Conical vibration absorber of mine vehicle

A technology for shock absorbers and mine vehicles, which is applied to springs/shock absorbers, vehicle components, and the upper structure of trucks, etc. It can solve problems such as endangering the lives of miners and explosions of underground tiles, and achieve the effect of improving explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

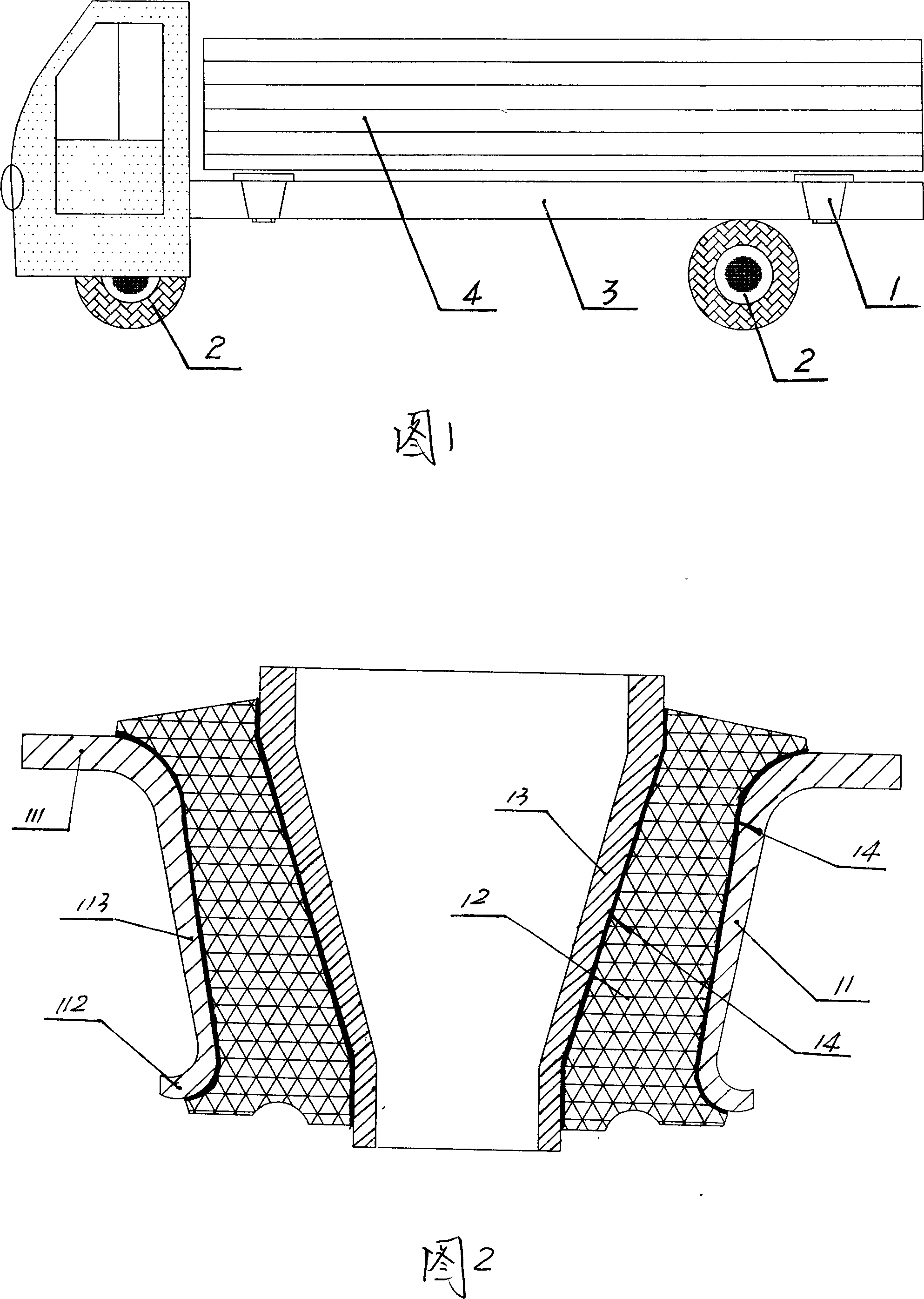

[0013] Embodiment: The conical shock absorber for mine trucks of the present invention is composed of a metal jacket 11, a conductive rubber layer 12, and a metal inner bushing 13. The upper end of the metal jacket 11 is provided with an upper flanging 111 and the lower end is provided with a lower flange. The flange 112, the middle section 113 is a tapered section, the metal inner bushing 13 is funnel-shaped, the conductive rubber layer 12 is arranged between the metal outer jacket 11 and the metal inner bushing 13, and the three are fixedly connected as one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com