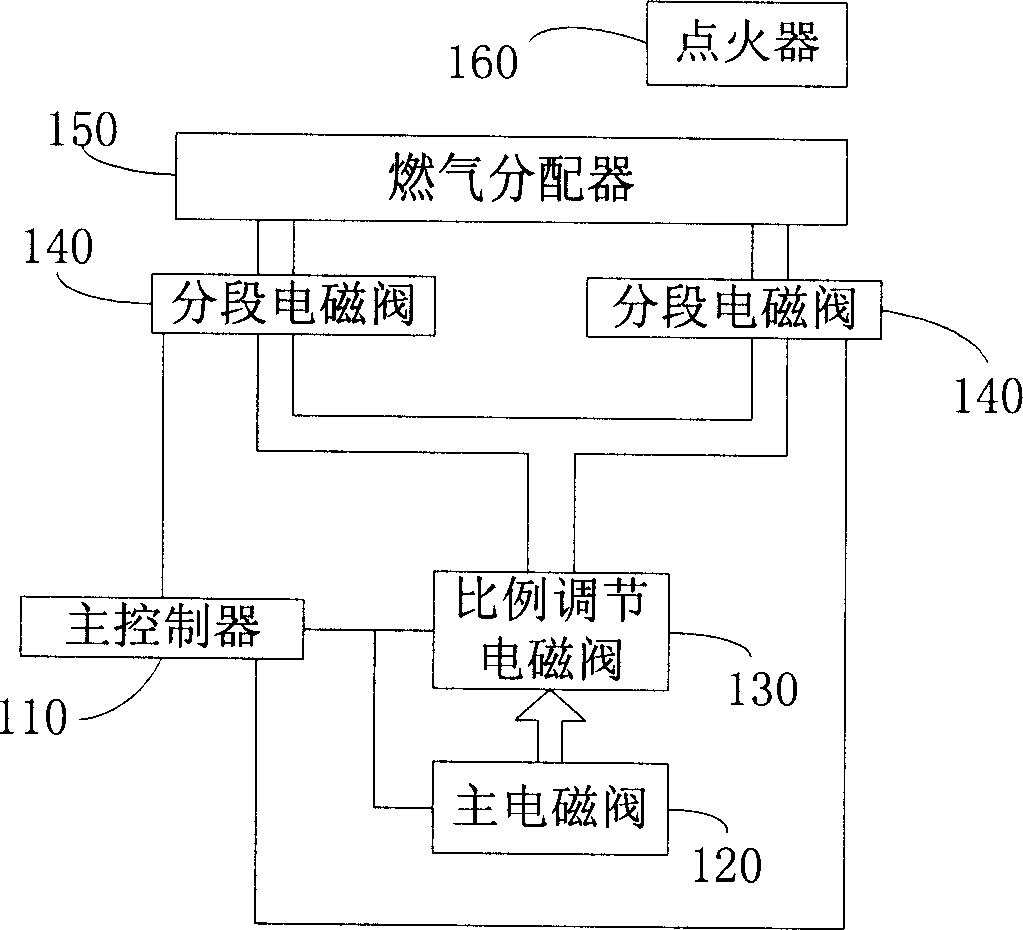

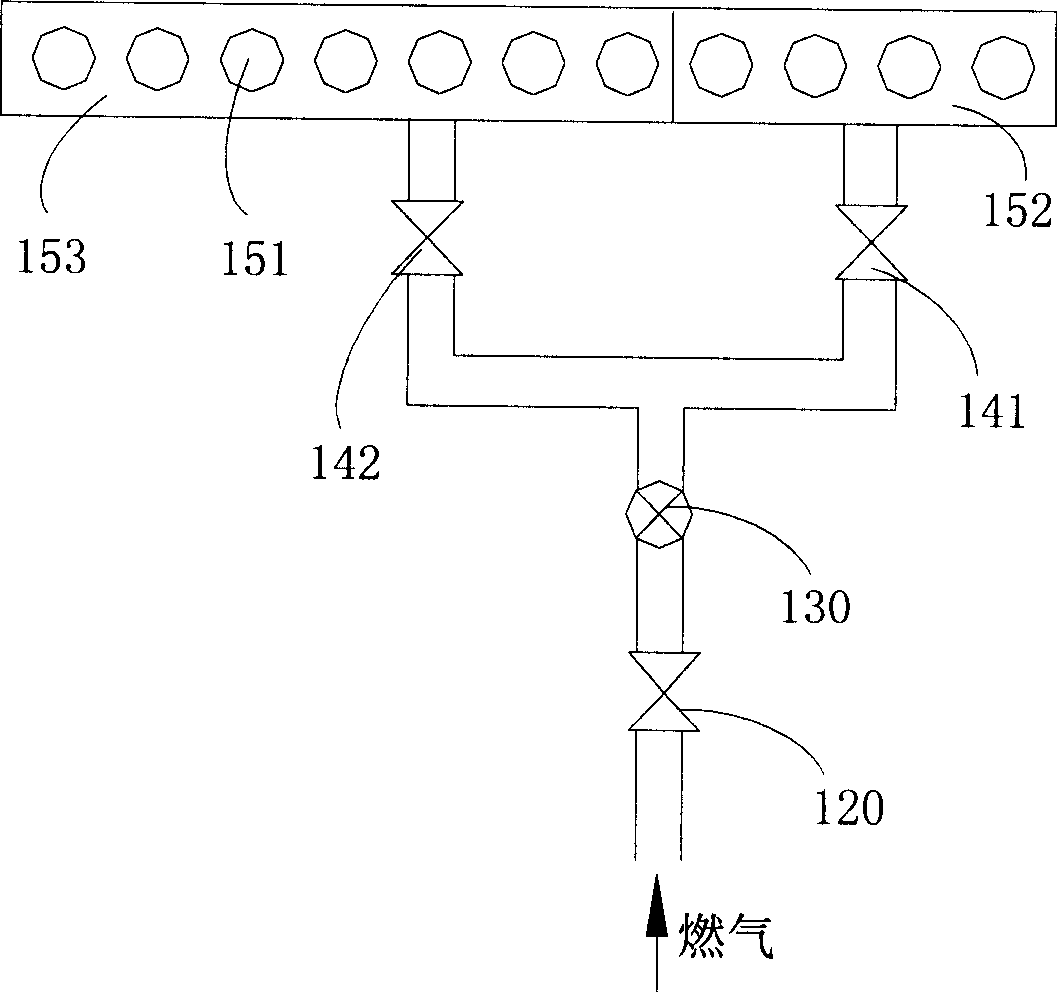

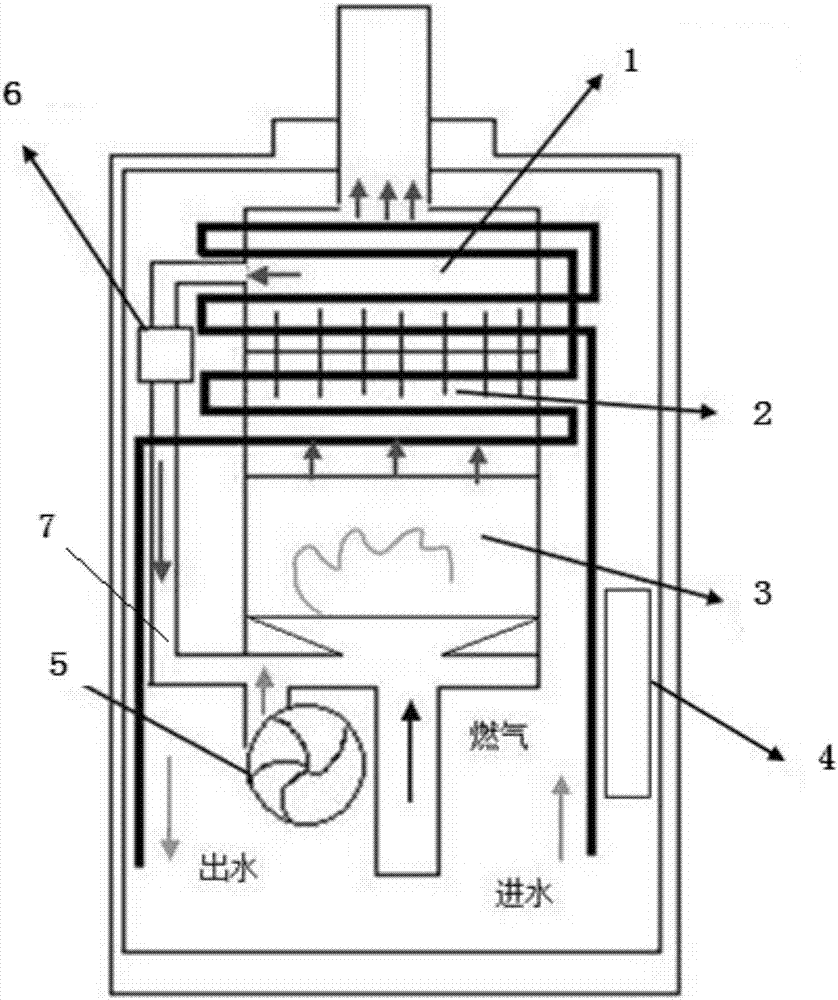

Anti-burst-burning gas water-heater

The present invention discloses explosion protection gas burning water heater. It contains main controller, lighter, blower fan and main solenoid valve, wherein said main solenoid valve located gas burning gateway for controlling gas burning gateway switch and connected to main controller, acting according to main controller instruction; said water heater also including: ratio regulation solenoid valve for regulating valve port opening to control gas burning gateway air inflow and having scheduled valve port opening in ignition; gas burning dispenser having at least two air inlet zone; solenoid valve with at least two section connected to main controller, and according to main controller instruction to act for controlling gas-fired inlet position.

Owner:HAIER GRP CORP +1

Coal mill outlet temperature control method and system based on flue gas inerting

PendingCN111520737AImprove explosion-proof performanceRealize free adjustmentDrying gas arrangementsDamper arrangementBoiler efficiencyAir volume

The invention discloses a coal mill outlet temperature control method and system based on flue gas inerting. Starting from the mechanism of detonation of a coal pulverizing system, the oxygen contentof the coal pulverizing system is reduced through the tail smoke of a boiler, the coal pulverizing system is inerting, and the anti-explosion capacity is improved. The concentration of combustible gasCO separated out through pyrolysis in the coal mill outlet pulverized coal heating process and the coal mill outlet air speed are monitored, a strategy is provided for adjusting the oxygen content, the air temperature and the air volume of inert media of the coal pulverizing system, and the temperature level of a coal mill outlet in an actual running process is determined. Compared with a traditional coal pulverizing system and method that the coal mill outlet temperature is determined according to an empirical formula, and a large amount of cold air needs to be doped, the remarkable coal type adaptation advantage and the safety guarantee advantage are achieved, the comprehensive output of the coal pulverizing system can be effectively improved, the coal pulverizing power consumption is reduced, and the boiler efficiency is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Completely-premixed intelligent cooking utensil

ActiveCN102853457AGreat potential for economic valueImprove combustion efficiencyDomestic stoves or rangesCooking fumes removalMetal sheetEngineering

The invention discloses a completely-premixed intelligent cooking utensil, which comprises a combined metal-sheet spraying cooking range, an integral metal hearth and a burning intelligent controller; the cooking range comprises an outer shell, an air inlet pipe, an inner cavity tube and a metal sheet group which is formed by superimposing at least two metal sheets, wherein the upper part of the air inlet pipe is connected with a turbine air mixing plate, the inner wall of the inner cavity tube forms an inner mixing cavity with a base and the turbine air mixing plate, and the outer wall of the inner cavity tube forms an outer mixing cavity with the outer shell and the metal sheet group. The intelligent burning controller comprises a box body, a controller which is arranged inside the box body, an ignition device which is arranged inside the box body, an ignition needle which is connected with the ignition device and a flame sensing needle which is used for detecting whether the ignition needle is fired or not; an electromagnetic proportional valve is arranged inside the box body, and a gas inlet of the electromagnetic proportional valve is connected with an external gas outlet; an air mixer is connected with an outlet of the electromagnetic proportional valve; an air inlet of the air mixer is connected with a direct-current brushless fan which is arranged inside the box body; and an outlet of the air mixer is connected with the lower part of the air inlet pipe.

Owner:南京金一燃节能科技股份有限公司

Efficient flue gas circulation system and gas water heater thereof

InactiveCN107120837AReduce the temperaturePrevent deflagrationAir heatersSustainable buildingsCombustion chamberDetonation

The invention discloses an efficient flue gas circulation system. The efficient flue gas circulation system comprises a main controller and a circulating gas inlet pipeline connected between heat exchanger flue gas and a combustor. The efficient flue gas circulation system is characterized in that the circulating gas inlet pipeline is a second-level heat exchanger connected to the gas water heater; and an electric control valve is arranged on the circulating gas inlet pipeline, and the main controller is connected with the electric control valve in an electric control manner. The invention further discloses a gas water heater of the efficient flue gas circulating system. By the adoption of the efficient flue gas circulating system and the gas water heater, the temperature of the combustor can be lowered, the gas detonation is prevented, the safety and reliability are achieved, the generation of nitrogen oxide can be inhibited effectively, the water heating efficiency is improved, and the emission of the nitrogen oxide is lowered as well.

Owner:GUANGDONG MACRO GAS APPLIANCE

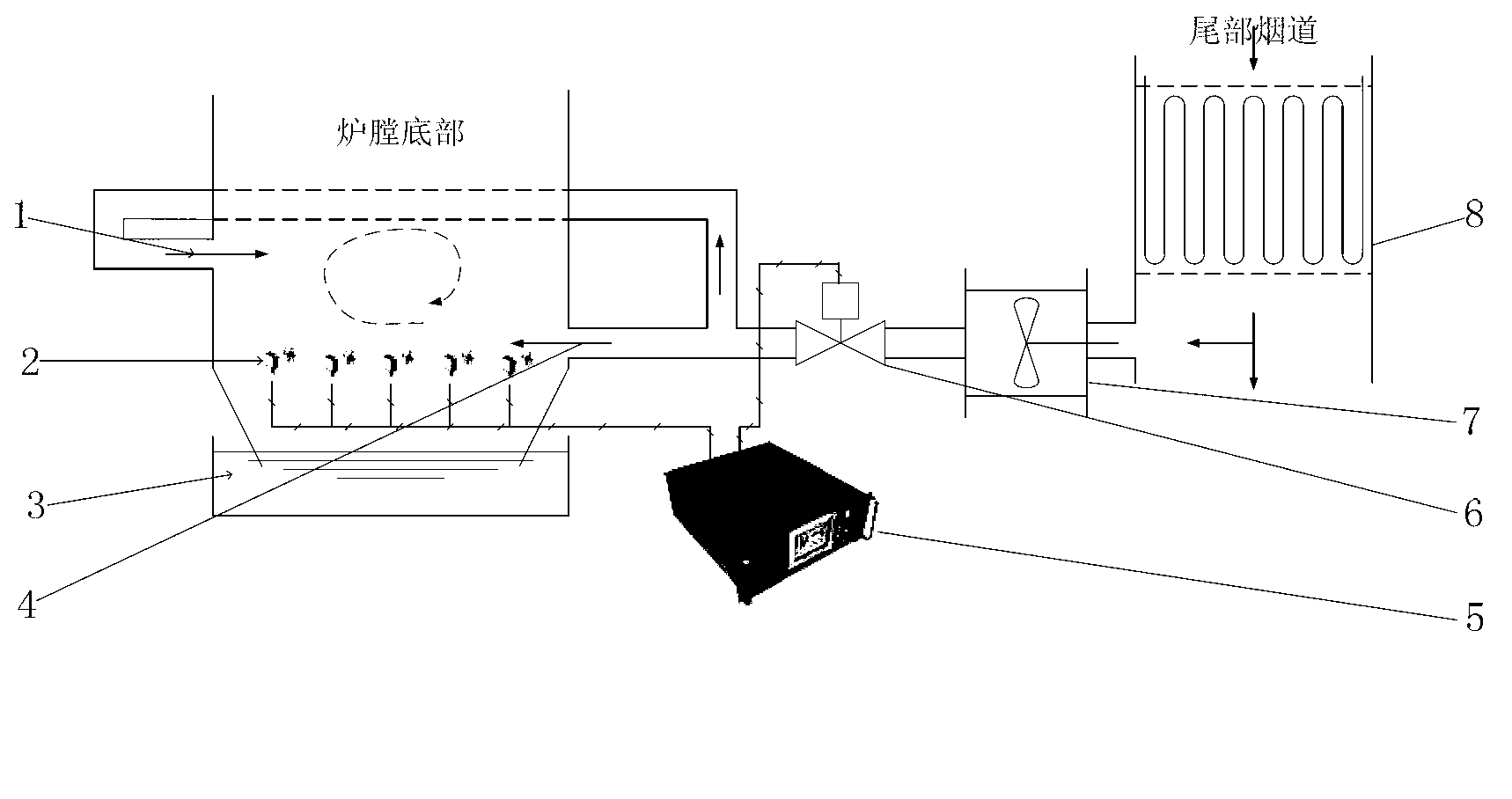

System and method for utilizing flue gas circulation to prevent deflagration of hearth bottom

ActiveCN103062789AReduce the deflagration intervalReduce deflagration intensityChamber safety arrangementHigh concentrationPower station

The invention discloses a system and method for utilizing flue gas circulation to prevent deflagration of a hearth bottom. A CO concentration online monitoring point is arranged at the bottom of a cold ash hopper area to monitor CO concentration signals of the area on line, opening of explosion suppression air regulating valves is controlled after analysis is performed through a CO concentration online monitoring system connected with the CO concentration online monitoring point, flue gas passing through a coal economizer is sent to the boiler cold ash hopper area through the explosion suppression air regulating valves in a vertically staggered hedging mode, good explosion suppression characteristics of high-concentration CO2, N2 and vapor in the flue gas are utilized to reduce a deflagration concentration interval of the reducing combustible gas CO in the area and deflagration strength which may occur, and the goal of preventing, weakening and eliminating deflagration is achieved. The system is of great significance for safe operation of a large power station boiler under the conditions of coal quality fluctuation.

Owner:XI AN JIAOTONG UNIV

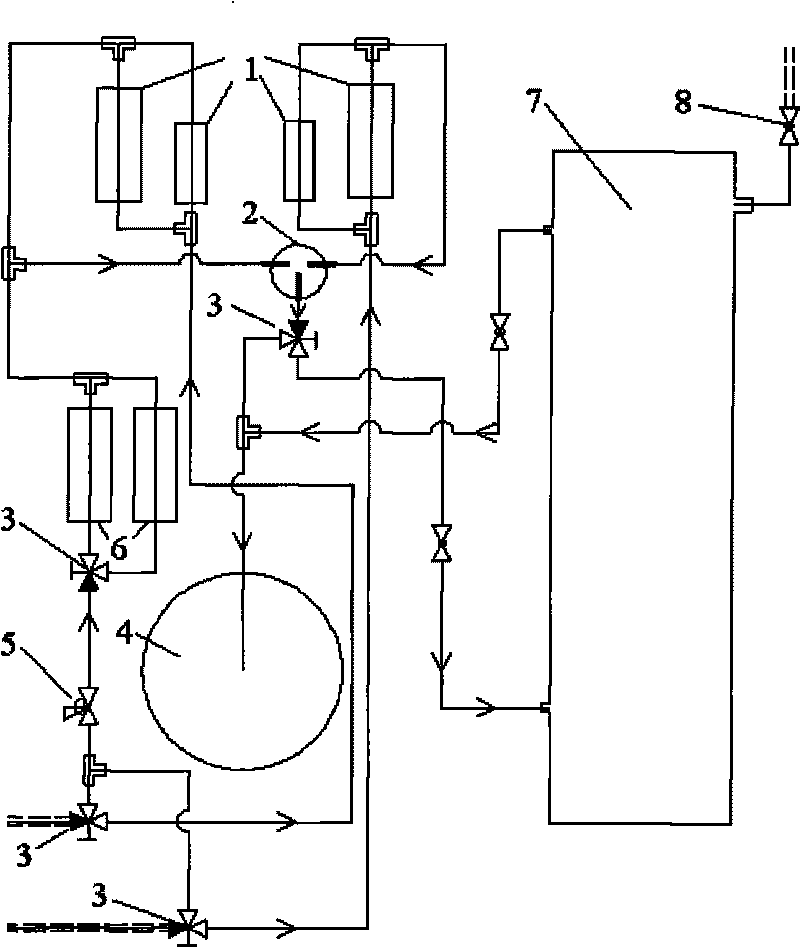

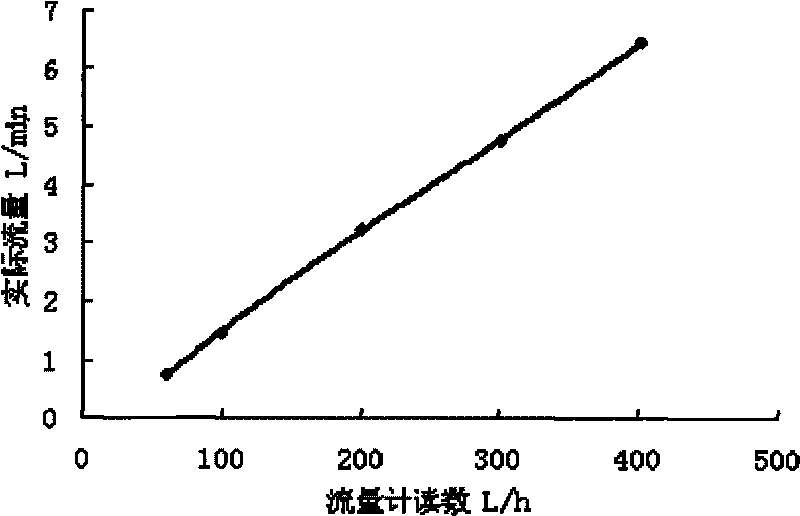

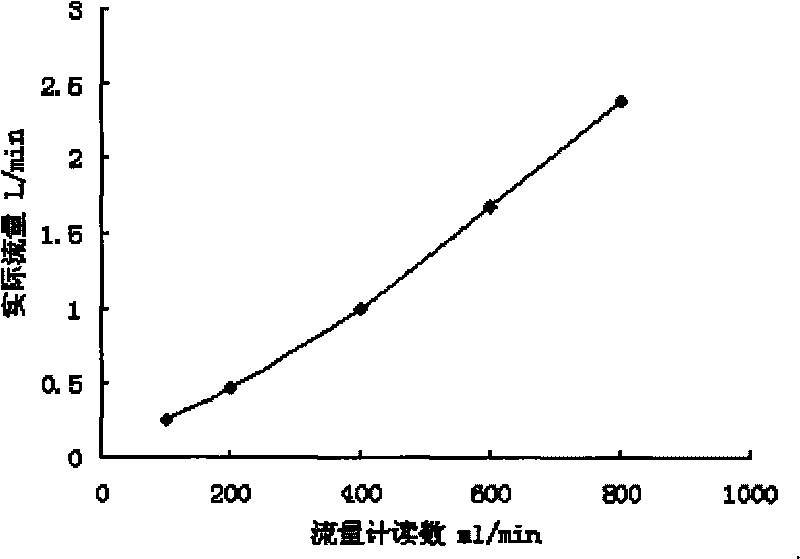

Method and device for calibrating flow of gas combustibility test

InactiveCN101696890AEasy to operateReduce volumeChemical analysis using combustionTesting/calibration apparatusGas cylinderGas passing

The invention relates to a method and a device for calibrating the flow of a gas combustibility test. The method comprises the following steps: introducing a gas into a manual glass rotameter or an electric flow meter; adjusting the flow of the gas, and recording the volume of the gas passing through a volume calibrating flow meter in certain time by a stopwatch; and acquiring a flow calibration curve of the gas by using the reading values of the flow meter as abscissas and the values of the actual flow as ordinates. The calibrating device comprises the flow meter, the calibrating flow meter, a gas mixing cylinder, a three-way valve and an electric control valve, wherein the flow meter and the calibrating flow meter are designed on a panel of the device; the gas mixing cylinder is connected with the flow meter and the calibrating flow meter; and the three-way valve is arranged between the gas mixing cylinder and the calibrating flow meter. The method and the device simplify the testing device and the operation steps and improve the operability of the test, have the advantages of small equipment volume, low cost, compact device structure, simple operation and low operation cost, save the testing time, improve the working efficiency, and have wide application and good security.

Owner:SHANGHAI RES INST OF CHEM IND +1

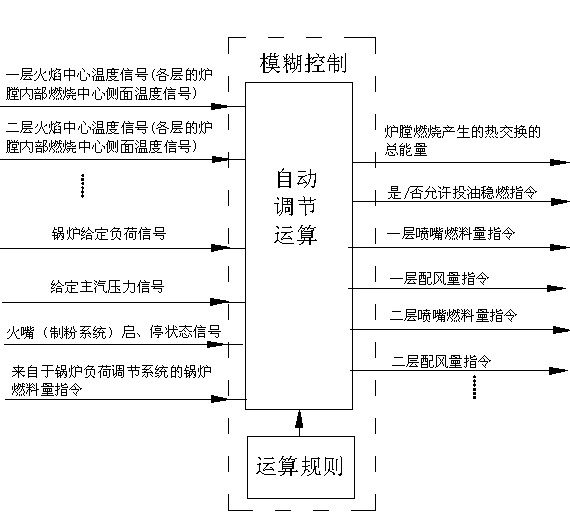

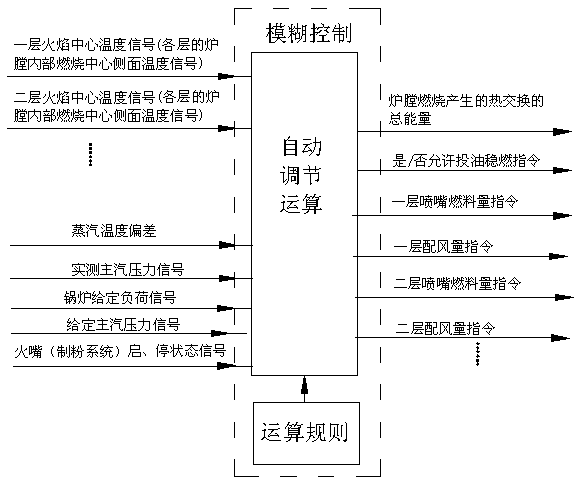

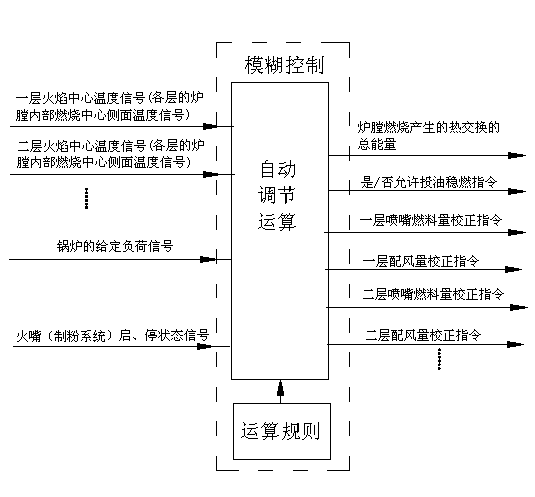

Automatic control method for preventing extinguishment and realizing ideal combustion for hearth

ActiveCN103047678AAutomatically adjust coal consumptionPrevent deflagrationCombustion regulationAutomatic controlCombustion

The invention discloses an automatic control method for preventing extinguishment and realizing ideal combustion for a hearth. The automatic control method is implemented by the aid of a full hearth control unit, signals inputted into the full hearth control unit at least include center temperature signals of various flame layers, given load signals of a boiler and starting and stopping state signals of various nozzles or pulverizing systems, automatic control operation is carried out inside the full hearth control unit, and signals outputted after automatic control operation at least include one type of fuel quantity instructions or fuel quantity correcting instructions of the various layers, air distribution quantity instructions or air distribution quantity correcting instructions of the various layers, oil feed combustion stabilizing instructions and total heat exchange energy signals generated during combustion of the hearth. The automatic control method has the advantages that the fuel coal quantity of the boiler and air quantities of the combustion nozzles can be adjusted automatically, excessively high temperature of the inside of the hearth is prevented, the boiler keeps in a stable combustion state, the extinguishment condition is stopped, the automatic control method is safe and convenient, and accordingly purposes of preventing extinguishment and realizing ideal low-nitrogen combustion are achieved for the hearth.

Owner:刘建松

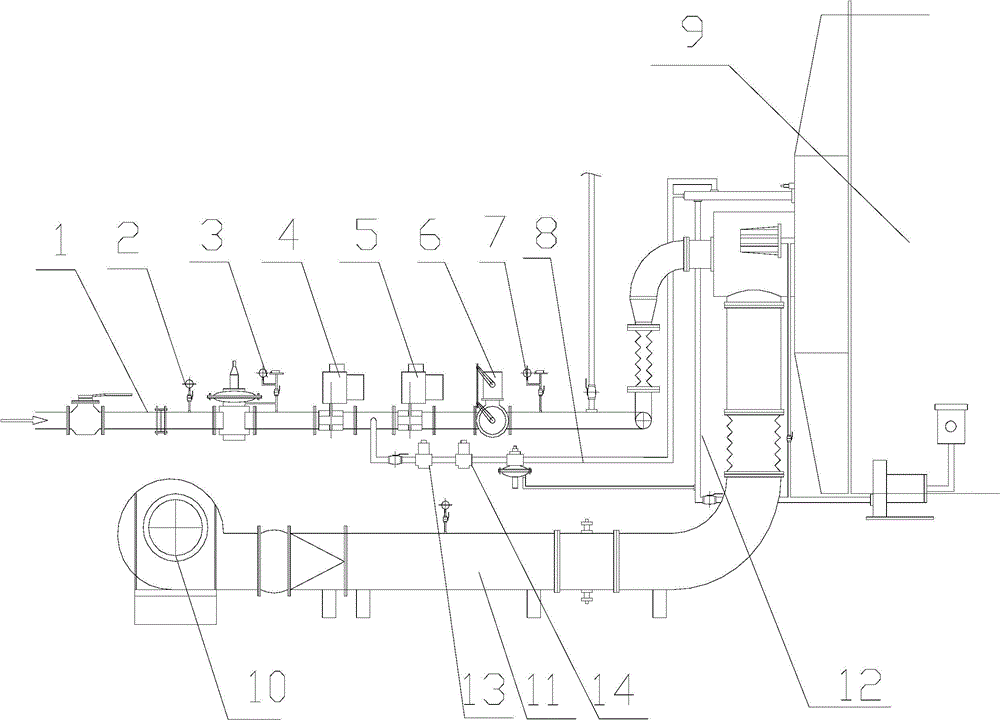

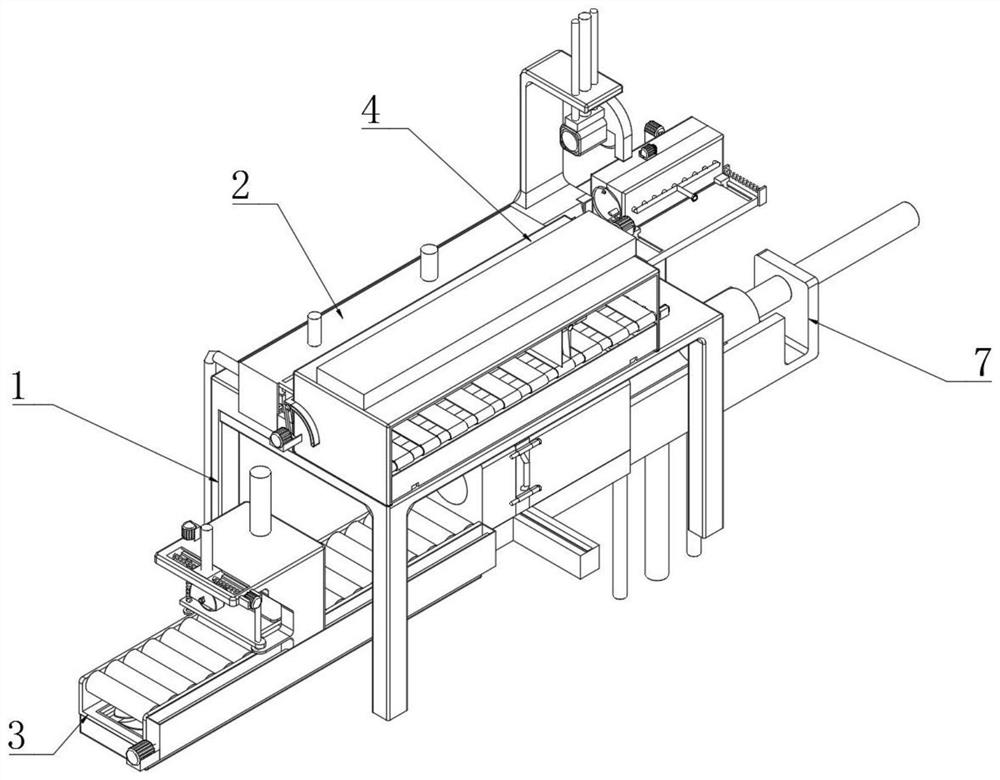

Low-concentration gas wet pressurization equipment and method of coal mine

InactiveCN104329565AReduce the temperaturePrevent deflagrationPipeline systemsFlame arresterInlet pressure

The invention relates to low-concentration gas wet pressurization equipment. The equipment comprises a gas delivery main pipeline, wherein the gas delivery main pipeline is provided with a first wet pressure relief and explosion venting device, a water seal flame arrester, a first spray device, a steam-water separator, a flow measurement device, a pressure and temperature measurement device, a centrifugal booster fan, a second spray device, a dry flame arrester and a second wet pressure relief and explosion venting device from an air flow direction in sequence. Since the series of devices are rationally arranged on the low-concentration gas delivery main pipeline to meet the requirement on pressurization in the low-concentration gas delivery process to achieve the purpose of guaranteeing the inlet pressure of a generating set, and the equipment cost is lower compared with the existing water circulating vacuum pump, the equipment is easy to mount, the safety precautions are complete, and the purpose of low-concentration gas pressurization can be achieved.

Owner:北京扬德环保能源科技股份有限公司

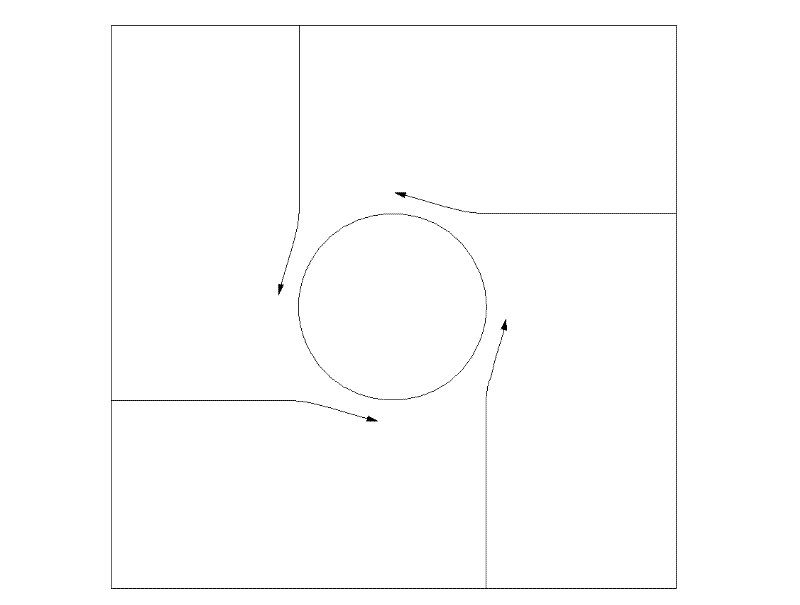

Low-load stable-combustion direct-current combustor

PendingCN106838895ATo achieve the purpose of premixingPrevent deflagrationPulverulent fuel combustion burnersCombustorSlag

A low-load stable-combustion direct-current combustor comprises a natural gas pipeline. The natural gas pipeline extends to a central air duct to supply natural gas, a cyclone arranged at the outlet of the central air duct conveys mixed gas to a precombustion chamber for combustion, a primary air pipe providing primary pulverized coal to the precombustion chamber is arranged outside the central air duct, an internal secondary blowdryer providing internal secondary air to the precombustion chamber is arranged outside the primary air pipe, an external secondary blowdryer providing external secondary air to the precombustion chamber is arranged outside the internal secondary blowdryer, the precombustion chamber is divided into an expansion section and a horizontal section along the inlet direction of the mixed gas, an internal-secondary-air annular nozzle is arranged in the intersection of the expansion section and the horizontal section, the internal secondary air is in annular direct-current incidence from the internal-secondary-air annular nozzle, combustion supporting function is achieved, slag build-up and pulverized-coal accumulation can be avoided; the external secondary air is injected in a direct-current oblique manner to supplement air needed for subsequent combustion of pulverized coal flow, and meanwhile, formation of NOx is reduced. By the arrangement, low-load stable combustion of a pulverized-coal combustor can be realized, and deep participation in peak regulating of a coal-fired power plant is favorably improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

Method for improving rating steady-state operation power of homogeneous water solution nuclear reactor

ActiveCN101271737ASmall fluctuationGuaranteed long-term uniform stabilityNuclear energy generationHomogenous reactorsIonDecomposition

The invention provides a method for improving the rated stable operation power of uniformity solution nuclear reactor, which is characterized in that a flat reactor core with the ratio of height and the diameter less than 0.5 is adopted to enlarge the surface area of reactor core fuel solution, to reduce the vacuolar coefficient of fuel solution, to control the surface releasing ratio of radiantly decomposed gas: hydrogen and oxygen and to control the reactor core specific power; ruthenium iron ions are added in reactor fuel solution and a device which converts nitrogen generated by the radiation and decomposition of HNO3 into HNO3 and an automatic continuous HNO3 supplementation system are additionally added, so as to enlarge the surface area of a heat exchanger, the gas circuit flux of nuclear reactor and hydrogen and oxygen composition capability of a hydrogen and oxygen compositor in the gas circuit, and to control the hydrogen consistency in the gas circuit. The method of the invention can ensure that the rated stable operation power of the uniformity solution nuclear reactor is higher than 200kW.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Energy-saving oil-combustion hot-air furnace

The invention relates to an energy saving fuel oil hot air oven, characterized in that it mainly comprises combustion chamber, heating room and fan; the heating room is an air heating channel, on which there are air inlet and air outlet; the fan is located on the flowing path in the heating room so as to make air flow from the air inlet to the air outlet; the combustion chamber is set in the heating room and there is an air flow space between the periphery of combustion chamber and the wall of heating room; the combustion chamber is a cylinder combustion room; one end is igniting end connected with adding fuel burner and the other end is closed as fireproof plate and reversal combustion end; a group of heat dissipation holes are set on the peripheral wall of cylinder at the igniting end evenly and a group of noise damping holes are set on the peripheral wall at the fireproof plate and reversal combustion end evenly; the hole diameter of said heat dissipation hole is larger than the one of noise damping hole. The invention makes flame burn secondly in the combustion chamber and burning is sufficient. Heat quantity after burning can be discharged directly to firing or drying so that it is more energy saving and heat efficiency can achieve 95% or so. It is provided with simple whole structure and convention manufacture.

Owner:SUZHOU GENSHENG COATING ENG

Regionalization and leveling lean combustion engine control method

ActiveCN104533642AEasy to chargeReduce lossesElectrical controlNon-fuel substance addition to fuelInlet channelEngineering

The invention discloses a regionalization and leveling lean combustion engine control method. According to the method, an air inlet conversion valve I, an air inlet conversion valve II, an oil sprayer I and an oil sprayer II are connected on an electronic control unit respectively. A combustion chamber is divided into a small combustion region and a large combustion region. A cylinder air inlet tube is connected onto the large combustion region and the small combustion region respectively, a cylinder air inlet tube channel dividing plate is arranged in each cylinder air inlet tube, and each cylinder air inlet tube is divided into a large air inlet channel and a small air inlet channel. By the aid of the method, the engine regionalization and leveling combustion is achieved, the engine inner combustion oil combustion efficiency is improved, exhaust waste and oil consumption of the engine are reduced, the engine can be used safely during large loads, and accordingly, the environment-friendly performance of automobiles during traveling is improved, and the usage cost is reduced.

Owner:广州强劲航空科技有限公司

Supercharged boiler deflagration-preventing device and method

The invention provides a supercharged boiler deflagration-preventing device and method. The supercharged boiler deflagration-preventing device comprises a sampling device, an oil-gas concentration detection device and a warning device. The oil-gas concentration detection device comprises a sampling probe, a filter, a cooling system, an automatic extracting device and a sampling chamber. The sampling probe is inserted into a boiler furnace, oil gas at the periphery of the sampling probe is extracted by the automatic extracting device, filtered and cooled to enter the sampling chamber, the mixing gas is extracted from the chamber by the oil-gas concentration detection device and subjected to catalytic combustion in a catalytic combustion device, the produced combustion product is analyzed by a gas analyzer, the gas analyzer displays the oil-gas concentration and compares the concentration with a setting value so as to determine whether to warn, and the warning device warns when needing alarm. The invention can be applied to the operation protection of land and ship supercharged boilers.

Owner:HARBIN ENG UNIV

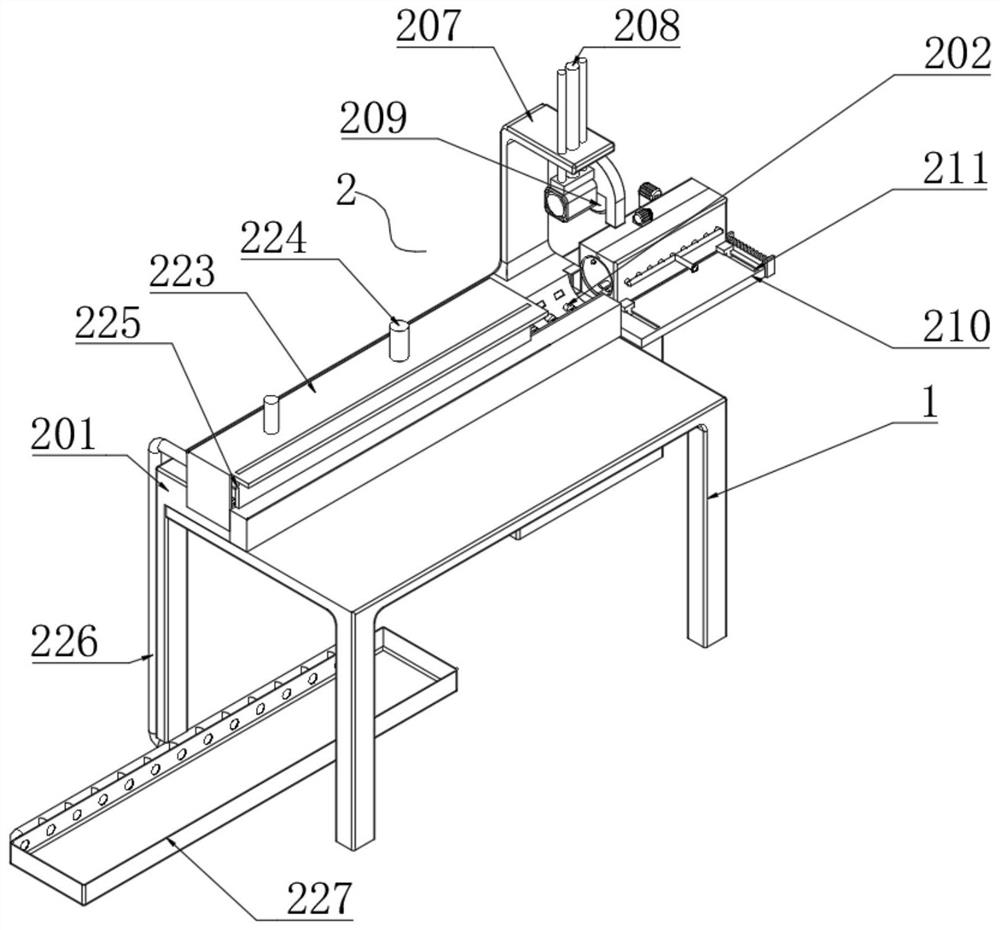

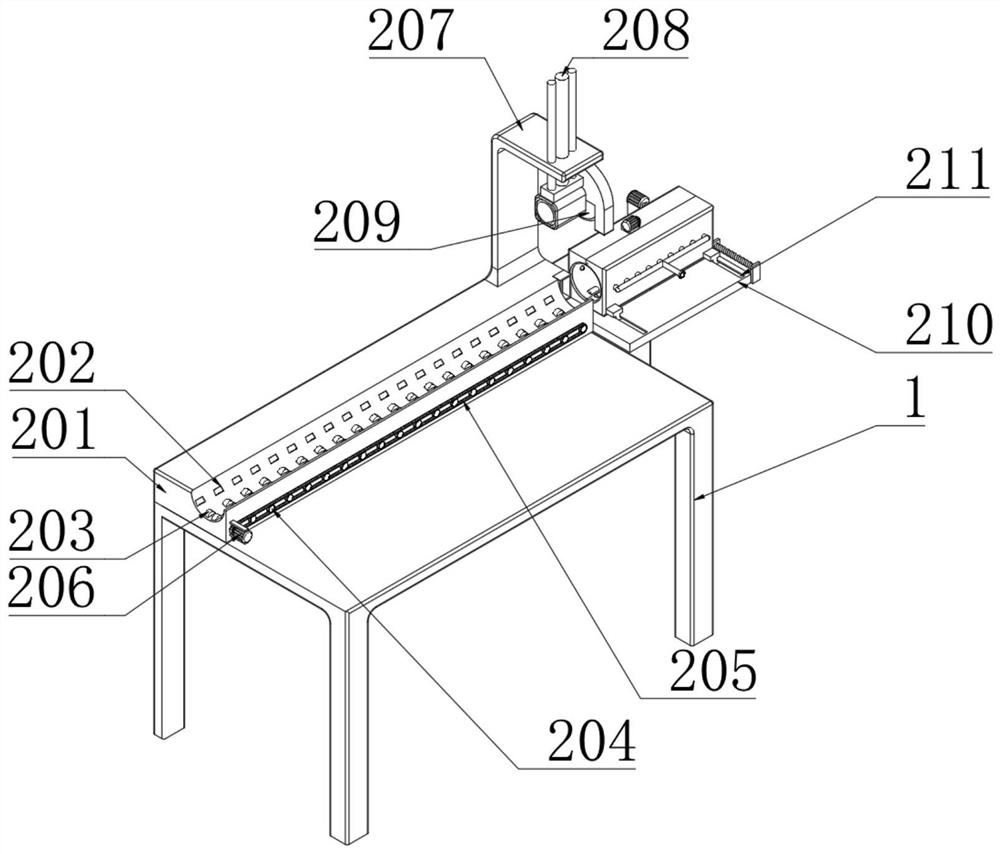

Aluminum profile machining device

InactiveCN112828396AScientific and reasonable structureEasy to useMetal working apparatusMaintainance and safety accessoriesHydraulic cylinderMetallurgy

The invention discloses an aluminum profile machining device. The aluminum profile machining device is characterized in that an arc-shaped conveying table is welded to the top end of a fixed supporting frame, roller mounting grooves are formed in the top end of the arc-shaped conveying table, moving rollers are installed on the inner side of the roller mounting grooves, and the moving rollers are connected to transmission gears through rolling rods; an aluminum ingot cutting knife set is fixedly installed at the bottom end of a lifting hydraulic cylinder, a heating box is embedded into the top end of a fixed supporting plate, a two-way lead screw penetrates through one end of the heating box, a rotating groove is formed in the inner side of the heating box, and rotating wheels are installed on the inner side of the rotating groove; an aluminum ingot is driven to move into the heating box through the moving rollers, an external mechanical arm is not needed, and the aluminum ingot can be directly conveyed to move, so that the cut aluminum ingots are conveniently and rapidly conveyed into the heating box; and the situation that thermal stress cracks occur to the aluminum ingots due to the fact that part of the aluminum ingots are heated unevenly when the aluminum ingots are heated is avoided through circulating heat supply, and the situation that the aluminum ingots influence follow-up manufacturing is avoided.

Owner:黄嘉欣

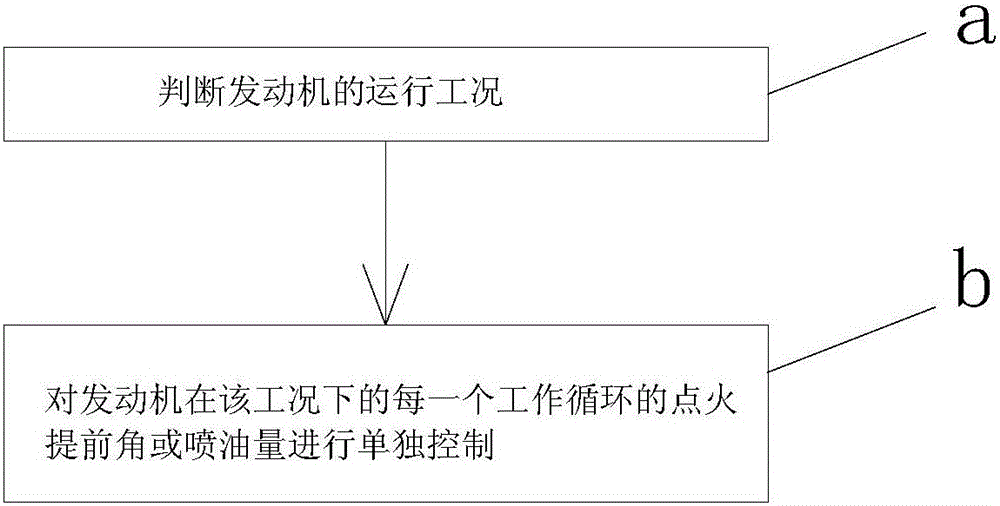

Engine ignition control and fuel injection control methods based on engine cycles

ActiveCN106246437AImprove powerImprove economyElectrical controlInternal combustion piston enginesWork cycleControl parameters

The invention discloses engine ignition control and fuel injection control methods based on engine cycles. The engine ignition control method comprises the steps of a, judging the operation condition of an engine; and b, and independently controlling the ignition angle of advance and fuel injection quantity of the engine in each working cycle under the condition. According to the engine ignition control and fuel injection control methods, control for ignition and fuel injection of the engine is refined in each working cycle of the engine, control parameters (ignition time, fuel injection pulse width and fuel injection phase position) of all the working cycles of the engine are more accurate, the accuracy of the control parameters under the transition working condition is guaranteed, and finally, the dynamic property, economy and emission level of the engine are improved to the greatest extent.

Owner:CHONGQING LONCIN MOTOR

Oxygen enriched combustion system

ActiveCN102588997APrevent deflagrationPrimary air temperature increasedPulverulent fuel combustion burnersDirect carbon-dioxide mitigationCombustion systemEngineering

The invention discloses an oxygen enriched combustion system, which comprises a boiler body, a cyclone combustor, a primary air circulating system, a secondary air circulating system and an oxygen supply system. The boiler body consists of a smoke exhaust pipeline, the cyclone combustor comprises a primary air channel and a secondary air channel and is disposed on the boiler body, the smoke exhaust pipeline is connected with the primary air channel of the cyclone combustor by the primary air circulating system, the smoke exhaust pipeline is connected with the secondary air channel of the cyclone combustor by the secondary air circulating system, and the oxygen supply system is connected with the primary air channel and the secondary air channel and inputs oxygen. The temperature of primary air of an outlet of a coal mill can be greatly increased by means of drying recycled smoke and conveying pulverized coal, the highest temperature of the primary air can reach about 200 DEG C, the pure oxygen can be quickly injected into the high-temperature primary air / airflow of the pulverized coal and is sufficiently mixed with the high-temperature primary air / the air flow of the pulverized coal, and accordingly the pulverized coal is injected into a boiler and is quickly ignited and combusted; combustion efficiency is greatly improved; and concentration of CO2 of the smoke exhausted from the boiler reaches 80% at least, and the CO2 can be captured conveniently.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com