Patents

Literature

130results about How to "Play a role in combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

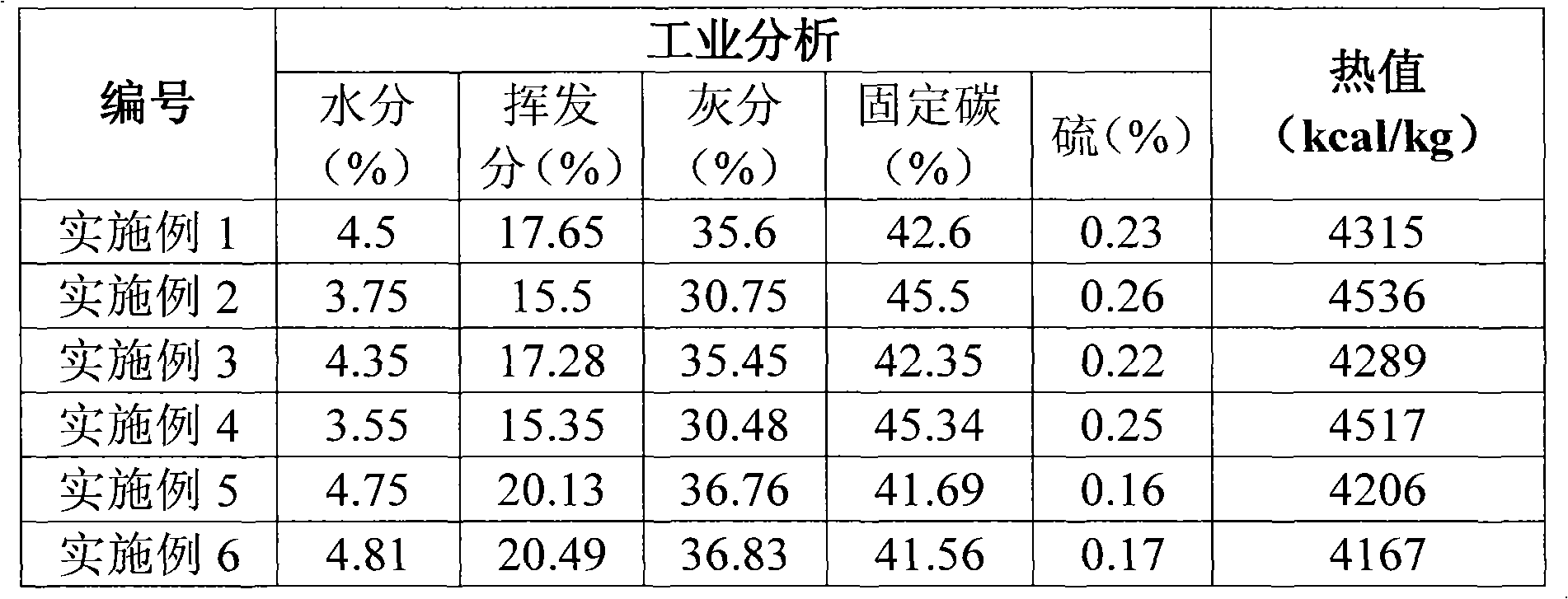

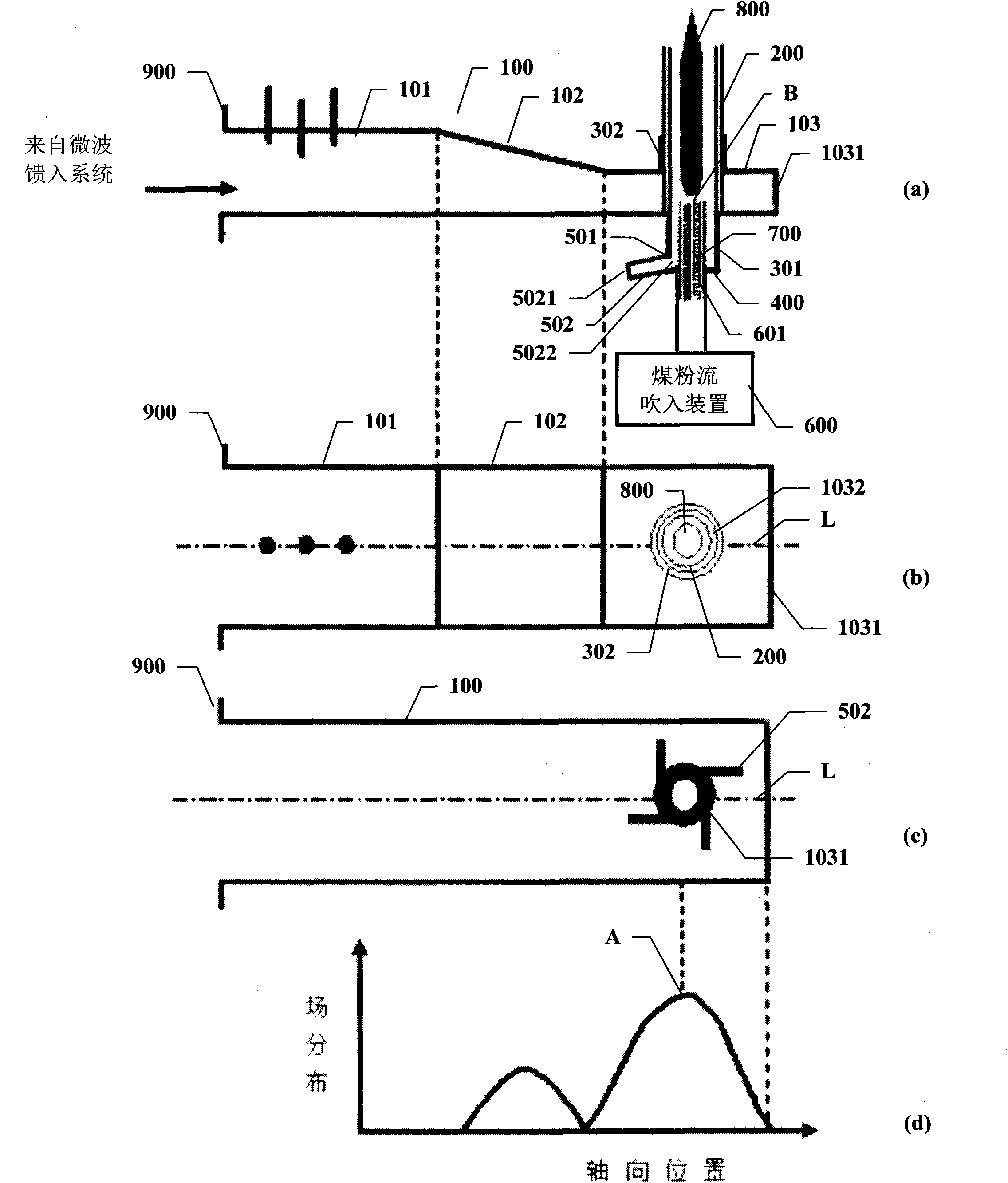

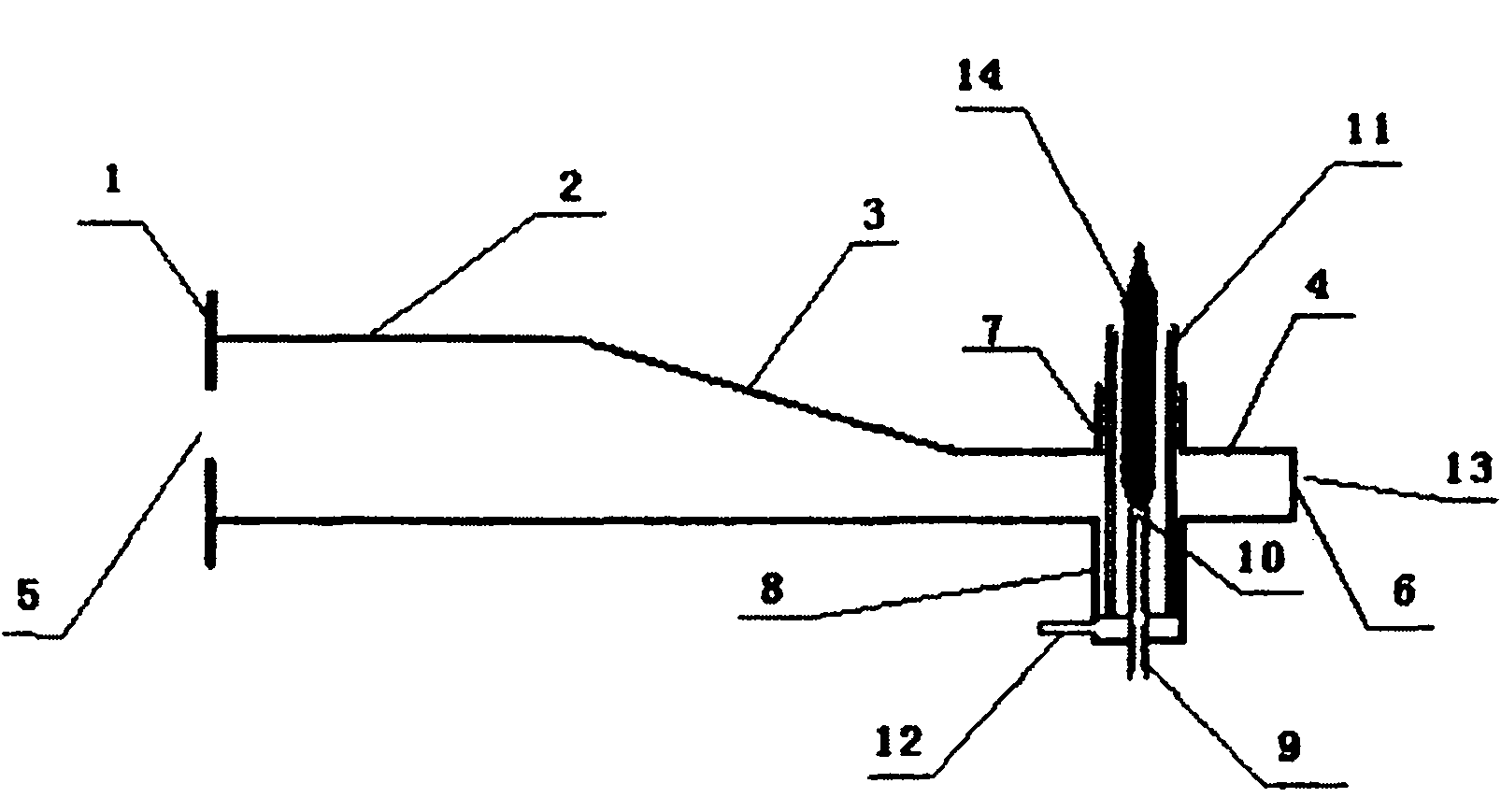

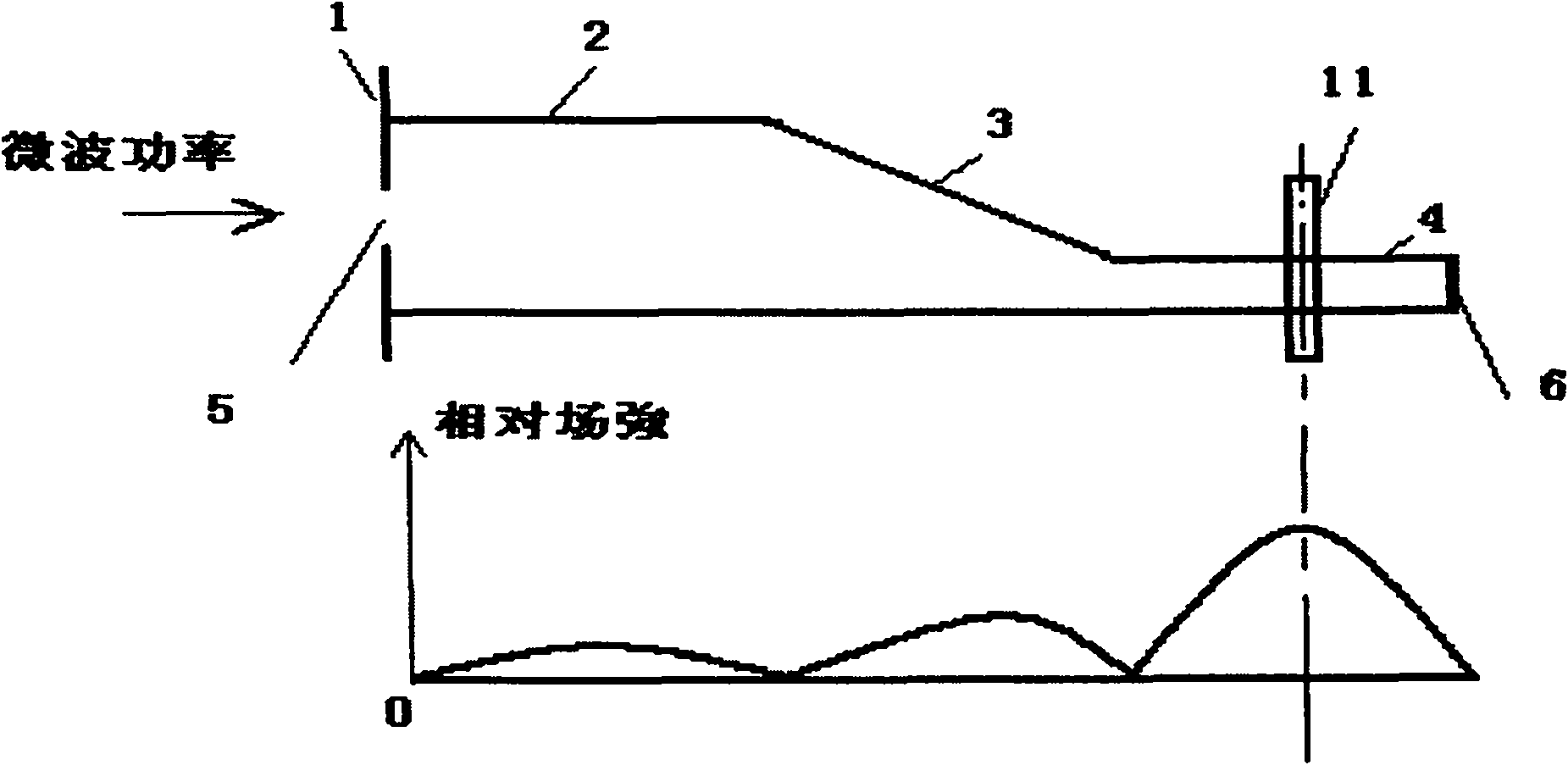

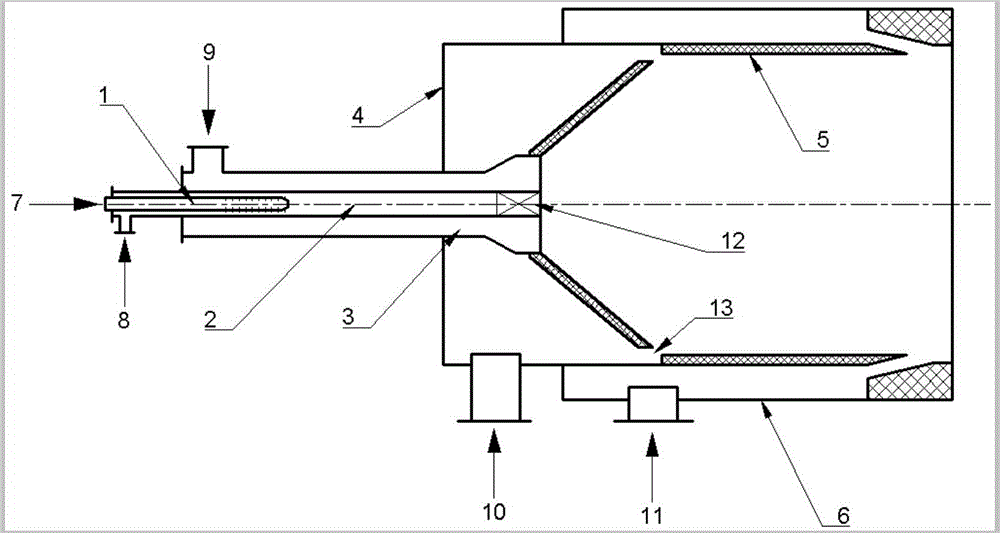

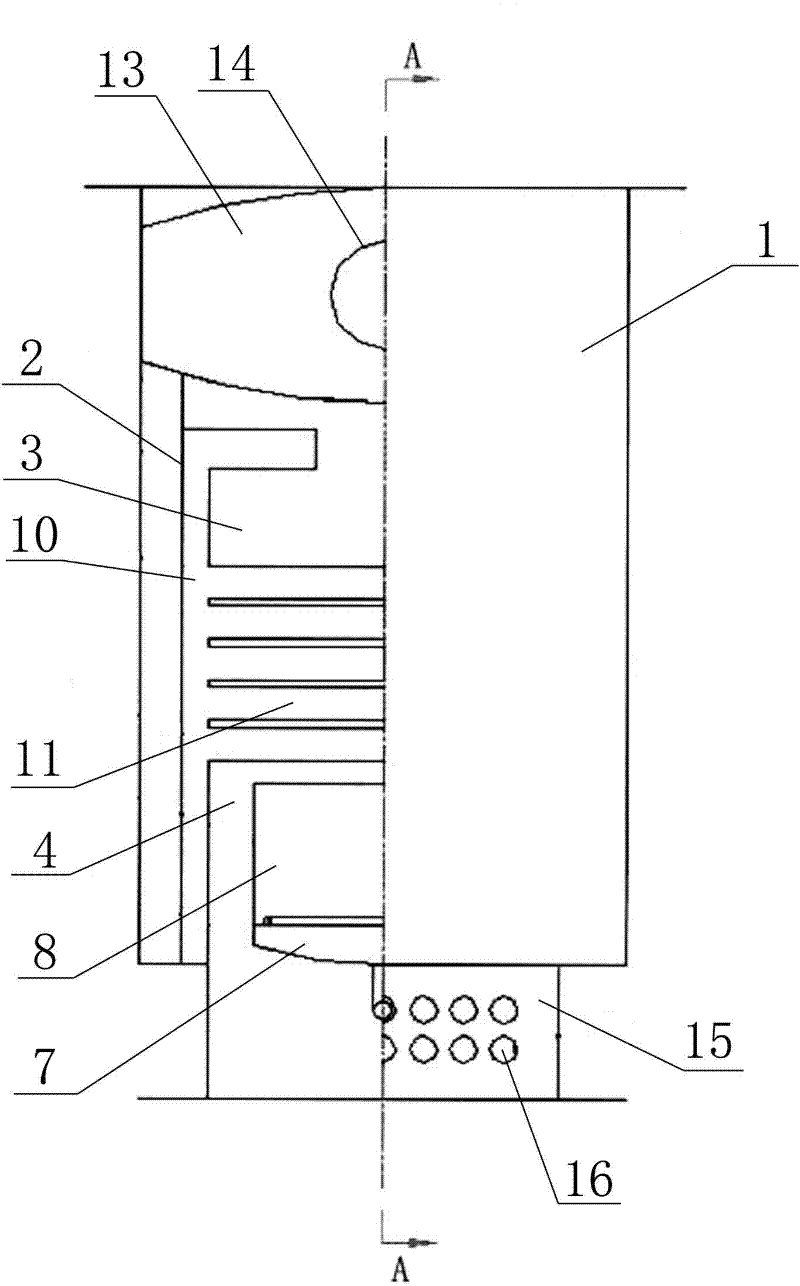

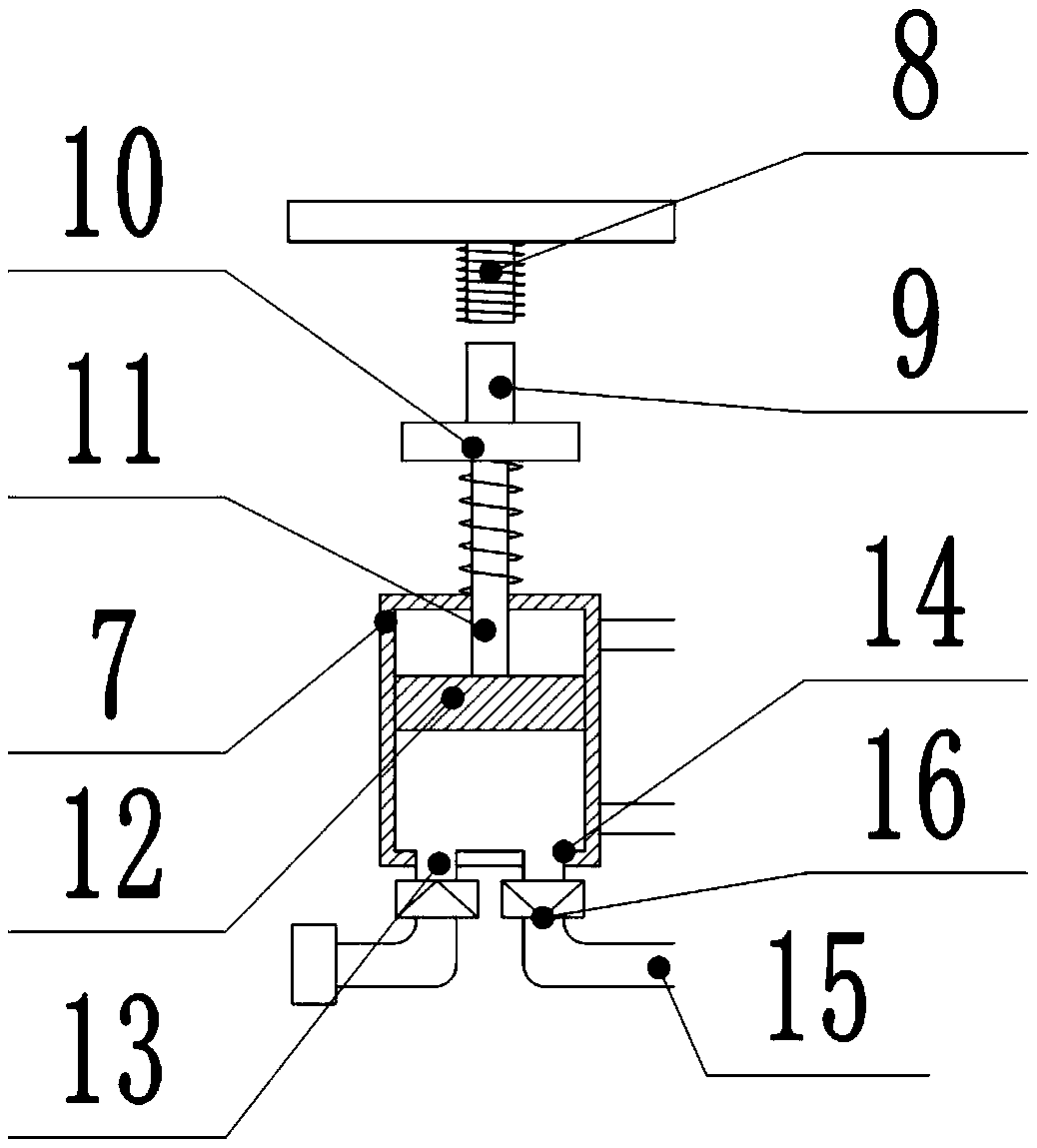

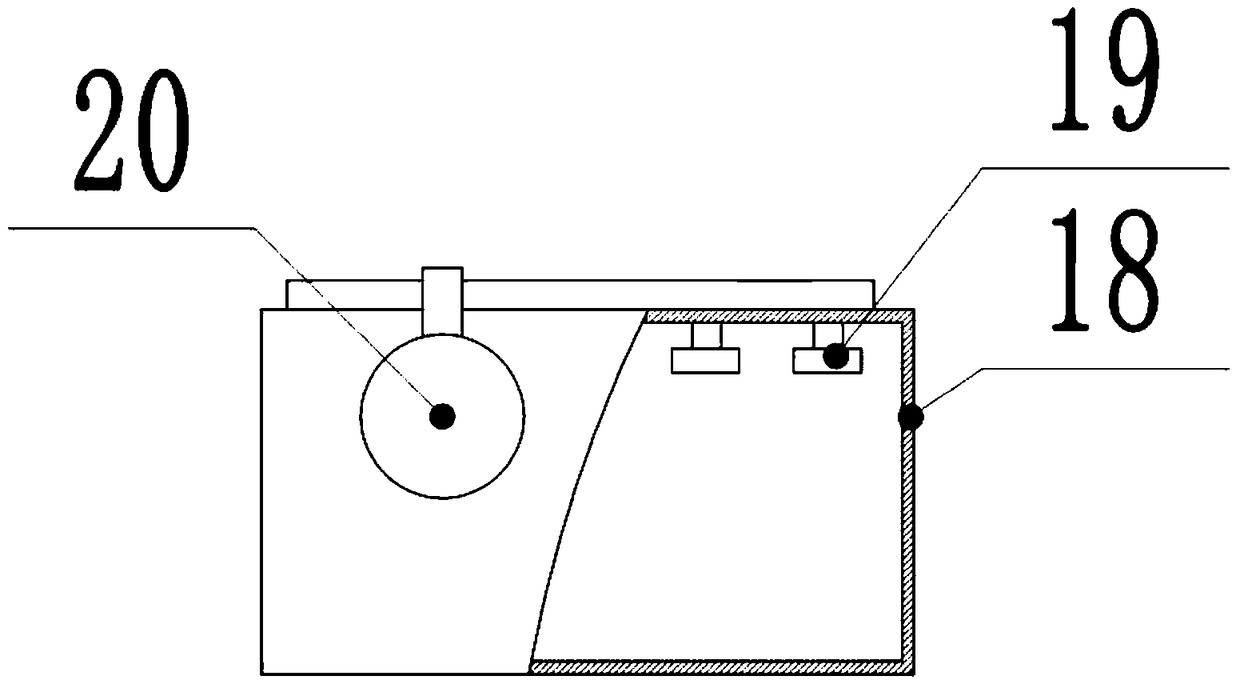

Microwave plasma ignition device

InactiveCN101852444APlay a role in combustionPlay a role in stabilizing combustionIncandescent ignitionPlasma techniqueElectrical conductorCoaxial line

The invention discloses a microwave plasma ignition device, which comprises a microwave resonance cavity, a quartz glass tube plasma generating area, a tangential air supply device and a coal dust flow blowing-in device. The coal dust flow blowing-in device axially blows coal dust flow into the microwave plasma generating area in a quartz glass tube; when the input microwave power exceeds a critical value, the microwave plasma generating area generates initial ionization under the excitation of micro coal dust in the coal dust flow, and the initial ionization is transited to the whole quartz glass tube through avalanche effect so as to form a microwave plasma torch. Meanwhile, the coal dust flow is ignited to form a coal dust microwave plasma torch and is blown out from the upper end of the quartz glass tube along the axial direction of the quartz glass tube. The coal dust and the microwave plasma are mutually acted so as to raise the temperature of the output torch of the ignition device, increase the ignition, combustion support and combustion stabilization capabilities of the microwave plasma ignition device and meanwhile overcome the defects that the microwave plasma torch is excited by coaxial inner conductors in the microwave plasma generating area and the high-temperature plasma torch melts the coaxial inner conductors due to long time.

Owner:白野 +1

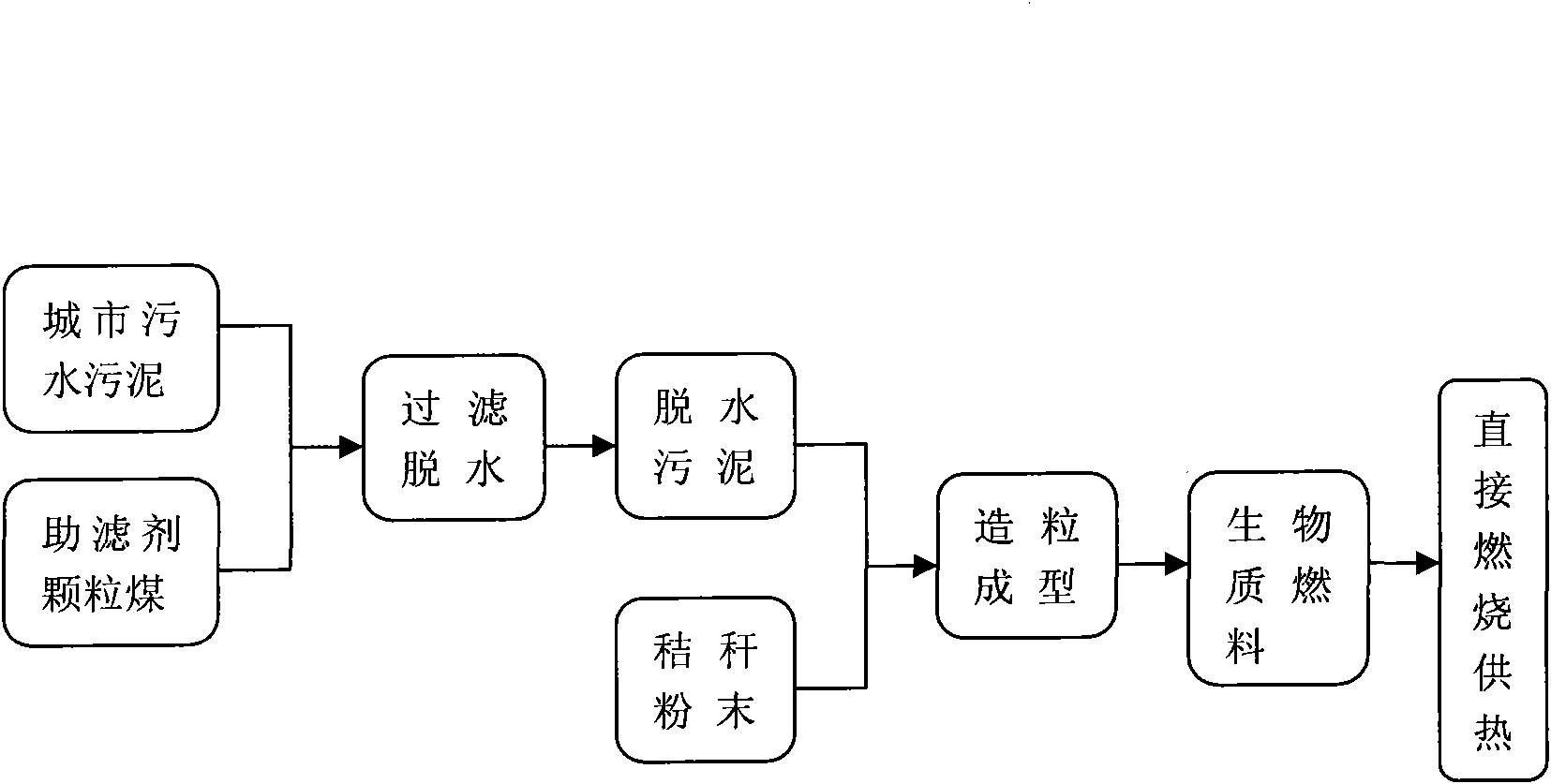

Preparation method of sludge straw biomass fuel

InactiveCN101928623AMake full use of the calorific value of combustionTake advantage of adhesionBiofuelsSolid fuelsAlternative fuelsResource utilization

The invention provides a preparation method of a sludge straw biomass fuel, which comprises the following steps: firstly mixing the excess sludge with the moisture content more than 96% from a municipal wastewater treatment plant with particle coal with the particle size of 0.15-0.18mm based on the mass ratio of 1:1-2; then filtering and dehydrating to obtain dewatered sludge with the moisture content of 40-60%; smashing the crop straws into crop powers to mix with the dewatered sludge based on the mass ratio of 1-10:90-99; and prilling and molding by a comminutor to prepare the sludge straw biomass fuel. The fuel can be used as an alternative fuel of the coal to directly be burnt for heat supply, is free of black smoke in the burning process, and can be applied in boilers or daily life cookware. The invention sufficiently utilizes the higher calorific value of the municipal sludge and the crop straws, realizes resource utilization of the fuel, and solves the treatment problem of the excess sludge from the municipal wastewater treatment plant and the crop straws.

Owner:卢秉威

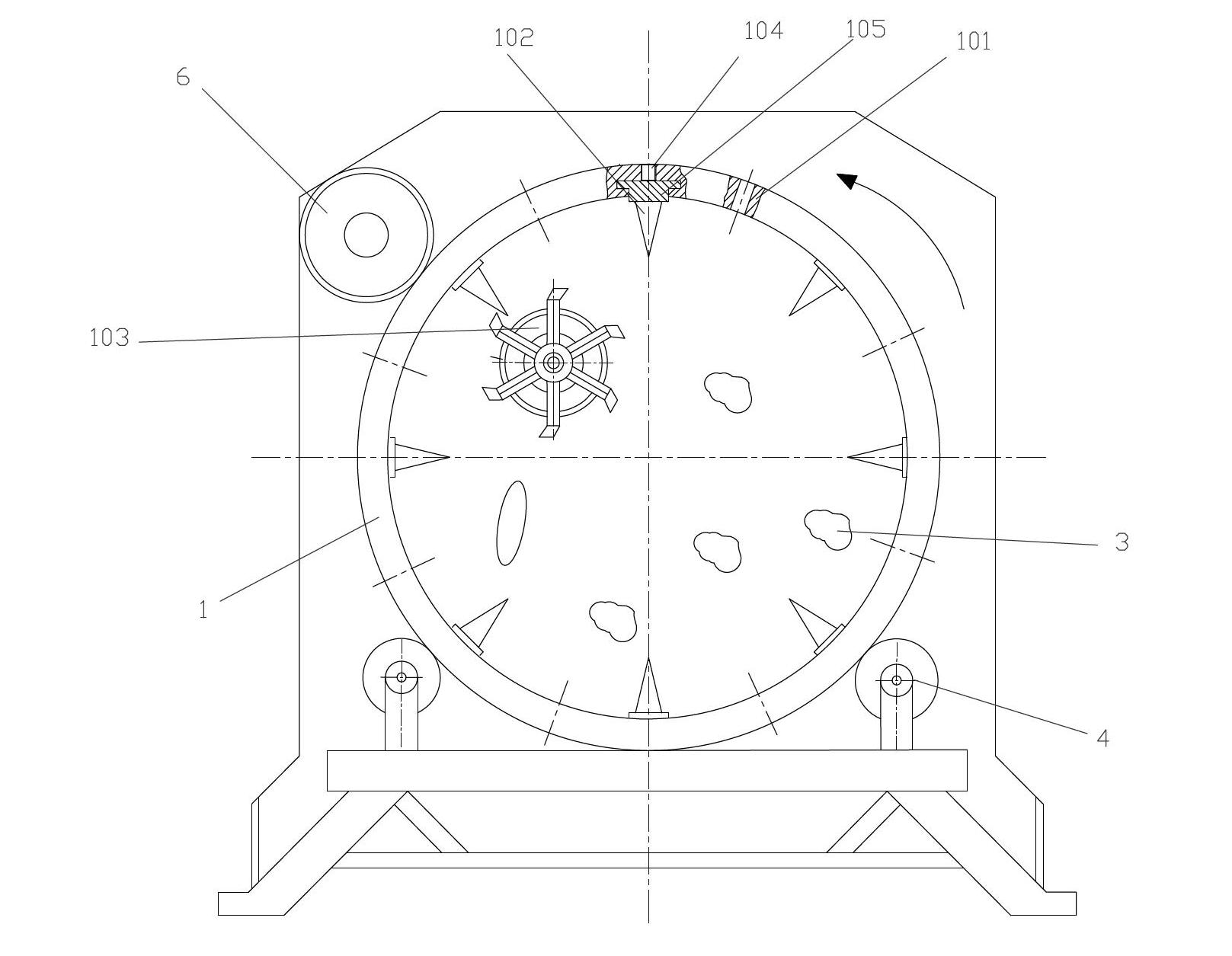

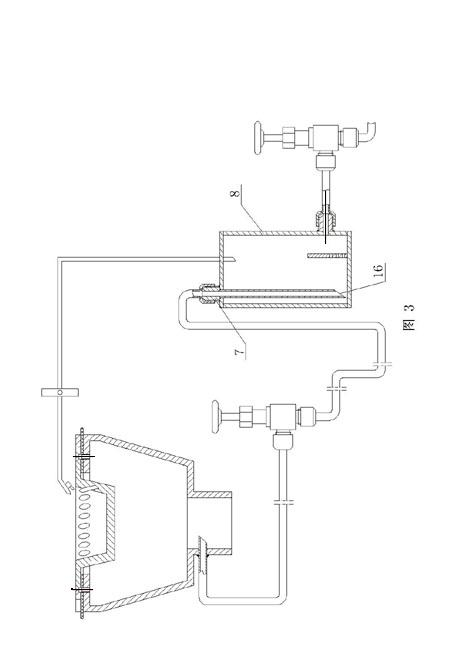

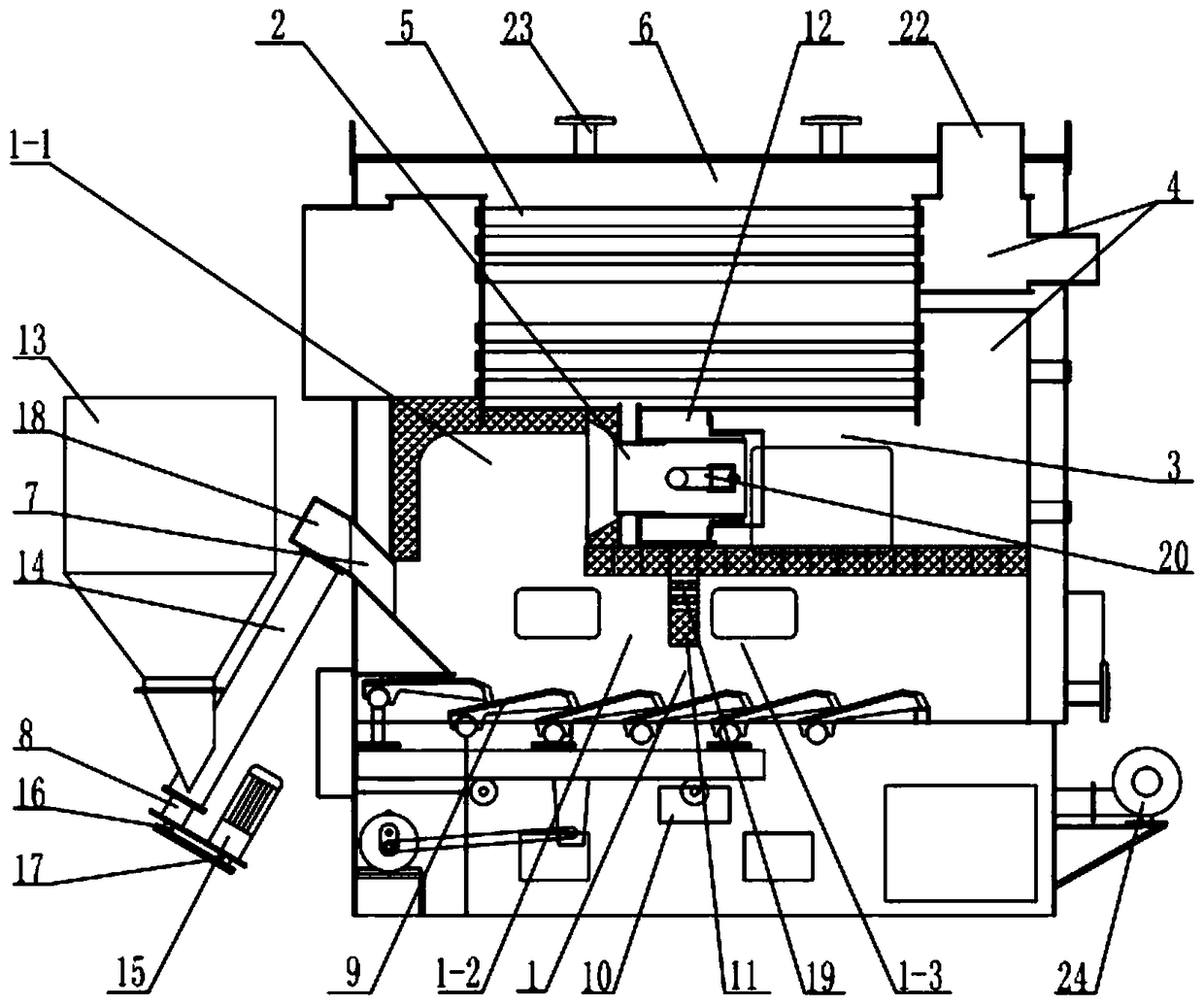

Hydrogen-oxygen combustion-supporting horizontal boiler

InactiveCN101408307AReduce pollutionImprove reliabilityFuel feedersCombustion using multiple fuelsPipingDecomposition

The invention provides a hydroxide combustion-supporting horizontal boiler; the upper part of the external wall of the boiler body is provided with a heat supply water tank and a combustion-supporting water tank and the lower part thereof is provided with a base; a grate above the base is arranged on a rotation wheel; the heat supply water tank is respectively provided with a hot water pipe and a cold water pipe which are communicated with a heat exchange pipe below the heat supply water tank; the combustion-supporting water tank is respectively provided with a steam outlet pipe and a sewer pipe which are communicated with the heat exchange pipe below the combustion-supporting water tank; the upper end of a steam heating disc pipe is positioned in the heat supply water tank and the lower end thereof is communicated on a high-temperature decomposition gas collecting pipe; a hydroxide injection pipe with a gas outlet hole is positioned below the grate; a gas inlet pipe is communicated with the internal side of the external wall of the boiler body; the boiler can utilizes a characteristic that the water can be decomposed as hydrogen and oxygen under the high temperature (more than 4000K) and has a combustion-supporting effect on the combustion of the coal, thus improving the combustion sufficiency of the coal; the heat efficiency is improved, the coal consumption is reduced, the environmental pollution is lightened, and the boiler has good economical benefits and social benefits. The heat supply water tank and the combustion-supporting water tank are arranged independently, thus having high reliability and improving the combustion-supporting effect further.

Owner:朱金贵

Multi-component regenerated fuel based on domestic garbage and preparation method thereof

The invention discloses a multi-component regenerated fuel based on domestic garbage and a preparation method thereof, which are suitable for resource processing of solid wastes. The regenerated fuel is formed by mixing combustible components in the domestic garbage, coal liquefaction residues, agricultural solid wastes and calcium oxide in proportion, and specifically comprises the following components in percentage by mass: 62.5%-77.0% of the combustible components in the domestic garbage, 10.0%-20.0% of the coal liquefaction residues, 5.0%-14.0% of the agricultural solid wastes and 4.5%-7.5% of the calcium oxide. The preparation method comprises the following steps: firstly separating the combustible components from the domestic garbage; then performing drying, crushing and other pretreatment on the combustible components in the domestic garbage, the coal liquefaction residues and the agricultural solid wastes; further mixing all the components according to the ratio, and uniformlystirring; and finally shaping. The regenerated fuel has the advantages of higher calorific value, stable combustion and low secondary pollution, and can realize resource utilization of the urban domestic garbage and the industrial and the agricultural solid wastes.

Owner:四川川润环保能源科技有限公司 +1

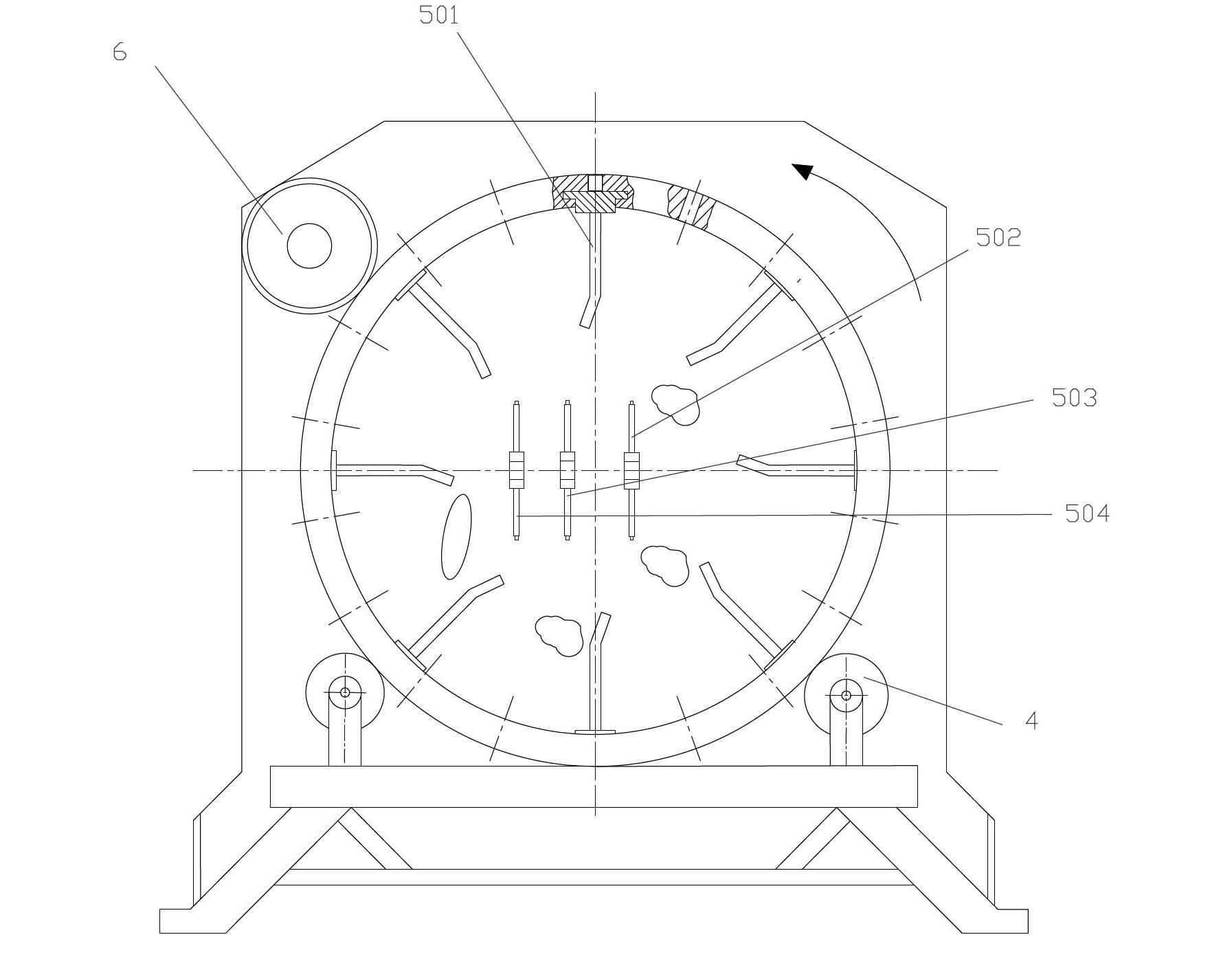

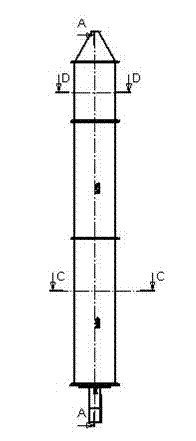

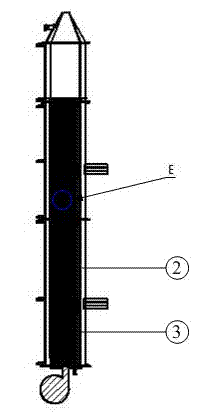

Limestone powder calcining furnace

The invention discloses a limestone powder calcining furnace which comprises a furnace body, wherein the left side and the middle of the upper surface of the furnace body are connected with a feedinghopper and a motor B respectively; a motor A is arranged below the furnace body; output shafts of the motor A and the motor B are respectively connected with a stirring shaft A and a stirring shaft B;stirring blades are connected to the stirring shaft A and the stirring shaft B; high-temperature belts are connected to the middle of the inner side wall of the furnace body; the upper and lower parts of the inner side wall of the furnace body are connected with guide plates; the lower surfaces of the guide plates and the high-temperature belts are connected with material blowing devices; the lower surfaces of the stirring blades are connected with poking devices; the outer side of the stirring shaft A is connected with a discharge tower through a bearing; the outer side of the lower part ofthe furnace body is sleeved by a cooling sleeve; the lower part of the right side of the cooling sleeve is connected with a liquid inlet pipe; the upper part of the left side of the cooling sleeve isconnected with the inlet end of a steam drum through a liquid outlet pipe; the outlet end of the steam drum is connected with the stirring shaft A through a steam pipe; and the left side and the rightside of the lower surface of the furnace body are connected with discharge tubes. The limestone powder calcining furnace has the advantages of thorough calcination, wall adhesion prevention, high discharge efficiency, energy conservation and environment protection.

Owner:河南越尔环保科技有限公司

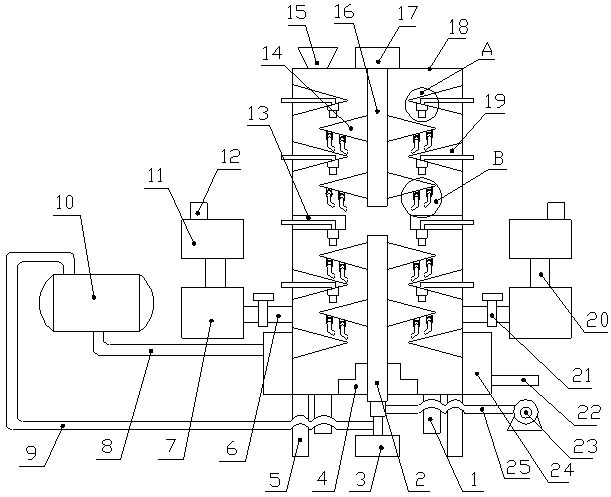

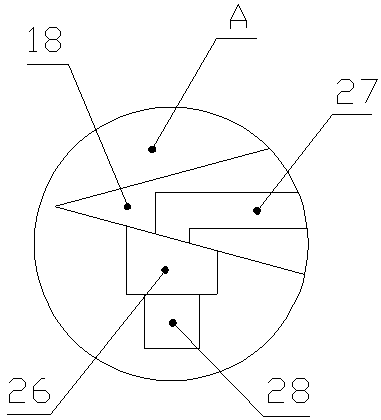

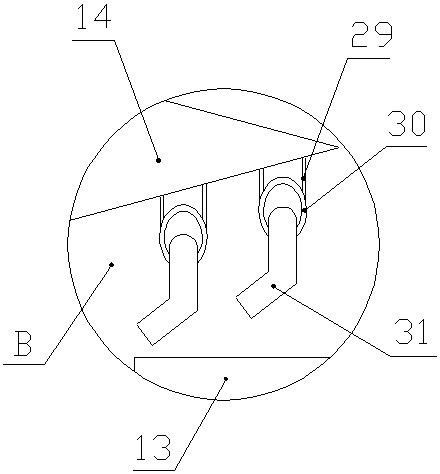

Low-load stable-combustion direct-current combustor

PendingCN106838895ATo achieve the purpose of premixingPrevent deflagrationPulverulent fuel combustion burnersCombustorSlag

A low-load stable-combustion direct-current combustor comprises a natural gas pipeline. The natural gas pipeline extends to a central air duct to supply natural gas, a cyclone arranged at the outlet of the central air duct conveys mixed gas to a precombustion chamber for combustion, a primary air pipe providing primary pulverized coal to the precombustion chamber is arranged outside the central air duct, an internal secondary blowdryer providing internal secondary air to the precombustion chamber is arranged outside the primary air pipe, an external secondary blowdryer providing external secondary air to the precombustion chamber is arranged outside the internal secondary blowdryer, the precombustion chamber is divided into an expansion section and a horizontal section along the inlet direction of the mixed gas, an internal-secondary-air annular nozzle is arranged in the intersection of the expansion section and the horizontal section, the internal secondary air is in annular direct-current incidence from the internal-secondary-air annular nozzle, combustion supporting function is achieved, slag build-up and pulverized-coal accumulation can be avoided; the external secondary air is injected in a direct-current oblique manner to supplement air needed for subsequent combustion of pulverized coal flow, and meanwhile, formation of NOx is reduced. By the arrangement, low-load stable combustion of a pulverized-coal combustor can be realized, and deep participation in peak regulating of a coal-fired power plant is favorably improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

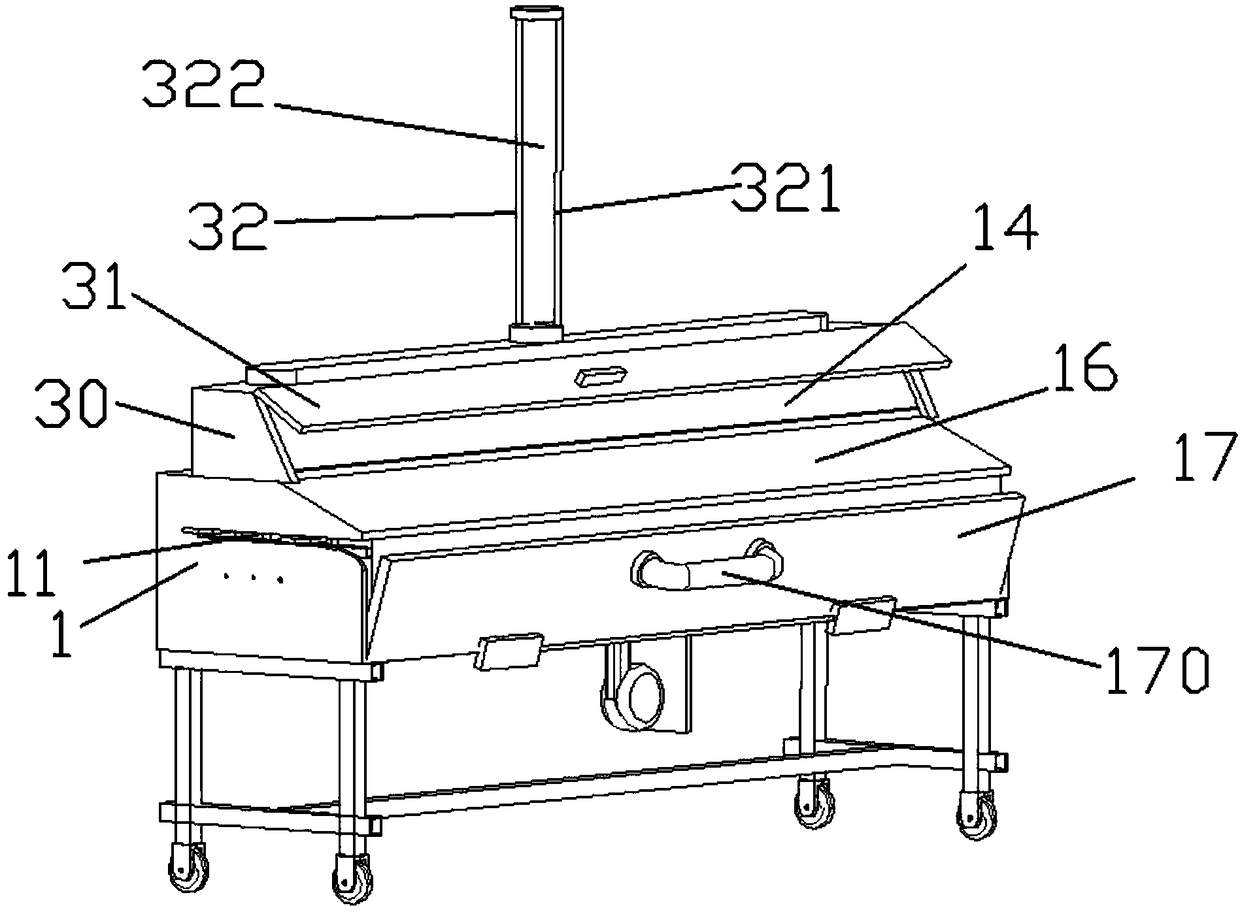

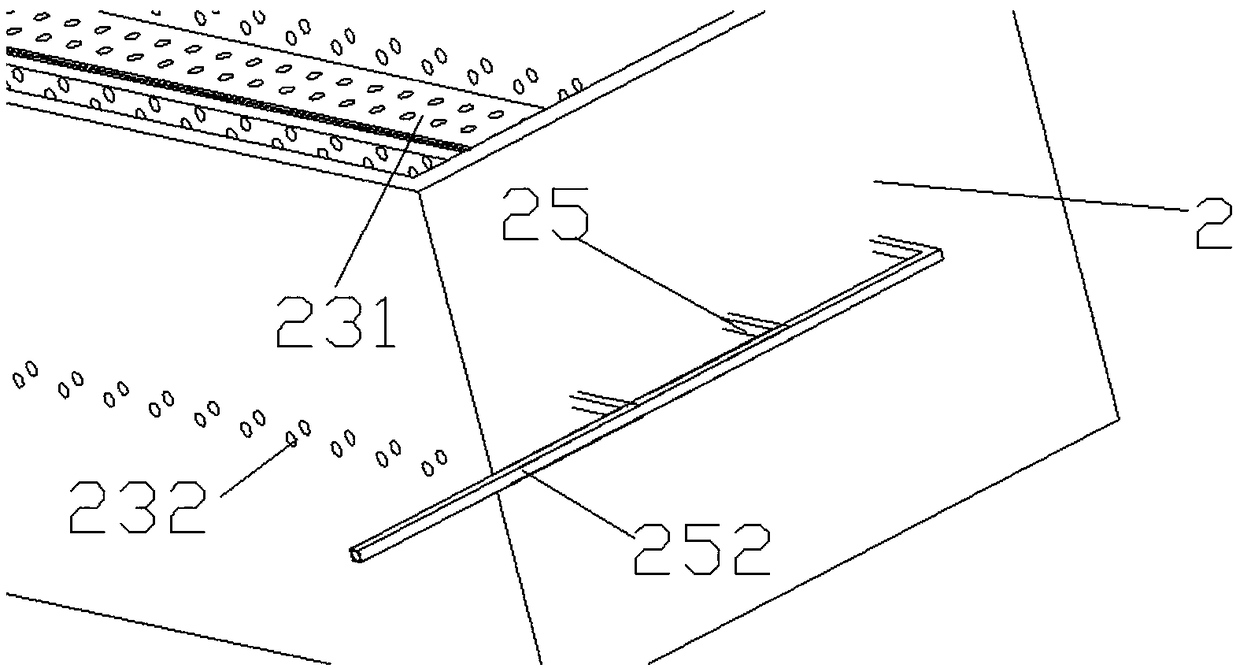

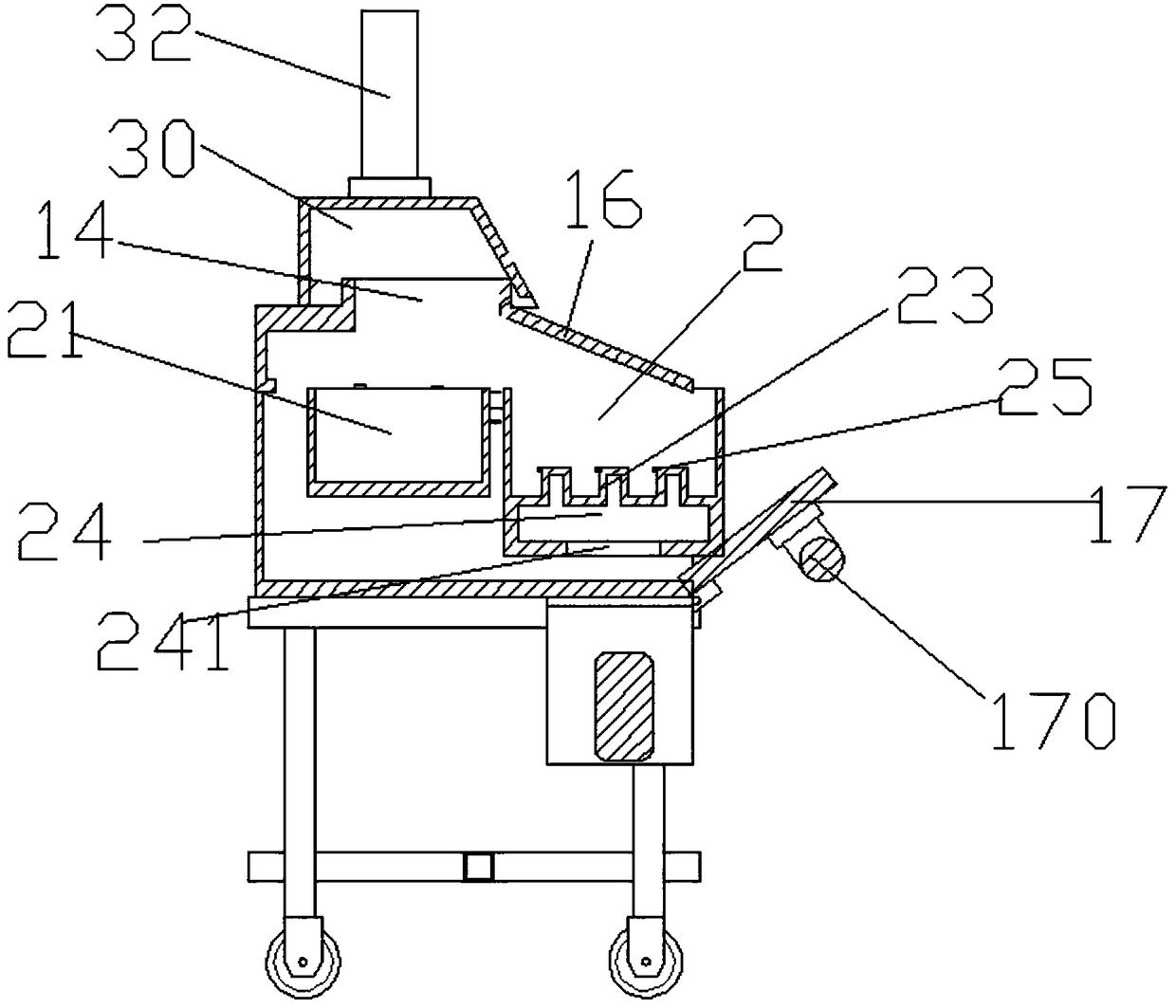

Smokeless barbeque oven with efficient and environment-friendly function

InactiveCN108209611AImprove combustion efficiencyEnsure safetyClimate change adaptationEngineeringAir blower

The invention relates to a smokeless barbeque oven with an efficient and environment-friendly function. The smokeless barbeque oven comprises an oven body, a bottom support, a slide rail, a charcoal groove, an oil connecting groove, an air blower and an oven side cover. The oven body is formed by welding metal sheets, a refractory material fits the inner side, and a heat preservation layer is sandwiched between the refractory material and the metal outer wall. The charcoal groove and the oil connecting groove are formed in the slide rail and are similar to drawers, the charcoal groove is conveniently taken out for replacing charcoal, an air channel is located below the charcoal groove, the air blower is connected to the lower portion of the air channel, and multiple small holes are formedin the upper portion of the air channel to solve the problems that the burning velocity of the charcoal is inconstant and heat of a barbeque operating opening is not uniform when the wind distributionis not uniform during barbequing. The bottom support is located below the barbeque oven, and universal walking wheels with brakes are arranged at the bottom of the bottom support. The smokeless barbeque oven facilitates ignition, charcoal ashes do not easily rise, the smokeless barbeque oven is hygienic, the device of the air channel makes the charcoal more uniformly burned, and the charcoal utilization rate is high.

Owner:淄博萃智工业设计咨询有限公司

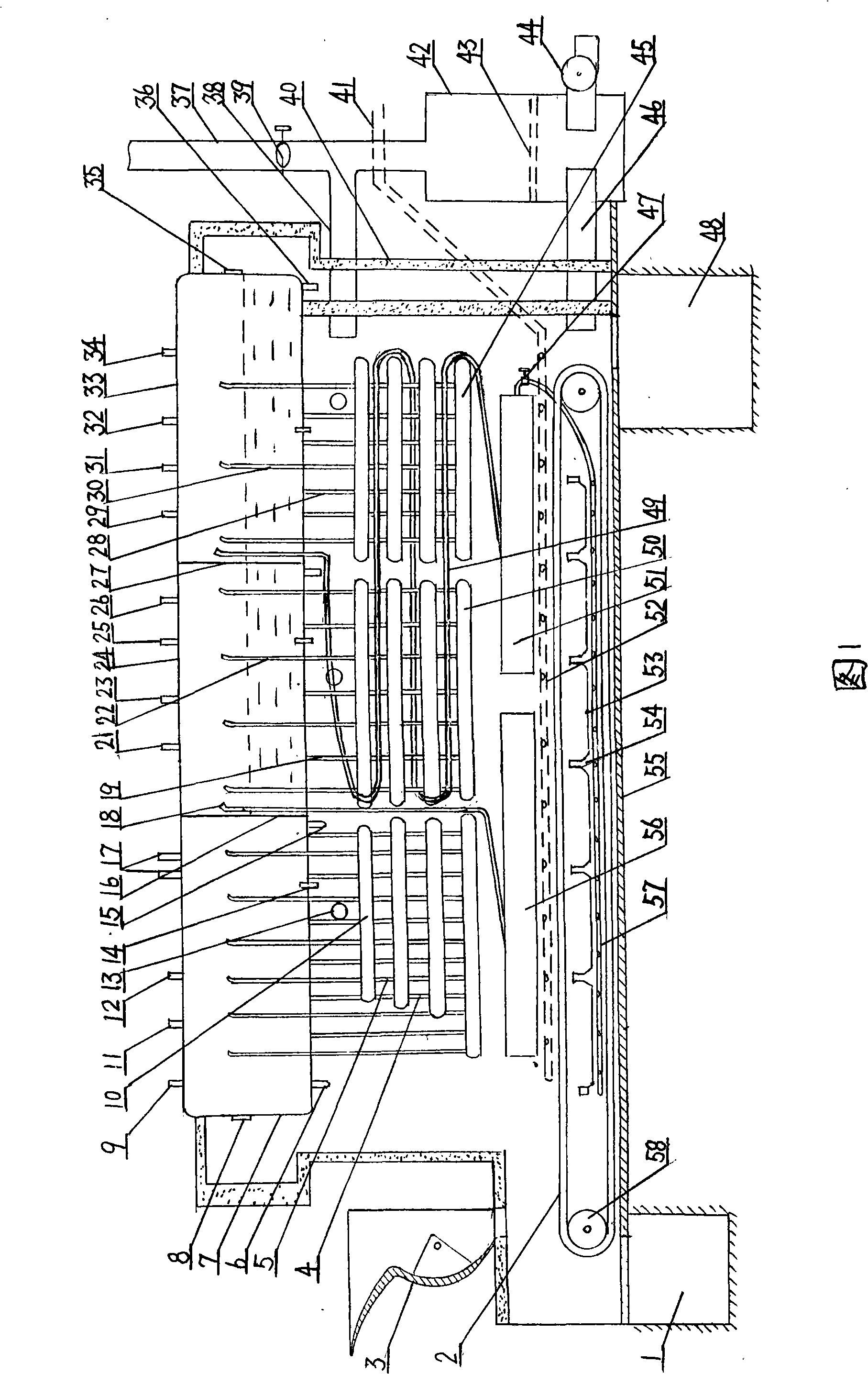

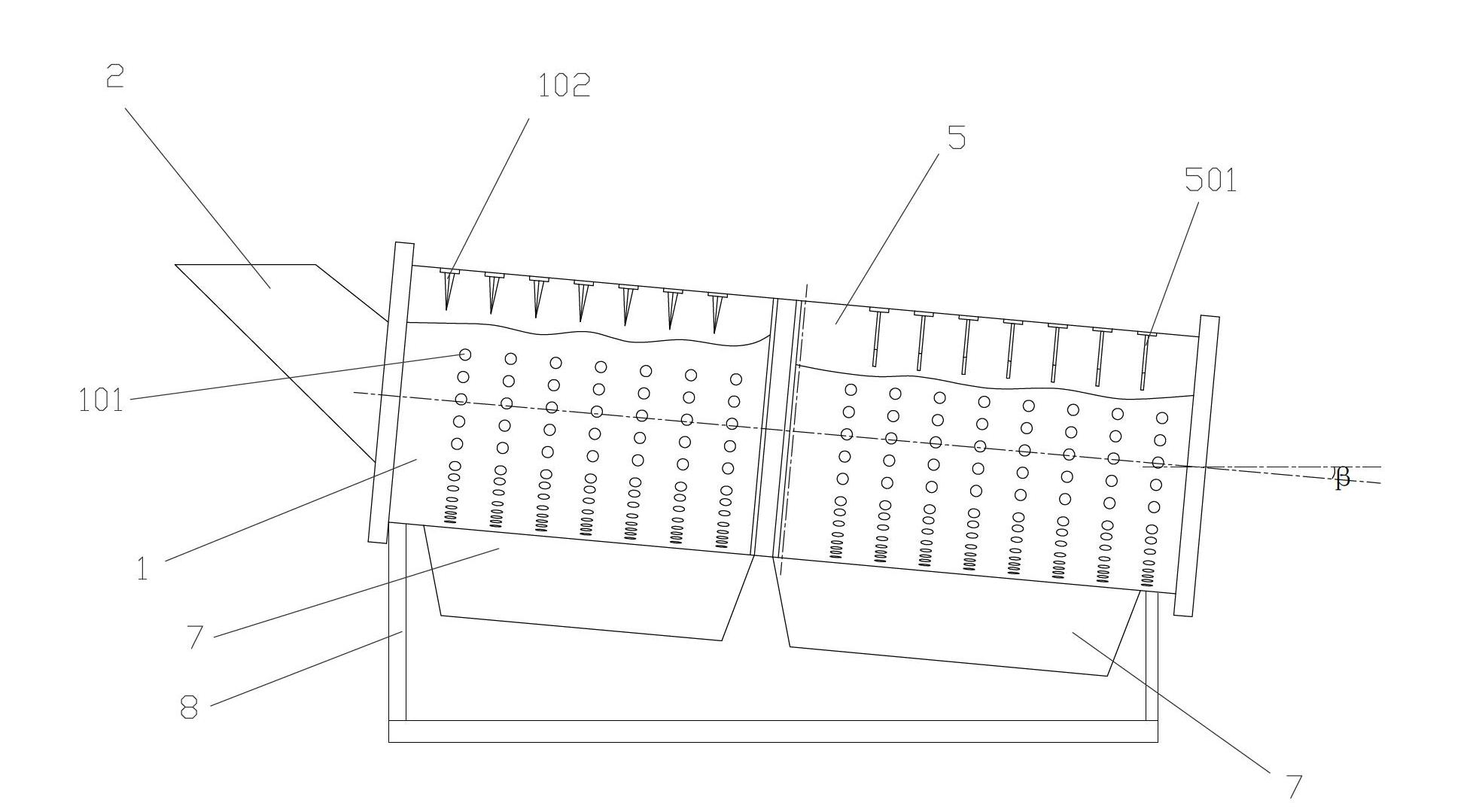

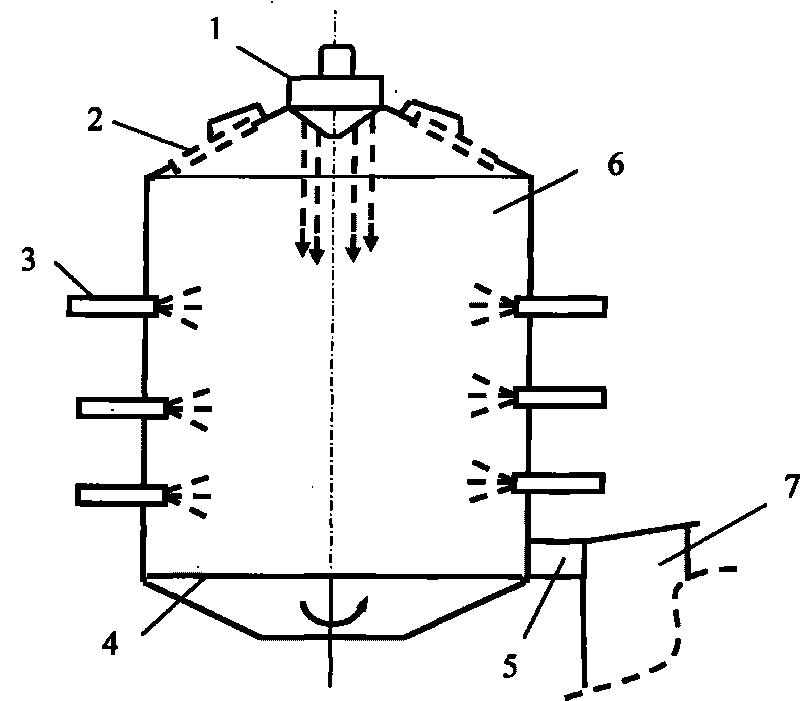

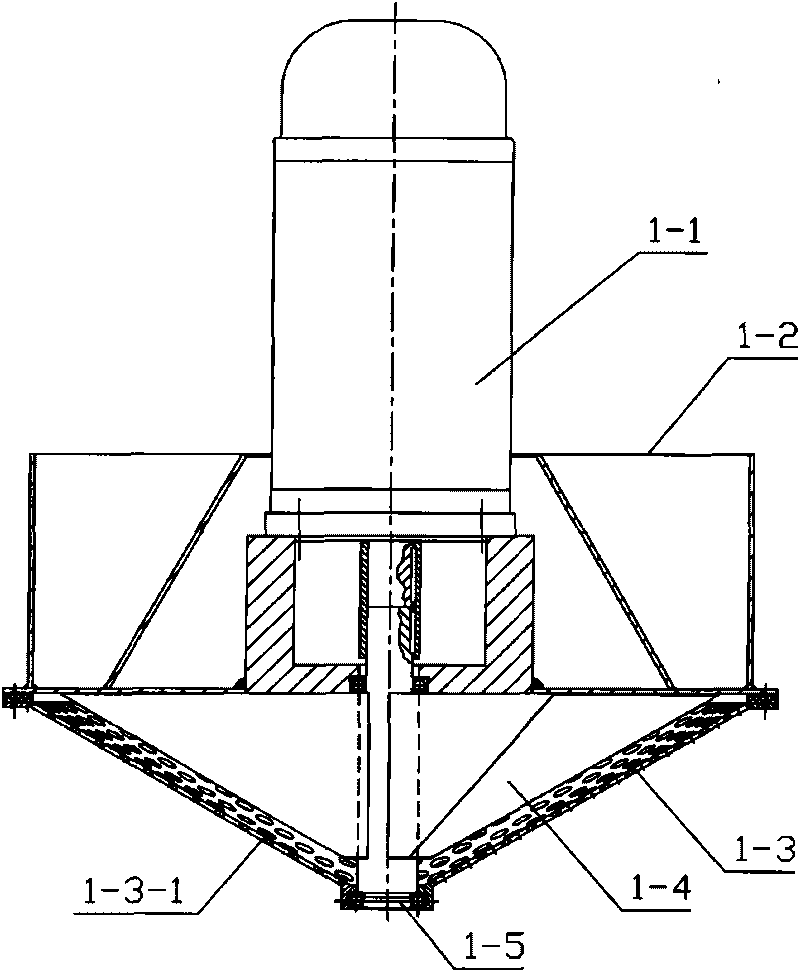

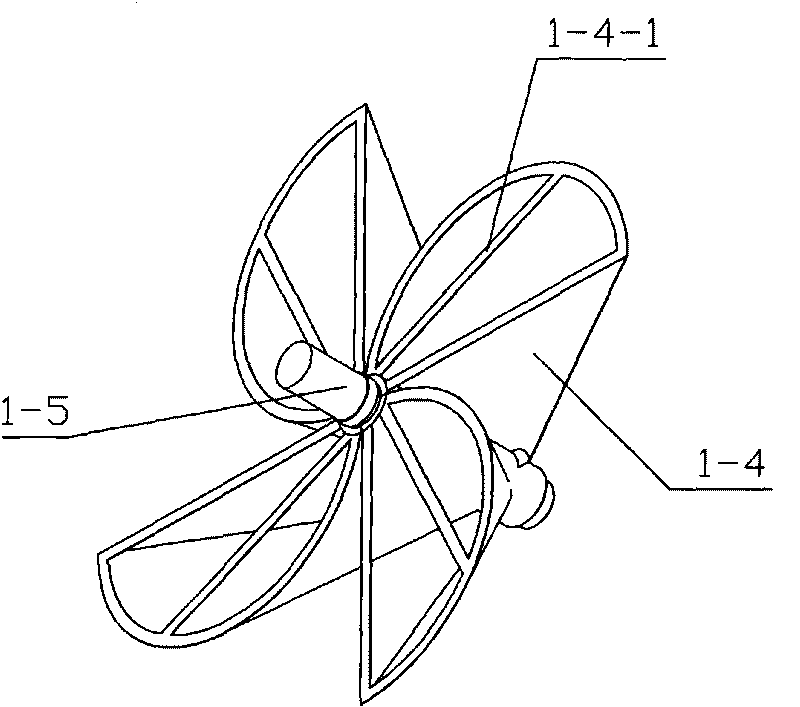

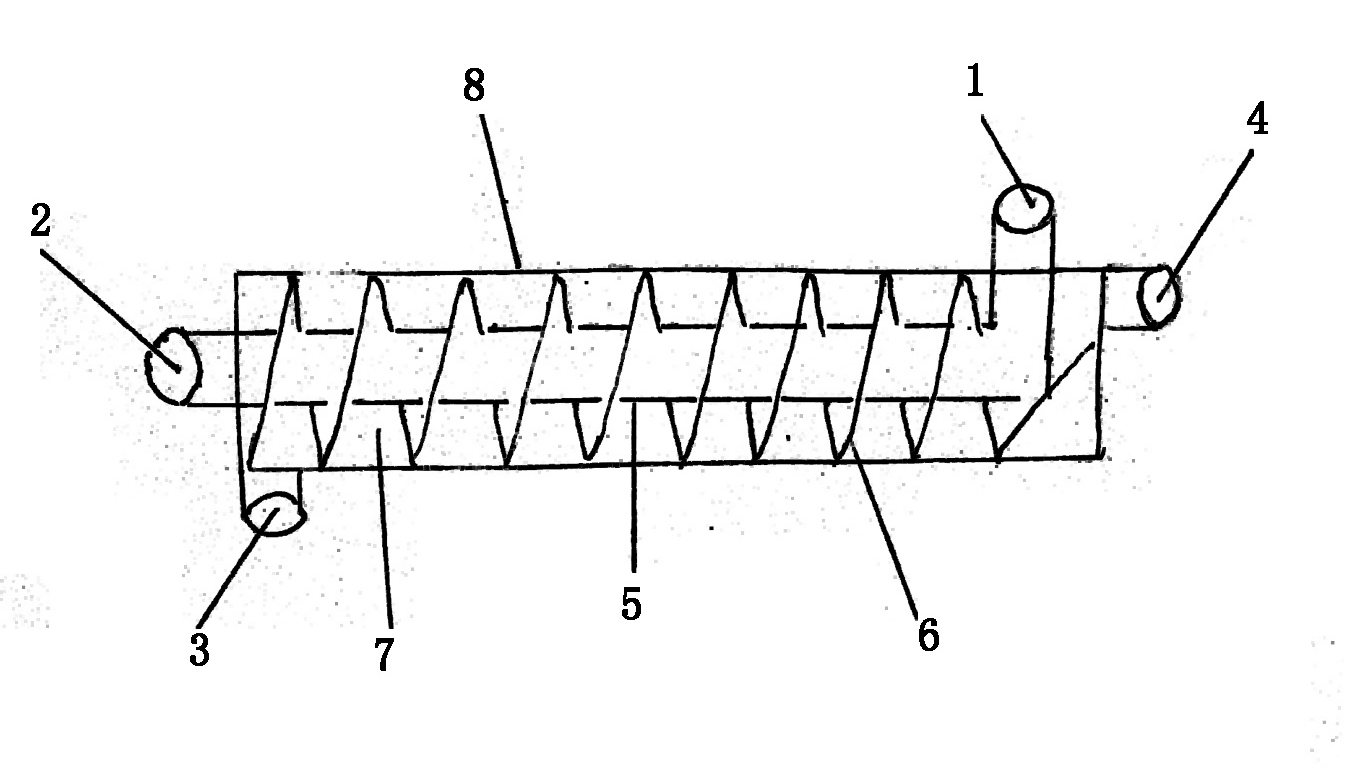

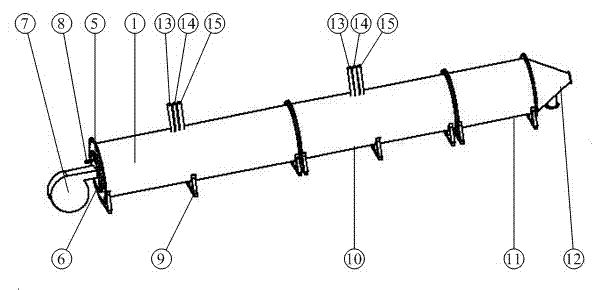

Method and equipment for granulating wet sludge soft particles

InactiveCN101703907AFine grainReduce drying costsSludge treatment by de-watering/drying/thickeningGranulation in rotating dishes/pansCombustionSludge

The invention discloses a method for granulating wet sludge soft particles. Sludge after being pressed and filtered is extruded into sludge strings by a sludge string extrusion machine at the top of a mixing tank, combustible powder is sprayed to the sludge strings for serving as an isolator by adopting a powder spraying machine of a powder spraying gun which is fixedly connected on the side wall of the mixing tank in the process that the sludge strings fall from top to bottom, the sludge strings coated with the combustible powder fall on a turntable granulating machine of which the bottom is laid with the combustible powder, and soft body granulation is carried out under the rotation of the turntable granulating machine to form dispersive wet sludge soft particles. The invention also discloses equipment for realizing the method. The invention simplifies a subsequent sludge drying process; the sprayed combustible powder can be used as the isolator, which is beneficial to sludge granulation and solves the problems of sludge caking and wall sticking effectively; moreover, the sprayed combustible powder can also act as a combustion-supporting function when sludge is incinerated; and the invention has simple equipment, low energy consumption and high benefit, is safe and sanitary, is convenient for popularization and use and can promote the industrialization progress of the drying incineration of the sludge.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Cigarette paper additive and its preparation method

InactiveCN1757826AGood water solubilityNot easy to scatterInorganic compound additionWater solubleAluminium

A functional improver for the cigarette paper is prepared from perchlorate (20-90 Wt%) and alkaline aluminium lactate Al(OH)2 Lac (10-80 Wt%) through mixing. It is applied through dissolving it in water and spraying the solution onto cigarette paper to prevent the burnt paper from being broken for wrapping the tobacco ash well.

Owner:郑州瑞普生物工程有限公司

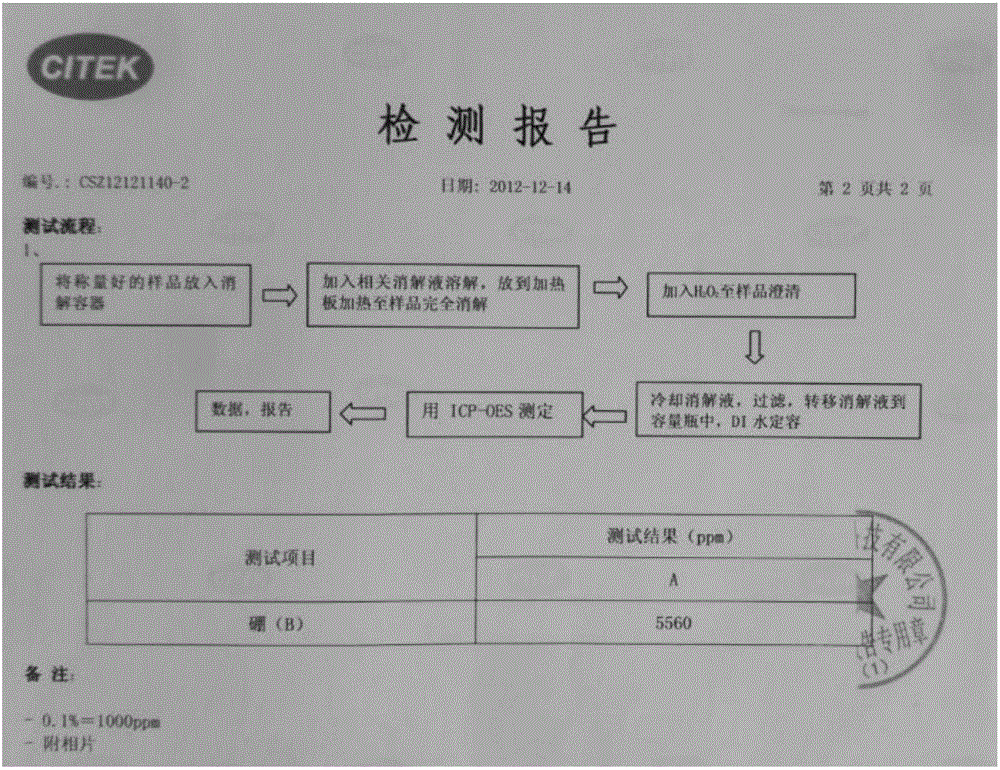

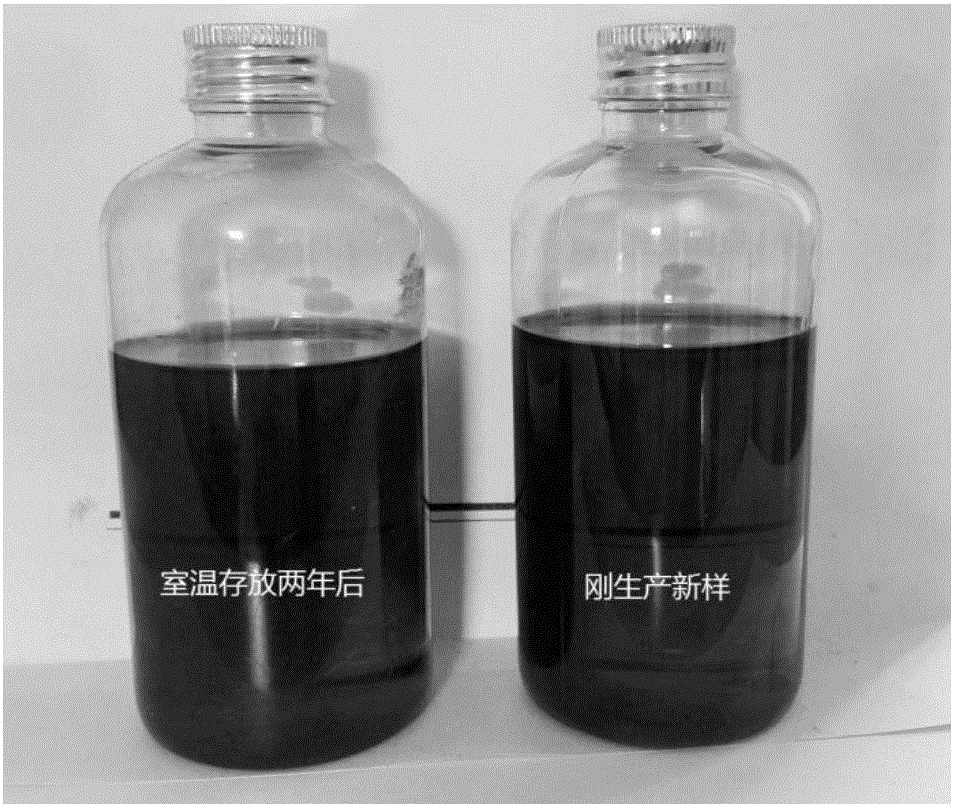

An oil-based nanometer boric acid additive capable of saving energy and reducing emission, a preparing method thereof and applications of the additive

ActiveCN106381191AGood anti-frictionSmall running resistanceLiquid carbonaceous fuelsAdditivesOrganic solventFuel oil

An oil-based nanometer boric acid additive capable of saving energy and reducing emission, a preparing method thereof and applications of the additive are disclosed. The additive is prepared from, by weight, 4-7 parts of boric acid, 55-75 parts of carrier oil, 10-20 parts of a dispersant, 5.2-7.5 parts of a silane coupling agent, 1-3 parts of an emulsifier, 10-20 parts of an organic solvent and 5-8 parts of a metal passivator. The preparing method includes fully mixing and reacting the boric acid, the silane coupling agent and the emulsifier to obtain modified boric acid, adding the modified boric acid into the carrier oil comprising an organic solvent, a Mannich base ashless dispersant and a polyamide ashless dispersant, shearing, dispersing, removing the solvent, adding the metal passivator, fully mixing the metal passivator, and reacting. The additive can be applied into lubricating oil or fuel oil.

Owner:青岛索孚润化工科技有限公司

Biological coal

The invention discloses biological coal, and belongs to the technical field of biomass carbonization. Coal ash, domestic sludge and corncobs are used as raw materials; modification is performed through the operations of ventilation preheating, high-temperature pyrolysis, carbonate liquid soaking and the like; the volatile matters in sludge are reduced; the aromatization degree and the crystallization degree are enhanced; along with the temperature improvement, the activation energy is reduced; the pyrolysis is facilitated, so that the charcoal ingredients are fully burned; the heat generationenergy efficiency is greatly improved; then, starch and oxidized graphene are used as raw materials; starch molecular chains generate crosslinking, so that the surface of a starch wall material of a porous structure is compacter; the oxygen storage quantity of the biological coal system is increased; in the use process, the starch and the oxidized graphene are combustibles; the oxidized graphene is heated and can fast generate free radicals; the combustion promoting effect is achieved. The problems that the heat value of the existing biological coal is insufficient, and the stability is poor during the storage are solved.

Owner:白婷婷

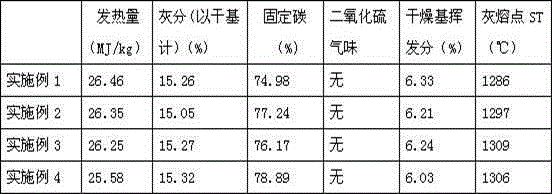

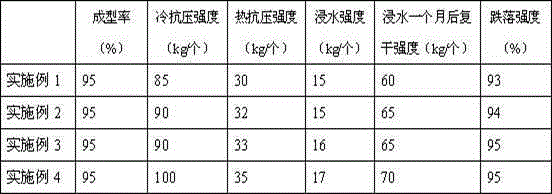

High viscosity briquette waterproof composite binder

InactiveCN105296045AImprove molding rateImprove cohesionSolid fuelsEconomic benefitsThermal stability

The invention discloses a high viscosity briquette waterproof composite binder, which includes the following raw materials by weight: 350-400 parts of pregelatinized starch, 400-450 parts of magnesium oxide, 100-150 parts of fly ash, 50-100 parts of red mud, 6-8 parts of soda ash, and 4-6 parts of polyacrylamide. The binder provided by the invention has viscosity of greater than or equal to 20000Mpa.s, granularity of 200-mesh up to 85%, a moisture content of less than or equal to 10% and a pH value of 8.5-9.0. The briquette provided from the binder provided by the invention not only has strong waterproof performance, but also has the advantages of flammability, good thermal stability, high cold-hot strength, high reaction activity, high thermal efficiency and environmental protection, also has the advantages of wide raw material sources, low cost, simple preparation process and the like, has very good social, ecological and economic benefits, and is easy to realize large-scale production.

Owner:GUANGXI JINZHUANGJIN ENERGY SAVING TECH

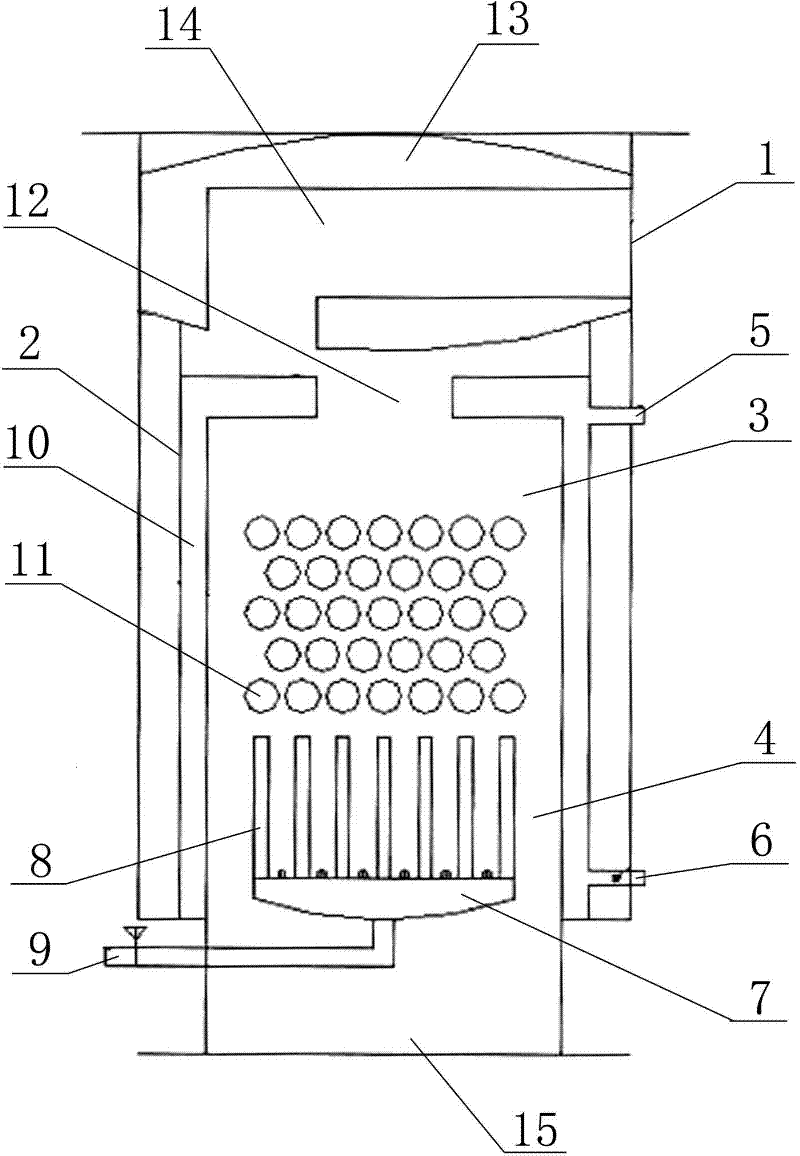

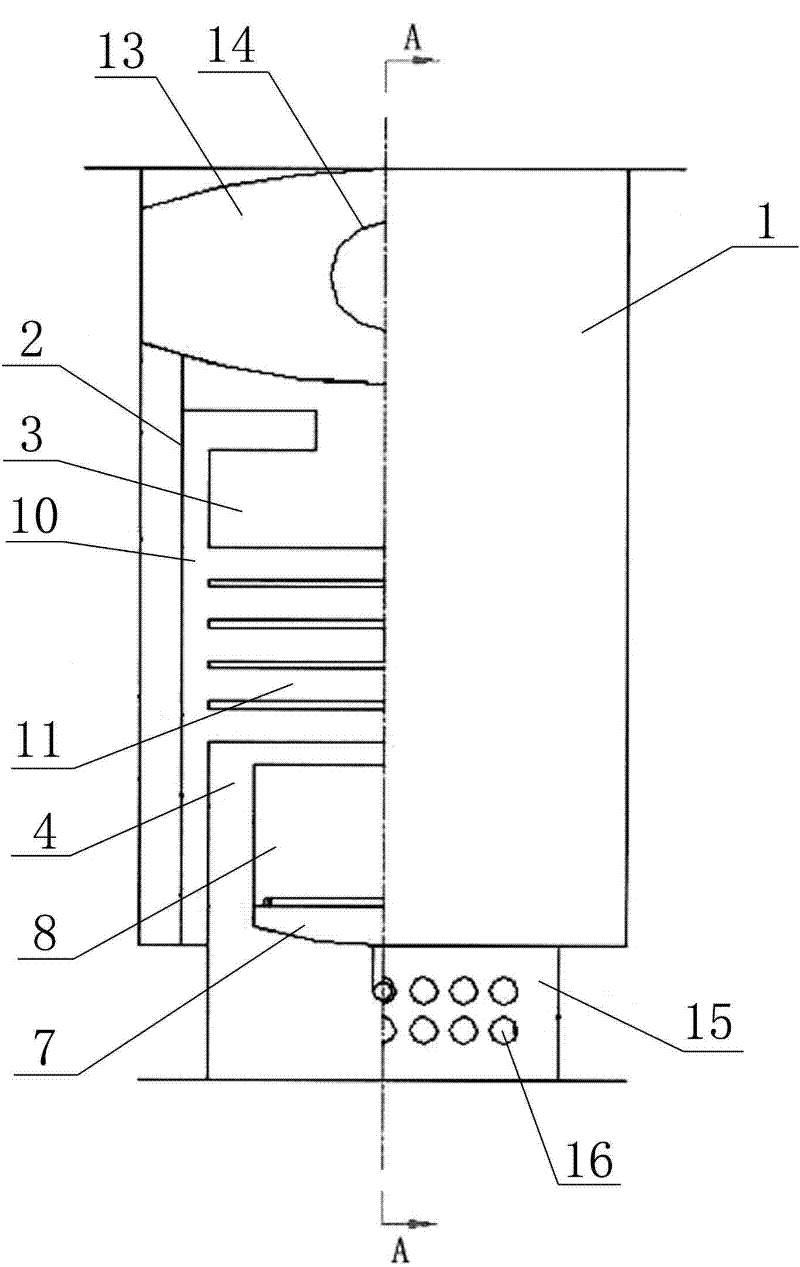

Household floor gas furnace

InactiveCN102353094ASolution areaSolve for uniformityLighting and heating apparatusSpace heating and ventilation detailsCombustion chamberEngineering

The invention relates to gas heating equipment, in particular to a household floor gas furnace. The invention solves the problems of small heating area, nonuniform heating, low thermal efficiency, high cost and low safety of the conventional gas heating equipment. The household floor gas furnace comprises a furnace shell, a furnace body arranged in the furnace shell, a furnace cavity arranged in the furnace body, and a combustion chamber arranged below the furnace cavity, wherein a water jacket is arranged between the outer wall of the furnace body and the inner wall of the furnace body; a layered pipe heat exchanger consisting of a heat exchange pipe array is arranged in the furnace cavity; the heat exchange pipe array comprises a plurality of heat exchange pipes which are horizontally and fixedly arranged in the furnace cavity; an excess heat absorption water tank is fixed at the upper end of the furnace body; and an excess heat recovery pipe is arranged in the excess heat absorption water tank. The household floor gas furnace adopts a new heat exchange structure, effectively solves the problems of small heating area, nonuniform heating, low thermal efficiency, high cost and low safety of the conventional gas heating equipment, and is suitable for household gas heating.

Owner:王文茂

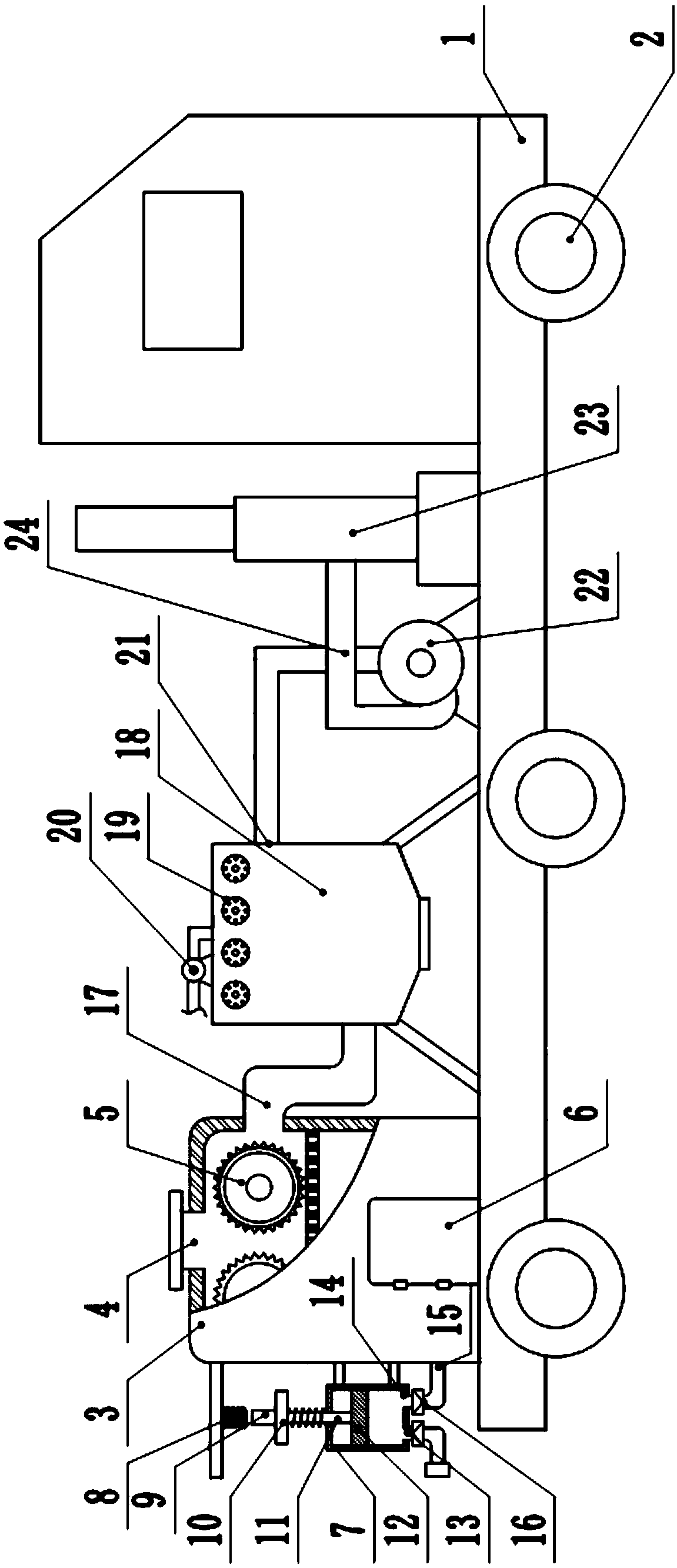

Straw incineration processing device with waste gas processing function

InactiveCN109307272AImprove purification effectPlay a role in combustionIncinerator apparatusCombustionIncineration

The invention discloses a straw incineration processing device with a waste gas processing function. The straw incineration processing device with the waste gas processing function comprises a bearingvehicle body, an incineration furnace, a smashing roller, an air blowing device, a smoke purifying box, mist sprayers and a vertical type chimney. A plurality of groups of moving wheels are installedon the lower side of the bearing vehicle body. A incineration furnace is further fixedly installed on the upper surface of the bearing vehicle body. The air blowing device is further installed on theouter wall of the left side of the incineration furnace. The smoke purifying box is arranged on the right side of the incineration furnace. Air in an inner cavity of the air blowing device is pressedinto the incineration furnace, so that the combustion supporting function is achieved, the incineration effect is improved, and the incomplete incineration phenomenon is avoided. In the incinerationprocess, an exhaust fan and a water pump are switched on to work, the exhaust fan exhausts smoke in the incineration furnace into the smoke purifying box, the mist sprayers spray water mist to adsorbdust in the smoke, and harmless gas is discharged from the vertical chimney. Compared with an existing straw incineration device, the straw incineration processing device with the waste gas processingfunction is higher in smoke purifying capacity and achieves the environmental protection function.

Owner:湖南米笠农业科技有限公司

Ashless additive for diesel engine and application of ashless additive

ActiveCN103725336AReduce consumptionEmission reductionLiquid carbonaceous fuelsFuel additivesCombustionHazardous substance

The invention relates to an ashless additive for a diesel engine and the application of the ashless additive, and belongs to the technical field of diesel additives. The ashless additive for the diesel engine comprises the following components in percentage by mass: 50 to 83 percent of ethyl lactate and 17 to 50 percent of tert-butyl peroxy-2-ethylhexyl carbonate. The ashless additive can be used for improving the combustion performance of diesel and fulfilling the aims of saving the diesel and reducing the emission of harmful substances after combustion used as an anhydrous metal-free diesel additive.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

High-fuel-efficiency biomass fuel

The invention relates to a high-fuel efficiency biomass fuel, and belongs to the field of fuels. According to the invention, octenyl succinic acid modified starch and bacterial cellulose are taken aswall materials, the surface of the wall materials is densified, so that the loss of effective ingredients in the processes of preparation and storage is effectively avoided, the effects of promoting combustion and improving fuel efficiency are achieved, the heat conductivity of the structure of the wall materials is improved; heat can be rapidly led into the inner part in the use process, and micro-explosion occurs to a micro-capsule structure; the occurrence of the micro-explosion, on one side, causes thermoresonance and produces secondary energy, so that the fuel can be completely burned rapidly at high temperature, and the fuel efficiency is further improved; the volume of magnesium oxide expands and shrinks in the use process, so that inner pores and melt materials in a system are redistributed, the excessive expansion of the volume of the fuel is avoided in the combustion process, and the product porosity is also effectively maintained. The invention solves the problems of low combustion efficiency and low use ratio of the current commonly-used biomass fuel.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Method for preparing biomass briquetting fuel from sisal hemp residues

The invention discloses a method for preparing biomass briquetting fuel from sisal hemp residues. Sisal hemp residue powder, magnesium oxide, manganese ore slag, starch, cerous sulfate, sodium carboxymethylcellulose mucilage and epoxy asphalt with the weight ratio of 100:(8-12):(5-10):(10-15):(2-4):(10-15):(5-8) are adopted as raw materials, and the biomass briquetting fuel is prepared through the procedures of smashing, forming, drying and the like. The method has the advantages that the preparation process is simple, energy consumption is low, production efficiency is high, the forming rate is high, and cost is low, the prepared biomass fuel is low in density, high in heat value, low in ash content, not prone to looseness, good in moisture resistance, capable of being saved for a long time and suitable for industrial production, and internal gaps of the product are small.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Water and heavy oil hybrid burner

The invention provides a water and heavy oil hybrid burner. The burner comprises heating equipment, a vapor nozzle, water supply equipment, oil supply equipment, a heavy oil cup and a heavy oil heater, wherein the heating equipment is connected with the vapor nozzle and the water supply equipment respectively; the vapor nozzle is positioned between the heating equipment and the water supply equipment and is matched with the heavy oil cup and the heating equipment respectively; the oil supply equipment is matched with the heating equipment through the heavy oil cup and the heavy oil heater; and a heavy oil metering pump is arranged between the heavy oil cup and the heavy oil heater. After the scheme is adopted, the heating capacity is improved by turning hydrogen into a fuel actually, and the emission of low-pollution gas can be realized, so the method achieves the highest efficiency by using the least fuel.

Owner:李德文

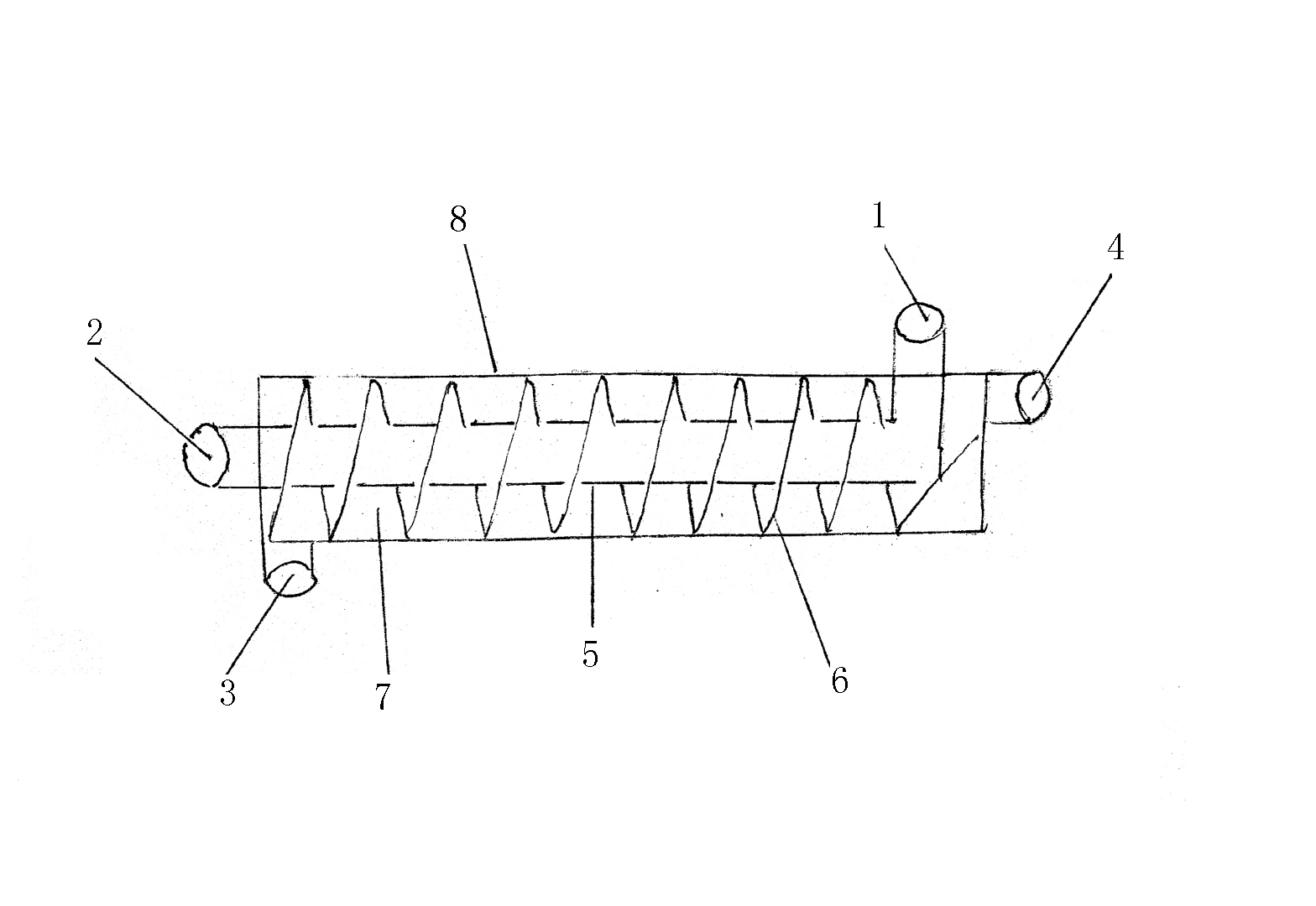

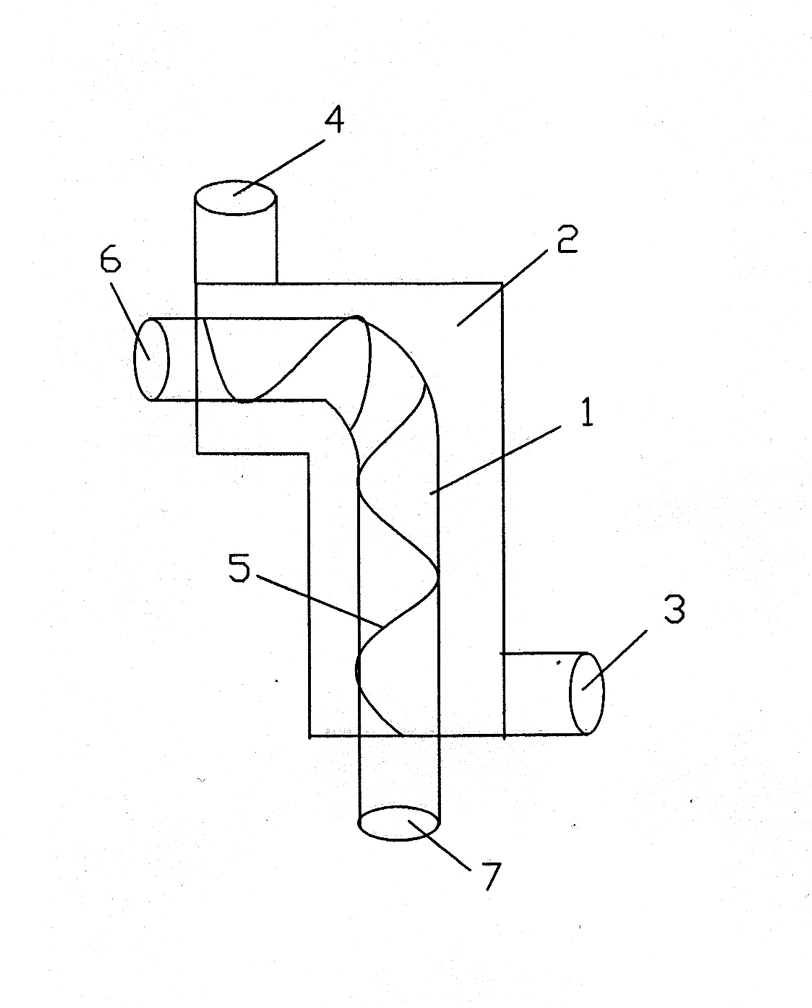

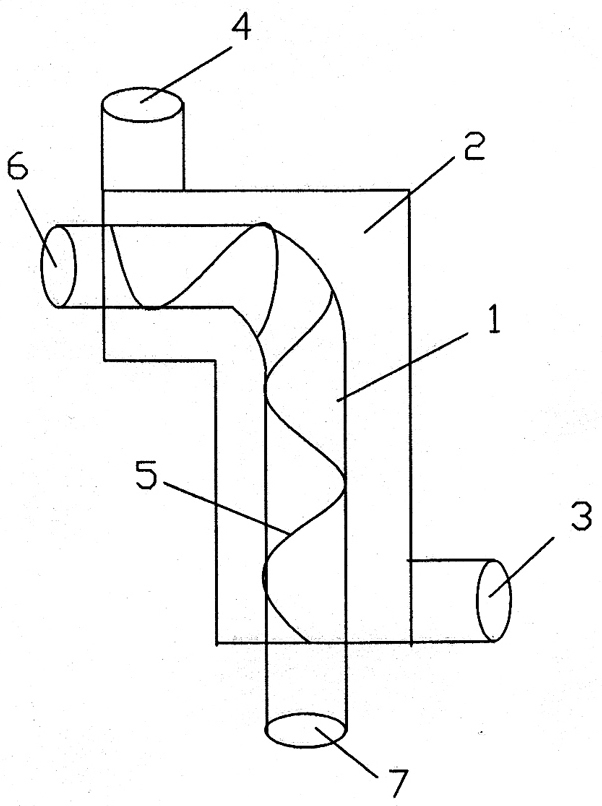

Vehicle combustion-supporting energy saver

InactiveCN102062028ASave fuelReduce dosageInternal combustion piston enginesExhaust apparatusCombustionHeat conducting

The invention relates to a vehicle combustion-supporting energy saver which is widely applied to all fuel mechanical equipment and big and small motor vehicles. The vehicle combustion-supporting energy saver has the structure that spiral heat conducting fins are arranged outside an exhaust tailpipe, spiral air ducts are arranged among the spiral heat conducting fins, and an air hood is arranged outside the spiral heat conducting fins and the spiral air ducts; an air inlet is arranged on one side of the spiral air ducts, and an air outlet is arranged on the other side of the spiral air ducts; and the air inlet is connected with an air filter, and the air outlet is connected with an air inlet of a vehicle engine. By adopting the vehicle combustion-supporting energy saver provided by the invention, the outside air temperature can be increased to 40-50 DEG C, 20-30% of fuel can be saved, products with different sizes and shapes can be produced according to the types and the actual situations of different vehicles, and meanwhile, the energy saving effect of the vehicle combustion-supporting energy saver can not be influenced. Air is converted into a heat energy gas by using heat discharged by tail gas, the waste gas is utilized, fuel is saved, and therefore, the vehicle combustion-supporting energy saver benefits both the country and the people.

Owner:王恩波

Environment-protecting energy-saving liquor

InactiveCN1403544AReduce concentrationReduce the speed of propagationLiquid carbonaceous fuelsBenzoic acidDistilled water

The environment-protecting energy-saving liquor is compounded with methanol, tert-butyl alcohol, clear dispersant, benzoic acid and distilled water. It is mixed with fuel inside internal combustion engine and can make the fuel burn fast and completely, so as to reduce CO content in tail gas, protect environment and save fuel.

Owner:周蕾

Lightweight aggregate based on coarse coal gasification slag and preparation method thereof

The invention discloses a lightweight aggregate based on coarse coal gasification slag and a preparation method thereof. The lightweight aggregate is prepared from the following raw materials of the coarse coal gasification slag, clay, feldspar, talcum powder, water, silicon carbide whiskers and a dispersing agent. The preparation method comprises the steps that the raw materials are weighed and subjected to pretreatment, the raw materials obtained after pretreatment are mixed, water is added, mechanical stirring is conducted, and a mixture is obtained; the mixture is pressed, drying is conducted, and a green body is obtained; the green body is sintered, and the lightweight aggregate based on the coarse coal gasification slag is obtained. Accordingly, the lightweight aggregate based on thecoarse coal gasification slag serves as the main raw material, the strength of the lightweight aggregate can be effectively improved, the application range of the lightweight aggregate is extended, the lightweight aggregate can be applied to high-rise buildings and long-span bridges, the durability of the buildings is improved, and the building cost is lowered; meanwhile, the industrial pollutionproblem of the coarse coal gasification slag is solved.

Owner:BAOJI HUIDE SANFEI DEV & UTILIZATION CO LTD

Energy-saving burner of commercial stove

InactiveCN101907310AIncrease supplyAvoid wastingDomestic stoves or rangesLiquid heating fuelHearthEngineering

The invention discloses an energy-saving burner of a commercial stove, comprising a burner seat, a burner upper cover and a gas-liquid separating tank, wherein the gas-liquid separation tank is provided with a liquid phase inlet and a liquid phase outlet; and the liquid phase outlet is connected with a conduit, and the conduit is provided with a control valve. The energy-saving burner of the commercial stove is characterized in that the other end of the conduit is arranged in the air inlet of the burner body, so that an inner cavity of the stove seat is used as a gas mixing chamber. The invention has the following advantages that: the liquid of the liquefied gas can be burned directly, and the liquid of the liquefied gas and the air introduced by a blower are mixed into a mixed gas in a fuel chamber; a large amount of oxygen participates in helping the combustion, so that the high combustion efficiency and the good combustion effect are obtained, and the energy is saved remarkably; the used steel cylinder has no residual liquid, so that the energy-saving burner of the commercial stove avoids the waste of the energy, meets the requirements for the environmental protection, and is particularly suitable for being used in the occasions such as hotels, restaurants, work unit restaurants and the like in the cold regions of the northern part of China.

Owner:武海涛

Automobile combustion-supporting economizer

PendingCN102003307AHigh-tech contentSave fuelInternal combustion piston enginesExhaust apparatusCombustionMechanical equipment

The invention relates to an automobile combustion-supporting economizer, which can be widely suitable for all fuel mechanical equipment and big and small motor vehicles. The automobile combustion-supporting economizer is structurally characterized in that the outer part of a tail gas exhaust pipe is provided with an airhood, one side of the airhood is provided with an air inlet, and the other side of the airhood is provided with an air outlet. The air outlet is connected with an air inlet of an automobile engine. The automobile combustion-supporting economizer can save 20%-25% of fuel oil. Various sizes and different shapes of products can be produced according to the type of different automobiles and the practical situation of automobiles, meanwhile the energy saving effect is not influenced. Moreover, the function of the economizer is completed by utilizing the heat for exhausting tail gas, and waste gas is utilized for benefiting the nation and people.

Owner:王恩波

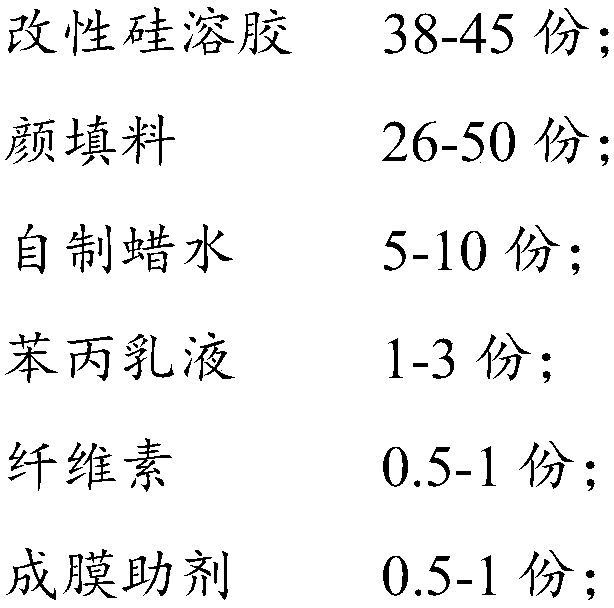

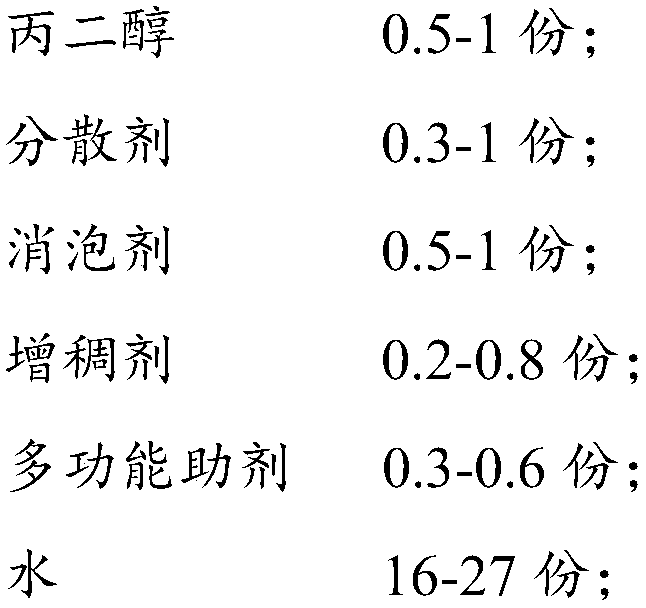

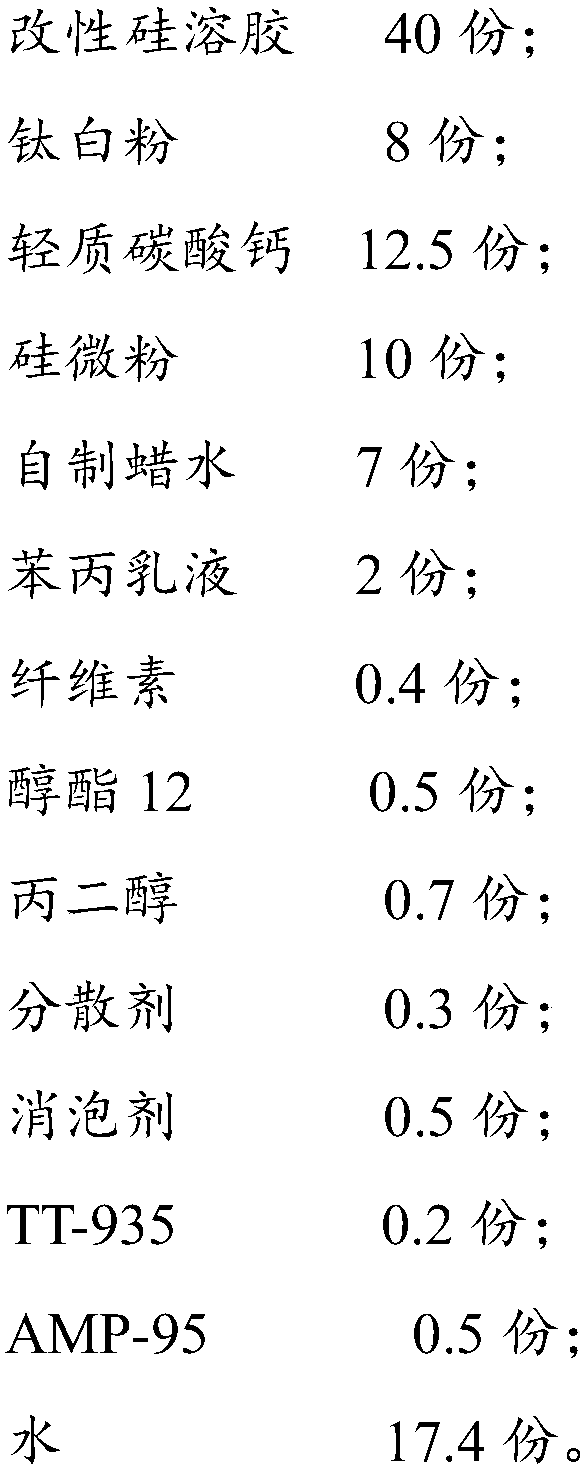

Inorganic composite modified interior wall flame-retardant and mildew-proof water paint and method for preparing same

PendingCN109439028AAvoid cracking of the paint filmGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsWaxEmulsion

The invention discloses inorganic composite modified interior wall flame-retardant and mildew-proof water paint and a method for preparing the same. The inorganic composite modified interior wall flame-retardant and mildew-proof water paint comprises, by weight, 38-45 parts of modified silica sol, 26-50 parts of pigment and fillers, 5-10 parts of self-made wax water, 1-3 parts of styrene-acrylic emulsion, 0.5-1 part of celluloses, 0.5-1 part of coalescing agents, 0.5-1 part of propylene alcohol, 0.3-1 part of dispersing agents, 0.5-1 part of defoaming agents, 0.2-0.8 part of thickeners, 0.3-0.6 part of multifunctional auxiliaries and 16-27 parts of water. The inorganic composite modified interior wall flame-retardant and mildew-proof water paint and the method have the advantages that theinorganic composite modified interior wall flame-retardant and mildew-proof water paint prepared by the aid of the method is good in acid and alkali resistance and water resistance and excellent in flame retardance and antibacterial and mildew-proof property; the inorganic composite modified interior wall flame-retardant and mildew-proof water paint does not contain formaldehyde or other organic solvents, is low in odor and is environmentally friendly and safe, heavy metal is omitted, and the VOC (volatile organic compound) content is close to zero.

Owner:丁贤勇

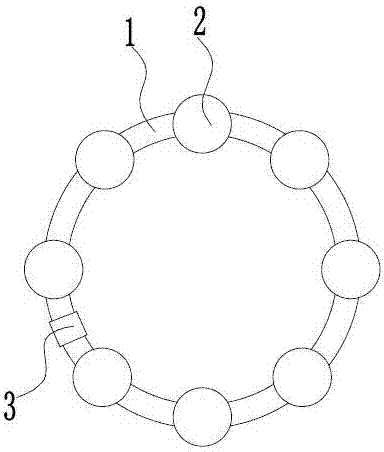

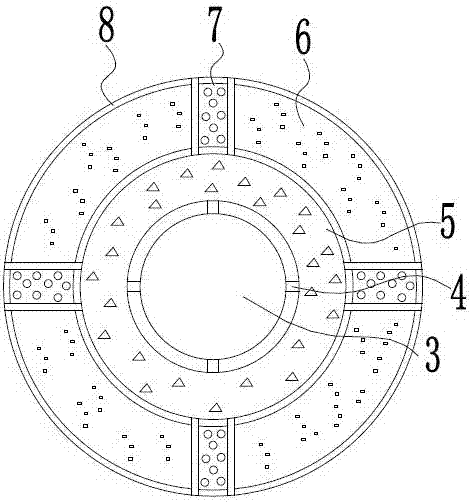

Fertilizer for planting radix polygonati officinalis

ActiveCN107278841ASolve the problem of heavy manual workloadImprove combustion performanceRoot feedersFertiliser distributersTelecommunicationsWater vapor

The invention discloses a fertilizer for planting radix polygonati officinalis. The device comprises a communicating pipe, a plurality of fertilizer pipes which are arranged on the communicating pipe and coaxial with the communicating pipe and a seal sleeve which is used for connecting the communicating pipe to form an annular structure; the communicating pipe is provided with a communicating pipe wall; inlet openings which are sealed by the seal sleeve are formed in the portion, at one end of the communicating pipe, on the communicating pipe wall; permeable holes which are used for inputting water vapor to the fertilizer pipes are formed in the communicating pipe wall, connected with each fertilizer pipe, of the communicating pipe; two seal plugs which are used for preventing the water vapor from being immersed into the fertilizer pipes are arranged between each fertilizer pipe and the communicating pipe, and cavities provided with quick lime is formed in the seal plugs; inlets which are used for being communicated with the cavities are formed in the seal plugs; the inlets are formed in one side face, close to the inlet openings, of each seal plug. According to the fertilizer for planting the radix polygonati officinalis, the radix polygonati officinalis can be subjected to fertilization automatically on time.

Owner:YINGCHENG SHINDOO CHEM COMPOUND FERTILIZER

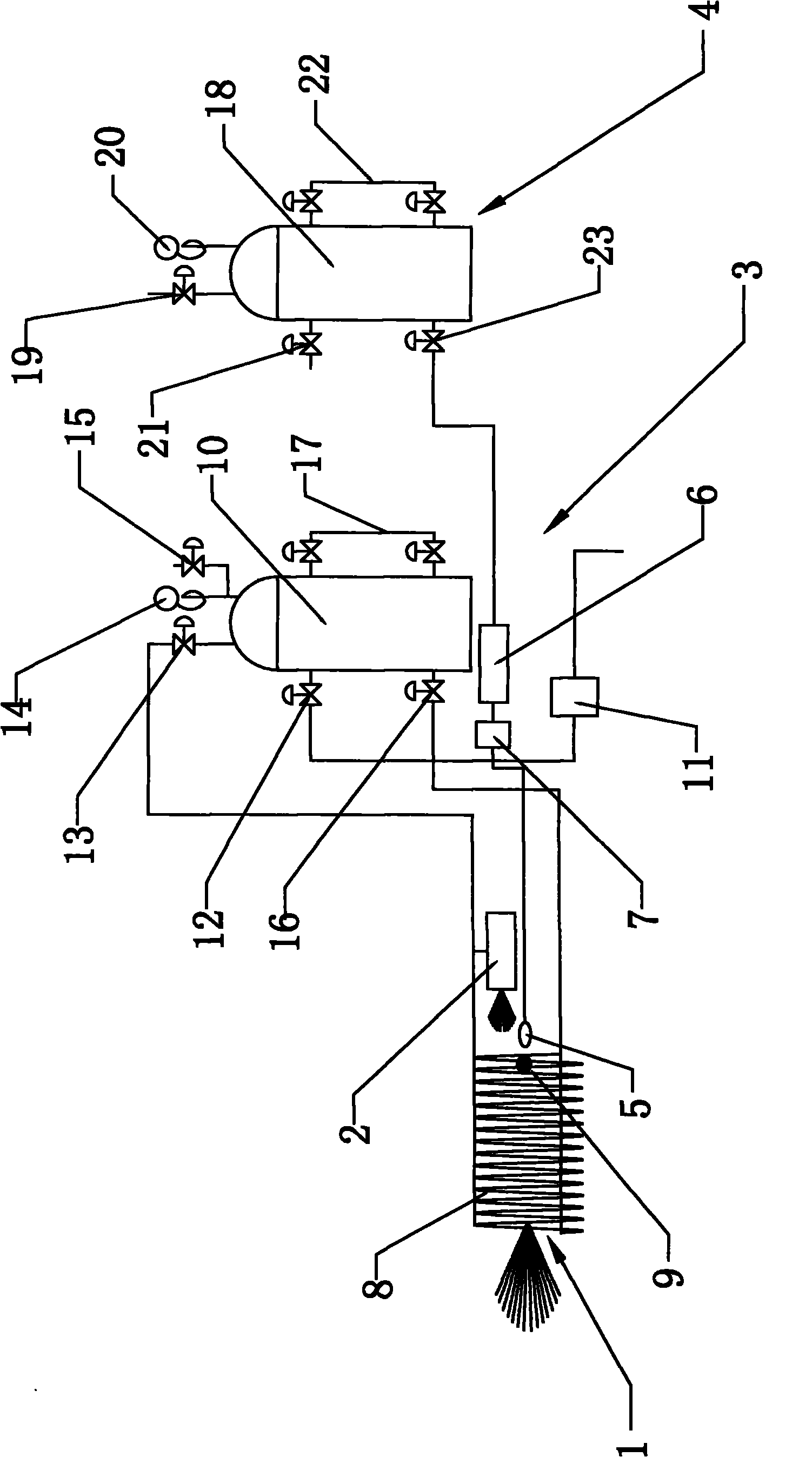

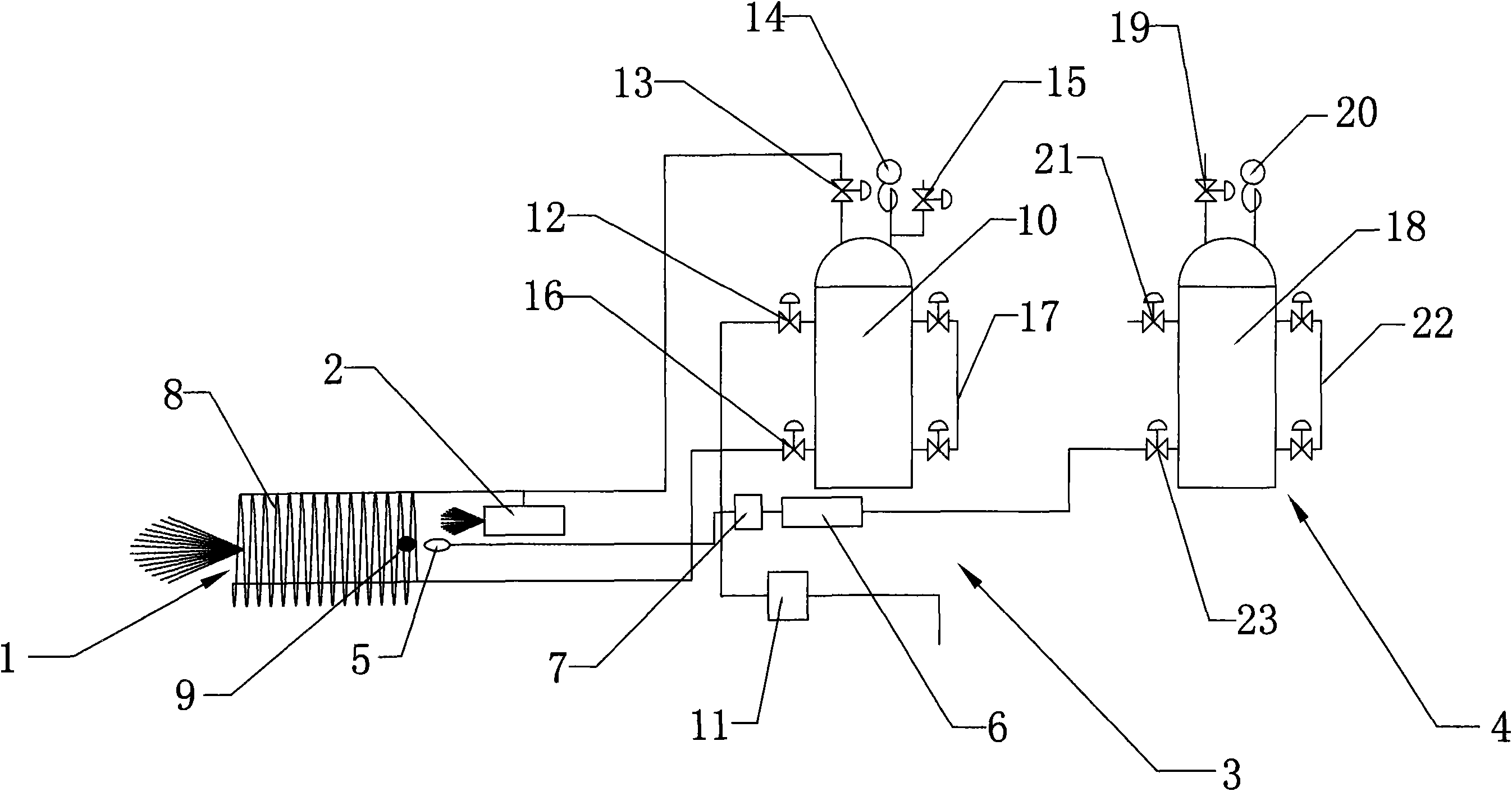

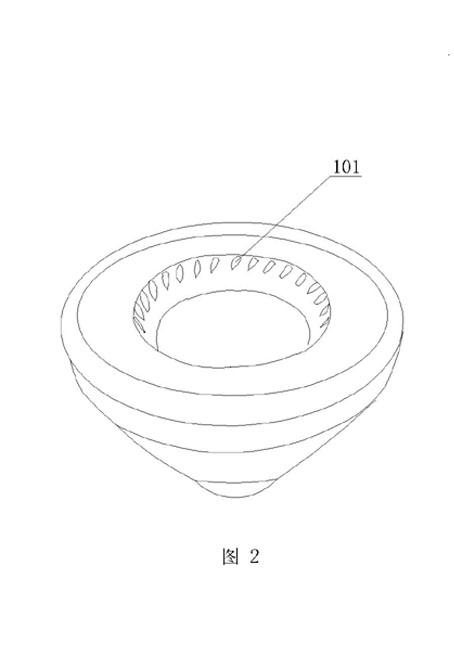

Biomass particle fuel gasification combustion normal-pressure water boiler

PendingCN108692456ABurn fullySafe and reliableSolid fuel combustionWater heatersFuel gasificationProcess engineering

The invention discloses a biomass particle fuel gasification combustion normal-pressure water boiler. The biomass particle fuel gasification combustion normal-pressure water boiler comprises a boilerbody, a spiral feeding device, a fire grate and a flue. A feeding port of the boiler body is connected with a discharging port of the spiral feeding device. The fire grate is arranged at the bottom ofthe boiler body. The flue is arranged at the upper portion of the boiler body. The biomass particle fuel gasification combustion energy-saving and environment-friendly normal-pressure water boiler which adopts biomass particles as fuel, and is efficient, capable of saving energy, low in pollution, capable of achieving zero emission, safe and environment-friendly is disclosed and provided.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

Combustor test device

InactiveCN102967477AReduce consumptionEmission reductionStructural/machines measurementAir preheaterCombustor

The invention discloses a combustor test device. The combustor test device comprises a combustor, a furnace body, a furnace tail smoke exhaust section, a two-section horizontal type furnace body, a high-temperature air pre-heater, a high-temperature camera, a temperature measuring system, a sampling system and a pressure measuring system, wherein a furnace head sealing flange and a furnace body air-tight door are arranged at the front end of a first-section horizontal type furnace body of the two-section horizontal type furnace body, the combustor and the high-temperature camera are installed at the front end of the first-section horizontal type furnace body through the furnace head sealing flange and the furnace body air-tight door, a refractory heat-insulating layer and a hot-air reheating pipe are arranged on the inner wall of a metal cylinder of the furnace body, a heat-resisting steel pipe which is laid on the inner side of the refractory heat-insulating layer and penetrates through the furnace body is bent to produce a water cooling wall, the water cooling wall is provided with a water supply accurate adjusting device, and the temperature measuring system, the sampling system and the pressure measuring system which are used for installing the furnace body are arranged on the two-section horizontal type furnace body respectively. The combustor test device is applicable to tests of small coal combustors and combustors of fuel oil, gas and the like and provides test parameters for quantitative study of combustors, so that the fuel consumption and the pollutant discharge amount of combustors can be reduced, and energy conservation and emission reduction can be achieved.

Owner:YANGZHOU UNIV

Paper mosquito coil and preparation method thereof

The invention discloses a paper mosquito coil and a preparation method thereof. The paper mosquito coil comprises a paper fragrant blank containing a mosquito repelling agent and a mosquito eradication agent, and comprises the following components in percentage by weight: 60 to 90 percent of waste paper, 0 to 25 percent of wood fiber, 8 to 33 percent of carbon powder and 2 to 7 percent of light calcium carbonate. The paper mosquito coil has the advantages of low cost, light weight, no pollution to hands and difficulty in fracture, is easy to ignite and cannot flame out. The preparation method comprises the following steps of: 1, crushing waste paper raw materials to form coarse pulp; 2, adding the wood fiber, the carbon powder and the light calcium carbonate into the coarse pulp, and uniformly mixing; 3, grinding the mixture by using a grinding disc to form waste paper pulp; 4, diluting the waste paper pulp by adding water, removing impurities, and manufacturing a mosquito coil paper board with the pulp; 5, punching the mosquito coil paper board, and drying to obtain a mosquito coil white blank; and 6, spraying the agents onto the white blank to obtain the paper mosquito coil. The method has the advantages of energy conservation, environment friendliness, high labor productivity and capability of production on a large scale.

Owner:HANGZHOU JIADEHAO COMMODITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com