Passive vision navigation unmanned forklift system for explosion-proof warehouse and navigation method

A passive vision, unmanned forklift technology, applied in control/adjustment systems, two-dimensional position/channel control, vehicle position/route/altitude control, etc., can solve the problems of harm to human health, low efficiency, and high labor costs , to achieve the effect of reducing manpower input, good explosion-proof performance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

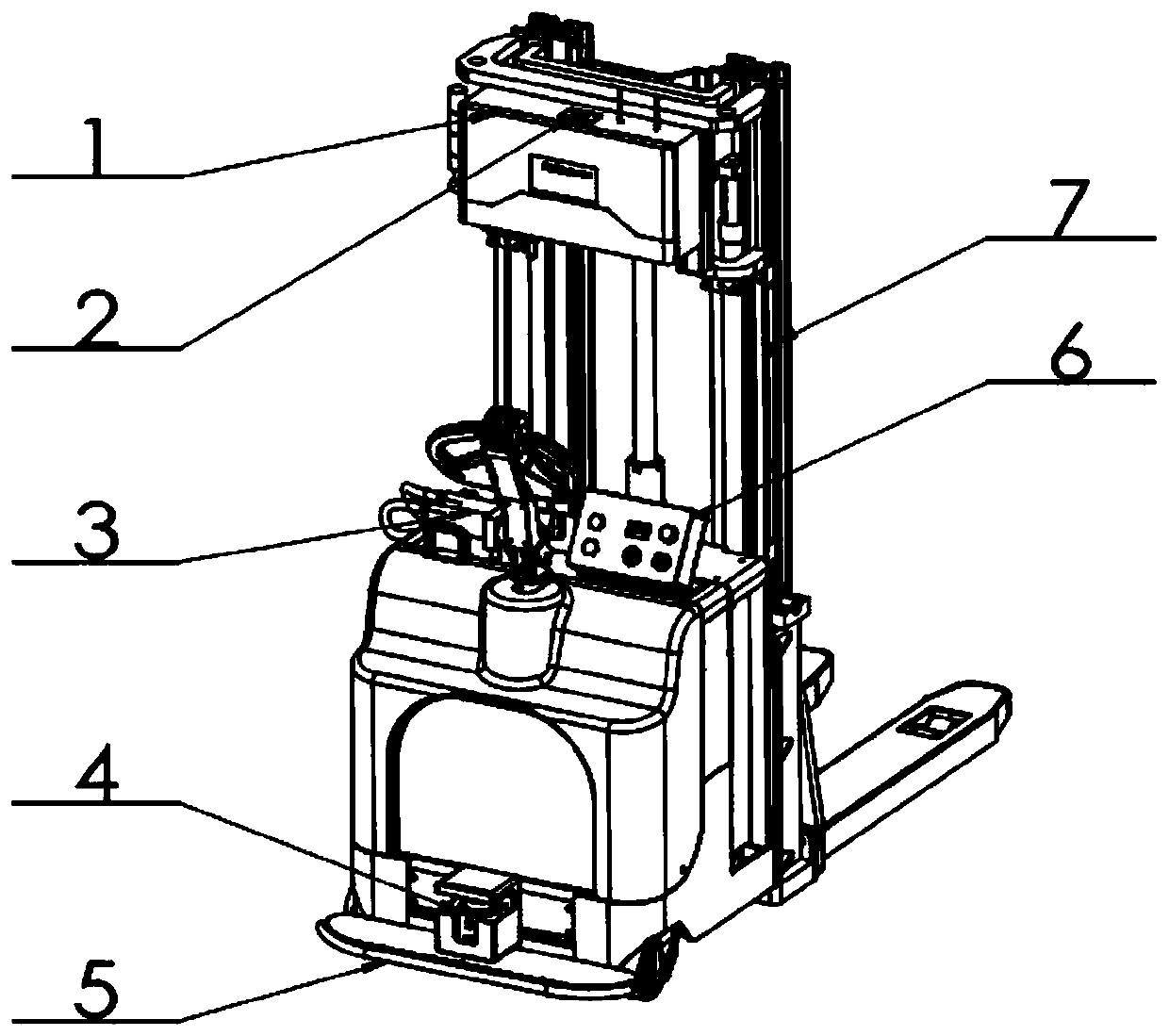

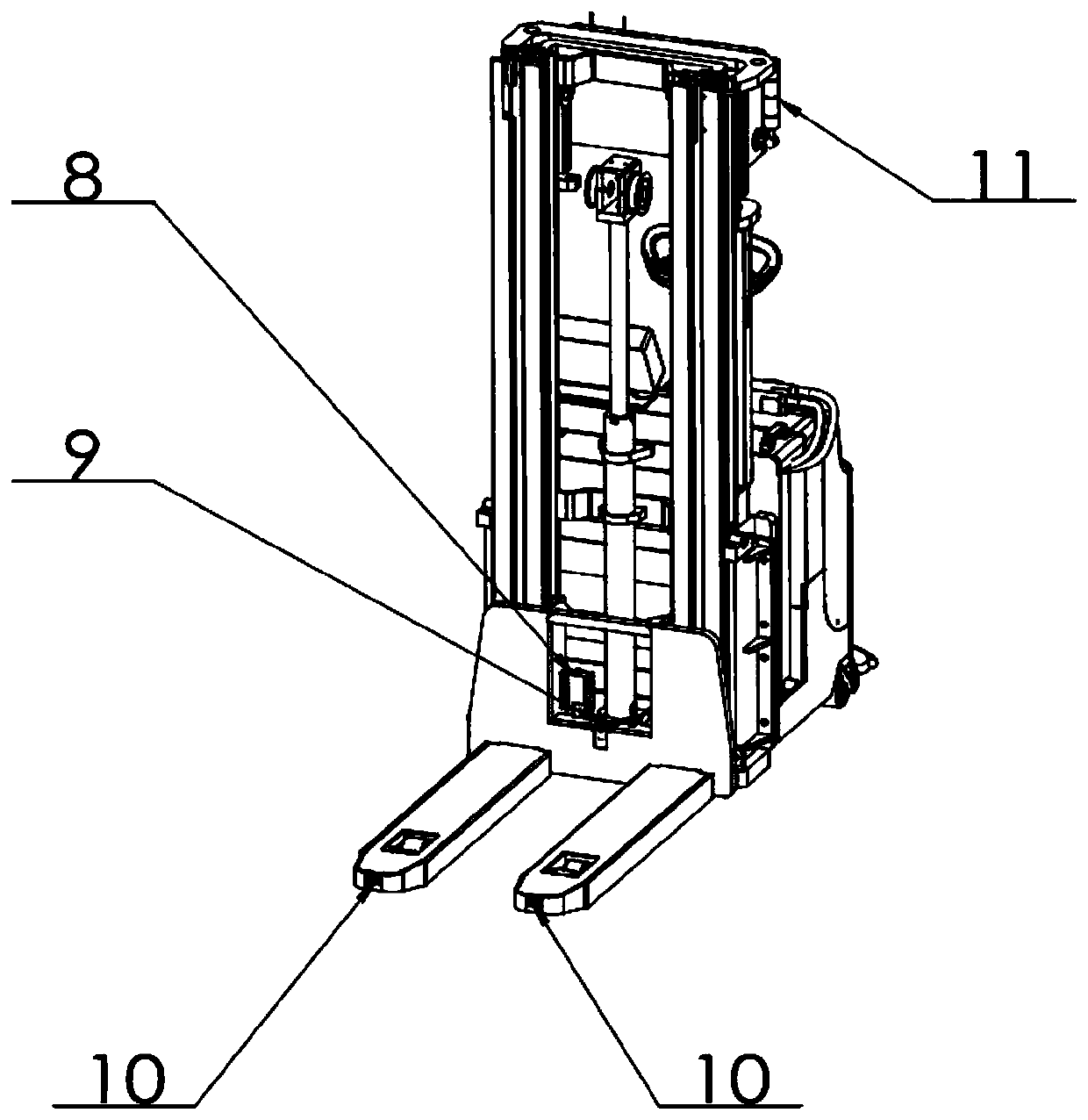

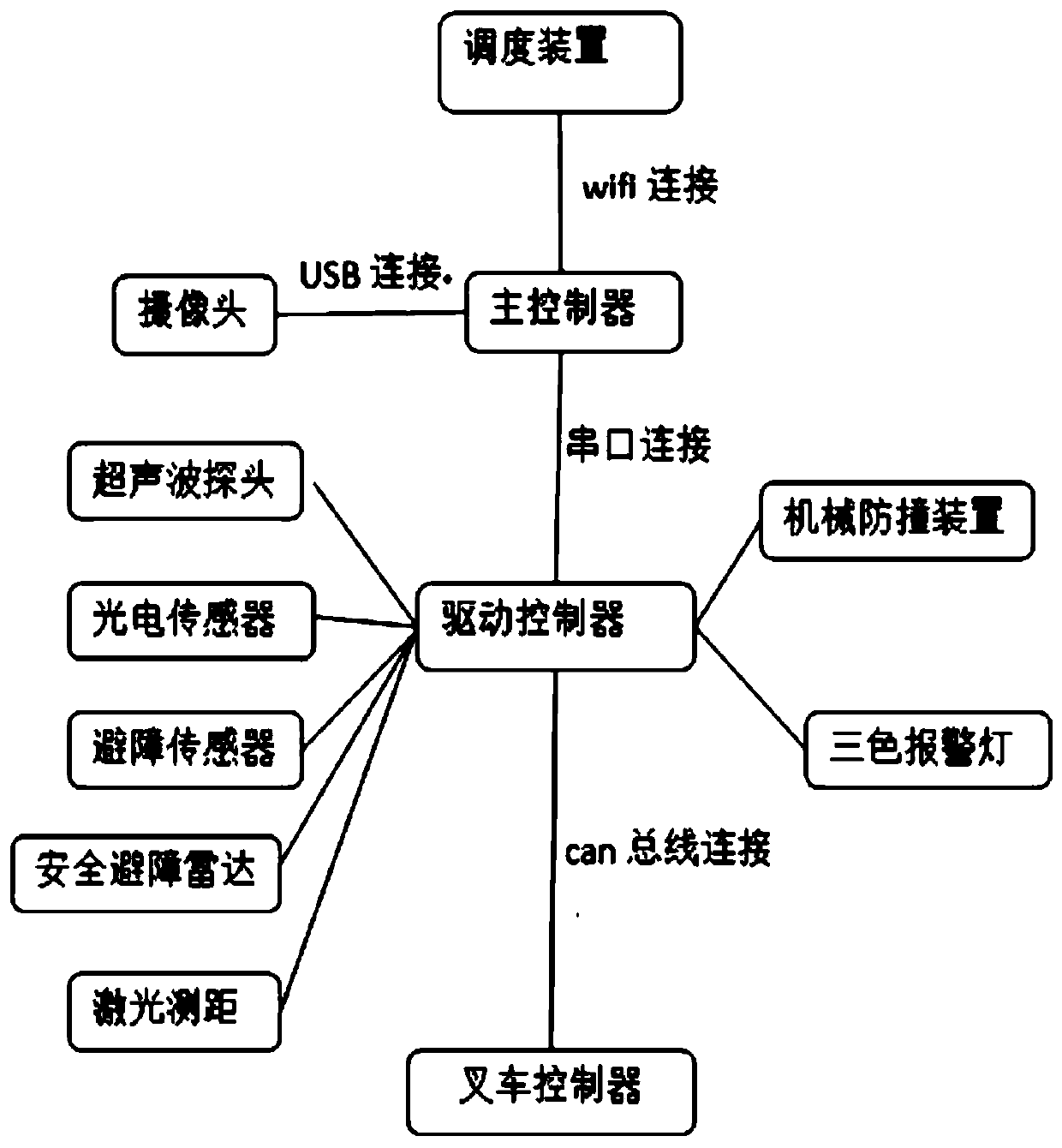

[0067] Such as Figure 1 to Figure 3 As shown, the present invention is a passive visual navigation unmanned forklift system for explosion-proof warehouse, including: forklift, also includes: dispatching device, explosion-proof camera 2, explosion-proof controller, sensor, alarm, mechanical anti-collision device 5 .

[0068] In this embodiment, the forklift is provided with an explosion-proof control box 1 and a control surface, and the explosion-proof controller and the explosion-proof camera 2 are installed in the explosion-proof control box 1, and the lens of the explosion-proof camera 2 is positioned at the top opening of the explosion-proof control box 1 for collecting Ceiling picture. The explosion-proof controller integrates the main controller, drive controller and forklift controller, and is fixed on the forklift mast. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com