Early-warning adjustment system and early-warning adjustment method for preventing detonation of large-scale power station pulverized-fuel boiler furnace

A pulverized coal boiler and furnace deflagration technology, which is applied in the control of combustion, lighting and heating equipment, indirect carbon dioxide emission reduction, etc. the effect of reducing the possibility of deflagration and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

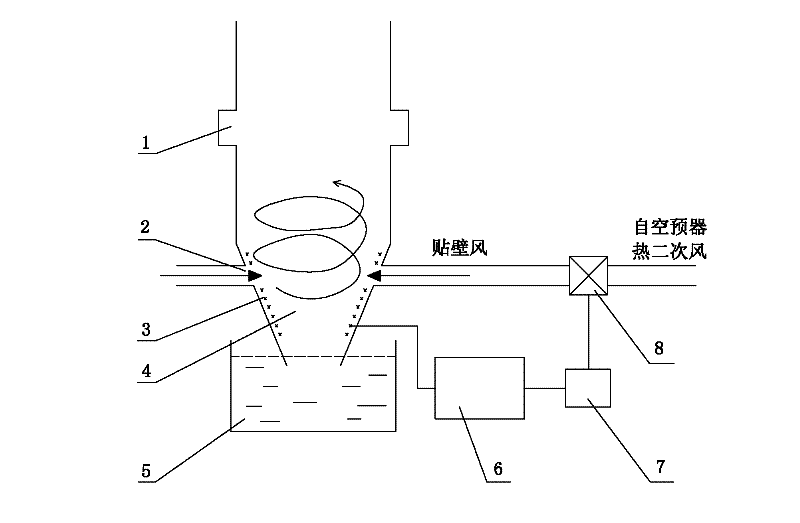

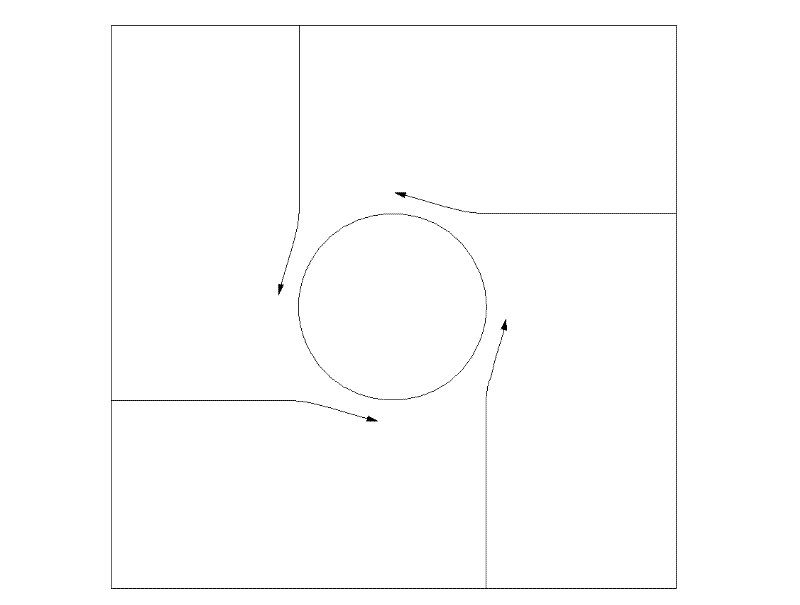

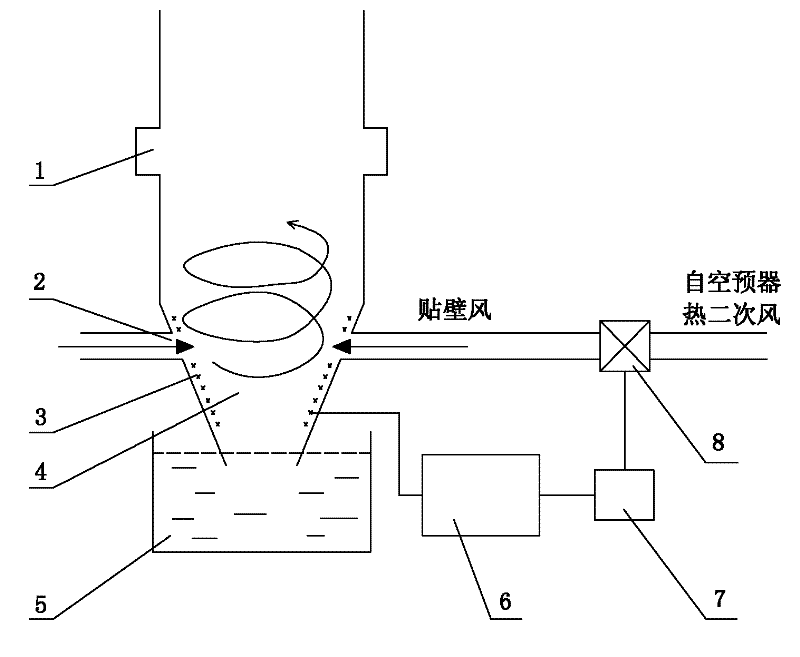

[0018] see figure 1 , 2, the present invention arranges a series of CO concentration measuring points 3 on the wall surface of the cold ash hopper platform 4 below the boiler burner 1, and the CO concentration measuring points 3 are connected with the CO concentration field analysis system 6, and the CO concentration field analysis system 6 passes through The DCS system 7 controls the wall-adhesive wind regulating valve 8, and the CO concentration field analysis system 6 provides a feedback signal for the wall-sticking wind regulating valve 8, and directly controls the opening of the wall-sticking wind regulating valve 8 through the DCS system 7, and the wall-sticking wind regulating valve 8. Through the air pipe, it is connected with the wall-attached air nozzle 2 installed on the wall of the cold ash hopper platform 4. The wall-attached air nozzle 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com