Preparation method and applications of boron quantum dots

A quantum dot and boron powder technology, applied in the field of quantum dot preparation, can solve the problems of long process cycle, high toxicity of raw materials, high cost, etc., and achieve the effect of simple process, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

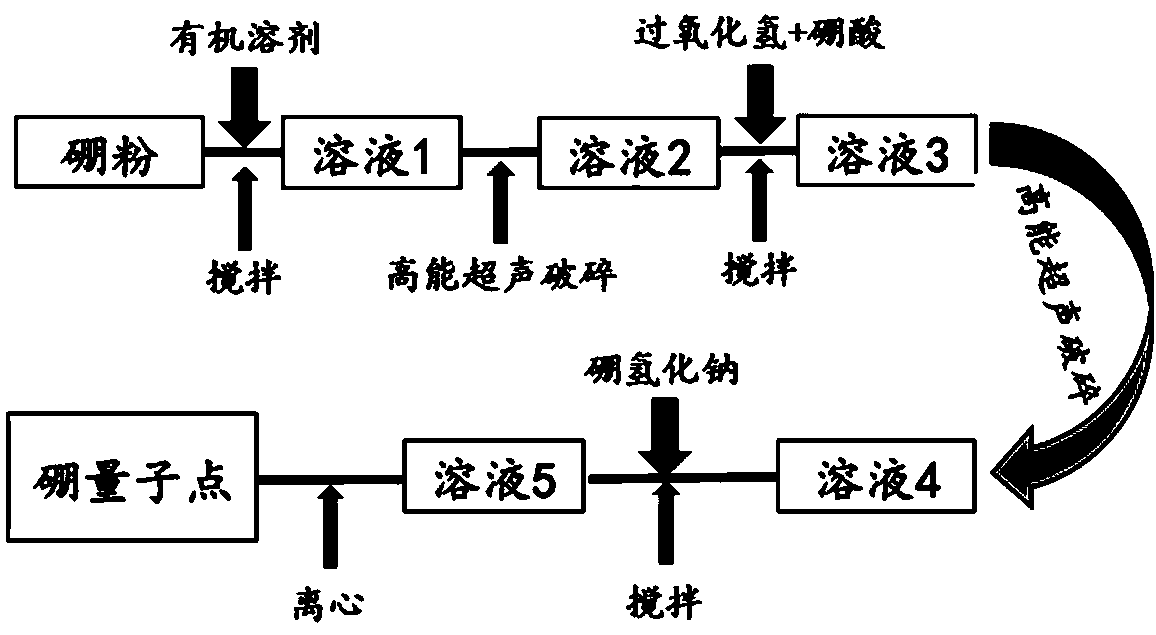

[0032] A preparation method of boron quantum dots, the steps are:

[0033] (1) Disperse 0.05g of amorphous boron powder in 50mL of organic solvent, stir thoroughly, and obtain a mixed solution containing boron particles after high-energy ultrasonic crushing, wherein the power of the high-energy ultrasonic crushing is 200W, ultrasonic The time is 6s, the interval is 10s, and the high-energy ultrasonic crushing is 10h;

[0034] (2) Add 5.0mL hydrogen peroxide solution (30%) and 0.01g boric acid powder to the mixed solution successively, set the power of the probe-type high-energy ultrasonic breaker to 200W, the ultrasonic time to 4s, and the interval time to 4s, Then, it was crushed by high-energy ultrasonic for 4 hours to obtain the initial product solution;

[0035] (3) Add 0.05g of sodium borohydride powder to the initial product solution, and then centrifuge at 3500rpm for 15min to obtain boron quantum dots;

[0036] (4) The boron quantum dots were dialyzed in deionized wa...

Embodiment 2

[0039] A preparation method of boron quantum dots, the steps are:

[0040] (1) Disperse amorphous boron powder with a mass of 0.25g in 50mL of organic solvent, and after stirring, undergo high-energy ultrasonic crushing to obtain a mixed solution containing boron particles, wherein the power of the high-energy ultrasonic crushing is 800W, ultrasonic time 5s, interval time 8s, high-energy ultrasonic crushing 2h;

[0041] (2) Add 1.0mL hydrogen peroxide solution (30%) and 0.03g boric acid powder to the mixed solution successively, set the power of the probe-type high-energy ultrasonic breaker to 800W, the ultrasonic time to 2s, and the interval time to 10s, Then, it was crushed by high-energy ultrasonic for 8 hours to obtain the initial product solution;

[0042] (3) Add 0.08g of sodium borohydride powder to the initial product solution, and then centrifuge at 9000rpm for 20min to obtain boron quantum dots;

[0043] (4) The boron quantum dots were dialyzed in deionized water f...

Embodiment 3

[0045] A preparation method of boron quantum dots, the steps are:

[0046] (1) Disperse 0.35g of nano-boron in 50mL of organic solvent, stir and undergo high-energy ultrasonic crushing to obtain a mixed solution containing boron particles, wherein the power of high-energy ultrasonic crushing is 1000W, and the ultrasonic time is 4s , The interval time is 4s, and the high-energy ultrasonic crushing is 8h;

[0047](2) Add 7.5mL hydrogen peroxide solution (35%) and 0.85g boric acid powder to the mixed solution successively, set the power of the probe-type high-energy ultrasonic breaker to 600W, the ultrasonic time to 3s, and the interval time to 4s, Then, it was subjected to high-energy ultrasonic crushing for 12 hours to obtain the initial product solution;

[0048] (3) Add 0.10g of sodium borohydride powder to the initial product solution, and then centrifuge at 6000rpm for 30min to obtain boron quantum dots;

[0049] (4) The boron quantum dots were dialyzed in deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com