Patents

Literature

135 results about "Boric acid powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precoated sand material applicable to laser sintering of magnesium alloy, and preparation method thereof

InactiveCN103551492APreform Strength GuaranteeImprove curing rateFoundry mouldsIncreasing energy efficiencyFire retardantUltimate tensile strength

The invention discloses a preparation method for a precoated sand material applicable to the laser sintering of a magnesium alloy. The precoated sand material comprises evenly mixed crude sand, an organic binder, a coupling agent, a curing agent and a flame retardant, wherein the flame retardant is a mixture of any two or three of boric acid powder, carbon powder and pyrite powder. By adding the composite flame retardant, the defects of surface ablation and formed holes, micropores and the like when in pouring a magnesium alloy can be greatly reduced; in addition, the composite flame retardant added in the precoated sand solves the problem that a single flame retardant can greatly reduce the strength of an initial precoated sand laser-sintered part blank. According to the preparation method, not only can the magnesium alloy flame retardance problem of an SLS precoated sand mold sand core be solved, but also the strength of the initial laser-sintered molding part blanks can be guaranteed, the precoated sand material can be directly applied to pouring of a magnesium alloy, especially to high-temperature pouring of the magnesium alloy, and has great advantages on the fast integral precise forming aspects of especially complicated inner cavity, and integrated sand mold sand core.

Owner:NANCHANG HANGKONG UNIVERSITY

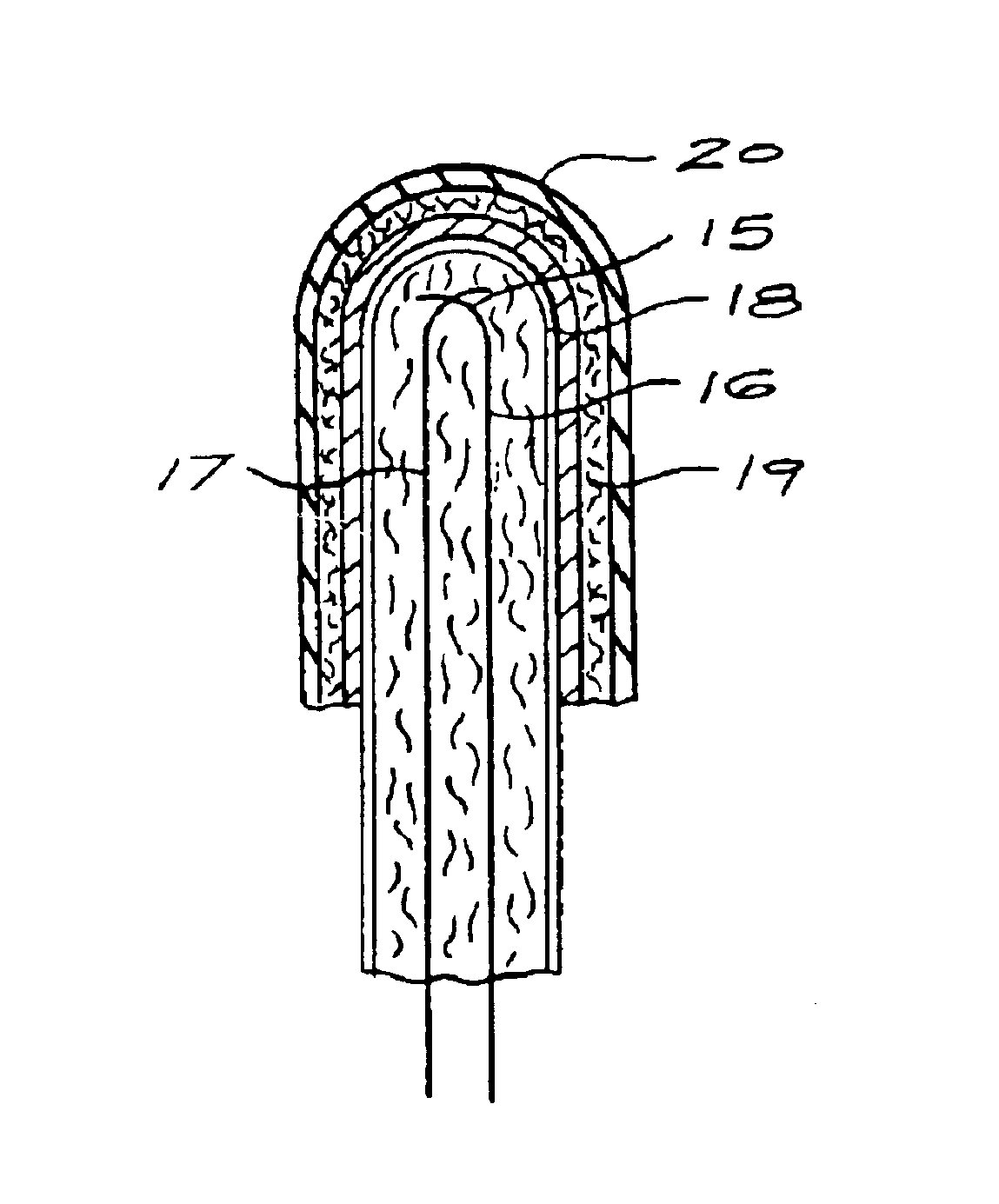

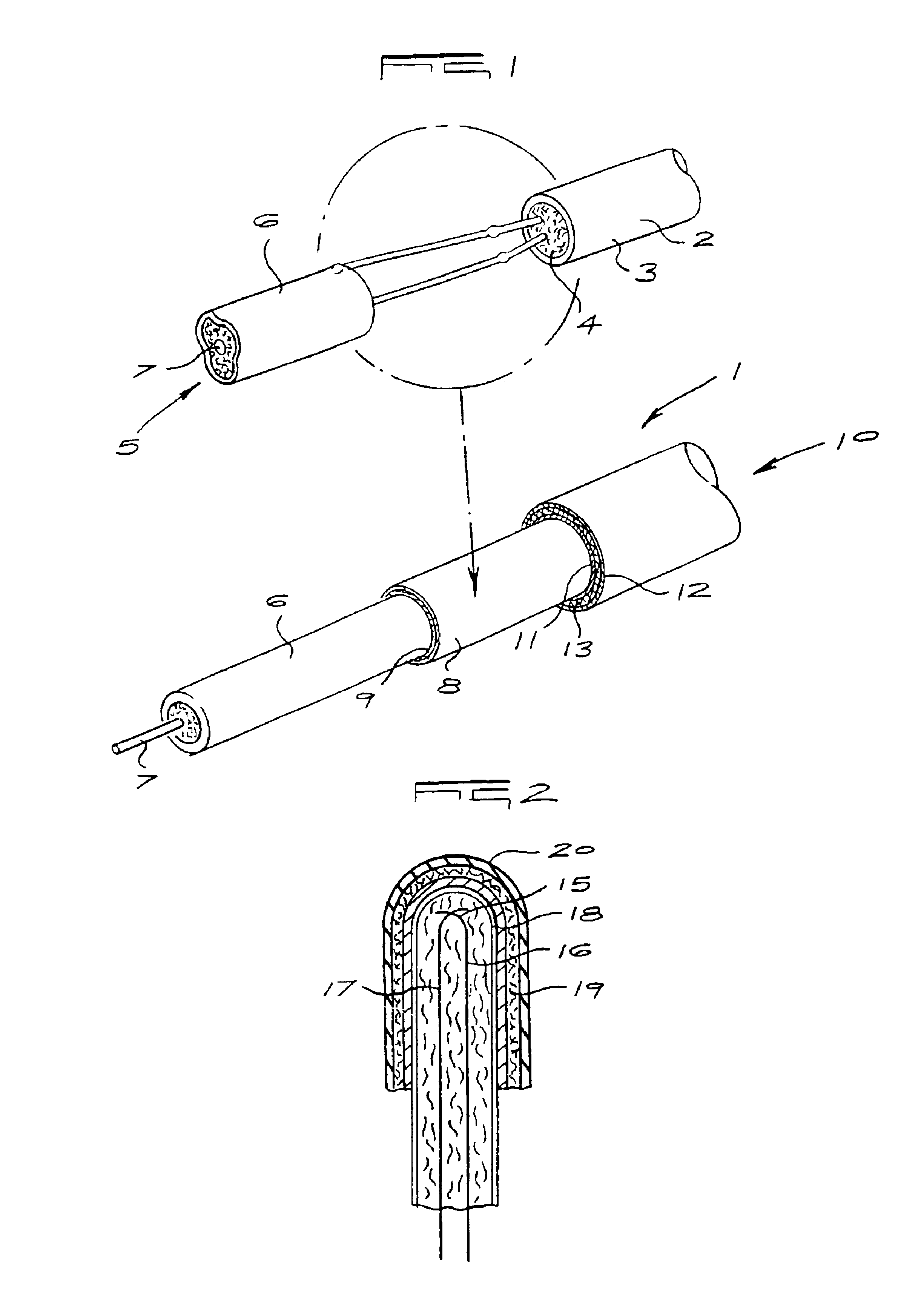

Metallurgical thermocouple

InactiveUS6830374B1Good value for moneyCost effectivenessThermometer detailsThermometers using electric/magnetic elementsRefractoryThermocouple

This invention concerns a thermocouple which is protected by an outer sheath comprising inner and outer tubes with the annular space filled with low temperature sintering refractory material which is preferably beaded before filling in the space and in which the outer tube is constricted to compact the material. The refractory material will include borosilicate and boric acid powder.

Owner:TEMPERATURE MANAGEMENT SYST

Tea tree hardwood cutting seedling nutrient solution and preparation method thereof

InactiveCN102992848AImprove survival rateHigh transplant survival rateFertilizer mixturesPhosphateManganese

The invention belongs to the technical field of tea tree cultivation, and particularly relates to a tea tree hardwood cutting seedling nutrient solution formula and a preparation method thereof. The nutrient solution of the invention comprises 460-480 mg / L of N, 60-65 mg / L of P, 85-90 mg / L of K, 29-30 mg / L of Ca, 10-11 mg / L of Mg, 0.041-0.045 mg / L of Zn, 0.110-0.113 mg / L of F, 0.04-0.05 mg / L of Cu, 0.11-0.12 mg / L of Mn, and 0.11-0.12 mg / L of Be. The preparation method of the nutrient solution comprises the following steps: weighing 10 g of urea, 3 g of potassium dihydrogen phosphate, 1 g of calcium sulfate, 0.5 g of magnesium sulfate, 0.01 g of zinc sulfate, 0.03 g of ferric sulfate, 0.01 g of copper sulphate, 0.03 g of manganese sulfate, and 0.02 g of boric acid powder, adding water and dissolving to 10 L, preparing 1 L of 100-time mother liquor, taking out 10 mL from the mother liquor as needed, diluting into 1 L for use. The nutrient solution of the invention can promote growth of tea tree hardwood cutting seedlings; robust and qualified tea seedlings can be cultivated at the same year; the tea seedling survival rate from nursery is improved; the tea seedling transplanting survival rate is increased; the tea tree improved variety propagation coefficient is increased; and the invention plays an active role in the promotion of tea tree improved variety systems.

Owner:JINLING INST OF TECH

Nutrient solution for heliophilous flowers and plants

The invention relates to nutrient solution for heliophilous flowers and plants, which is prepared by dissolving 3 to 7 grams of urea, 2 to 5 grams of monopotassium phosphate, 0.5 to 1.5 grams of calcium sulfate, 0.3 to 0.7 gram of magnesium sulfate, 0.001 gram of zinc sulfate, 0.003 gram of ferric sulfate, 0.001 gram of copper sulfate, 0.003 gram of manganese sulfate, 0.002 gram of boric acid powder and 10 kilograms of water. The nutrient solution is applied to the heliophilous flowers and plants, facilitates the growth of roots, complements nutrient elements required by the flowers and plants, improves survival rate, makes flower leaves lush and dark green, facilitates the flower bud differentiation of the flowers and plants, endows the flowers and plants with a plurality of large flowers with attractive appearances and bright colors, and improves the drought resistance, flood resistance and cold resistance of the flowers and plants.

Owner:王国刚

Antibacterial and hygroscopic plus material for socks

ActiveCN107869004AGood hygroscopicityComfortable and healthy to useWeft knittingBiochemical fibre treatmentPolyesterCotton fibre

The invention relates to the technical field of plus materials for socks, and particularly relates to an antibacterial and hygroscopic plus material for socks. The antibacterial and hygroscopic plus material is formed by blending an antibacterial modified polyester fiber, a cotton fiber, a modal fiber, an apocynum venetum fiber, a bamboo fiber and a viscose fiber, wherein the cotton fiber is driedfor use after being soaked through antibacterial feed liquid. A bamboo charcoal particle, nano titanium oxide, magnetite powder, lignin powder, boric acid powder, benzalkonium chloride powder and diatomite powder are added into the antibacterial modified polyester fiber. The plus material for the socks, which is provided by the invention, is used for inhibiting a bacterium and is good in hygroscopic property and conformable and healthy to use through the joint action of the antibacterial modified polyester fiber, the modal fiber, the viscose fiber, the apocynum venetum fiber, the bamboo fiberand the cotton fiber which is coated with the antibacterial feed liquid.

Owner:HUZHOU KEBO INFORMATION TECH CO LTD

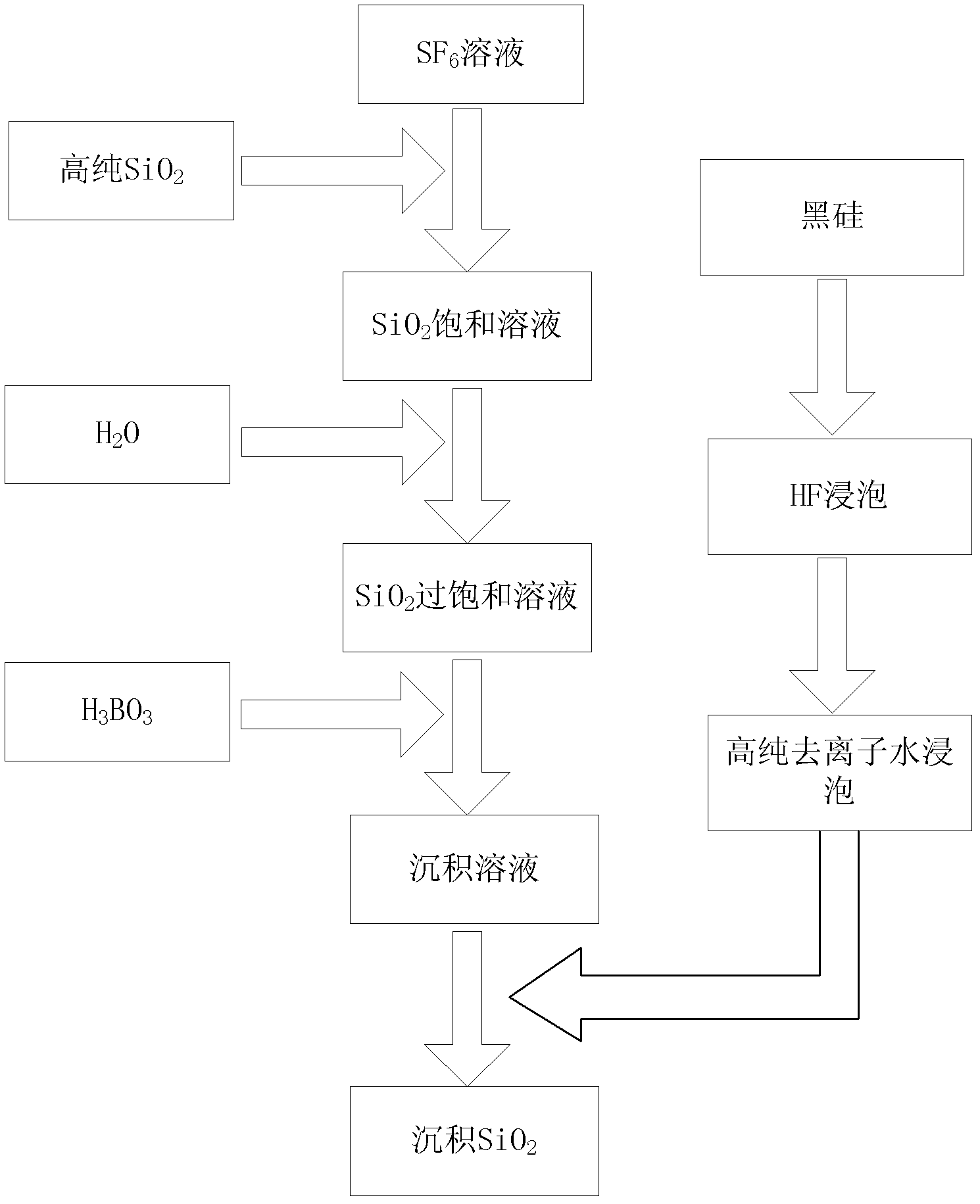

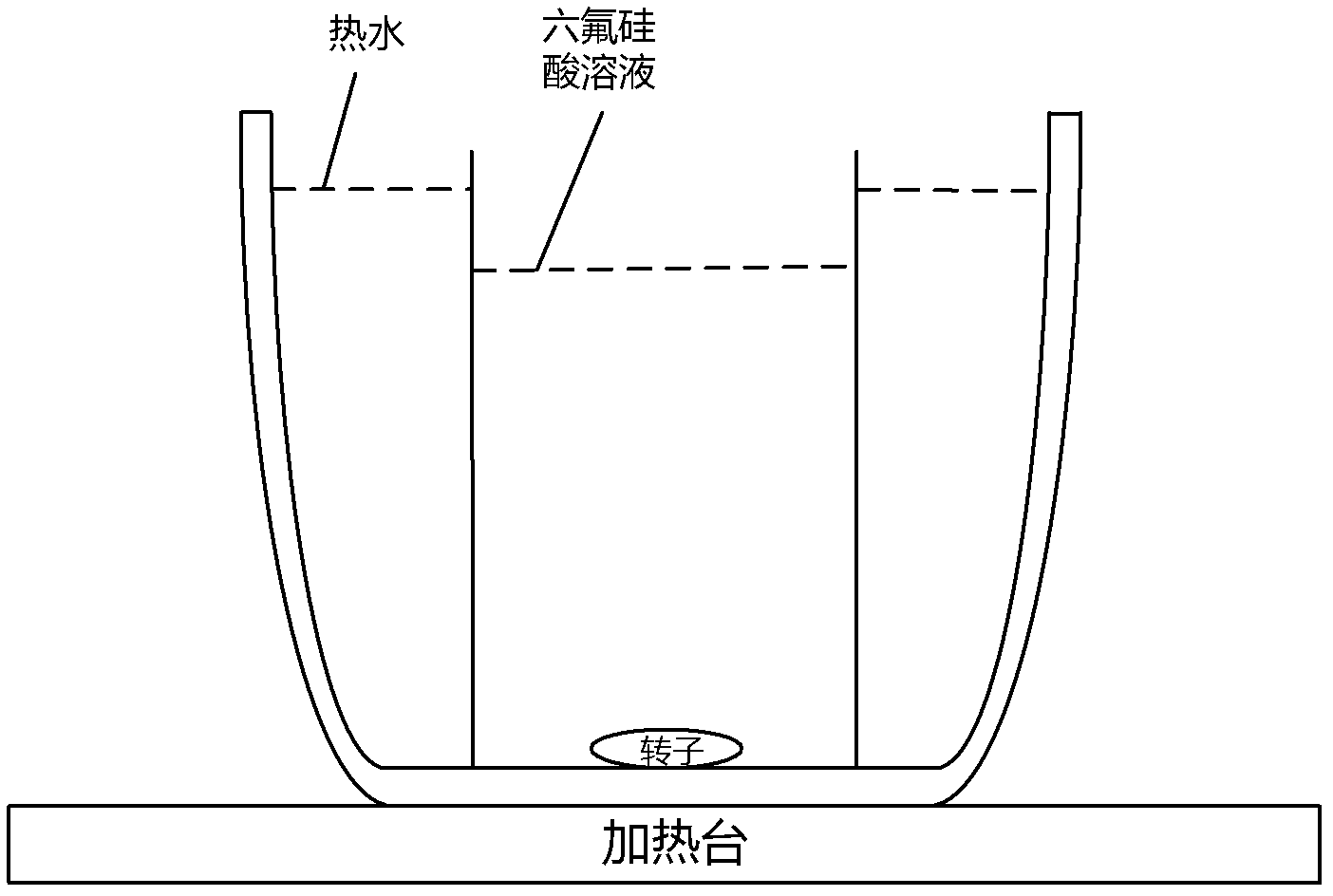

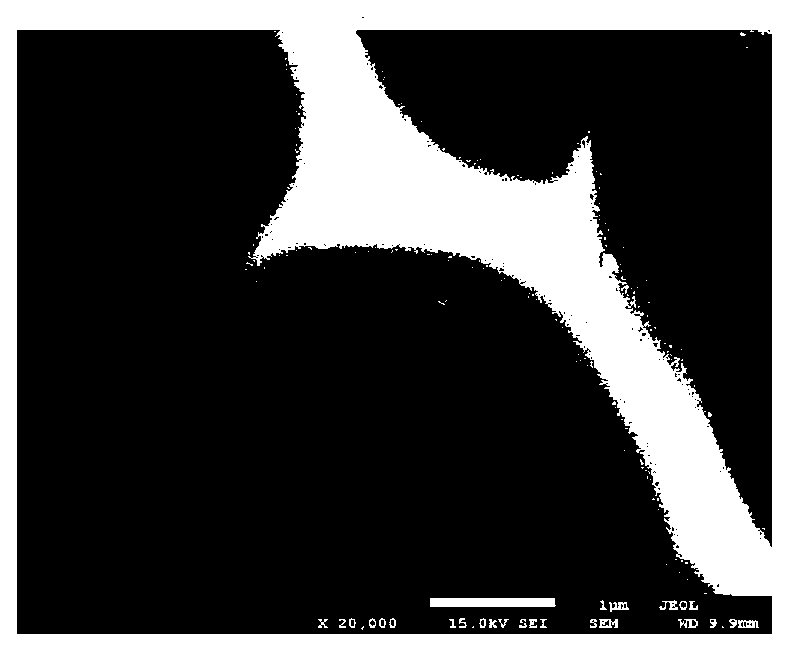

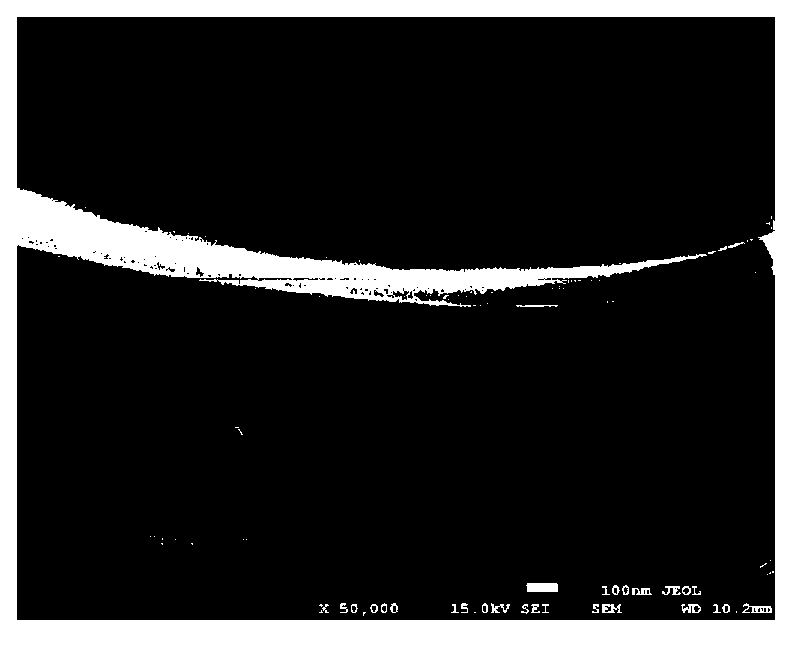

Passivation method for surface of black silicon solar cell

InactiveCN102437236AImprove life expectancyIncrease the open circuit voltageFinal product manufactureSemiconductor devicesDangling bondSilicon dioxide

The invention discloses a passivation method for the surface of a black silicon solar cell, belonging to the technical field of manufacturing of crystalline silicon solar cells. The method comprises the steps of: adding silicon dioxide powder, deionized water and boric acid powder into a hexafluosilicic acid solution respectively to prepare a silicon dioxide precipitated solution; and immersing diffused black silicon wafers into the silicon dioxide precipitation solution, and depositing and generating a layer of silicon dioxide film on the surface of the surfaces of the black silicon wafers. According to the invention, by using a liquid phase silicon dioxide deposition method, a layer of uniform and high-quality silicon dioxide film is plated on the surfaces of the black silicon wafers, so that dangling bonds on the surfaces of black silicon are better passivated, the minority carrier life of the black silicon solar cell is effectively prolonged, the open-circuit voltage of the black silicon solar cell is effectively improved, and the photoelectric conversion efficiency of the black silicon solar cell is increased.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

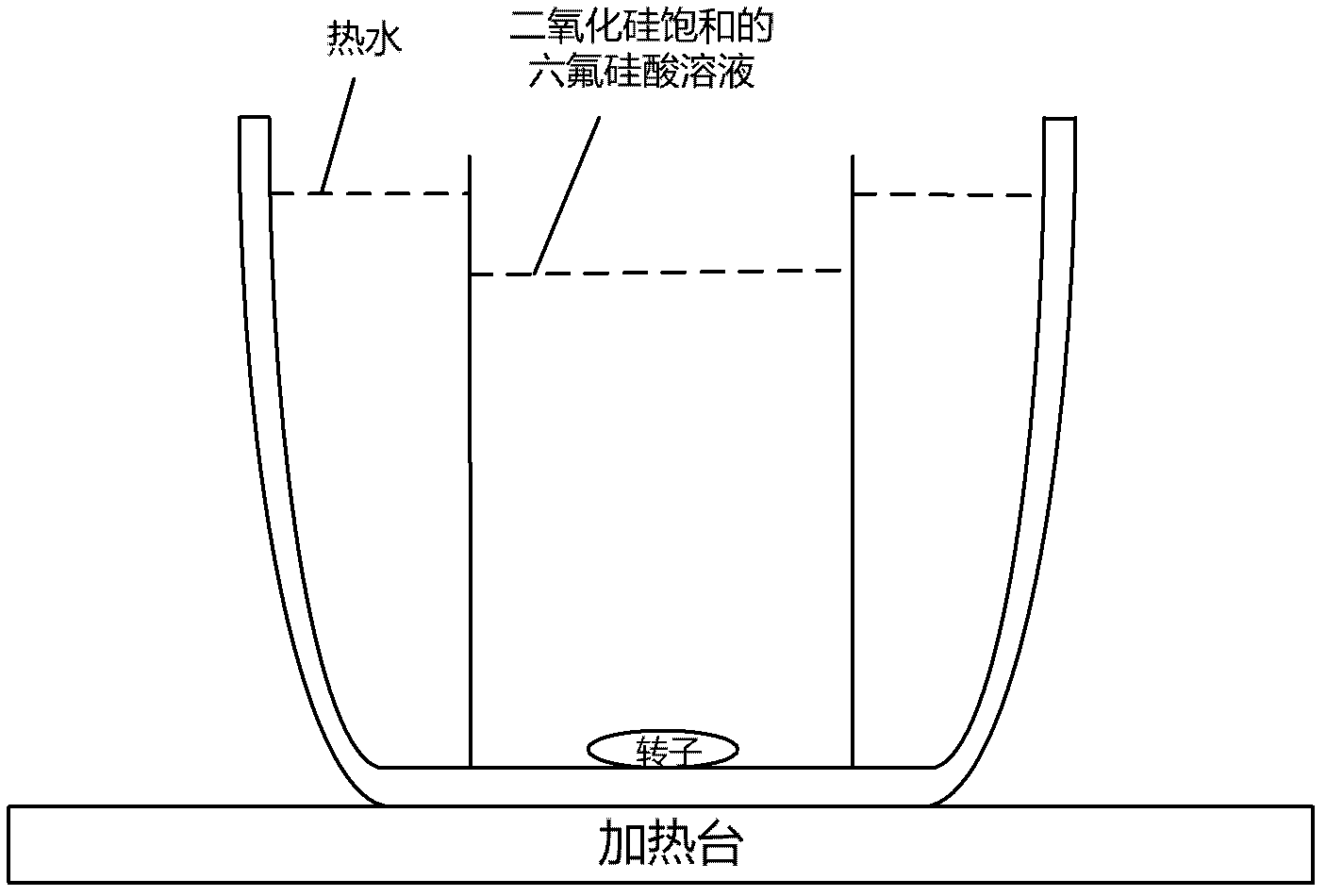

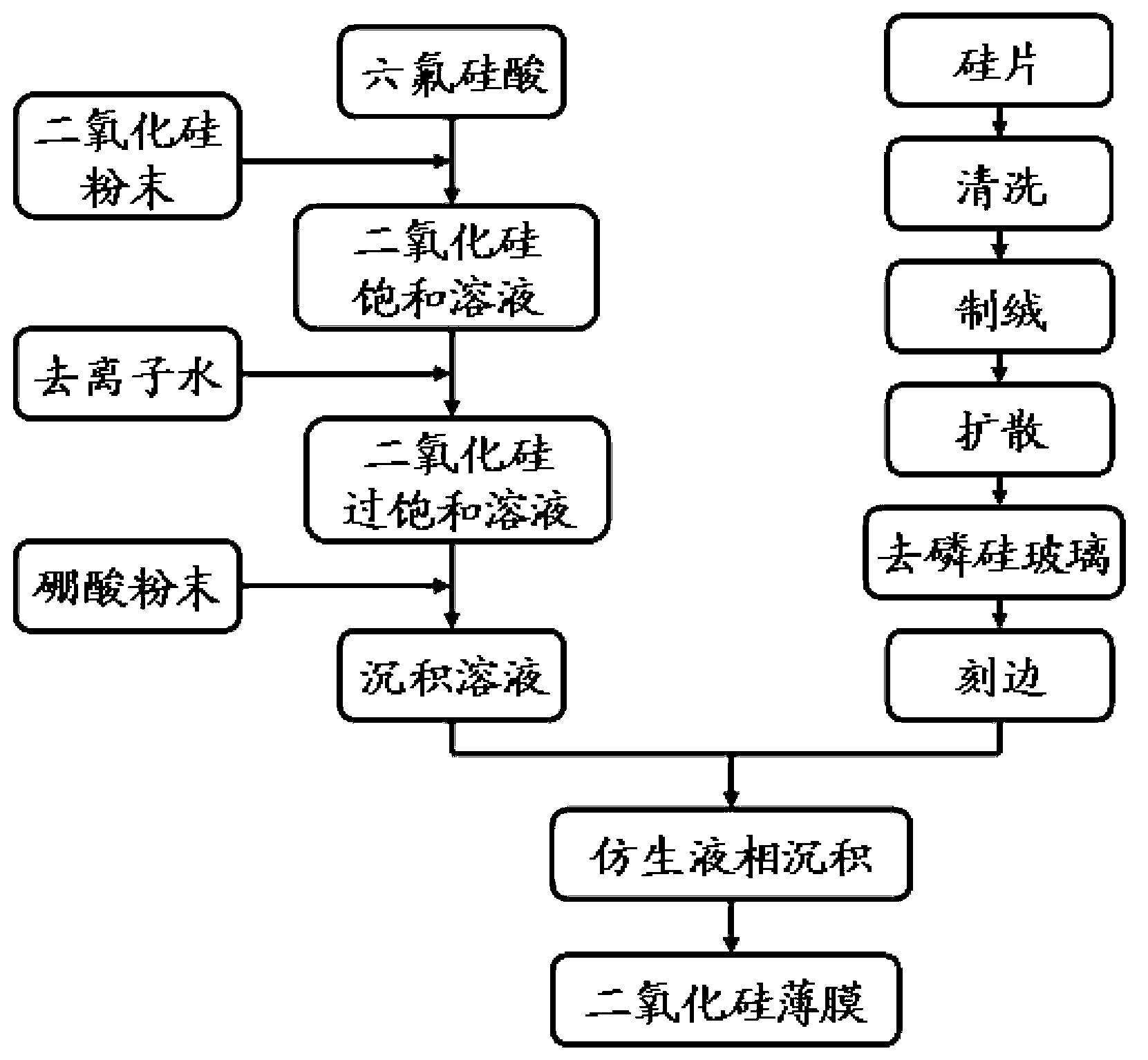

Biomimetic preparation method for passivation layer on surface of crystalline silicon solar cell

InactiveCN102800758AImprove life expectancyIncrease the open circuit voltageFinal product manufactureSemiconductor devicesSilicon solar cellHexafluorosilicic acid

Owner:夏洋

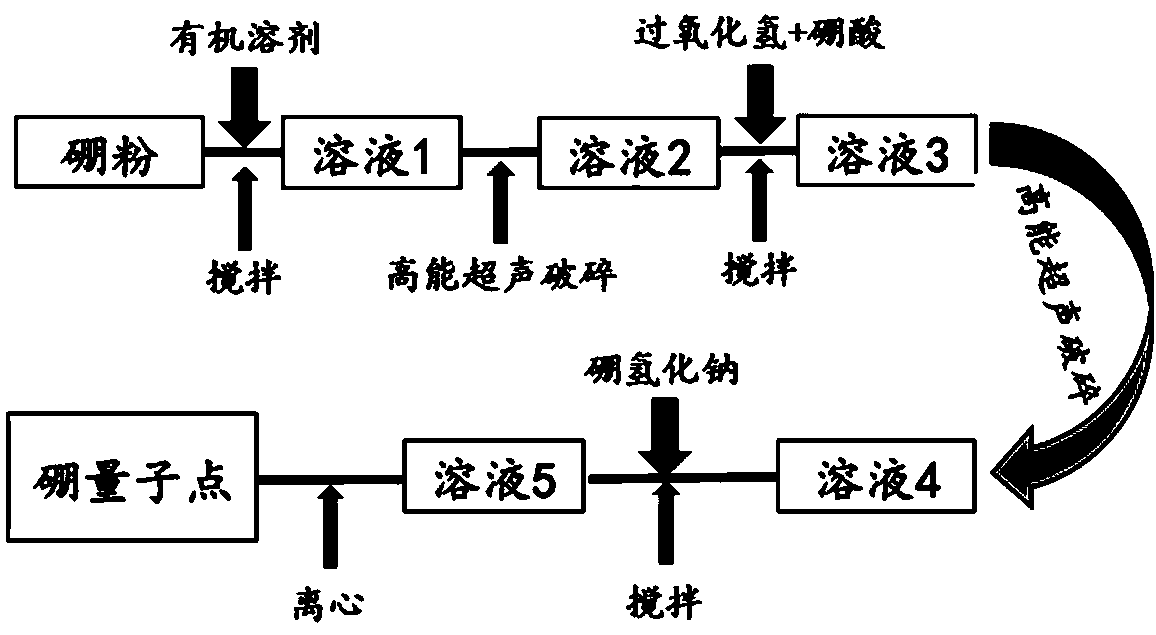

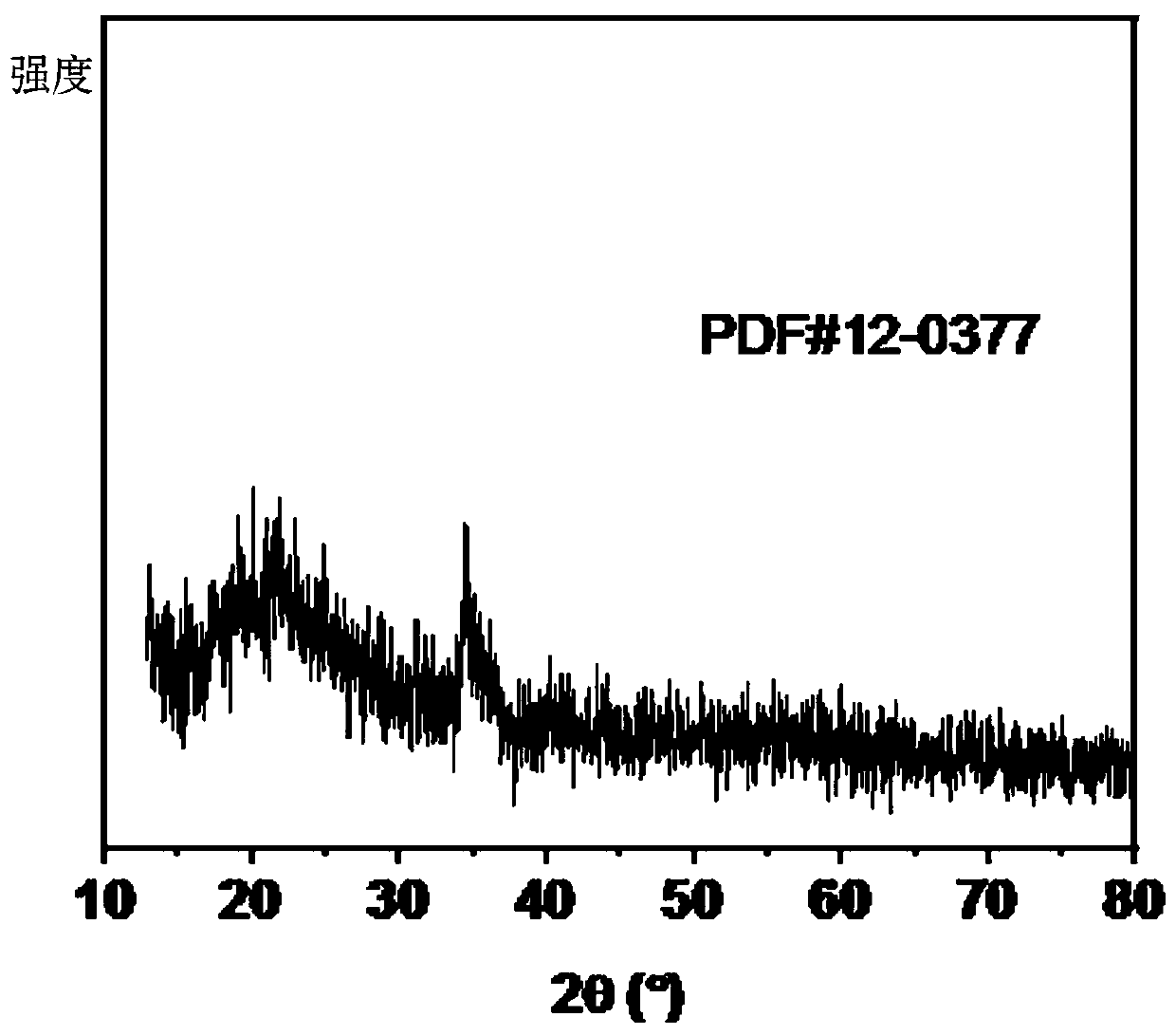

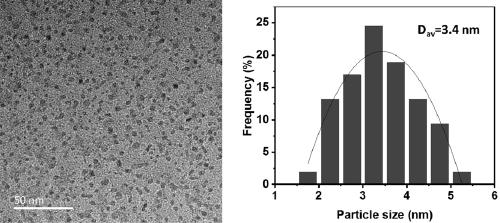

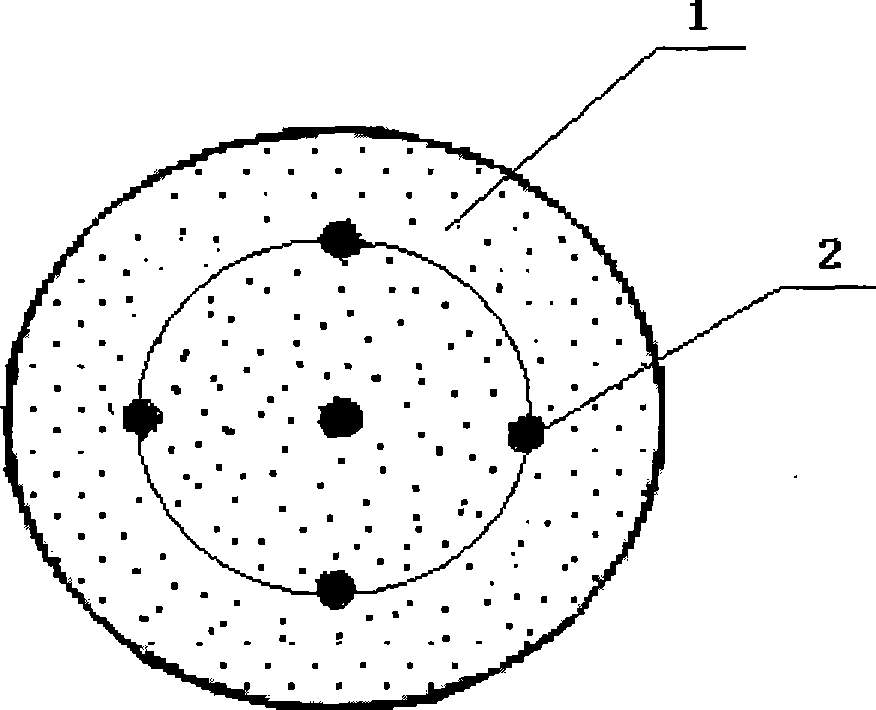

Preparation method and applications of boron quantum dots

The invention relates to a preparation method and applications of boron quantum dots, and belong to the technical field of preparation of quantum dots. The preparation method comprises: dispersing boron powder in an organic solvent, and stirring uniformly to obtain a mixed solution containing boron particles; adding a hydrogen peroxide solution and boric acid powder, and carrying out high-energy ultrasonic breaking to obtain a primary product solution; and adding sodium borohydride, and carrying out centrifugation to obtain the boron quantum dots. According to the present invention, the boronquantum dots are prepared by using the boron powder as the boron source for preparing fluorescent boron quantum dots and using the organic solvents isopropanol and tetrahydrofuran as the double-drivechemical etching agent through the high-energy ultrasonic breaking assisted liquid phase stripping method, have characteristics of uniform size and slight green fluorescence, can be used as a boron-containing drug for boron neutron capture therapy, and has large-scale production potential and broad commercial application prospects.

Owner:ZHONGBEI UNIV

Antimicrobial and moisture-absorbing bath towel fabric

ActiveCN108095617AInhibitionGood hygroscopicityElectroconductive/antistatic filament manufactureBiochemical fibre treatmentPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to the technical field of bath towel fabrics, and in particular to an antimicrobial and moisture-absorbing bath towel fabric. The bath towel fabric is formed by blending antimicrobial modified polyurethane fibers, polyethylene terephthalate fibers, cotton fibers, apocynum venetum fibers and bamboo fibers, wherein the cotton fibers become available as being soaked in antimicrobial material liquid and dried; and the antimicrobial modified polyurethane fibers are added with nano bamboo charcoal particles, nano titanium oxide, magnetite powder, lignin powder, boric acid powder, benzalkonium chloride powder and diatomite powder. The bath towel fabric provided by the invention, through combined actions of the antimicrobial modified polyurethane fibers, the apocynum venetumfibers, the bamboo fibers and the cotton fibers coated with the antimicrobial material liquid, can inhibit the generation of bacteria, and moreover, the bath towel fabric is good in moisture-absorbingperformance and is comfortable and healthy to use.

Owner:HUZHOU KEBO INFORMATION TECH CO LTD

X-ray fluorescence spectrum trace sample preparation and sample preparing method thereof

InactiveCN101413854AReduce usageHigh measurement intensityMaterial analysis using wave/particle radiationPreparing sample for investigationSoft x rayX-ray

The invention discloses an X ray fluorescence spectrum micro sample preparation and a preparation method thereof, which comprises the following steps: boric acid powder is punched, formed in a standard mold, and made into boric acid tablets; and then the diameter and the depth of the holes of samples are determined according to the number of the samples to be tested and the quantity of each kind of detected samples; a drilling device which has the equal diameter with the holes of the samples is selected; a plurality of sample wells which are uniformly distributed or symmetrical, or unevenly distributed or unsymmetrical are bored on the boric acid tablets along the circle less than the excircle diameter of the boric acid tables and the bottoms of the sample wells are impervious; then each kind of different samples to be tested are loaded into the corresponding sample wells, compressed and planished; finally, the sample preparation is put on the X ray fluorescence spectrometer for detecting and analyzing. The invention can detect and analyze micro samples, has the advantages of large measuring strength, high sensitivity, simultaneously continuous analysis on a plurality of samples, saving usage amount of boric acid, simple operation, high detection efficiency, etc.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Flower nutrient solution and preparation method thereof

The invention provides a flower nutrient solution and a preparation method thereof. The flower nutrient solution mainly comprises the following ingredients: urea, monopotassium phosphate, calcium sulfate, magnesium sulfate, zinc sulfate, ferric sulfate, copper sulfate, manganese sulfate and boric acid powder. The flower nutrient solution has moderate pH value and comprehensive and balanced nutrients, is nontoxic, odorless and harmless to the people, and can meet the nutrient requirements of each growth period of the flowers in a year so that the leaves of the flowers are deep green, the flowers are big and have beautiful colors, the fruits are big and shiny, the crowns are full and the flowers are disease-resistant and insecticidal.

Owner:张家港市塘桥果艺园

Aluminium borate composite porous ceramics and its preparation method

The invention relates to an aluminium borate composite porous ceramic and method for preparation, which comprises mixing aggregate with mixed powder by the weight ratio of 20-90 / 10-80, charging 1-6 wt% anchoring agent, mixing and forming, drying 20-30 hours at 90-120 deg. C, elevating temperature to 200-500 deg. C then thermally insulating 20-280 minutes, then elevating temperature to 700-1700 deg. C then thermally insulating 30-600 minutes, naturally cooling, wherein the process for preparing the mixed powder comprises, mixing fines containing aluminium compounds with boracic acid powder, thus obtaining AlxByOz, wherein x=16-22, y=2-5, z=30-36. The fines comprise Al2O3, Al2O3.3H2O and Al2O3.H2O by the proportion of 0-70 wt%, 0-80 wt% and 0-70 wt%.

Owner:WUHAN UNIV OF SCI & TECH

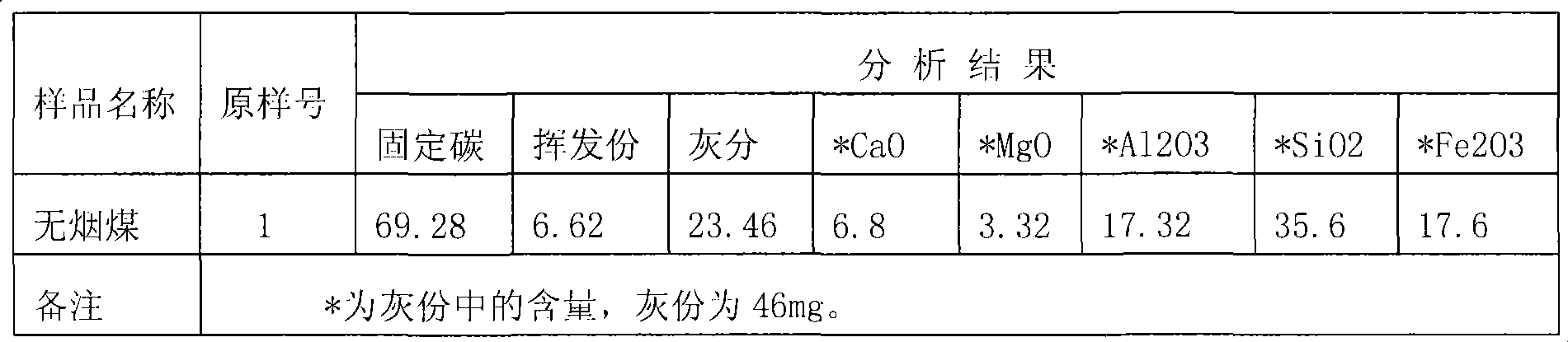

10B boron carbide and preparation method thereof

ActiveCN102115080AHigh neutron capture cross sectionCapture spectrum widthElectric arc furnaceCarbonization

The invention relates to the technical field of protection and control materials, and in particular relates to 10B boron carbide and a preparation method thereof. In the 10B boron carbide, the content of B4C is 97wt%, the content of B2O3 is 0.3wt%, the content of free boron is 1.3wt%, and 10B abundance is 25-99% (at.). The preparation method comprises the following steps: mixing 75-85 parts of boric acid powder with 25-99% (at.) of 10B abundance and 25-35 parts of high-purity graphite powder; pressing the mixed material into tablet particles with the diameter of 20mm and thickness of 10mm; respectively carrying out sectional roasting and dehydrating on the tablet particles at the temperature of 100-200 DEG C and 500-700 DEG C; and putting the roasted tablet particles in an induction heating furnace, or a graphite heating furnace or an arc furnace for carbonization at the carbonization temperature of 1855-2100 DEG C, thus the 10B boron carbide product meeting the quality requirement is obtained.

Owner:DALIAN BORONTEN SCI & TECH

Ointment composition for treating decubitus ulcers and methods for its making and its use

ActiveUS7655717B2Simple and inexpensive to manufactureEasy to useBiocideInorganic boron active ingredientsAdditive ingredientDimethyl siloxane

An ointment composition for treating decubitus ulcers and methods for its making and its use. The composition includes a skin protestant ointment, a rash cream, an antibiotic ointment, virgin olive oil, and boric acid powder. The skin protestant ointment includes active ingredients petroleum 53.4%, lanolin 15.5%, and inactive ingredients cod liver oil containing vitamin A & vitamin D, a fragrance, light mineral oil, microcrystalline wax, and paraffin. The rash cream includes active ingredients dimethicone 1% and zinc oxide 10%, and inactive ingredients aloe barbadensis extract, benzyl alcohol, coconut oil, cod liver oil containing vitamin A & vitamin D, a fragrance, glycerol oleate, light mineral oil, ozokerite, paraffin, propylene glycol, sorbitol, synthetic beeswax, and water. The antibiotic ointment includes active ingredients polymyxin B sulfate 5,000 units, bacitracin zinc 400 units, and neomycin base (as sulfate) 3.5 mg., and an inactive ingredient white petroleum.

Owner:GOULBOURNE MARY J

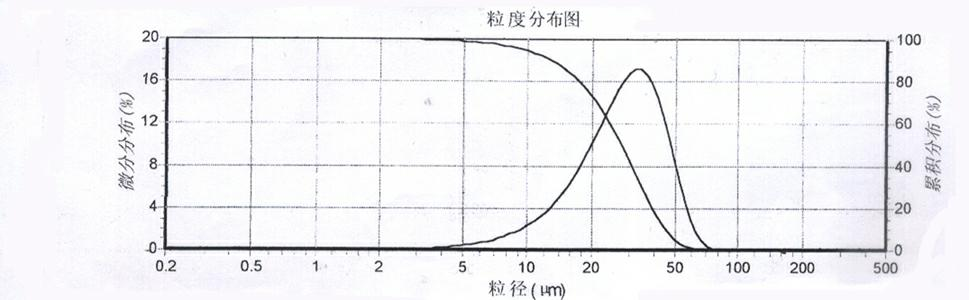

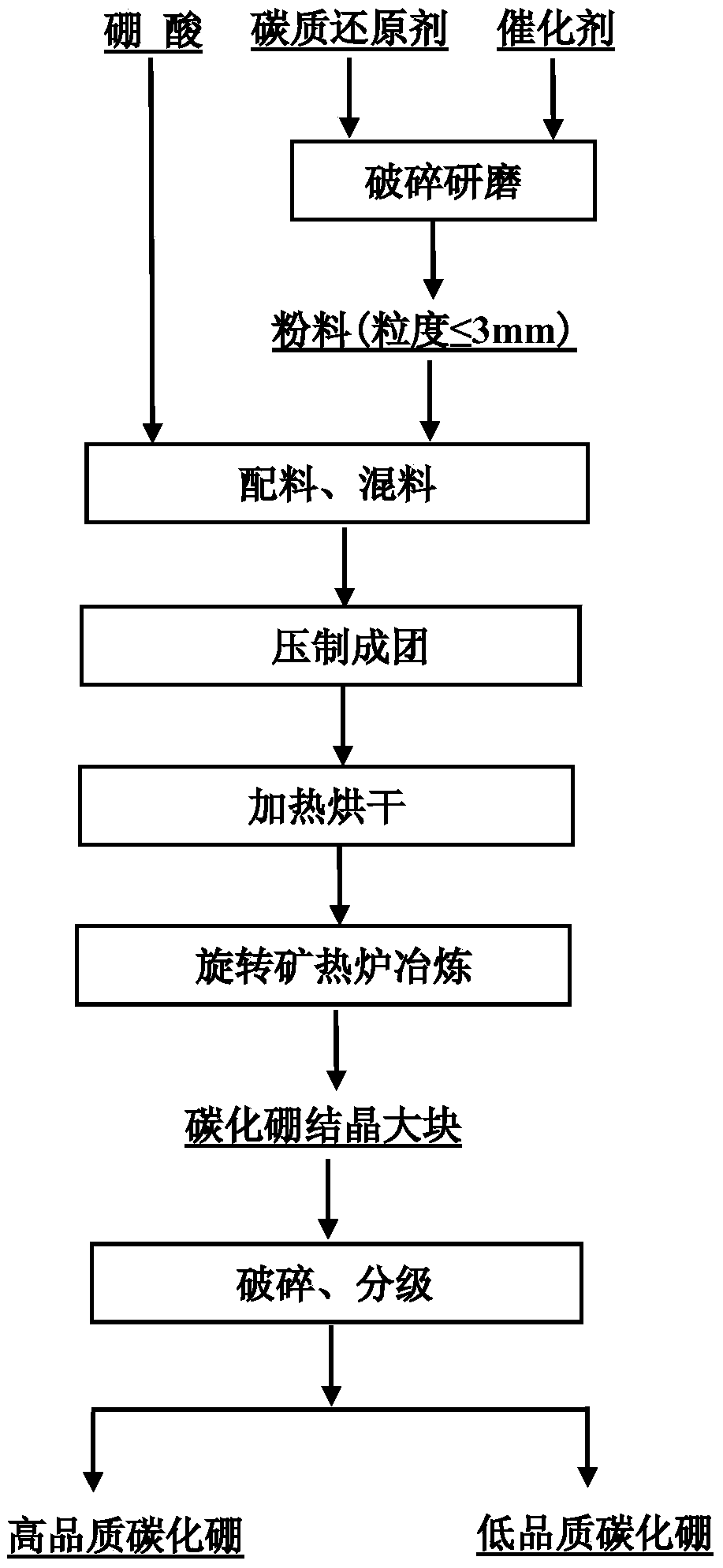

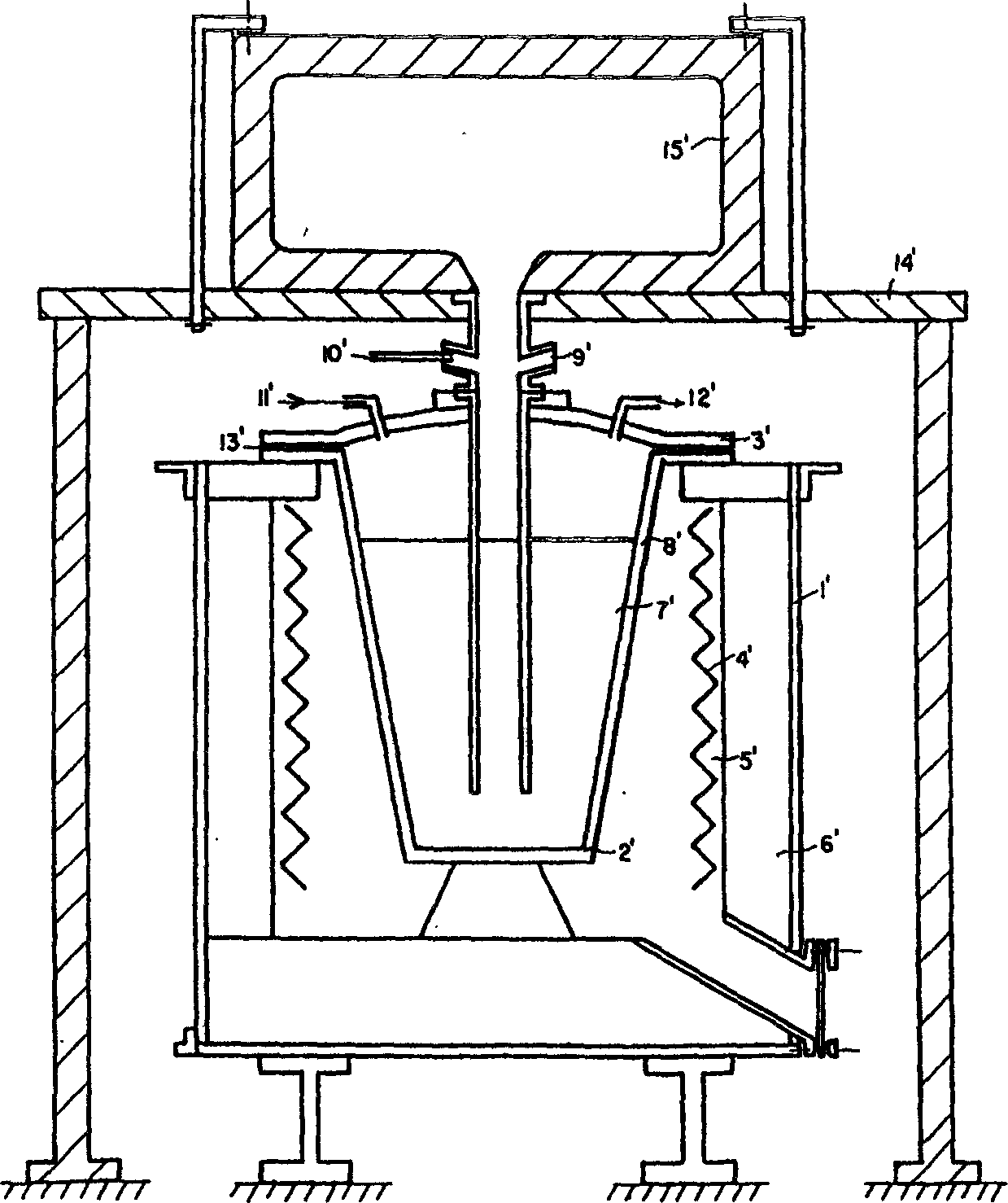

Method for smelting preparation of high-quality boron carbide crystals

ActiveCN105502404ALarge specific surface areaHigh reactivityChemical industryBoron carbideHigh pressure

The invention discloses a method for smelting preparation of high-quality boron carbide crystals to overcome the defects of the current boron carbide smelting technique and current products and meet the requirement of the sapphire industry for high-quality boron carbide. The method comprises the steps of breaking a carbonaceous reducing agent and a catalyst into powder independently; taking boric acid powder, carbonaceous reducing agent powder and catalyst powder according to the weight ratio, adding a proper amount of water for blending, conducting stirring, and then pressing the mixture on a high-pressure ball presser into lumps; drying the pressed lumps, and placing the dried lumps in a submerged arc furnace to be smelted, so that large boron carbide crystals are prepared; breaking the large boron carbide crystals into small pieces, and then conducting classification, so that the high-quality boron carbide crystals are obtained. The raw material utilization rate is high, production cost is low, energy is saved, the raw material volatilization rate is low, dust pollution is reduced greatly, the produced boron carbide has high purity, hardness and density, the high-quality boron carbide yield is high, and the requirement for sapphire grinding can be totally met.

Owner:NORTHEASTERN UNIV

Ceramic glaze with self-cleaning function

The invention relates to a ceramic glaze with a self-cleaning function. The ceramic glaze is prepared from melilite, white glass, boric acid powder, calcite, knar clay, glaze paste, green glass, tin crystal material, and copper barium silicate. The ceramic glaze with the self-cleaning function is good in water resistance and weather resistance, can resist the bacteria continuously for a long time,can also decompose volatile organic matters, and is high in self-cleaning capacity; the ceramic glaze is suitable for sanitary ceramics of construction, can also be applied to the surface of a product such as concrete boards, plastic boards, gypsum boards, paint, plastics, textiles and the like, and is wide in application range and good in popularization value; and the ceramic glaze is simple inpreparation process, stable in performance and low in preparation cost.

Owner:NANNING SHENGRUN TECH

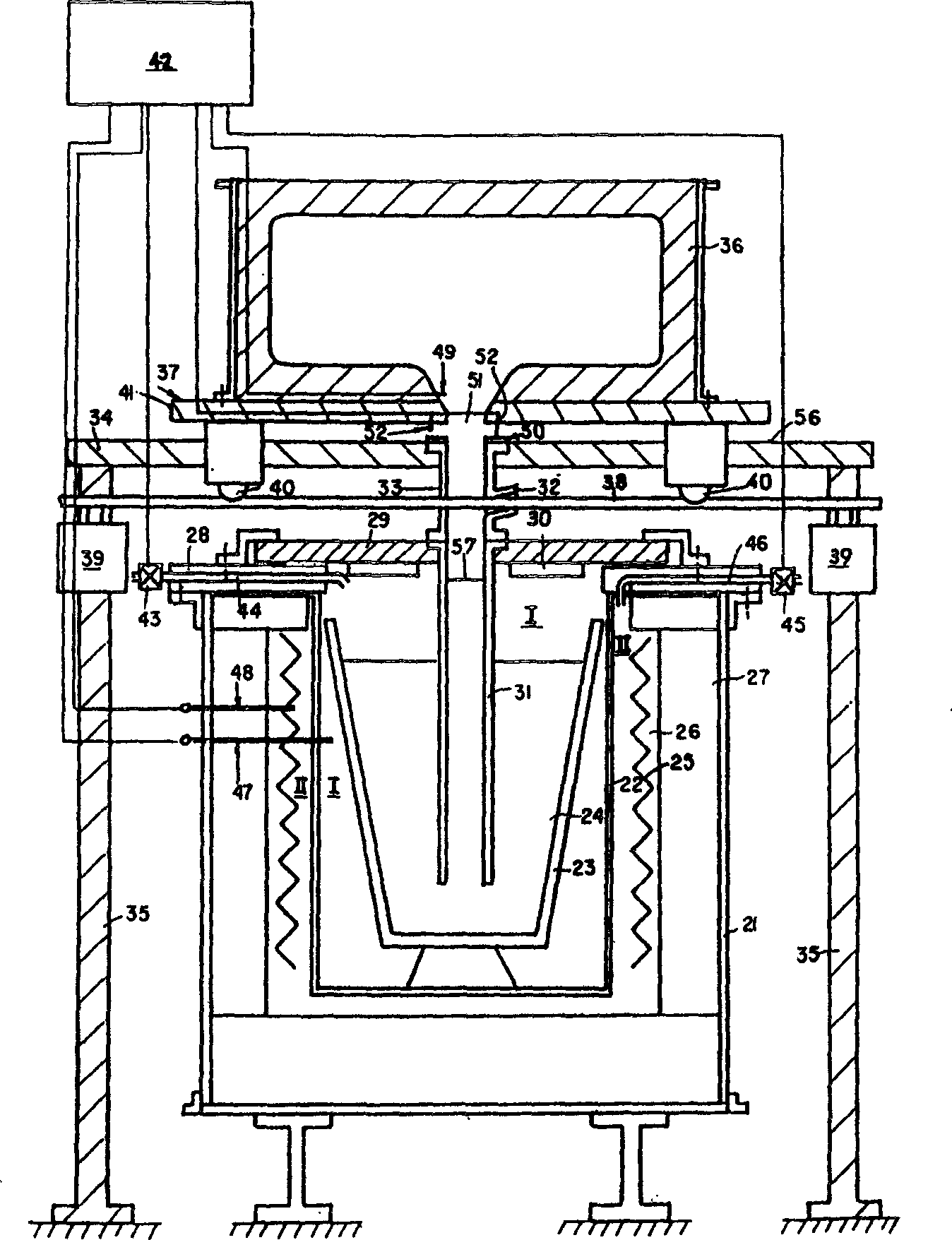

Magnesium alloy low-pressure casting method

The invention is the magnesium alloy low-pressure casting method, which is to put the protective gas creator on the cover of the crucible or in the crucible that is in the pressure tank of the casting machine. The protective gas creator comprises: the protective agent 1, 2 and 3; the protective 1 is composed of sulfur powder and boric acid powder or of the mixing of sulfur powder, boric acid and magnesium sands; the protective agent 2 comprises sulfur powder or pyrite and carbon powder; the protective agent 3 is sulfur powder or pyrite, or the mixture of sulfur powder, pyrite and boric acid. The side wall of the container filled with the protective agent 1 has gas outlet and in the crucible; the protective agents 1 and 2 are in the open containers and on the crucible cover. The invention ensures the safe operation of the low-pressure casting, improves the quality of magnesium alloy cast, lowers the cost and reduces the environmental pollution.

Owner:SHENYANG RES INST OF FOUNDRY

Lining type container used for precious metal crucible and preparation method thereof

Owner:象山惠丰机械模具有限公司

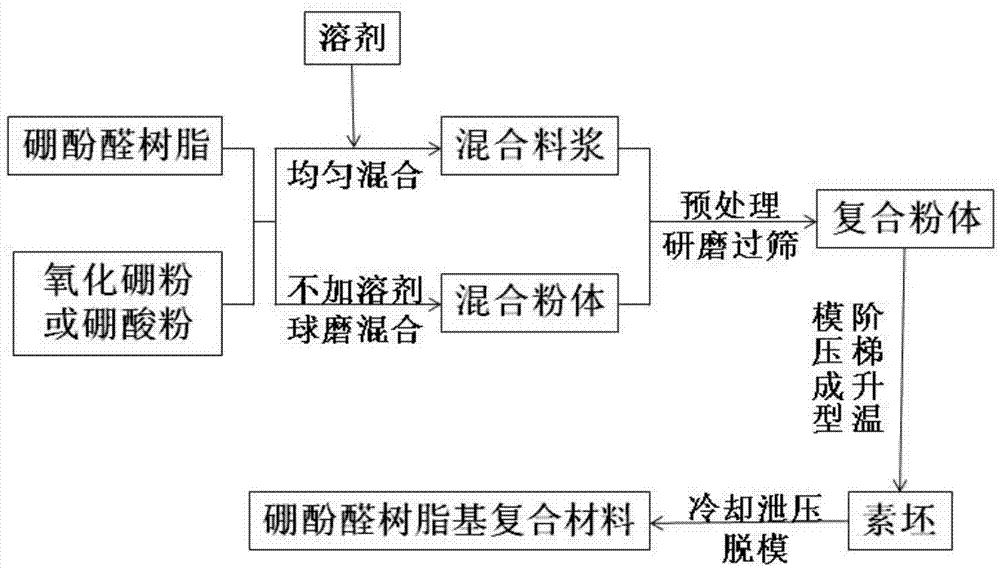

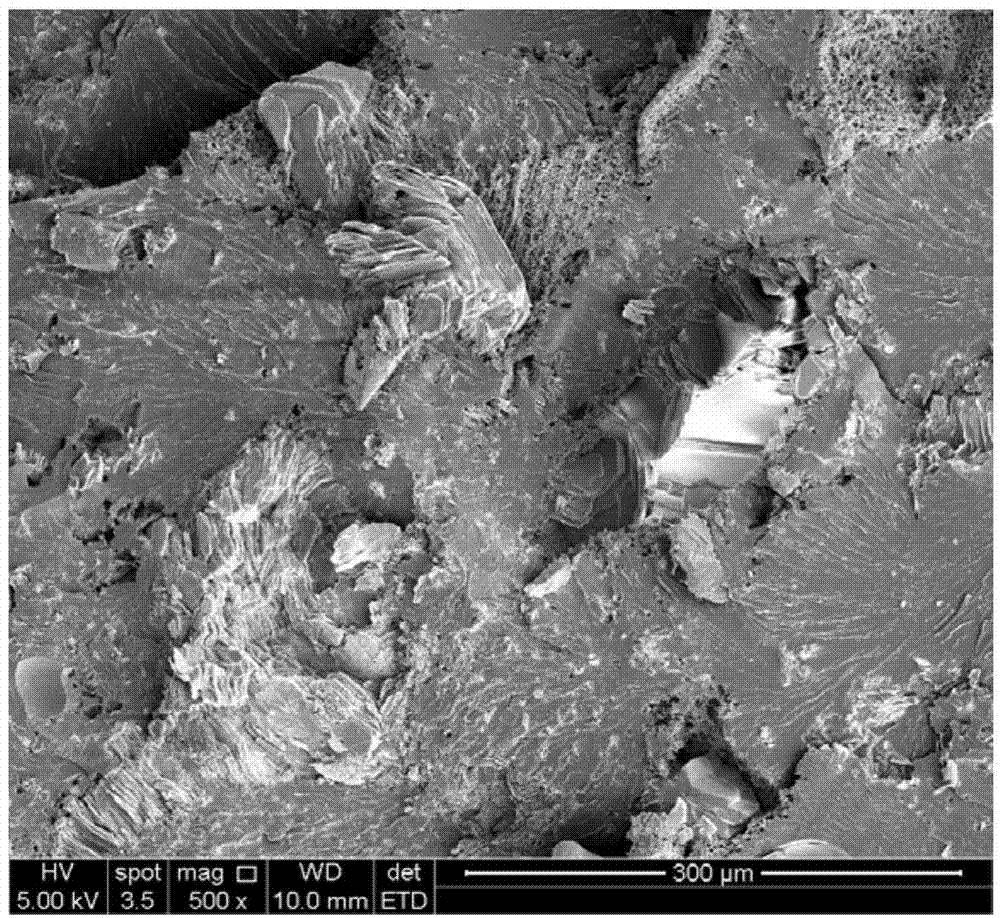

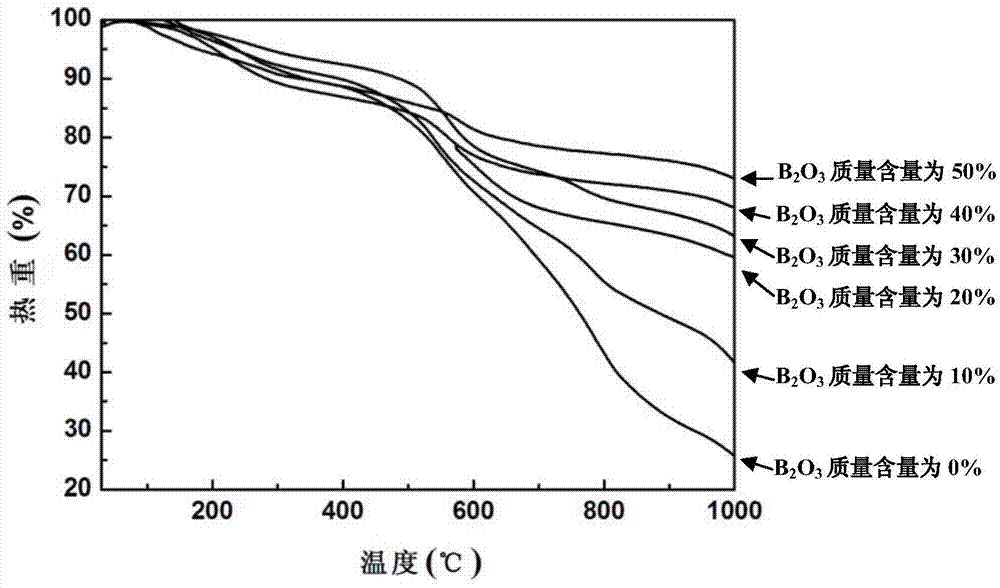

Method for improving ablation resistance of boron-containing phenolic resin-based composite material

The invention provides a method for improving ablation resistance of a boron-containing phenolic resin-based composite material. The method comprises the following steps of 1, breaking boron-containing phenolic resin, carrying out sieving, and mixing the boron-containing phenolic resin powder with boron oxide powder or boric acid powder by a solid phase method or a liquid phase method to obtain a uniform mixture according to a mass ratio of 1: 1 to 9: 1, wherein the solid phase method comprises ball milling mixing for 12-36h and the liquid phase method comprises dissolving the boron-containing phenolic resin in an organic solvent and carrying out stirring and mixing for 1-5h by a magnetic stirring device, 2, carrying out pre-treatment on the uniform mixed powder or slurry and carrying out grinding and sieving, and 3, molding the composite powder by a gradient heating molding technology, carrying out cooling in a furnace, and carrying out pressure-release demolding. Low-density and low-melting point boron oxide or boric acid powder is used as a filling material and the boron-containing phenolic resin-based composite material is prepared by physical blending hot mold pressing. The boron-containing phenolic resin-based composite material can keep a high heat retention rate, mechanical strength and size stability at a high temperature, has good heat protection performances and ablation resistance and can be used in the field of high-temperature thermal protection materials.

Owner:WUHAN UNIV OF TECH

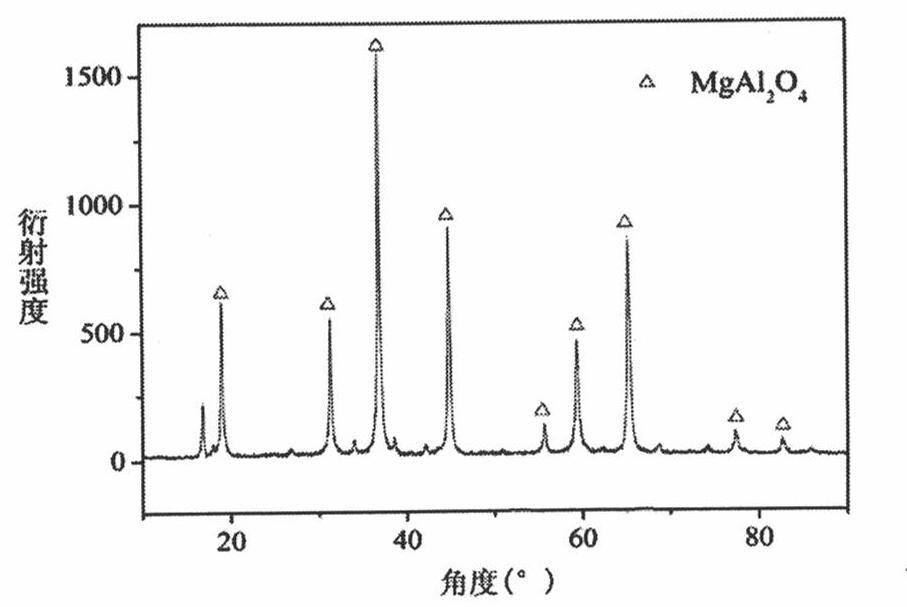

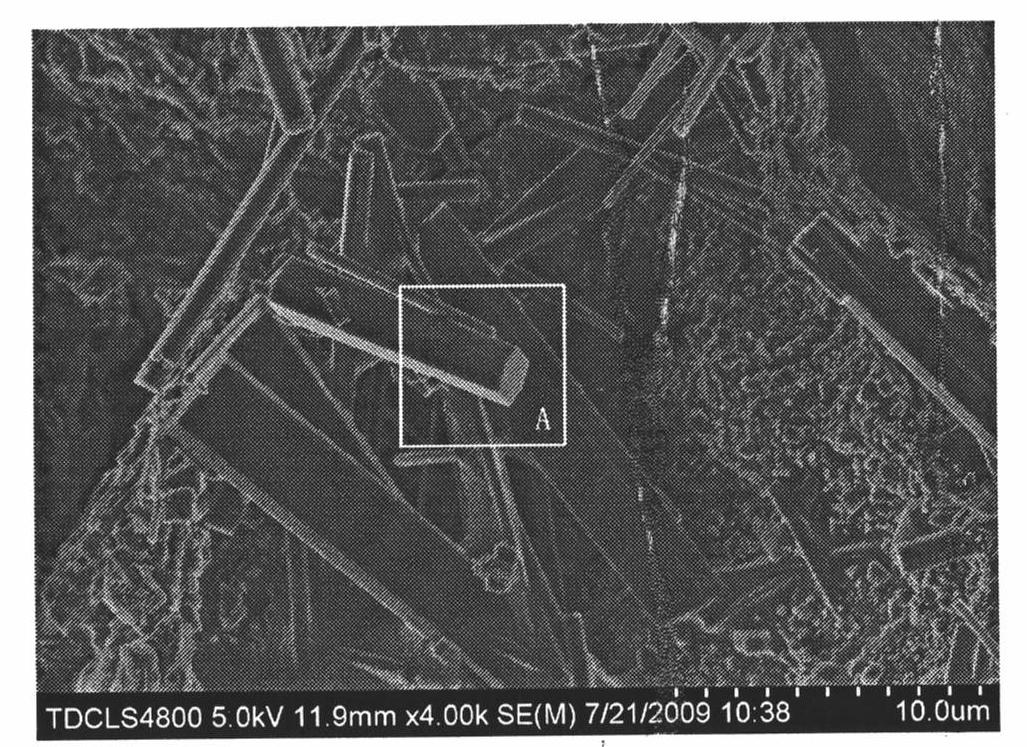

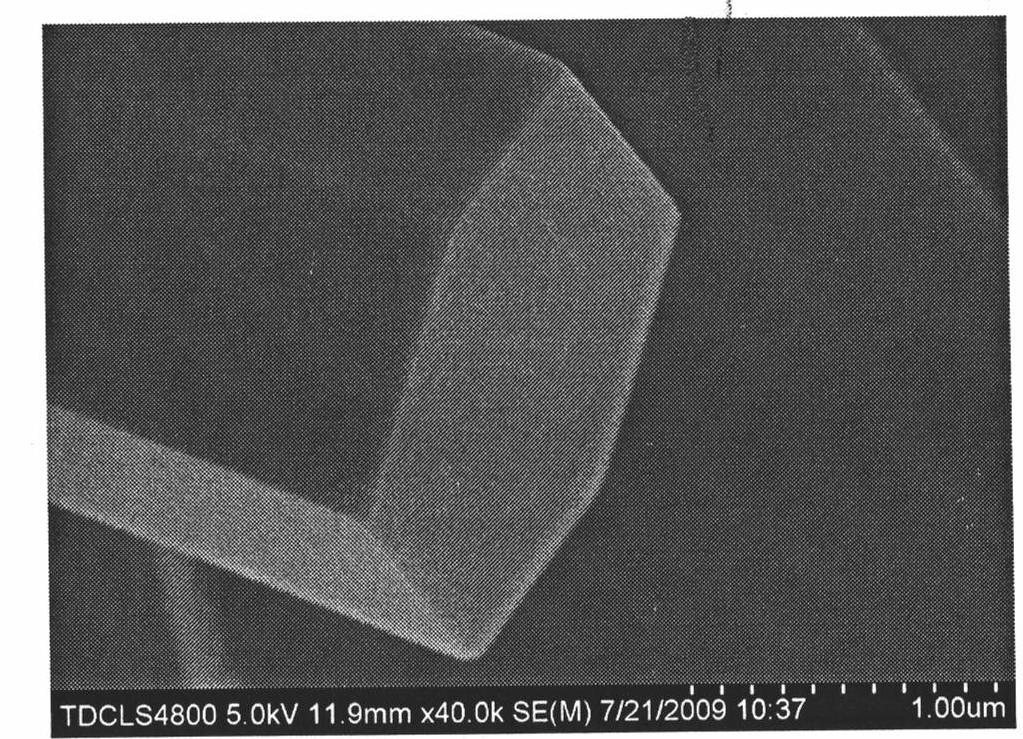

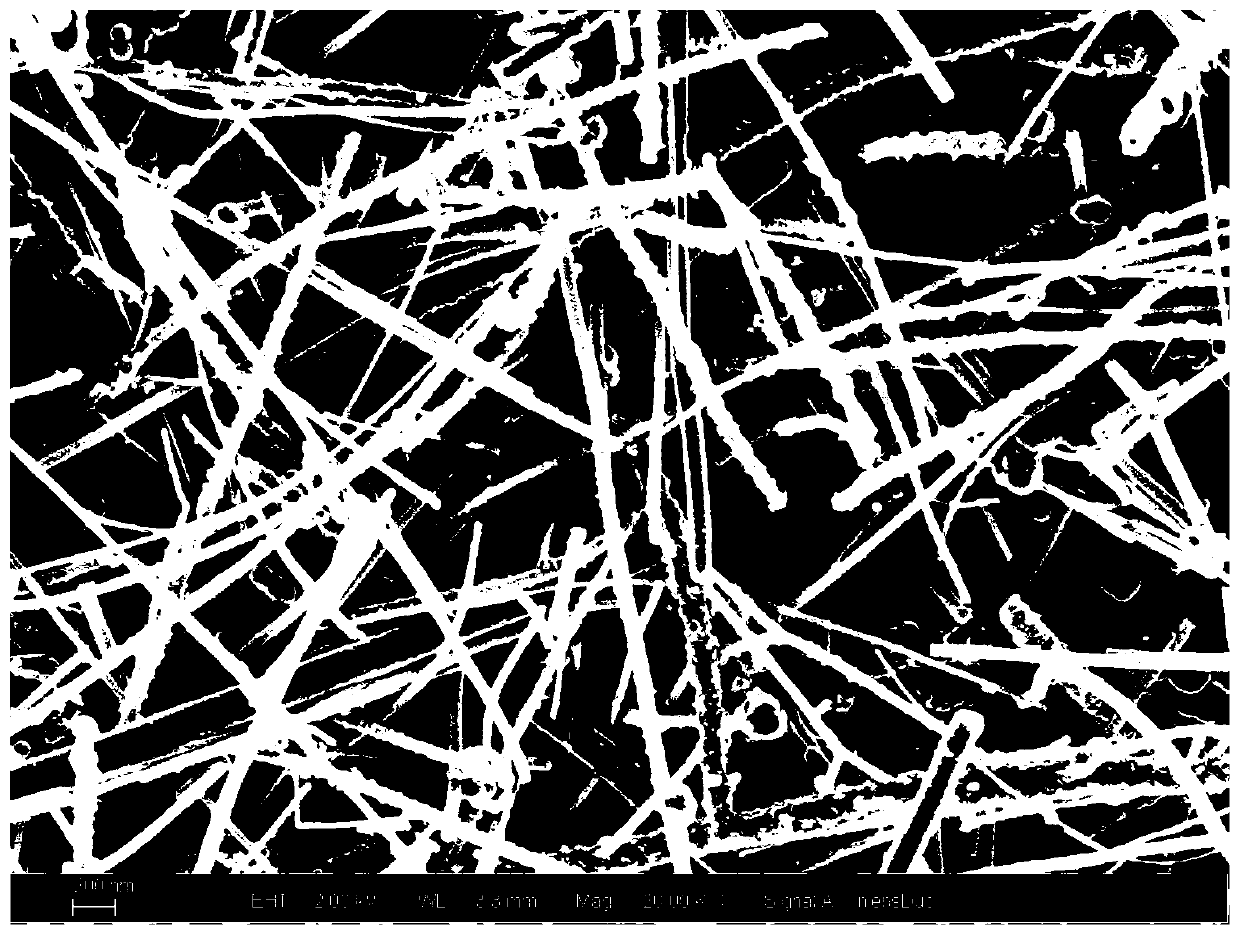

Method for preparing spinel whisker/aluminum composite block material by in-situ growth in aluminum matrix

The invention discloses a method for preparing a spinel whisker / aluminum composite block material by in-situ growth in an aluminum matrix. The process of the method comprises the following steps: mixing aluminum powder, magnesium powder and boric acid powder and adding to a stainless steel jar mill with zirconium oxide balls for ball milling pretreatment; after adding the aluminum powder to the ball milling prepared powder, mechanically mixing to prepare fully mixed powder, and adding the fully mixed powder to a mold for pressure molding under certain pressure; and putting the molded block into a quartz heating furnace, and calcining at constant temperature under argon shield to obtain the spinel whisker / aluminum composite block material. The method has simple process, the spinel whisker in the aluminum matrix simultaneously grows in situ in the block sintering process, the whisker and the matrix combine tightly, the production rate of the whisker is stable, the whisker is distributed evenly in the aluminum matrix, the hardness and wear resistance of the whisker / aluminum composite block material are obviously improved, and the whisker / aluminum composite block material has good over-all properties.

Owner:TIANJIN UNIV

Low-temperature lead-free glass powder for household appliance anti-impact ink, and preparation method thereof

PendingCN110092589AProcess environmental protectionNo pollution in the processGlass shaping apparatusChemical stabilityPotassium carbonate

The invention provides low-temperature lead-free glass powder for household appliance anti-impact ink, and a preparation method thereof, wherein the low-temperature lead-free glass powder is preparedfrom the following raw materials by mass: 15-30% of quartz powder, 40-60% of bismuth oxide powder, 10-25% of zinc oxide powder, 1.5-4.0% of sodium carbonate powder, 0.5-5% of potassium carbonate powder, 0.3-1.0% of alumina powder, 1.0-10% of boric acid powder, 1.0-5% of sodium fluoride powder, 1.0-5% of titanium oxide powder, 0.5-3% of lithium carbonate powder, and 1.0-5% of zirconia powder. According to the present invention, the glass powder does not contain lead, and meets the requirements of environmental protection and sustainable development; the preparation process is non-toxic, harmless and non-polluting; the raw materials of the formula are simple, and the wide softening temperature and the suitable expansion coefficient can be obtained while the glass softening temperature can bereduced; the product has excellent impact resistance and excellent cold-thermal shock resistance; and the obtained glass powder has good chemical stability, good blackness and good hiding power.

Owner:湖南衡义材料科技有限公司

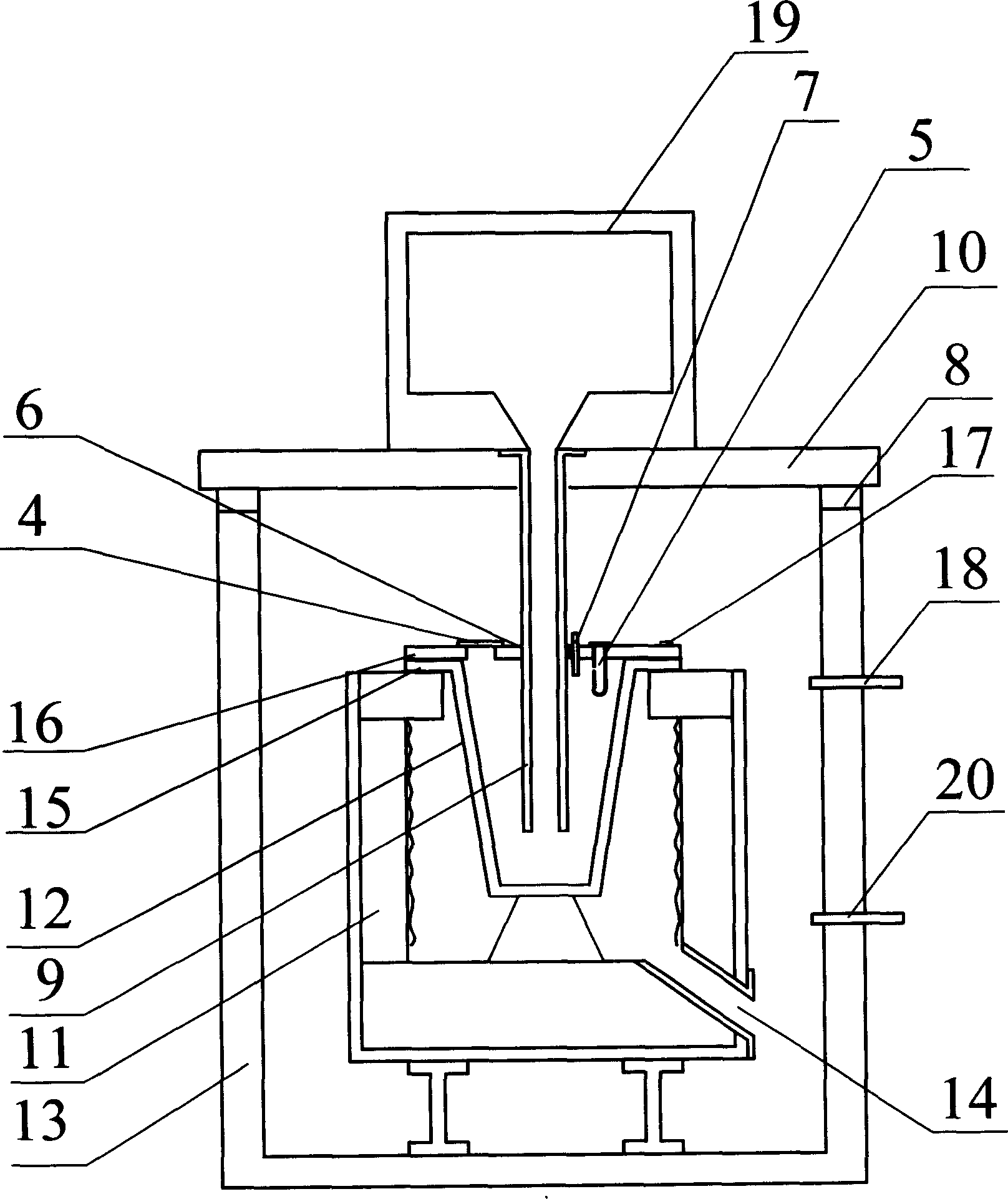

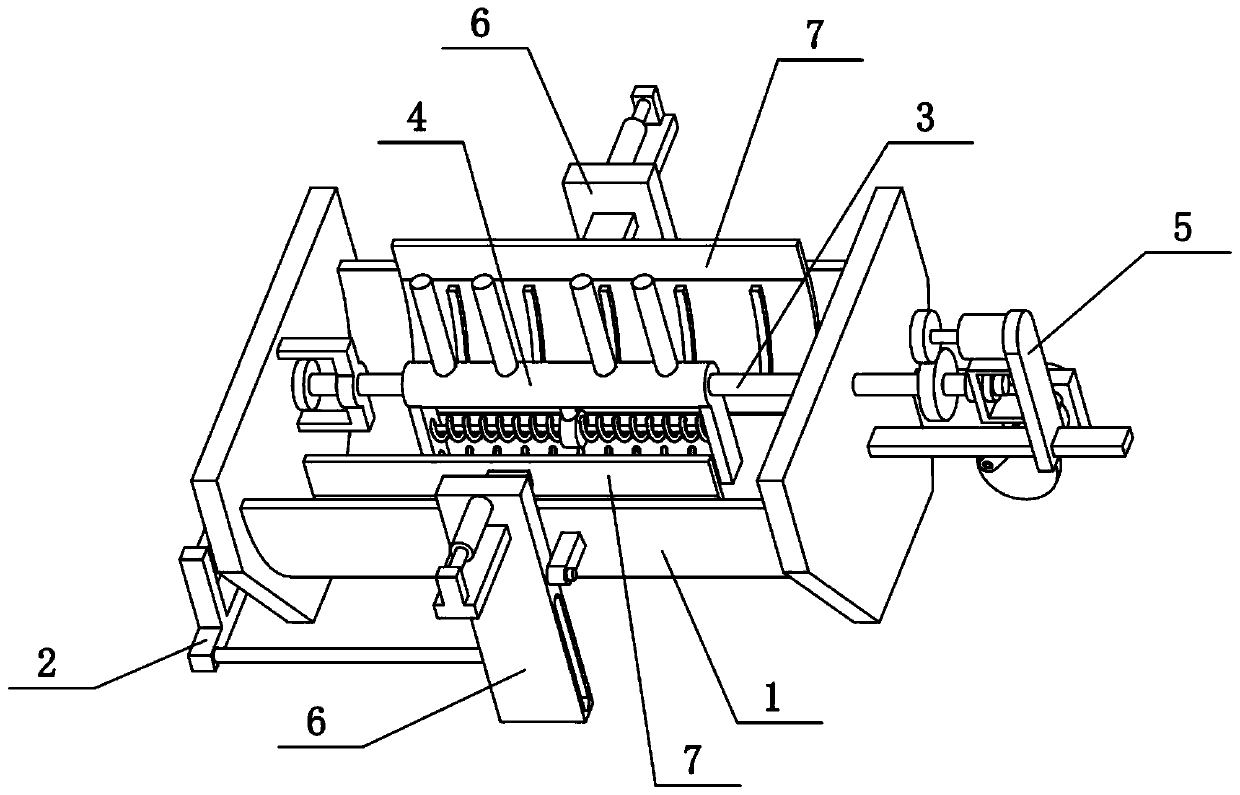

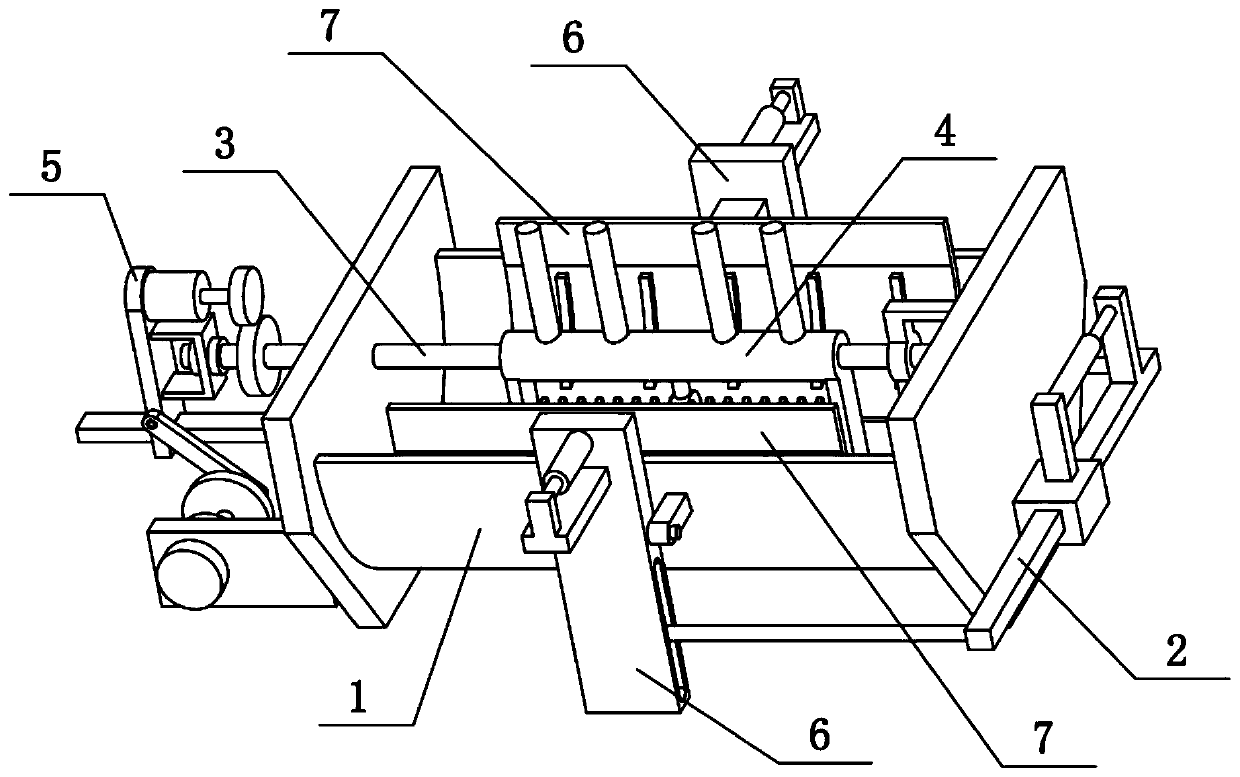

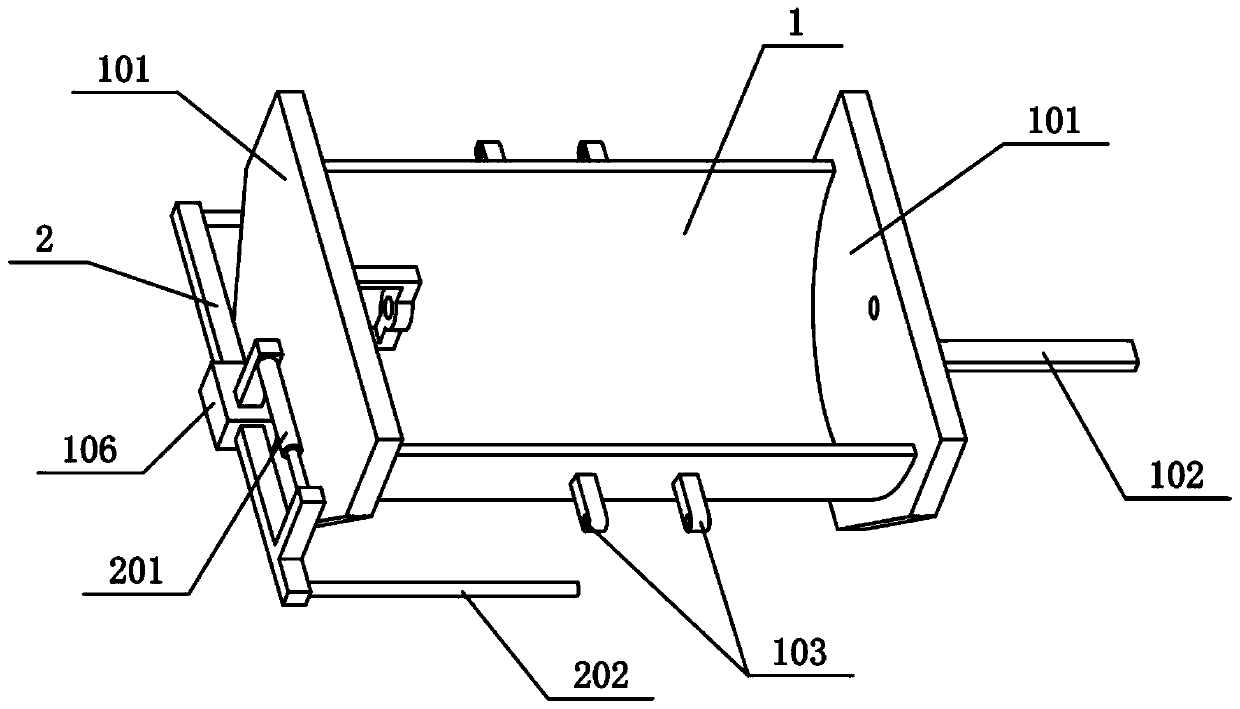

Ceramic glaze, processing device, and ceramic glaze processing method

ActiveCN110841543AImprove the mixing effectTransportation and packagingMixer accessoriesCelluloseHexafluorosilicic acid

The invention discloses a ceramic glaze, a processing device, and a ceramic glaze processing method. The ceramic glaze is composed of following raw materials in parts by weight: 10 parts of carboxymethyl cellulose, 5 parts of ammonium dichromate, 1 part of ammonium borofluoride, 2 parts of boric acid powder, 1 part of ochre, 1 part of potassium nitrate, 10 parts of green glass, 7 parts of ammoniumfluorosilicate, 3 parts of tin frit, 8 parts of copper oxide, and 1 part of ferric oxide. The processing method comprises following steps: step one, adding raw materials of ceramic glaze into a semi-cylinder container; step two, starting a motor (I) and a motor (II), wherein the motor (I) drives a horizontal shaft to rotate around the axis of the horizontal shaft, the motor (II) drives the horizontal shaft to reciprocate left to right, a compression spring (I), a compression spring (II), a spring sleeve column (I), and a spring sleeve column (II) horizontally stir the raw materials of the ceramic glaze, and multiple stirring rods vertically stir the raw materials of the ceramic glaze; and step three, closing the motor (I) and the motor (II), wherein when an electric telescoping rod (II) extends or retracts, arc plates are driven to move front to rear, and two arc plates evenly heat the raw materials of the ceramic glaze.

Owner:佛山意达加精密陶瓷科技有限公司

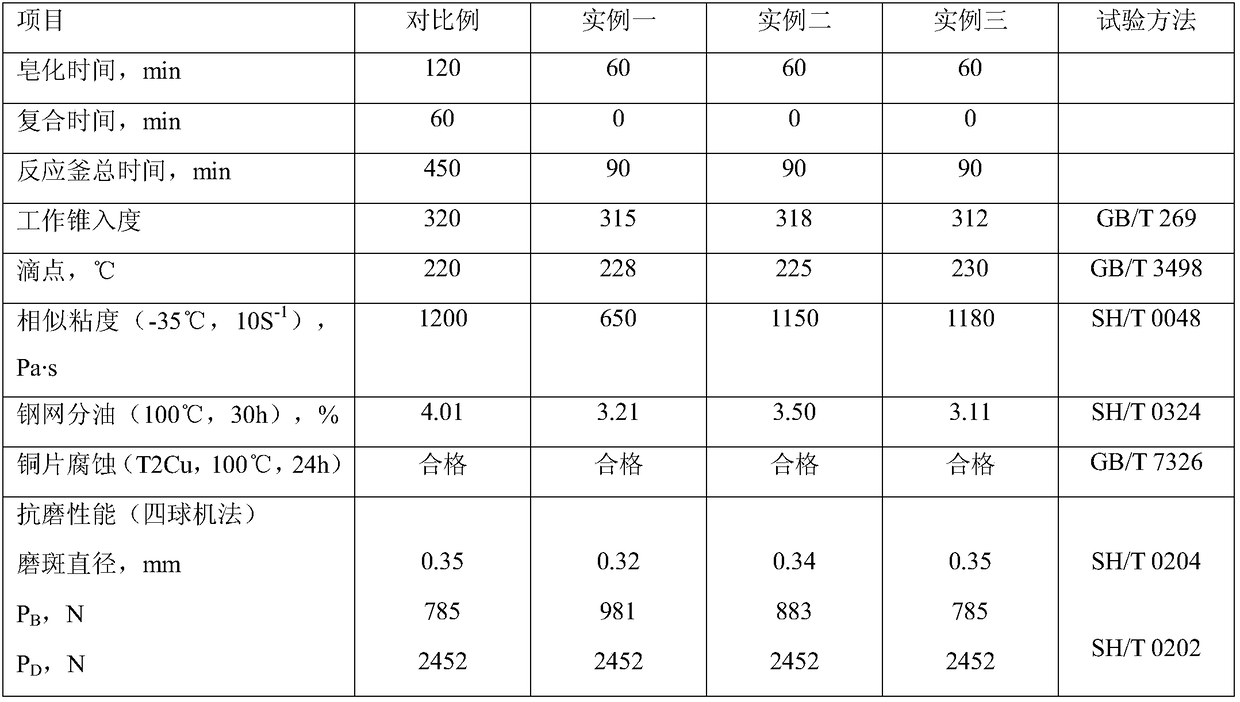

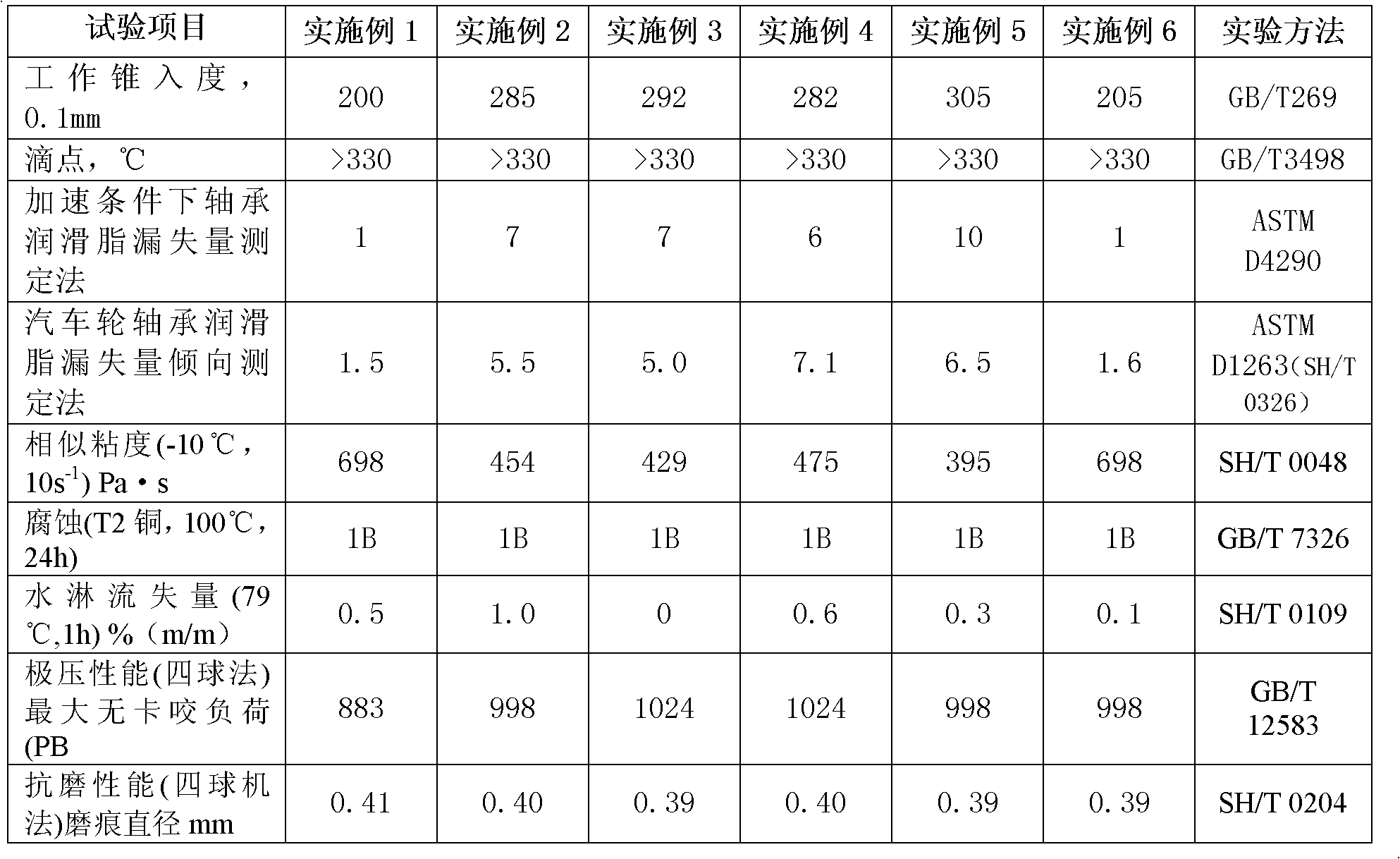

Lubricating grease special for gears and racks of automobile steering device and preparing method of lubricating grease

InactiveCN108559586AEliminates tendency to overflowEliminate dehydration stepLubricant compositionThiocarbamateOrganic acid

The invention discloses lubricating grease special for gears and racks of an automobile steering device and a preparing method of the lubricating grease. The lubricating grease is prepared from, by mass, 60-85% of base oil, 7-15% of C12-C22 monoprotic organic acid, 0.2-1.0% of boric acid, 1.3-2.5% of lithium hydroxide monohydrate powder, 0.5-1.0% of antioxygen, 0.3-1.0% of antirust agent, 0.5-2.0%of dialkyl dithiophosphate and 1.5-3.0% of dialkyl thiocarbamate, wherein the C12-C22 monoprotic organic acid, the boric acid and the lithium hydroxide monohydrate powder serve as thickening agents,and the antioxygen, antirust agent, dialkyldithiophosphate, dialkyl dithiophosphate and dialkyl thiocarbamate serve as additives. Compared with the prior art, the lubricating grease has the followingadvantages that a contactor and a pressure reaction still are adopted for saponification, lithium hydroxide powder and boric acid powder are directly adopted instead of corresponding aqueous solutions, the trend of still overflowing in the production process is avoided, a large number of dehydration steps are omitted, the efficiency of the saponification reaction is greatly improved, and the production time is shortened; meanwhile, the technology is more controllable, and the product quality is stable.

Owner:吉尔润科(湖南)石油化工有限公司

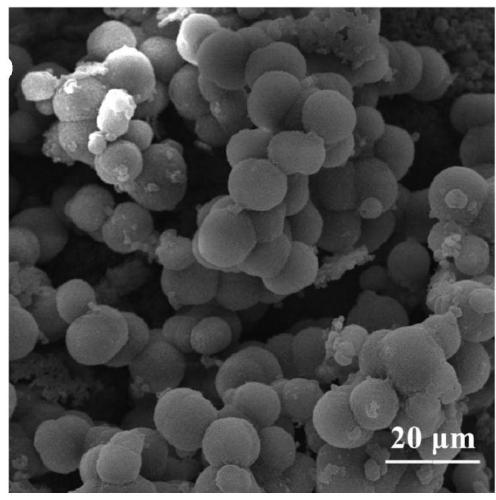

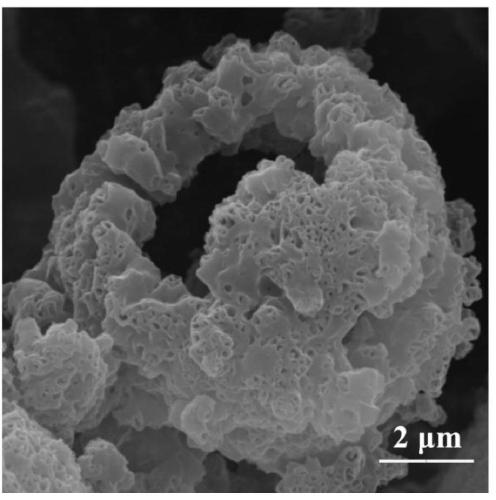

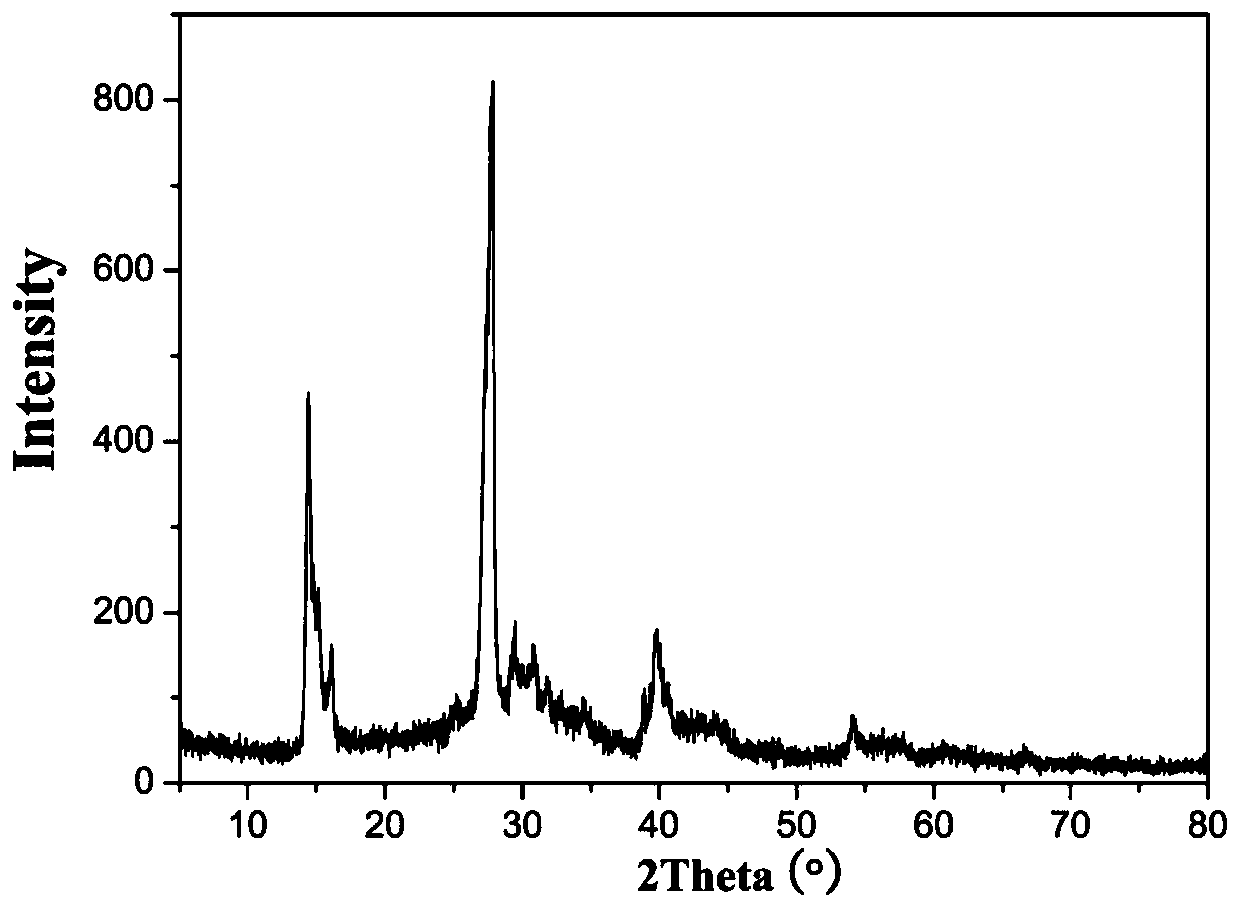

Method for preparing high-purity spherical instant boric acid by induction of organic molecules

The invention belongs to the technical field of inorganic functional materials and provides a method for preparing high-purity spherical instant boric acid by induction of organic molecules. The high-purity spherical boric acid with no aggregation is prepared by: dissolving analytically pure boric acid or industrial boric acid in a hot solvent which is a mixture of water with a lower alcohol, ketone, ether or acid with carbon number of less than 4, cooling the boric acid solution based on the solubility and surface free energy control principle, adjusting exposed crystal face of boric acid crystal and morphology of aggregated particles by inducing crystallization via organic molecules so that recrystallized boric acid microspheres are separated from the oversaturated solution, carrying outsuction filtering, and drying. Instant spherical boric acid powder prepared via the method is simple to operate, the technical conditions are easy to control, consuming a surfactant or aid is not required, material utilization rate is high, and the finished product has high purity. The problems are solved that, for instance, the traditional common boric acid has low dissolving speed and cakes easily.

Owner:DALIAN UNIV OF TECH

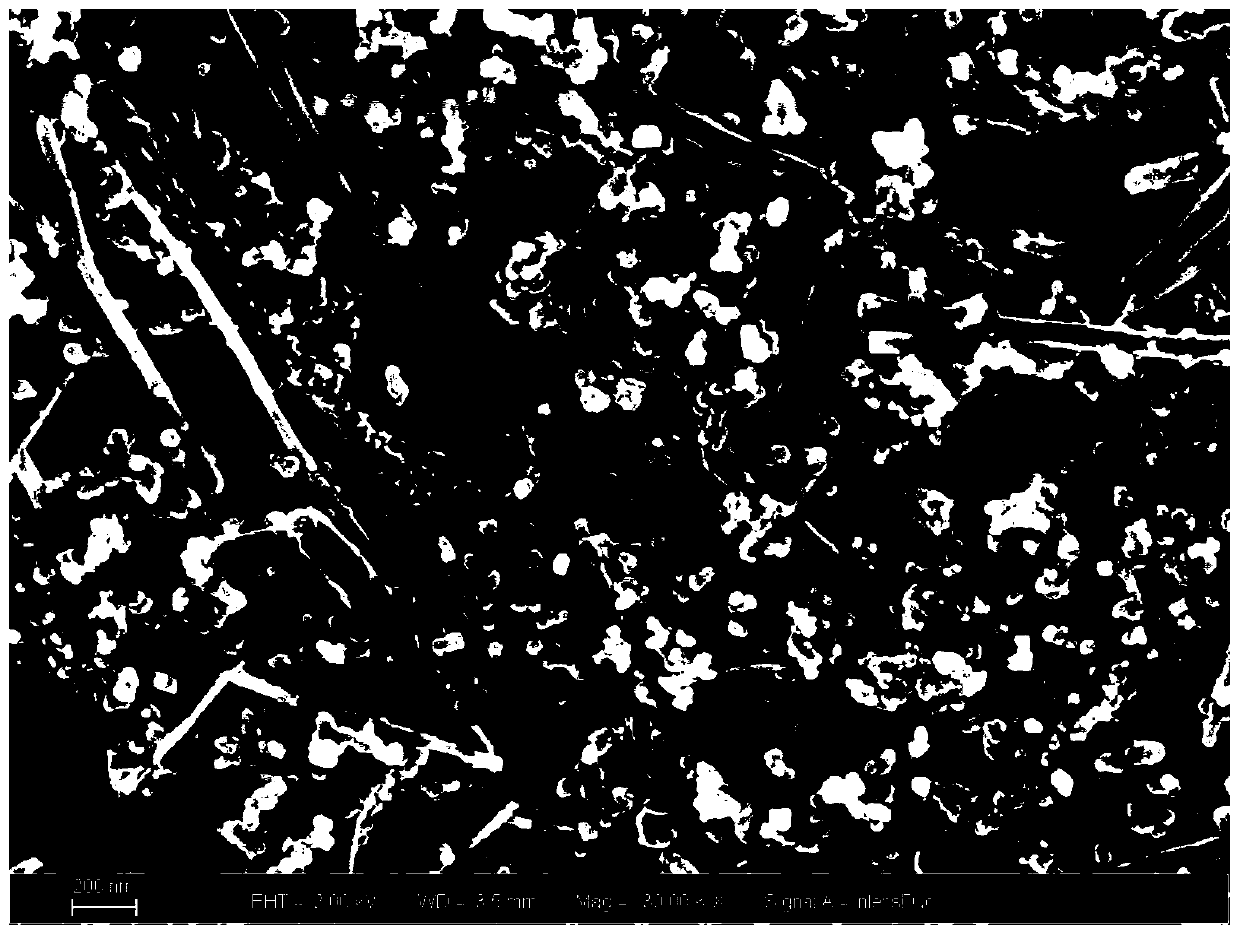

Preparation method of carbon nanotube toughened boron carbide ceramic

The invention discloses a preparation method of carbon nanotube toughened boron carbide ceramic, which belongs to the technical field of composite materials. The preparation method of the carbon nanotube toughened boron carbide ceramic comprises the following steps: S1, uniformly mixing carbon nanotubes and carbon black in proportion, putting a mixture into a synthesis cavity, and putting boric acid powder into a preheating cavity; S2, continuously introducing inert gas into the synthesis cavity from the preheating cavity, then heating the synthesis cavity to a set temperature, then heating the preheating cavity to a set temperature, and carrying out a reaction; S3, naturally cooling to room temperature, opening the synthesis cavity, and taking out the high-purity boron carbide / carbon nanotube composite material; and S4, adding water and glucose into the high-purity boron carbide / carbon nanotube composite material, carrying out ball milling, uniformly mixing, carrying out spray granulation, carrying out cold press molding, and carrying out vacuum hot press sintering to obtain the high-toughness and high-hardness carbon nanotube toughened boron carbide ceramic. According to the method, the carbon nanotube toughened boron carbide ceramic can be efficiently prepared.

Owner:赛福纳米科技(徐州)有限公司

Dry magnesia carbon material

InactiveCN104944982ARealize comprehensive utilizationReduce production and use costsBrickConstruction aggregate

The invention discloses a dry magnesia carbon material which consists of waste magnesia carbon brick particles with the particle size ranges of 0.3-1 mm and 1-3 mm, magnesia matrix, phenolic resin powder, boric acid powder and so on, wherein the weight of the waste magnesia carbon brick particles with the particle size range of 0.3-1 mm accounts for 25-35% of the total weight of the raw materials; the weight of the waste magnesia carbon brick particles with the particle size range of 1-3 mm accounts for 40-50% of the total weight of the raw materials; the weight of the magnesia matrix accounts for 13-30% of the total weight of the raw materials; the weight of the phenolic resin powder accounts for 1-4% of the total weight of the raw materials; the weight of the boric acid powder accounts for 0.5-1.5% of the total weight of the raw materials. The dry magnesia-carbon material has the advantages that remaining waste magnesia carbon bricks after steel ladle using are used to replace magnesia aggregate, so that not only can waste and old materials be reused, but also the enterprise production cost is greatly reduced; in addition, the produced continuous casting tundish working layer lining is excellent in anti-scouring and anti-erosion properties, so that the production safety is improved.

Owner:JIANGSU YONGGANG GROUP CO LTD

Composite calcium-sulfonate-based lubricating grease composition and preparation method thereof

InactiveCN102433189AImprove high temperature resistanceImprove retentionThickenersMixed materialsStearic acid

The invention discloses a composite calcium-sulfonate-based lubricating grease composition and a preparation method thereof. The preparation method comprises: filling high-alkalinity calcium sulfonate serving as a cleaning agent and methanol into a reaction kettle, heating to 80 to 100 DEG C, and after the mixed material is thick, adding calcium hydroxide powder, boric acid powder, C12 to C16 dicarboxylic acid and stearic acid at 90 to 100 DEG C to perform a saponification for 30 minutes; after saponification is finished, raising the temperature, keeping the temperature constant at 130 to 140 DEG C for 1 hour, slowly raising temperature to 220 to 225 DEG C, keeping the temperature constant for 5 to 10 minutes, and performing thickness regulation and homogenization treatment by using 4 to 78.6 percent base oil, wherein keeping the homogenization temperature between 100 and 120 DEG C; and when the thickness is proper, reducing temperature to 80 to 90 DEG C, filling when the temperature drops to 40 to 60 DEG C, and obtaining the finished composite calcium-sulfonate-based lubricating grease composition. The lubricating grease provided by the invention has high high-temperature resistance; leakage experiments carried out in accordance with ASTM D4290 and ASTM D1263 (SH / T0326 industrial standards) prove that the leakage range of the lubricating grease is within 5 to 10; and the retaining property of the lubricating grease in friction pair can be improved, and the operation reliability of the equipment can be guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP

Mosquito-repelling flower hydroponics nutrient solution and preparation method thereof

The invention relates to the technical field of plant cultivation, in particular to mosquito-repelling flower hydroponics nutrient solution, made from 6-8 parts of ammonium sulfate, 8-10 parts of urea, 6-8 parts of zinc sulfate, 6-8 parts of boric acid powder, 3-5 parts of an enzyme preparation, 6-8 parts of trace elements, 3-5 parts of betel nut, 2-4 parts of dried ginger, 5-7 parts of smoked plum, 6-8 parts of Chinese rhubarb rhizome, 3-5 parts of hawthorn, 2-4 parts of Cyrtomium rhizome, 2-4 parts of sodium cocoate, 3-5 parts of sodium palmitate, 2-4 parts of dodecyl polyglucoside, 2-5 parts of alkyl glycoside, 2-4 parts of fennel, 2-4 parts of Sichuan pepper, and 80-100 parts of deionized water. A formula of the solution is scientific, the solution is safe and pollution free and provides various required nutrient elements for flower plants to grow, the problem that hydroponic flower plants are commonly in shortage of nutrition during growth is effectively solved, biological enzymes contained in the solution are effective in degrading organic acids secreted by plant roots and rotten substances in water, and with the added Chinese herbs, and the solution is an effective pest repellent, effective preparation ensuring environmental sanitation and ideal choice of hydroponics nutrient solutions and is convenient to popularize.

Owner:蚌埠龙达农业专业合作社

Special fertilizer for walnuts

InactiveCN104671931ASimple structureNutritional diversityCalcareous fertilisersMagnesium fertilisersIron sulfatePhosphate

The invention provides a special fertilizer for walnuts and belongs to the technical field of agricultural chemical fertilizers. The special fertilizer comprises the following main components: calxes (silicate slag), grass carbon powder, urea, powdered rock phosphate, boric acid powder, potassium nitrate, calcium chloride, zinc sulfate, magnesium sulfate, manganese sulfate, iron sulfate and copper sulfate, wherein all the nutrient elements are prepared into the special fertilizer in proportion by weight. The special fertilizer provided by the invention, serving as a base fertilizer, is reasonable in nutrition collocation, can fully meet requirements of walnut trees on various nutrient elements after being applied, is lasting and efficient in fertility, can improve the soil structure and control root diseases and insect pests, and can obviously improve the yield and quality of fruits.

Owner:冯祥茂

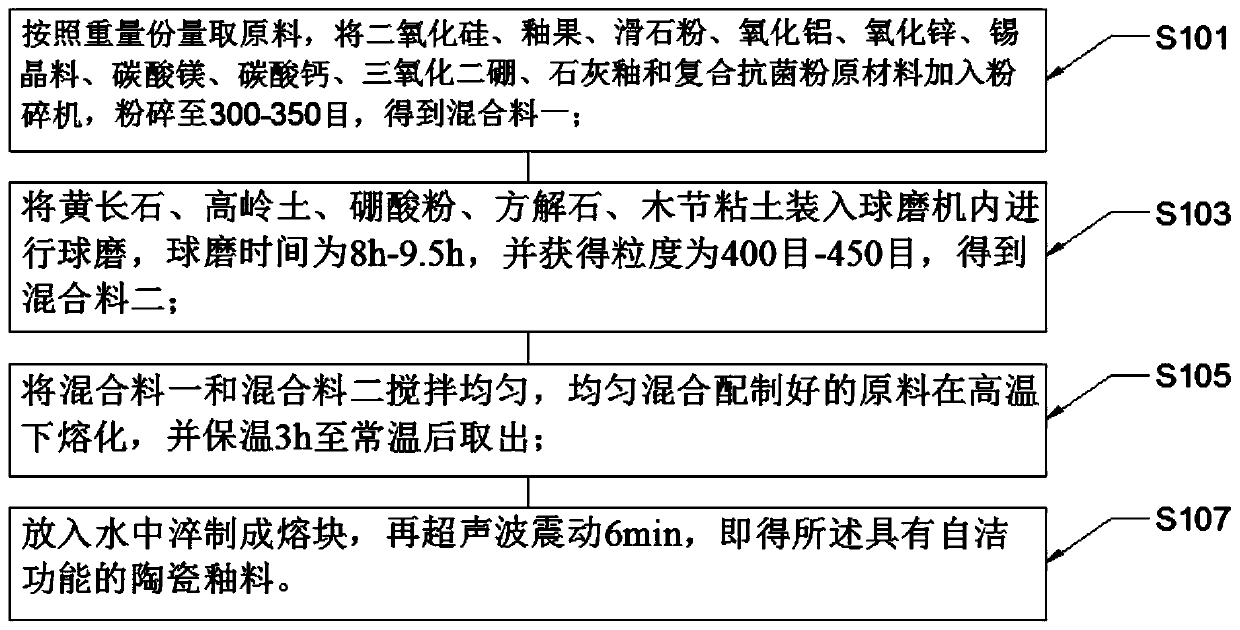

Ivory white ceramic glaze with self-cleaning function and preparation method of ivory white ceramic glaze

The invention discloses an ivory white ceramic glaze with a self-cleaning function and a preparation method of the ivory white ceramic glaze. The ivory white ceramic glaze comprises 25-35 parts of silicon dioxide, 20 to 30 parts of melilite; 20-25 parts of kaolin, 10-16 parts of boric acid powder, 10-15 parts of calcite, 15-20 parts of kapok clay, 15-20 parts of glaze stone, 10-20 parts of talcumpowder, 15-20 parts of aluminum oxide, 2-8 parts of zinc oxide, 2-5 parts of tin crystal materials, 2-6 parts of magnesium carbonate, 1-4 parts of calcium carbonate, 0.8-1.8 parts of diboron trioxide,2-5 parts of lime glaze and a composite antibacterial powder. The ivory white ceramic glaze has the beneficial effects that repeated washing by using a cleaning agent and water is greatly reduced, the ivory white ceramic glaze has a strong self-cleaning function, and the ivory white ceramic glaze with quick and lasting antibacterial performance and a good self-cleaning function can be obtained.

Owner:林丽品

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com