Aluminum profile machining device

A technology of aluminum profile processing and mounting frame, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems that affect the pressing efficiency and effect, thermal stress cracks of aluminum ingots, and temperature reduction of aluminum ingots, etc., to achieve reduction The effect of cutting and heating time, low loss rate, and strong absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

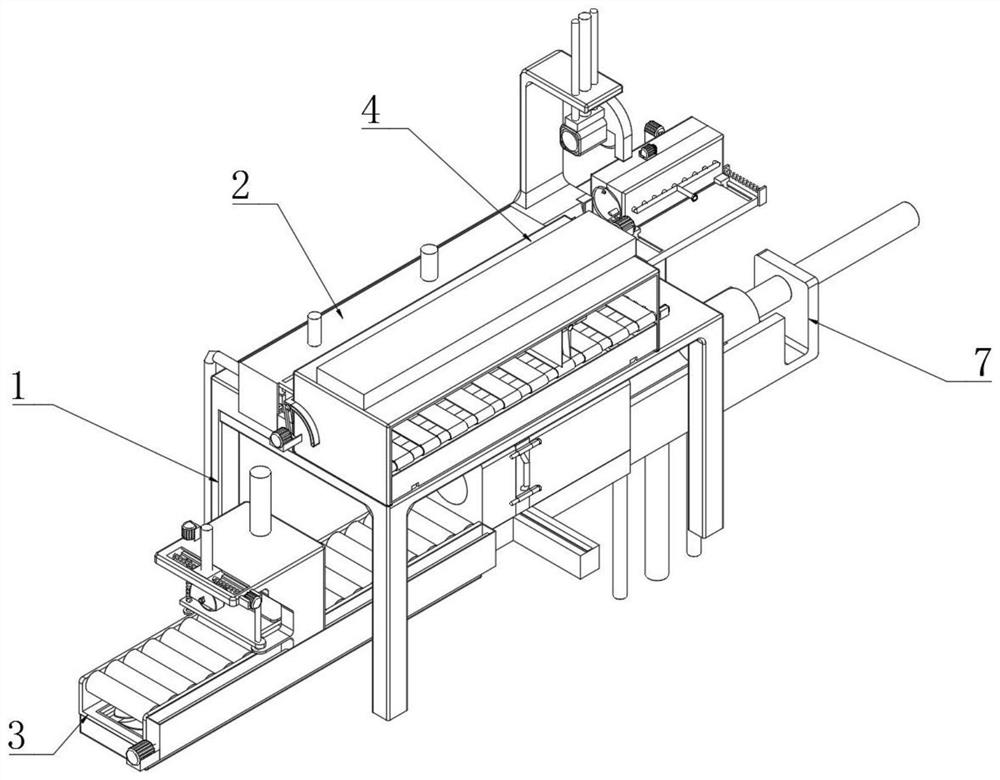

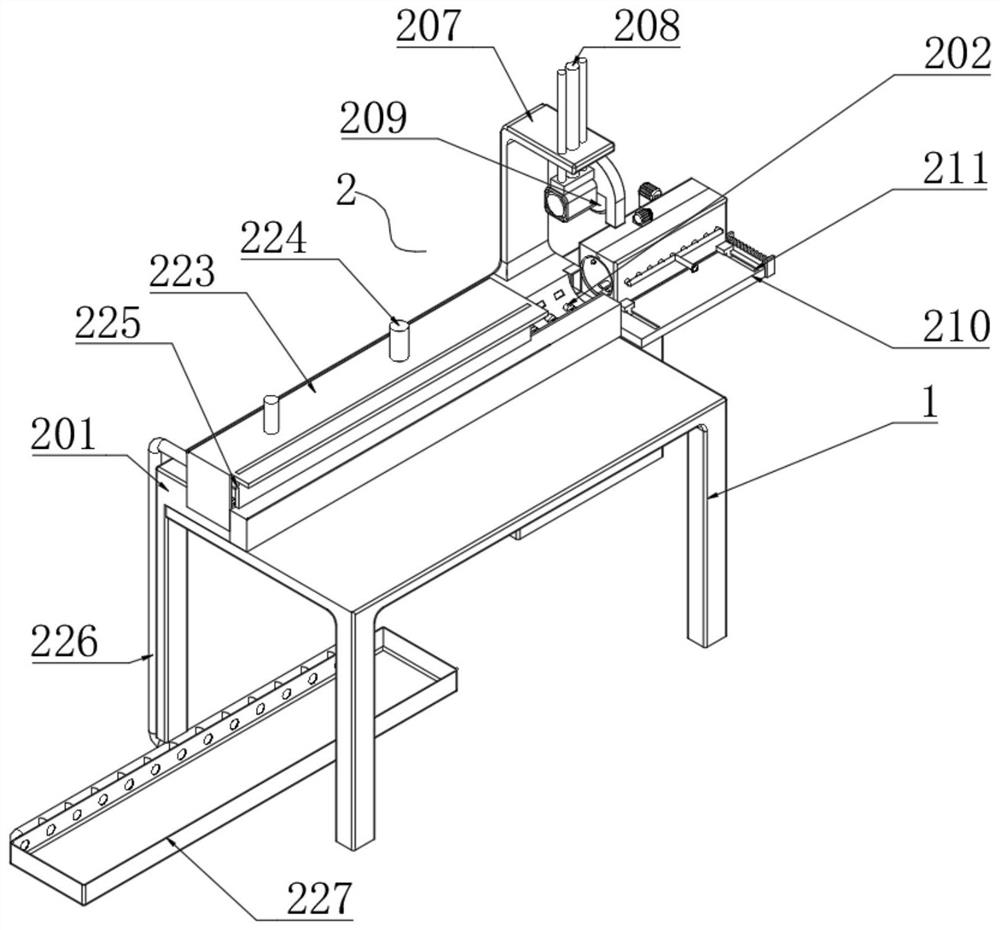

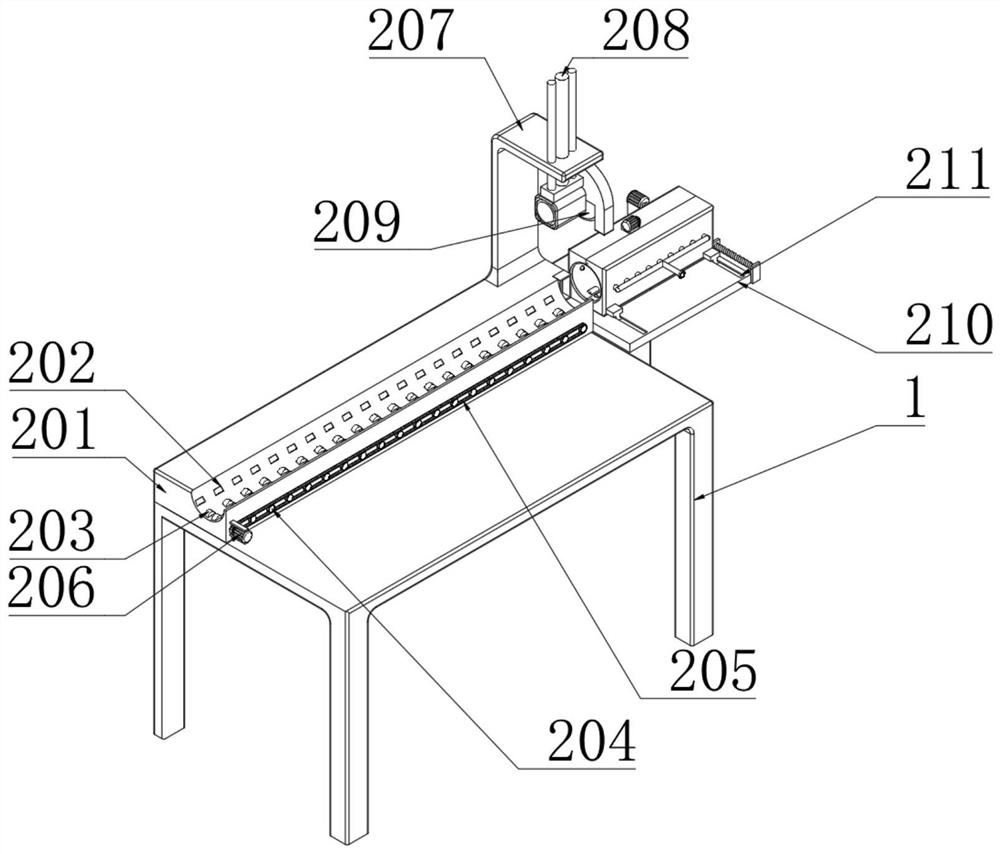

[0041] Example: such as Figure 1-14 As shown, the present invention provides a technical solution, an aluminum profile processing device, including a fixed support frame 1, a preheating assembly 2 is installed on one side of the fixed support frame 1, and the aluminum ingot is driven by the moving roller 203 to move, and its transported into the heating box 212, and cut it through the aluminum ingot cutting knife group 209, so as to facilitate the adjustment of the aluminum ingot according to the required size, and at the same time facilitate the rapid transportation of the aluminum ingot to the heating position, through the rotating wheel 217 and gas The heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com