Efficient flue gas circulation system and gas water heater thereof

A gas-fired water heater and circulation system technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of uncontrollable addition amount, inability to achieve results, affecting combustion performance, etc., to reduce emissions and improve heat. Water efficiency, effect of preventing gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The patent of the present invention will be further described below with reference to the drawings and embodiments.

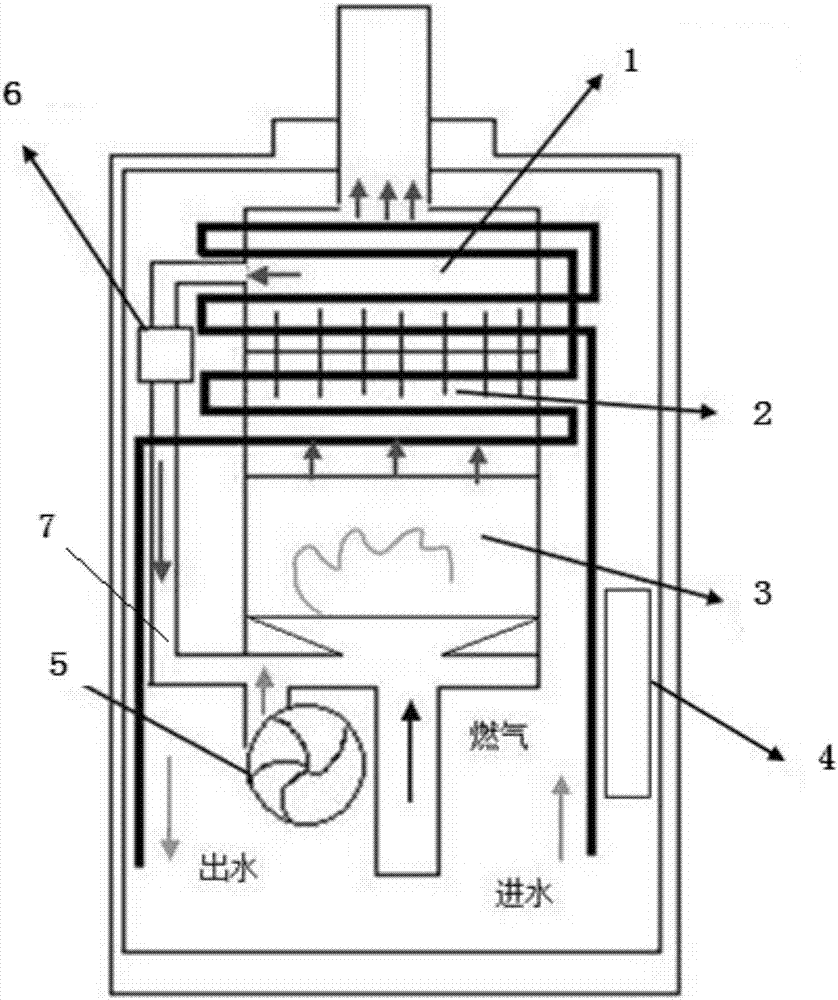

[0018] Such as figure 1 As shown, the water heater of the present invention is mainly composed of a primary heat exchanger 2, a secondary heat exchanger 1, an electronically controlled air valve 6, a strong blower DC fan 5, a combustion chamber 3, a main controller 4 and other components. The direct current fan 5 is arranged on the air intake pipe of the combustion chamber 3, a circulating intake pipe 7 is arranged between the flue gas of the secondary heat exchanger 1 and the combustion chamber 3, and an electric control valve 6 is arranged on the circulating intake pipe 7 , The flue gas guide port of the circulating air inlet pipe 7 is arranged on the right side of the secondary heat exchanger 1, and the circulating air inlet pipe 7 communicates with the air inlet pipe. The opening and closing of the passage is controlled by the electronic control air val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com