Coal mill outlet temperature control method and system based on flue gas inerting

A technology of outlet temperature and control system, applied in the direction of combustion method, dryer, valve configuration, etc., can solve the problems of insufficient output of the pulverizing system and reduced economic efficiency, achieve significant advantages of coal type adaptation, improve comprehensive output, The effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

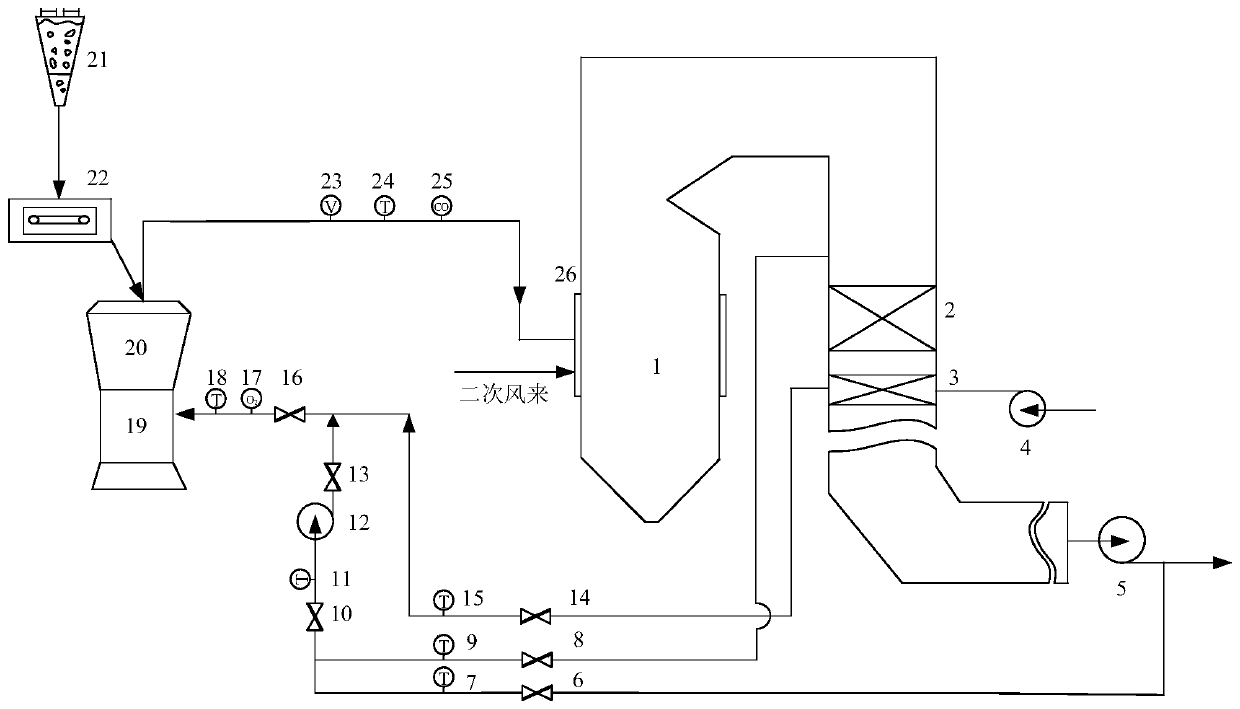

[0026] see figure 1 , the coal mill outlet temperature control method and system based on furnace fume inertization in the present invention include a boiler 1, a tail flue heat exchanger 2, an air preheater 3, a primary fan 4, an induced draft fan 5, a low-temperature furnace smoke damper 6, Low temperature furnace smoke temperature measuring point 7, high temperature furnace smoke damper 8, high temperature furnace smoke temperature measuring point 9, furnace smoke fan inlet damper 10, mixed furnace smoke temperature measuring point 11, furnace smoke fan 12, furnace smoke fan outlet damper 13, heat Primary damper 14, hot primary air temperature measuring point 15, coal mill inlet damper 16, mill inlet oxygen measuring point 17, mill inlet temperature measuring point 18, coal mill 19, pulverized coal separator 20, coal bunker 21, supply Coal machine 22, pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com