Low-load stable-combustion direct-current combustor

A burner and low-load technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve problems such as difficult to achieve stable combustion and impossible to achieve, so as to improve the ability of deep peak regulation and prevent backfire , Avoid the effects of slagging and powder accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

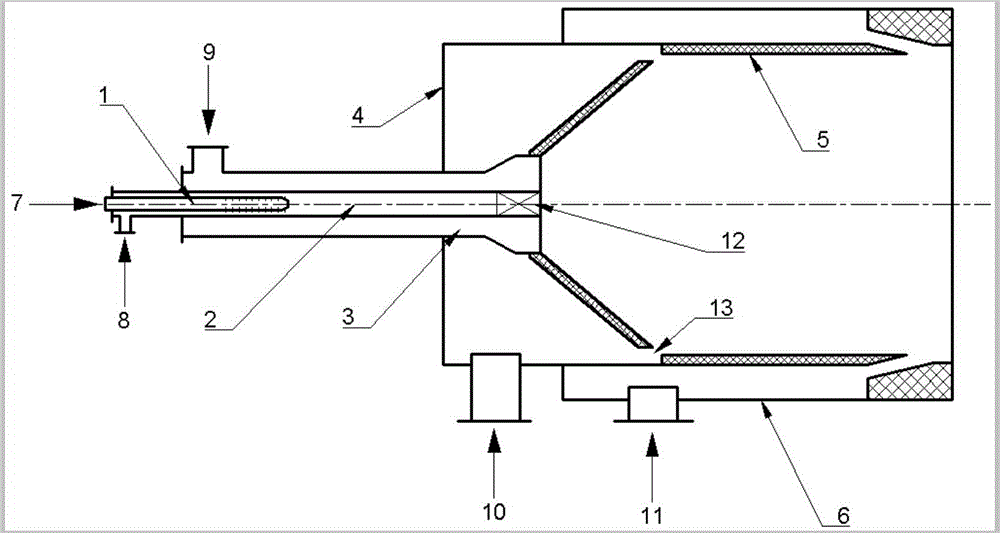

[0026] Such as figure 1 As shown, a new low-load stable combustion once-through burner is characterized in that it includes a natural gas pipe 1, a central air pipe 2, a primary air pipe 3, an internal secondary air cylinder 4, a pre-combustion chamber 5 and an external secondary air Tube 6 etc. are formed.

[0027] The wall surface at the end of the natural gas pipe 1 has a porous structure, and the natural gas is incident in multiple streams, and the direction is perpendicular to the flow direction of the central wind air, so that the two are fully mixed. The outlet of the central air pipe 2 is equipped with a cyclone 12, which is beneficial to the mixing and combustion of the natural gas-air premixed gas and the surrounding primary air powder, while preventing backfire and avoiding the risk of deflagration or explosion of natural gas. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com