Automatic polishing device and polishing system thereof

A technology for grinding heads and workpieces, which is used in automatic grinding control devices, grinding/polishing safety devices, and grinding machines. The effect of improving human health, improving product grinding quality, and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

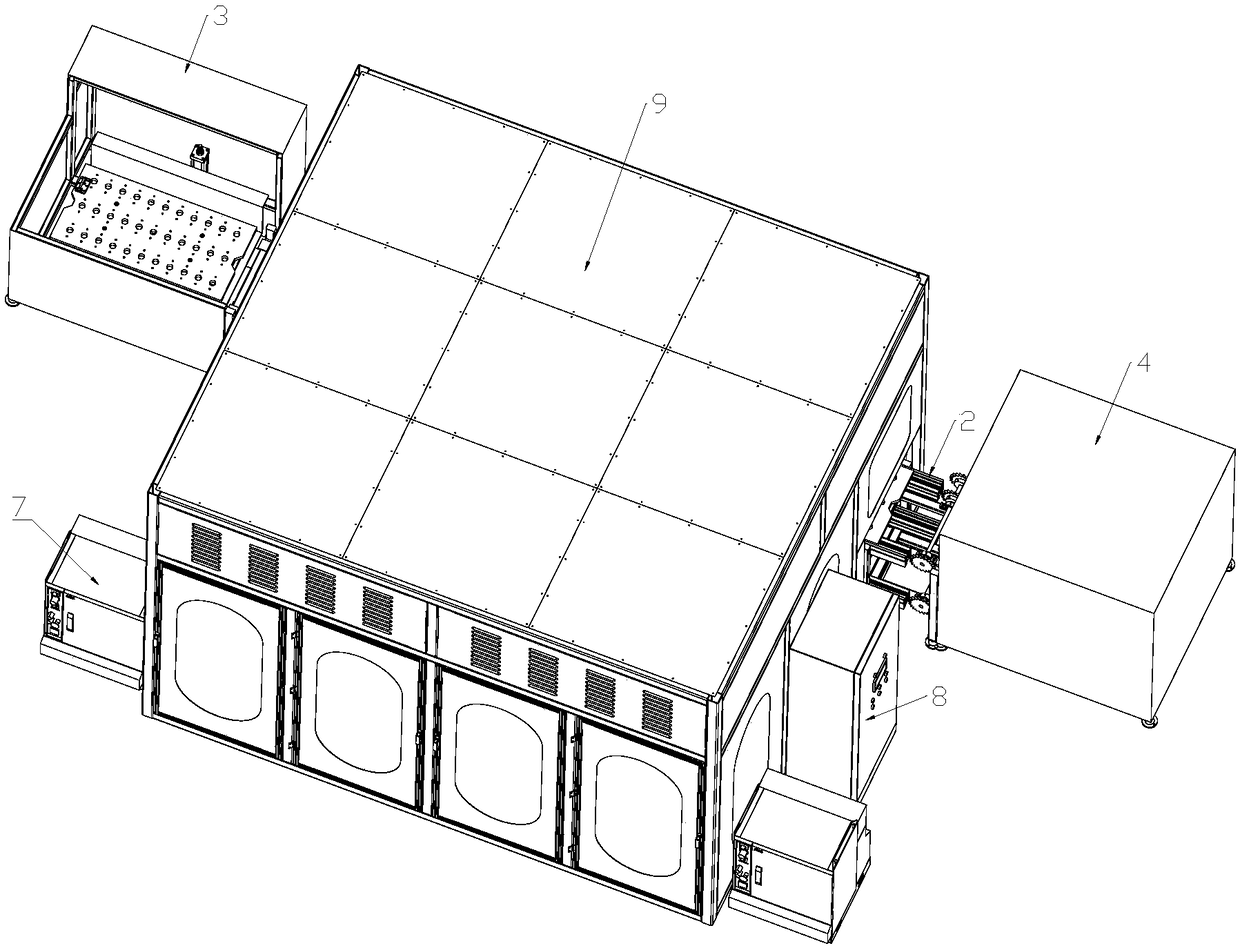

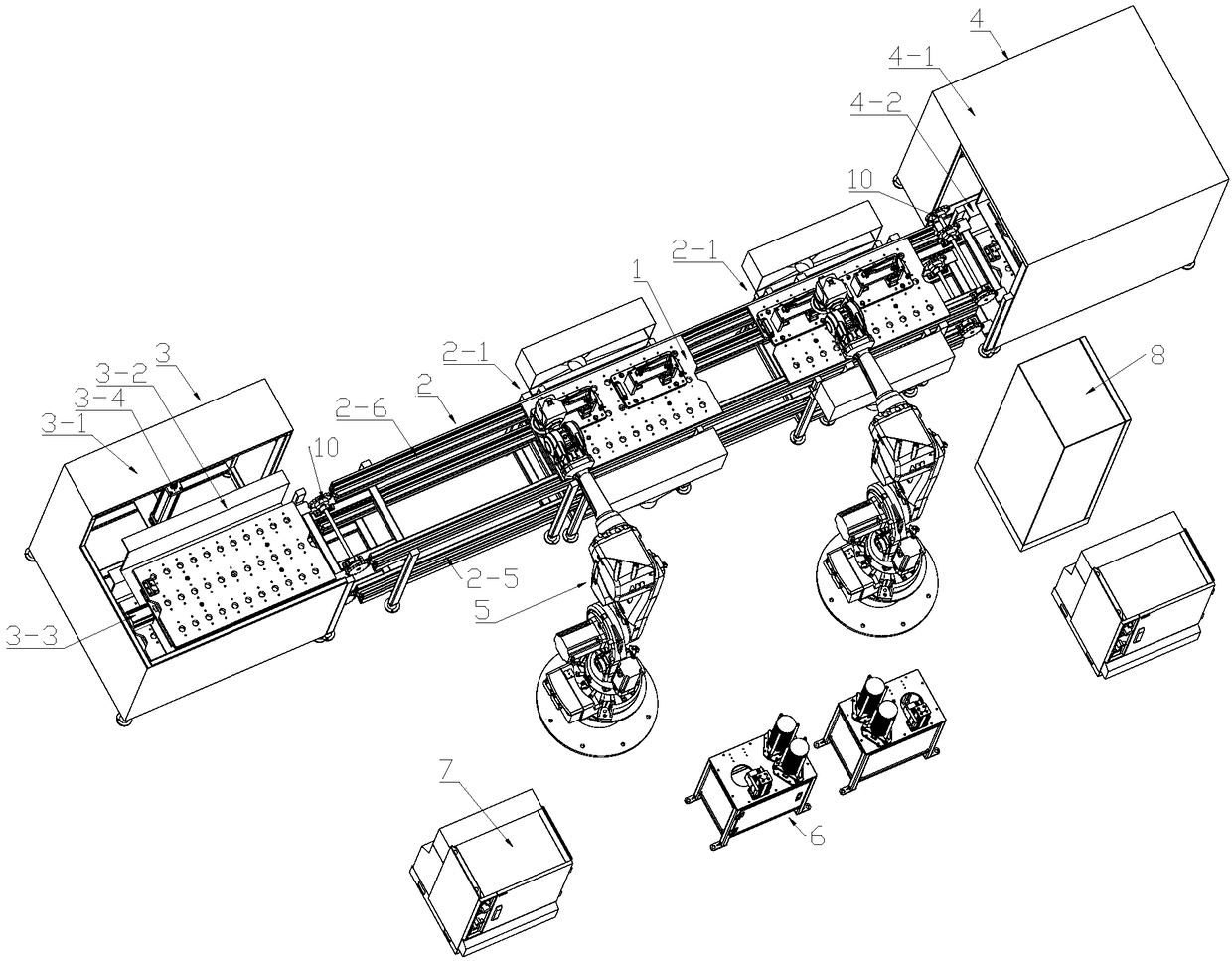

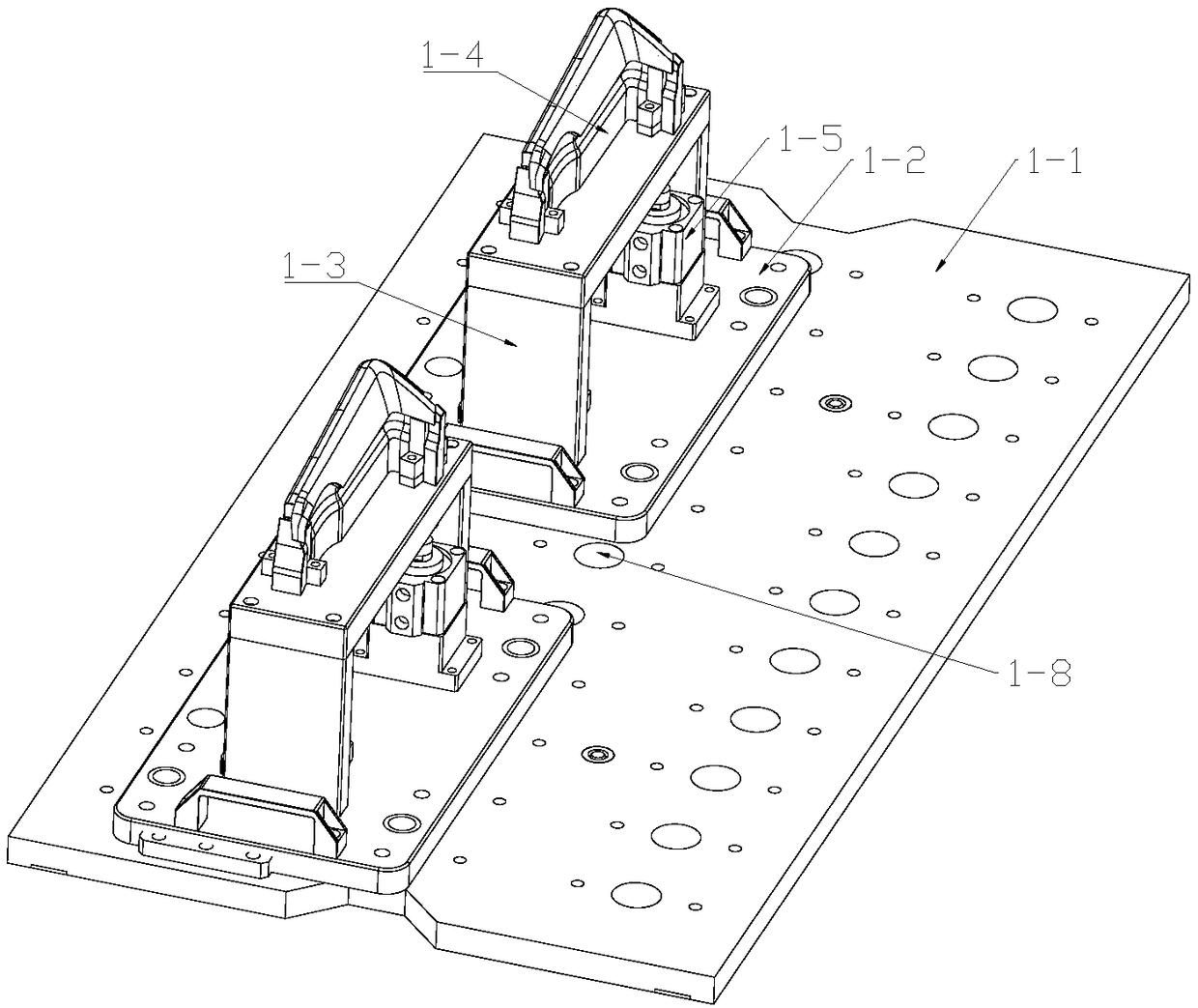

[0042] Such as Figure 1-9 Shown, a kind of automatic polishing device comprises:

[0043] Workpiece positioning mechanism 1: used to fix the workpiece to be polished, the workpiece positioning mechanism 1 includes a feeding plate 1-1, a positioning plate 1-2, a positioning frame 1-3, a workpiece fixing seat 1-4, a positioning cylinder 1-5, Position the chuck 1-6 and the chuck holder 1-7, wherein the positioning plate 1-2 is arranged on the feed plate 1-1, and the feed plate 1-1 has a positioning hole 1-8, so The positioning frame 1-3 is arranged on the positioning plate 1-2, the workpiece fixing seat 1-4 is arranged on the positioning frame 1-3, and the two ends of the workpiece fixing seat 1-4 are provided with fixed openings 1-9, The chuck fixing seat 1-7 is inserted in the fixing opening 1-9, the positioning chuck 1-6 is inserted in the chuck fixing seat 1-7, and the positioning cylinder 1-5 is arranged on the positioning frame 1-3, the telescopic end of the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com