An oil-based nanometer boric acid additive capable of saving energy and reducing emission, a preparing method thereof and applications of the additive

A technology of energy saving and emission reduction, nano-boric acid, applied in the field of lubricating oil additives and fuel oil additives, can solve the problems of unsuitable application of fuel oil, blockage of exhaust device, combustion residue, etc., and achieve the effects of saving fuel, reducing mechanical wear and preventing deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of preparation method of the oily nano boric acid additive of energy saving and emission reduction, it comprises the following steps:

[0056] (1) Put 5 parts of boric acid in an oven at 120°C, dry for 2 hours, take it out, put it into a high-speed pulverizer and pulverize it into a powder without agglomerates.

[0057] (2) Add 5 parts of KH-550 silane coupling agent and 2 parts of S-80 emulsifier into the reaction kettle, raise the temperature to 40°C and stir evenly.

[0058] (3) Slowly pour 5 parts of the boric acid powder prepared in step ⑴ into the reaction kettle of step ⑵, and stir at 40°C for 2 hours at high torque and high speed until it becomes transparent and viscous to obtain modified boric acid.

[0059] (4) 71 parts of AN23 alkylnaphthalene are added in the high-speed shear esterification reactor, and add 10 parts of xylene solvents successively, 5 parts of Mannich base ashless dispersants, 5 parts of polyisobutylene bis-succinimide ( T152), 0.2 pa...

Embodiment 2

[0065] A kind of preparation method of the oily nano boric acid additive of energy saving and emission reduction, it comprises the following steps:

[0066] (1) Put 7 parts of boric acid in an oven at 120°C, dry for 2 hours, take it out, put it into a high-speed pulverizer and pulverize it into a powder without agglomeration.

[0067] (2) Add 7 parts of KH-560 silane coupling agent and 3 parts of S-80 emulsifier into the reaction kettle and raise the temperature to 40°C and stir evenly.

[0068] (3) Slowly pour 7 parts of the boric acid powder prepared in step ⑴ into the reaction kettle of step ⑵, and stir at 40°C for 2 hours at high torque and high speed until it becomes transparent and viscous to obtain modified boric acid.

[0069] (4) Add 63 parts of AN23 alkylnaphthalene into the high-speed shear esterification reaction kettle, and successively add 15 parts of xylene solvent, 10 parts of Mannich base ashless dispersant, 10 parts of polymer polyisobutylene polysuccinyl Am...

Embodiment 3

[0075] (1) Put 4 parts of boric acid in an oven at 120°C, dry for 2 hours, take it out, put it into a high-speed pulverizer and pulverize it to a powder without agglomerates.

[0076] (2) Add 5 parts of KH-570 silane coupling agent and 1 part of S-80 emulsifier into the reaction kettle, raise the temperature to 50°C and stir evenly.

[0077] (3) Slowly pour 4 parts of boric acid powder prepared in step ⑴ into the reaction kettle of step ⑵, and stir at 50°C for 2 hours at high torque and high speed until it becomes transparent and viscous to obtain modified boric acid.

[0078] (4) Add 55-75 parts of AN23 alkylnaphthalene into the high-speed shear esterification reaction kettle, and sequentially add 10 parts of xylene solvent, 5 parts of Mannich base ashless dispersant, and 5 parts of high-molecular polyisobutylene dobutane Imide (T161), 0.2 parts of KH-570 silane coupling agent, heated up to 90°C and stirred evenly.

[0079] (5) Add 10 parts of the modified boric acid prepare...

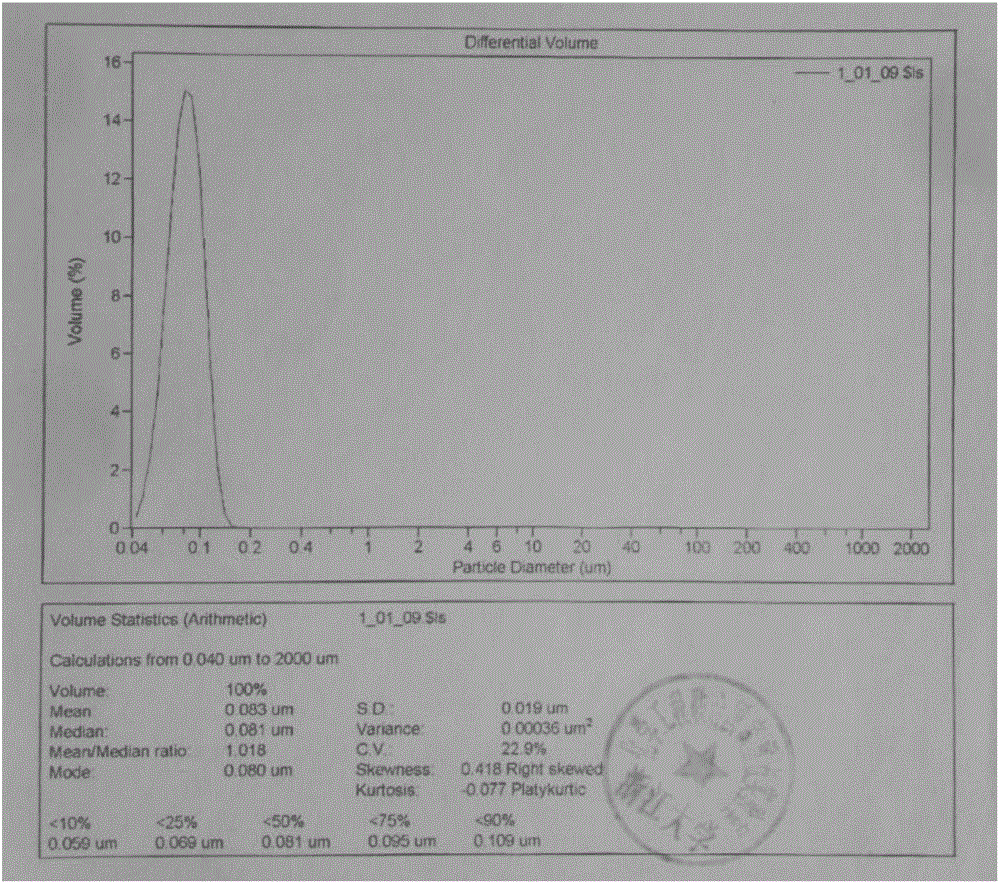

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com