Microwave plasma ignition device

A technology of microwave plasma and igniter, which is applied in the direction of plasma, combustion ignition, combustion method, etc., can solve the problem that the microwave plasma igniter cannot be used for a long time, and achieve the effect of full effect and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

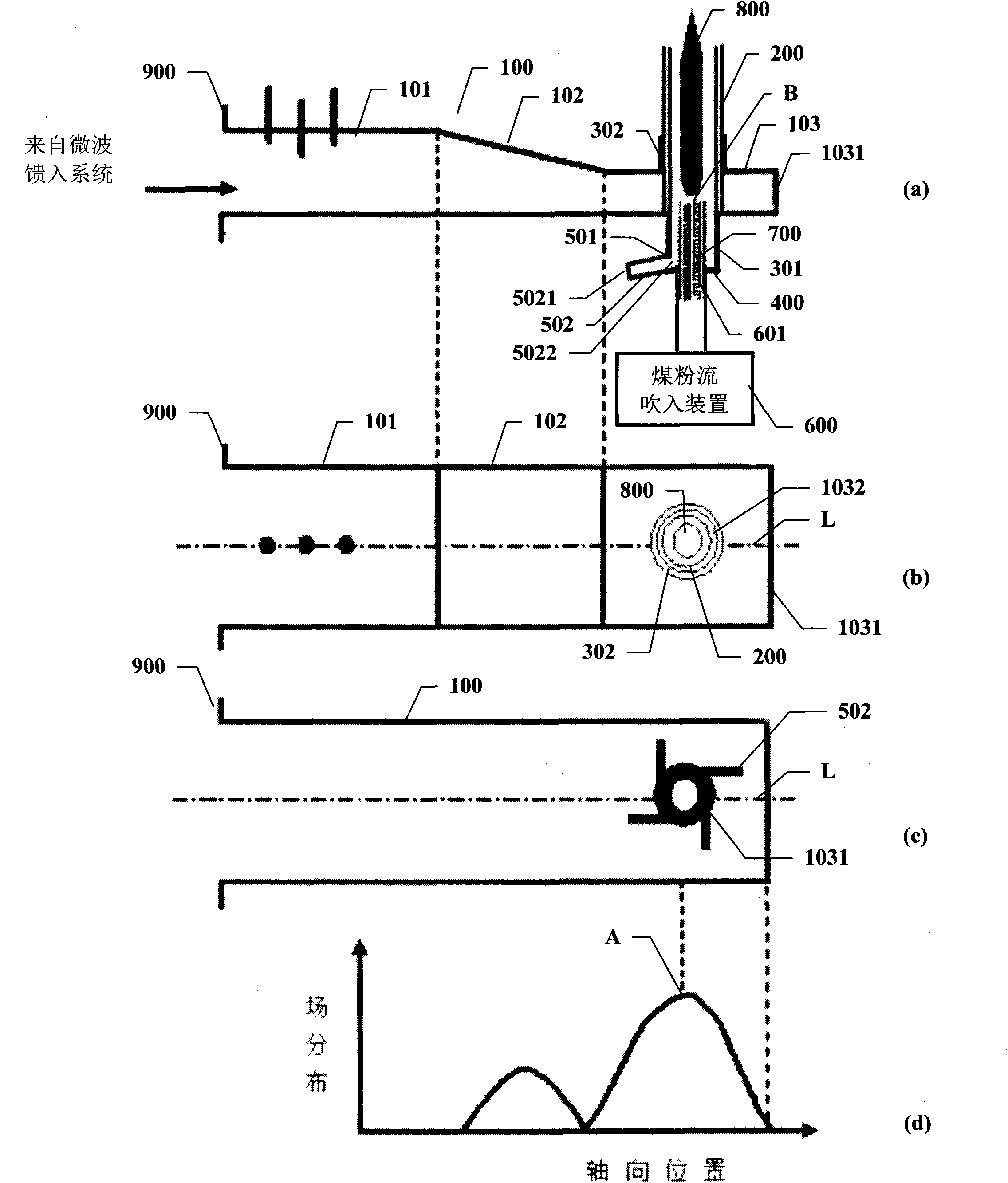

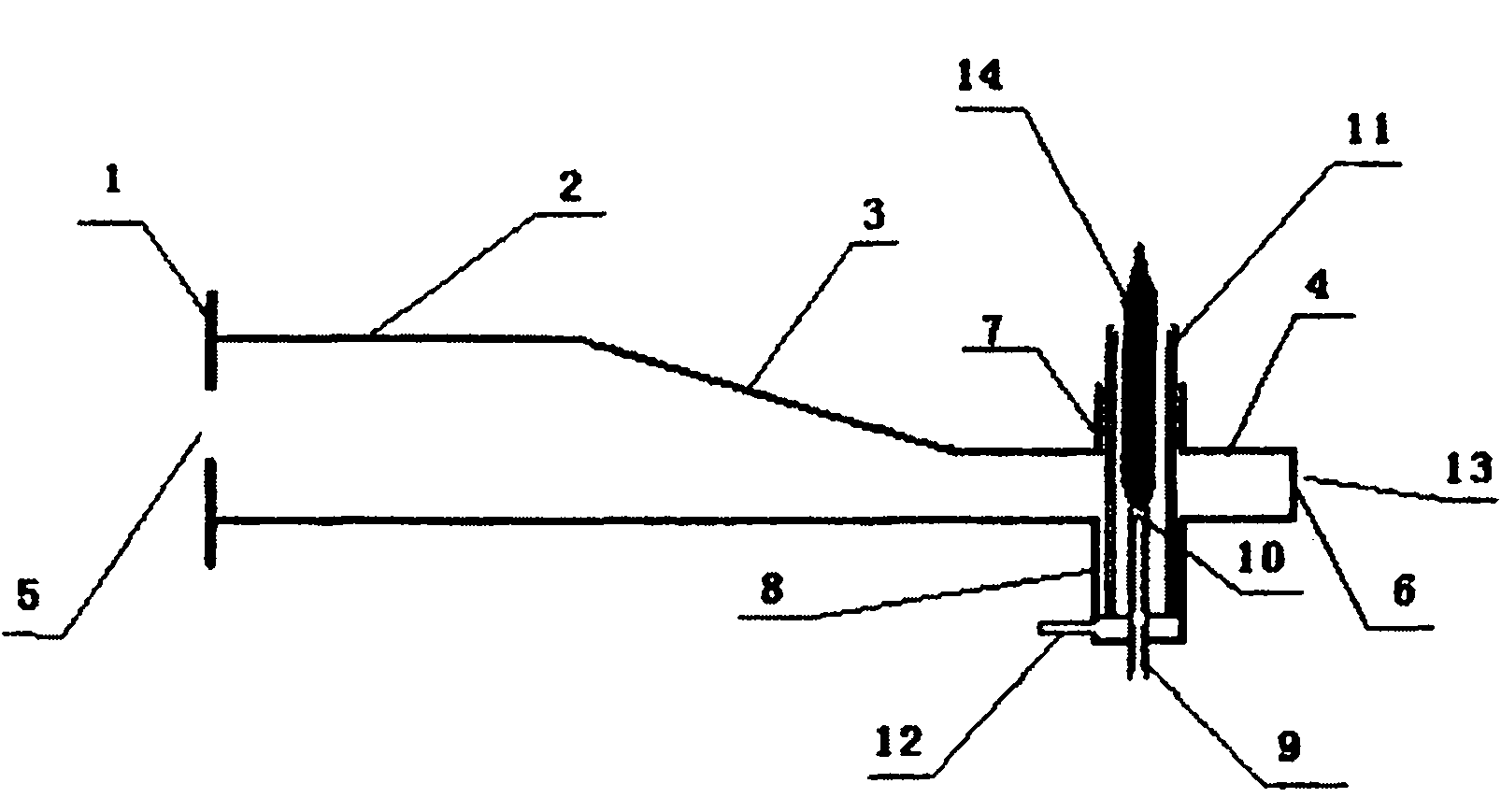

[0022] In this embodiment, as figure 1 As shown in (a), the microwave resonant cavity 100 includes:

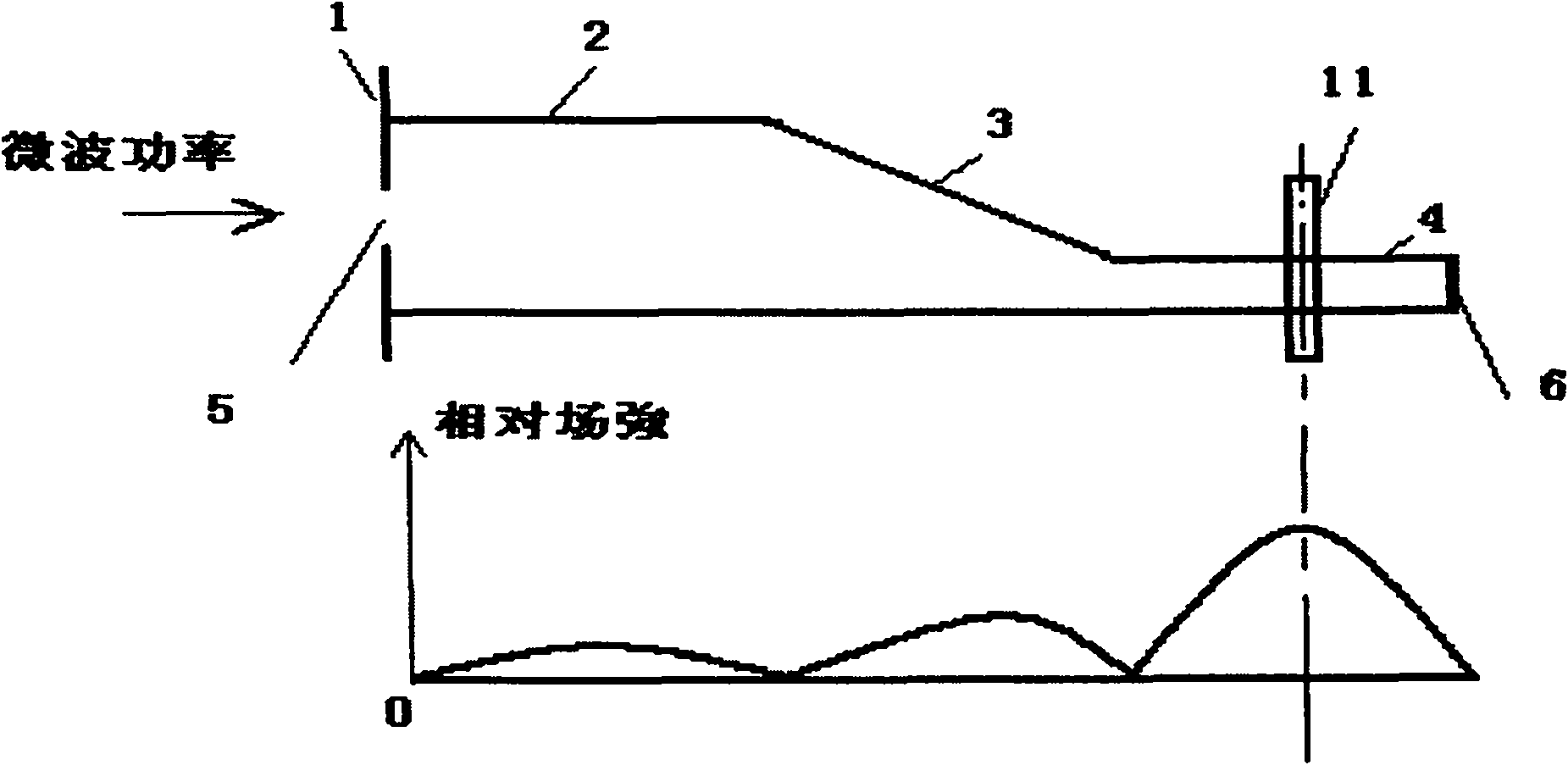

[0023] A standard rectangular waveguide 101, the beginning of which is connected to the microwave power feeding system and having an equivalent short-circuit surface forming device; the microwave power feeding system inputs high-power microwaves to the standard rectangular waveguide 101;

[0024] A tapered rectangular waveguide 102, the beginning of which is connected to the end of the standard rectangular waveguide 101; from the beginning to the end of the tapered rectangular waveguide 102, its narrow side is compressed according to a linear law;

[0025] A narrow-side compressed rectangular waveguide 103, the beginning of which is connected to the end of the tapered rectangular waveguide 102, and the height of the narrow side at the end of the tapered rectangular waveguide 102 is the same, and the end is a metal short-circuit plate 1031; the upper and lower sides of the narrow-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com