Piston type hydrogen conveyor for fuel cell

A fuel cell and hydrogen technology, which is applied in the direction of fuel cells, fuel cell additives, electrical components, etc., can solve problems such as instability, narrow working range, and small flow, and achieve reduced adverse effects, good explosion-proof effects, and easy production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

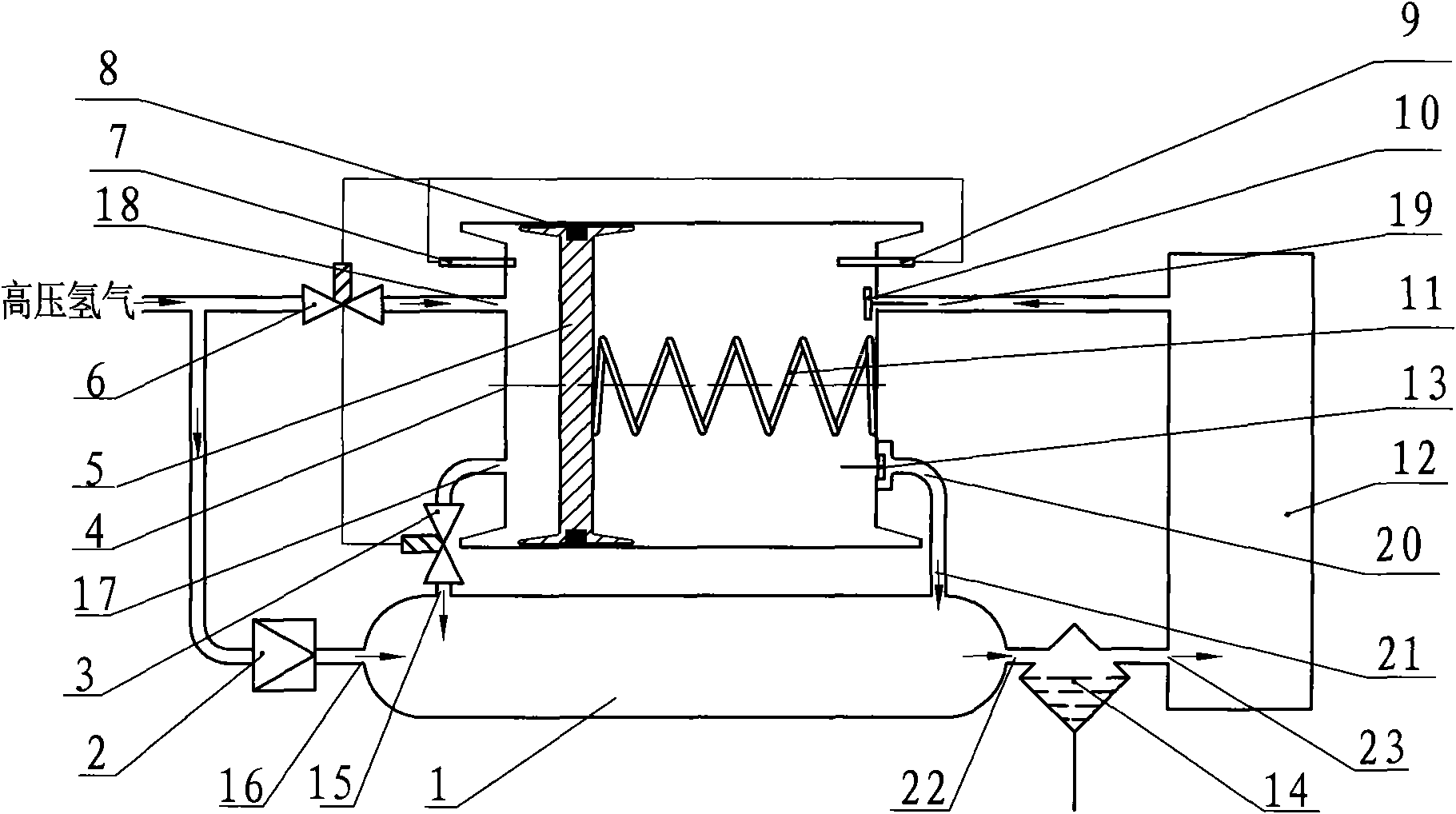

[0017] The present invention will be further described below with reference to the accompanying drawings.

[0018] The cylinder consists of a cylinder block 4, a piston 5 and a return spring 11. The piston 5 is installed in the cylinder block 4, and the return spring 11 is installed between one side of the piston in the cylinder and the cylinder block, and is installed on the cylinder blocks on both sides of the piston. There are position sensor 1 7 and position sensor 2 9, the cylinders on both sides of the piston are respectively provided with hydrogen inlets 18, 19 and hydrogen outlets 17, 20; the buffer tank 1 is provided with a hydrogen inlet 16, a hydrogen outlet 22 and two The ports 15 and 21 connected to the cylinder; the hydrogen outlet 22 of the buffer tank is connected to the hydrogen inlet (23) of the fuel cell 12 through the water separator 14, and the hydrogen inlet 16 of the buffer tank is connected to a pipeline of the high-pressure hydrogen source through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com