Preparation method of carbon nanotube toughened boron carbide ceramic

A technology of boron carbide ceramics and carbon nanotubes, applied in the field of composite materials, can solve the problems of high cost and difficult industrialization, and achieve the effect of low production cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment relates to a preparation method of carbon nanotube toughened boron carbide ceramics, the specific process is as follows:

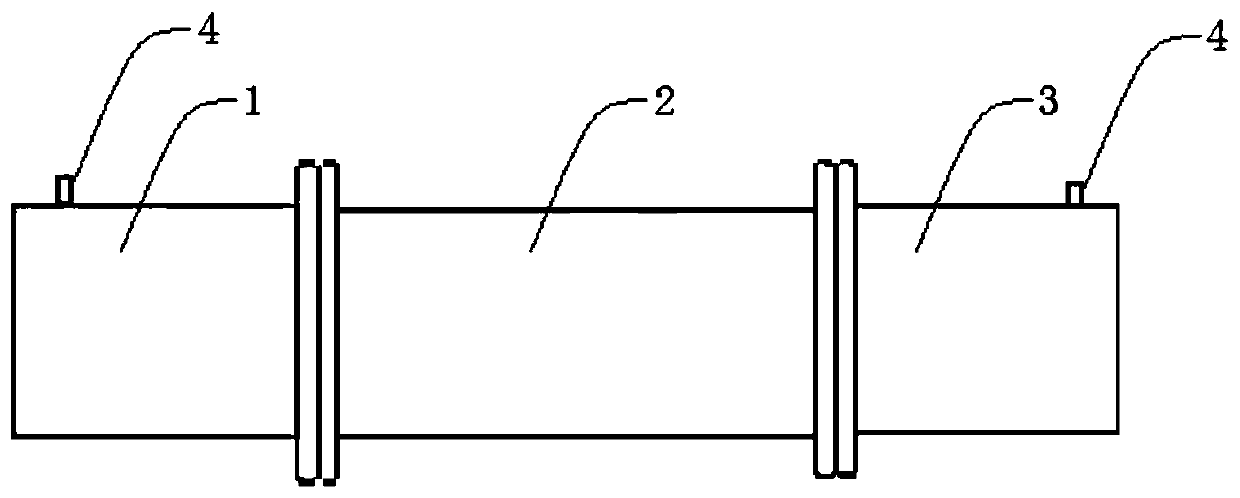

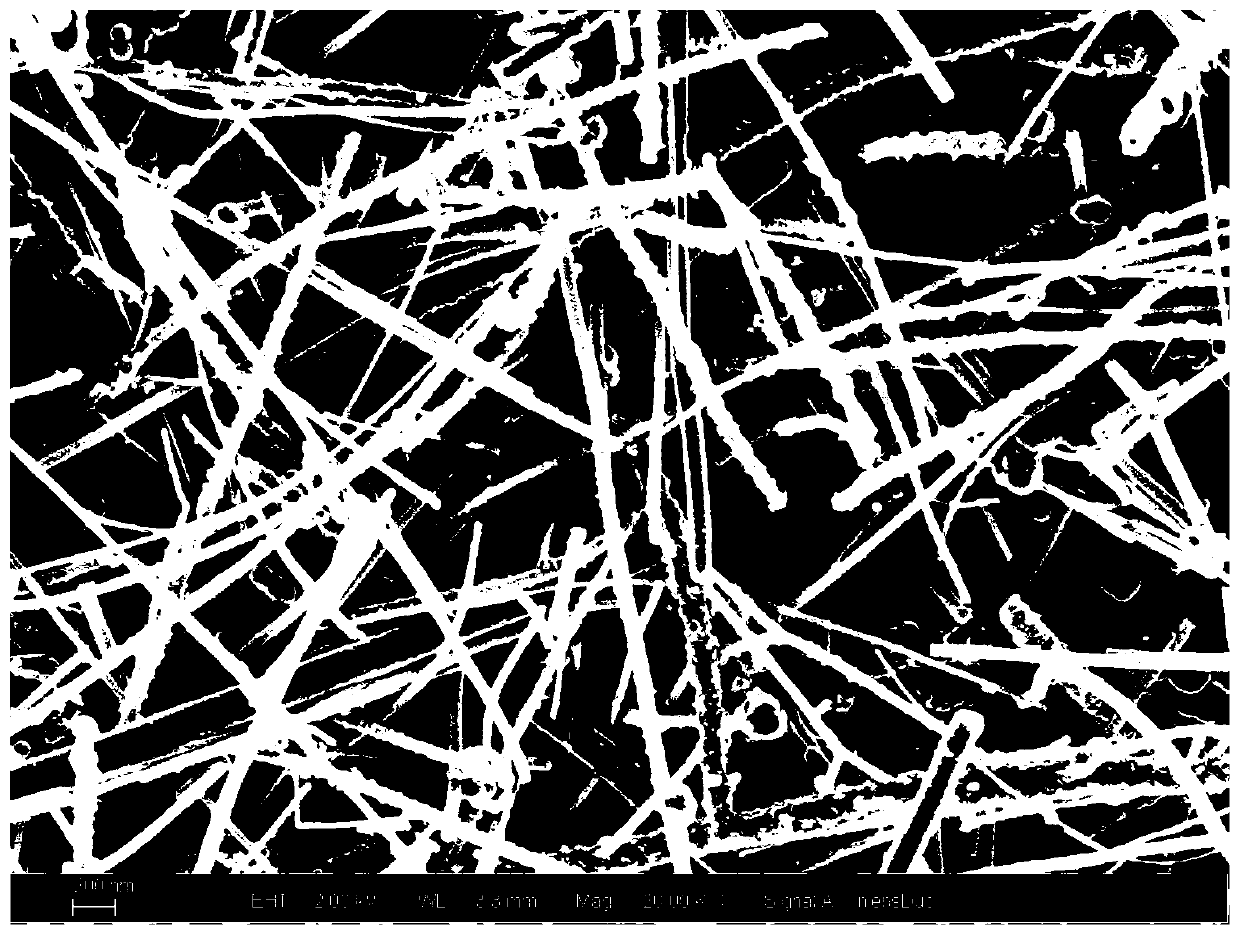

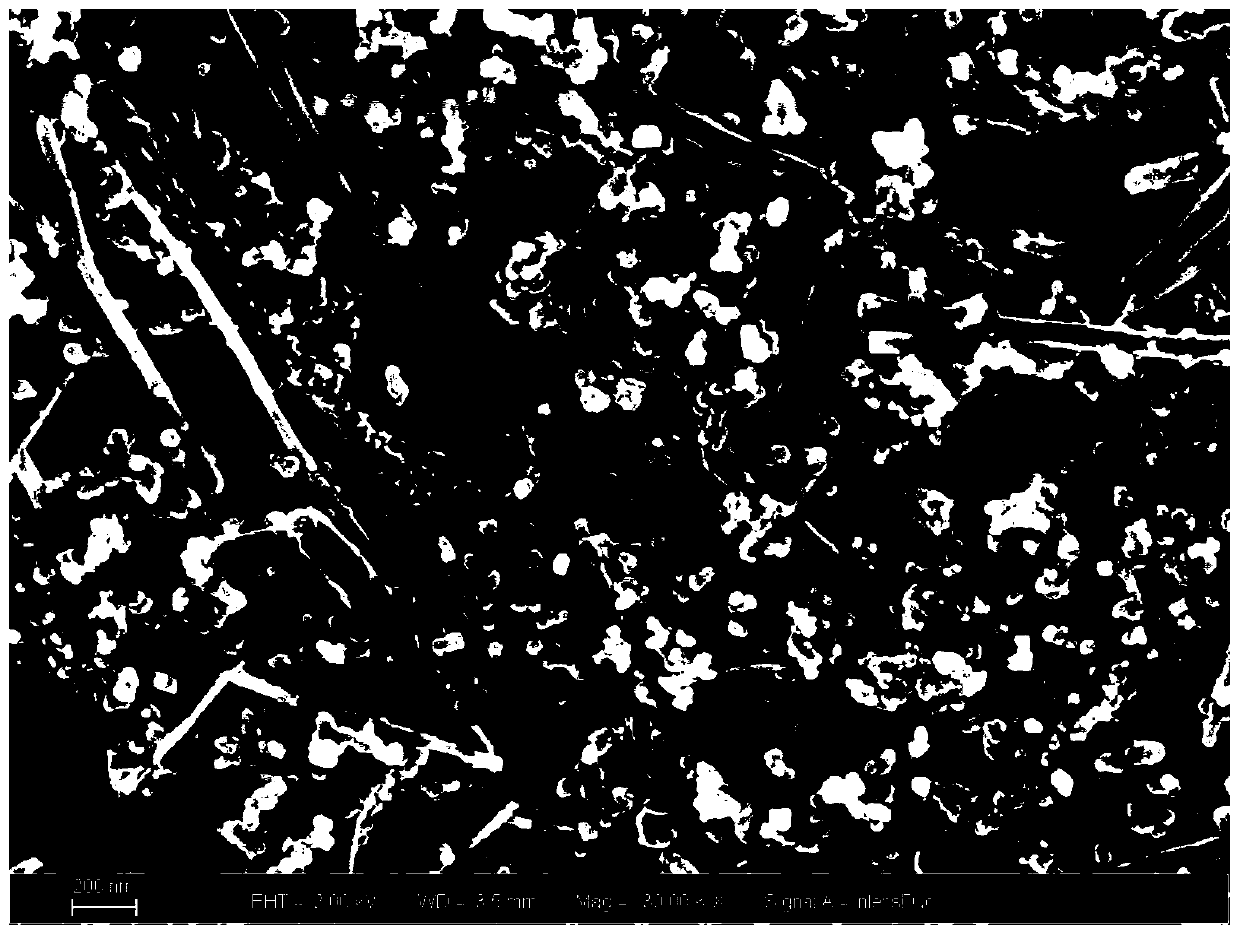

[0028] S1, 100g carbon nanotubes (SEM photo as figure 2 Shown) mixes with 850g carbon black and obtains mixture, and the SEM photo of mixture is as image 3 As shown, put it into the synthesis chamber, put 2.5kg of chemically pure boric acid powder into the preheating chamber, connect the preheating chamber, synthesis chamber and condensation chamber through the flange and vacuumize and seal them. The connection is filled with porous graphite insulation felt coated with boron carbide, such as figure 1 shown;

[0029] S2, continuously feed argon gas from the preheating chamber to the synthesis chamber at a flow rate of 0.5L / min, then heat the preheating chamber and synthesis chamber to a temperature of 400°C, and heat the condensation chamber until the temperature reaches 100°C. The boric acid powder decomposes to produce water va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com