Energy-saving burner of commercial stove

A technology for commercial stoves and burners, which is applied in household stoves/stoves, applications, and household heating, etc. It can solve problems such as energy waste, residual liquid, and insufficient liquid combustion, so as to reduce use costs, avoid energy waste, Obvious effect of energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

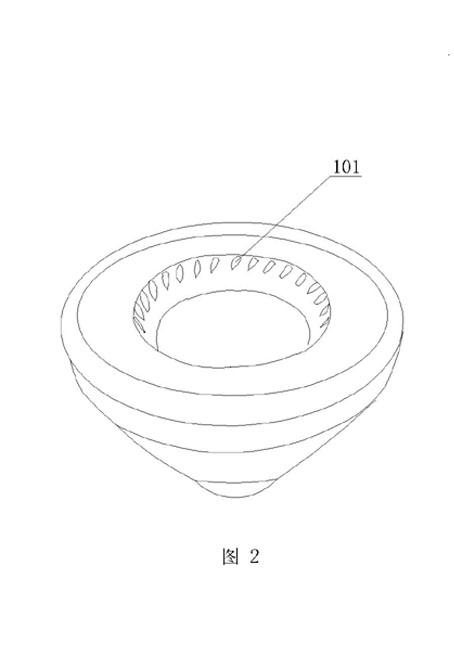

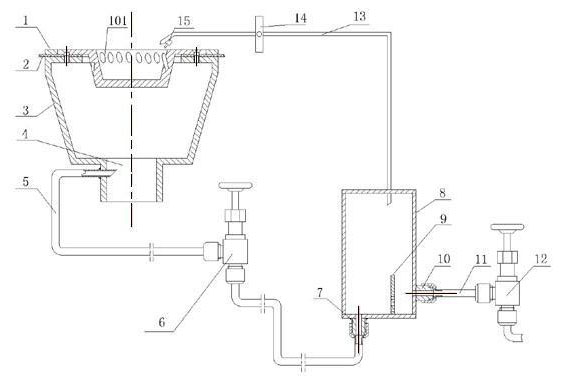

[0019] Such as Figure 1 ~ Figure 2 As shown, the burner head energy-saving device for a commercial stove has a burner base 3, and an air inlet 4 is provided on the burner base 3. The air inlet 4 can be located at the bottom or side of the burner base 3. In this embodiment, Take the bottom of the burner seat 3 as an example. A burner upper cover 1 is installed on the upper opening of the burner base 3 by screws, and a plurality of through holes 101 are evenly distributed on the circumferential wall of the burner upper cover 1 . This energy-saving burner head of commercial stove is also provided with gas-liquid separation tank 8, is provided with liquid phase inlet 10 and liquid phase outlet 7 on gas-liquid separation tank 8, is connected with conduit 5 on liquid phase outlet 7, described conduit 5 The other end is located in the air inlet 4 of the burner seat 3. An on-off valve 6 is provided on the conduit 5, a liquid inlet pipe 11 is provided at the liquid phase inlet 10 of...

Embodiment 2

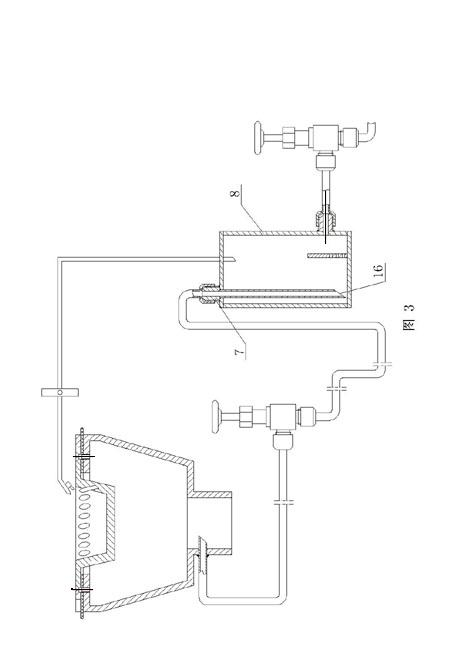

[0022] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that the liquid phase outlet 7 is located on the top surface of the gas-liquid separation tank 8, and a guide connected to the liquid phase outlet 7 is provided in the gas-liquid separation tank 8. The liquid pipe 16 and the lower end of the liquid guide pipe 16 are located at the inner bottom of the gas-liquid separation tank 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com