Patents

Literature

121results about "Boron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

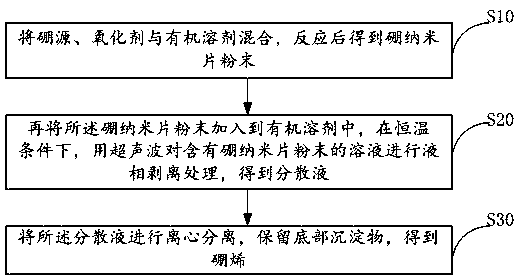

Boron alkene and preparation method thereof

The invention discloses a boron alkene and a preparation method thereof. The preparation method comprises the following steps: adding a boron source and an oxidant into a polar organic solvent, carrying out long-term stirring treatment under a sealing condition to obtain a reaction product, carrying out suction filtration on the obtained reaction product to obtain boron nanosheet powder, further dispersing the boron nanosheet powder into the polar organic solvent, carrying out ultrasonic liquid phase peeling treatment to obtain dispersion liquid, and further carrying out centrifugal treatmentto obtain the boron alkene. Compared with the prior art, the preparation method has the advantages of being simple in chemical process, relatively low in production cost and applicable to large-scalepreparation of boron alkene.

Owner:SHENZHEN UNIV

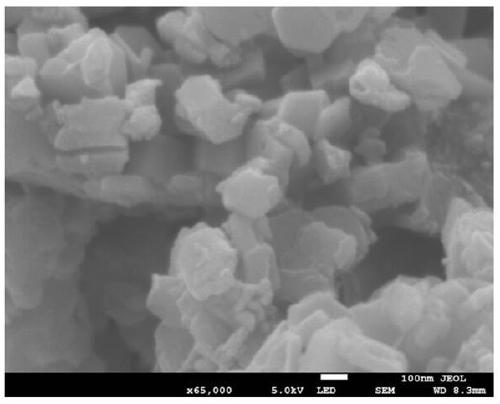

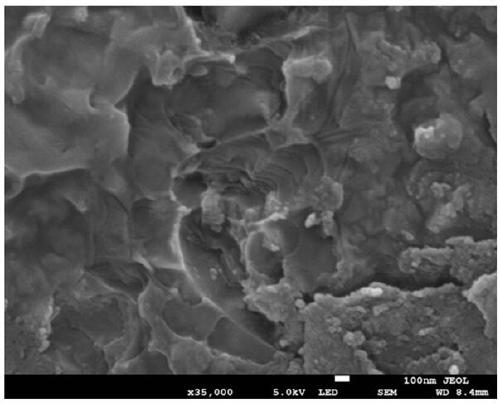

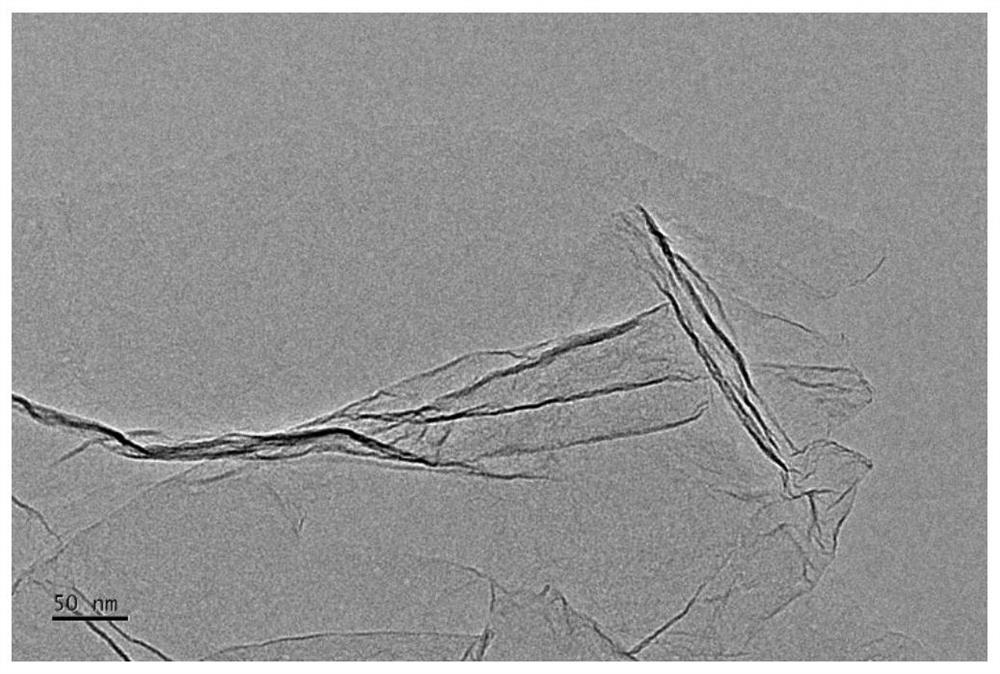

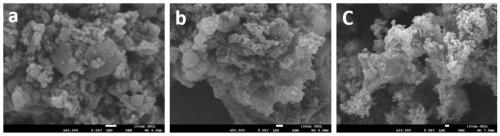

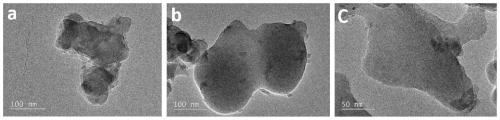

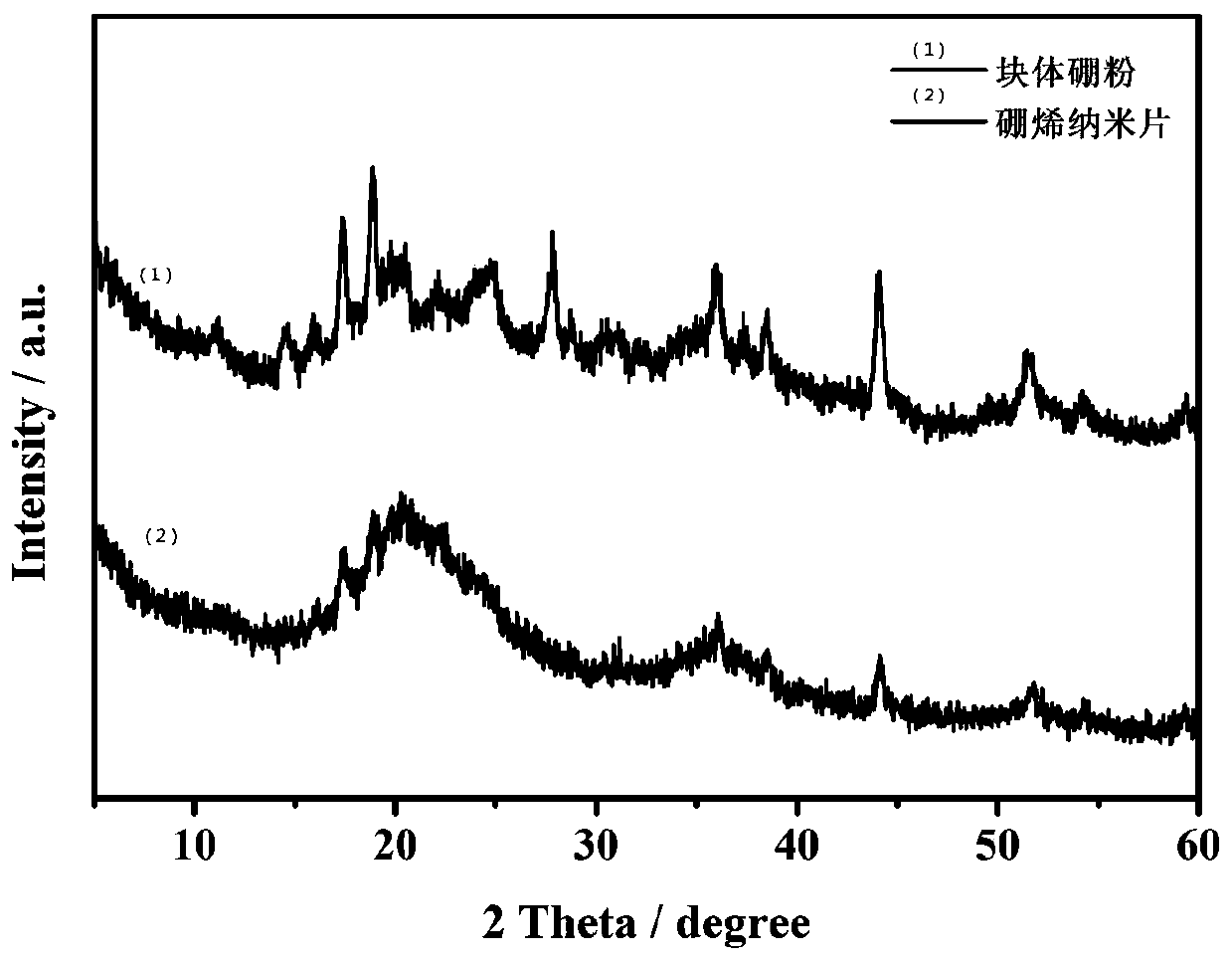

Borophene nanosheet and preparation method thereof

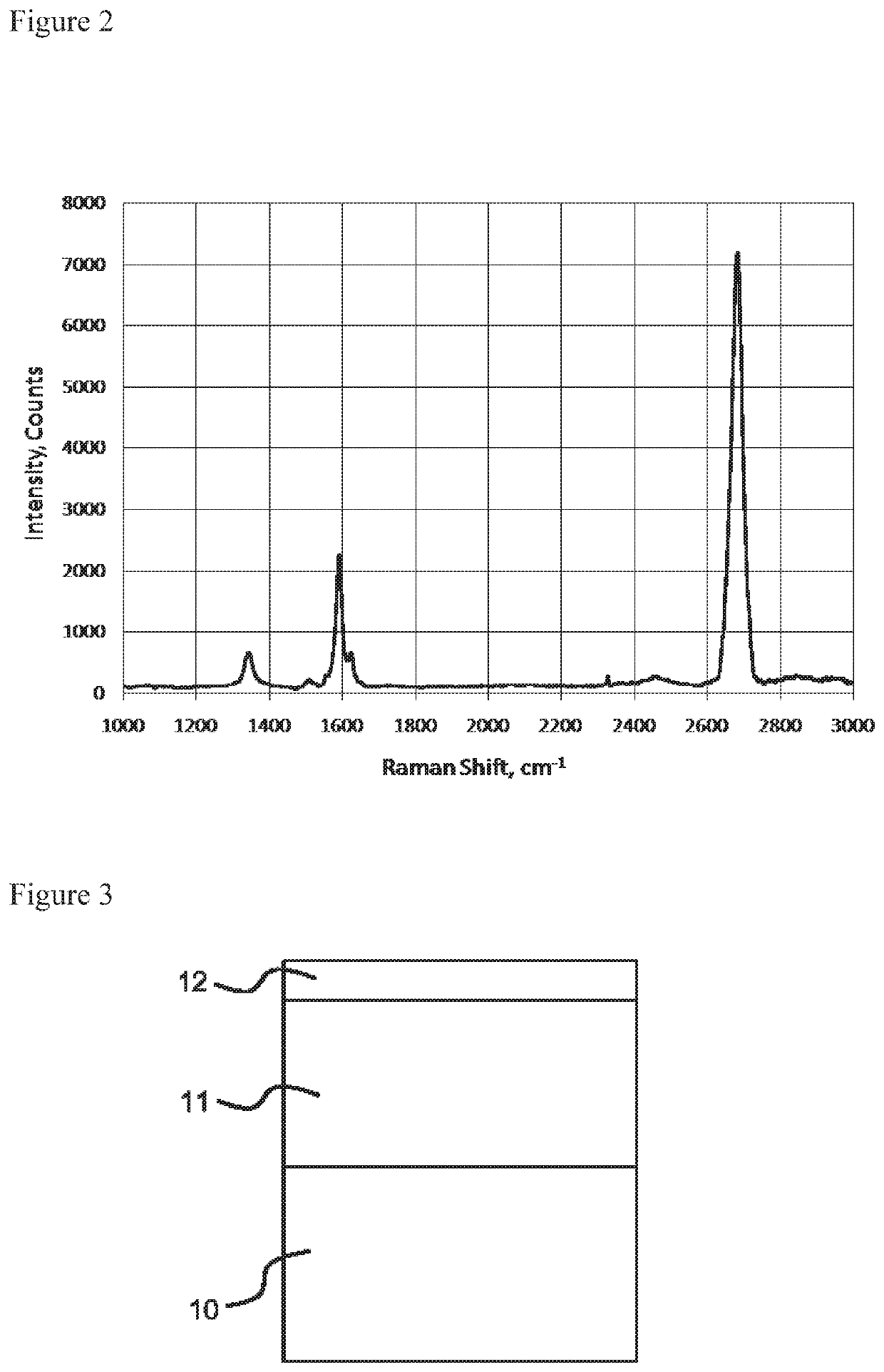

PendingCN112758950AMitigate edge oxidation problemsThe method is simpleBoronNanotechnologyFluid phaseChemistry

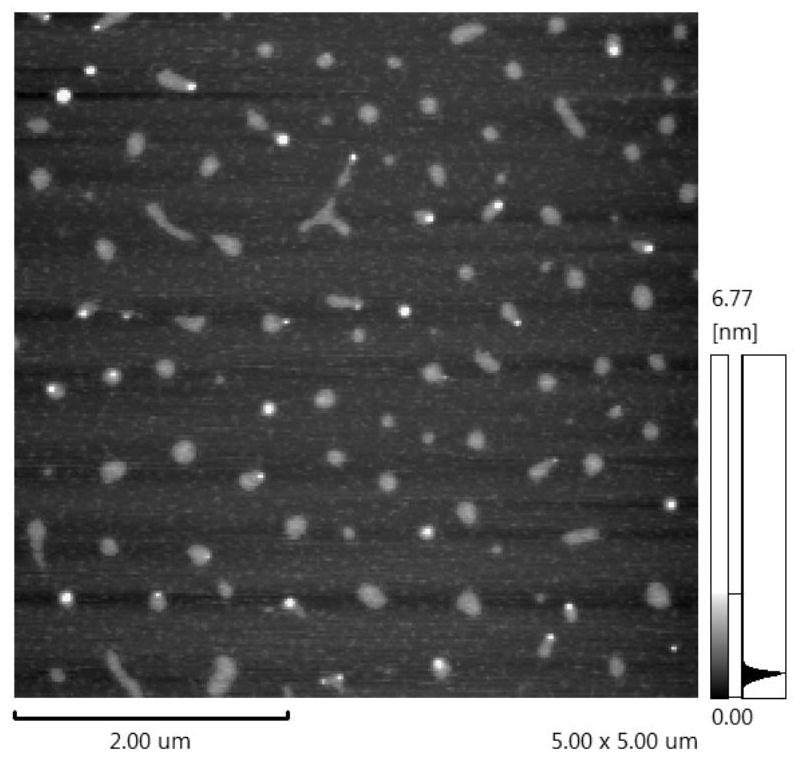

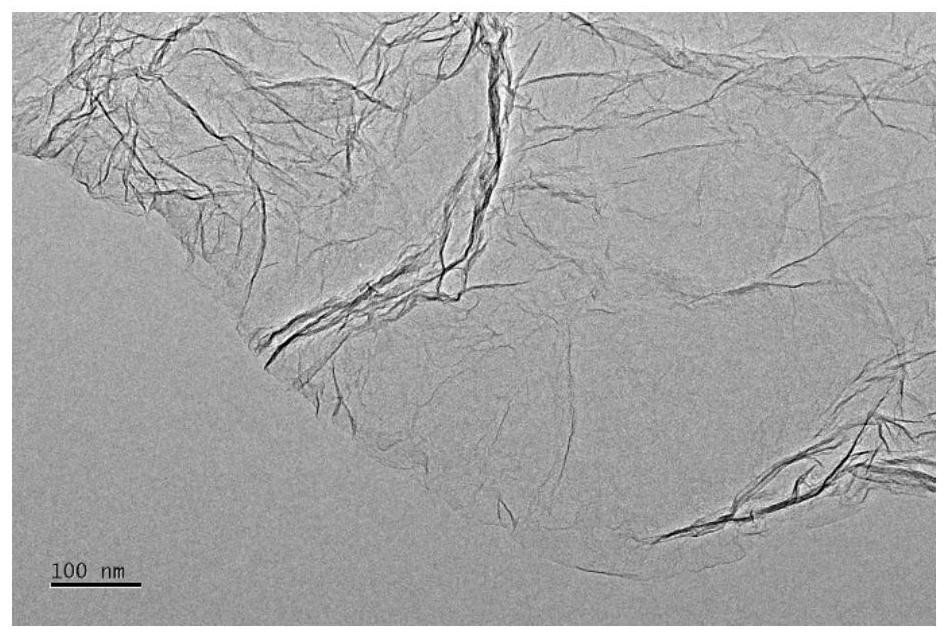

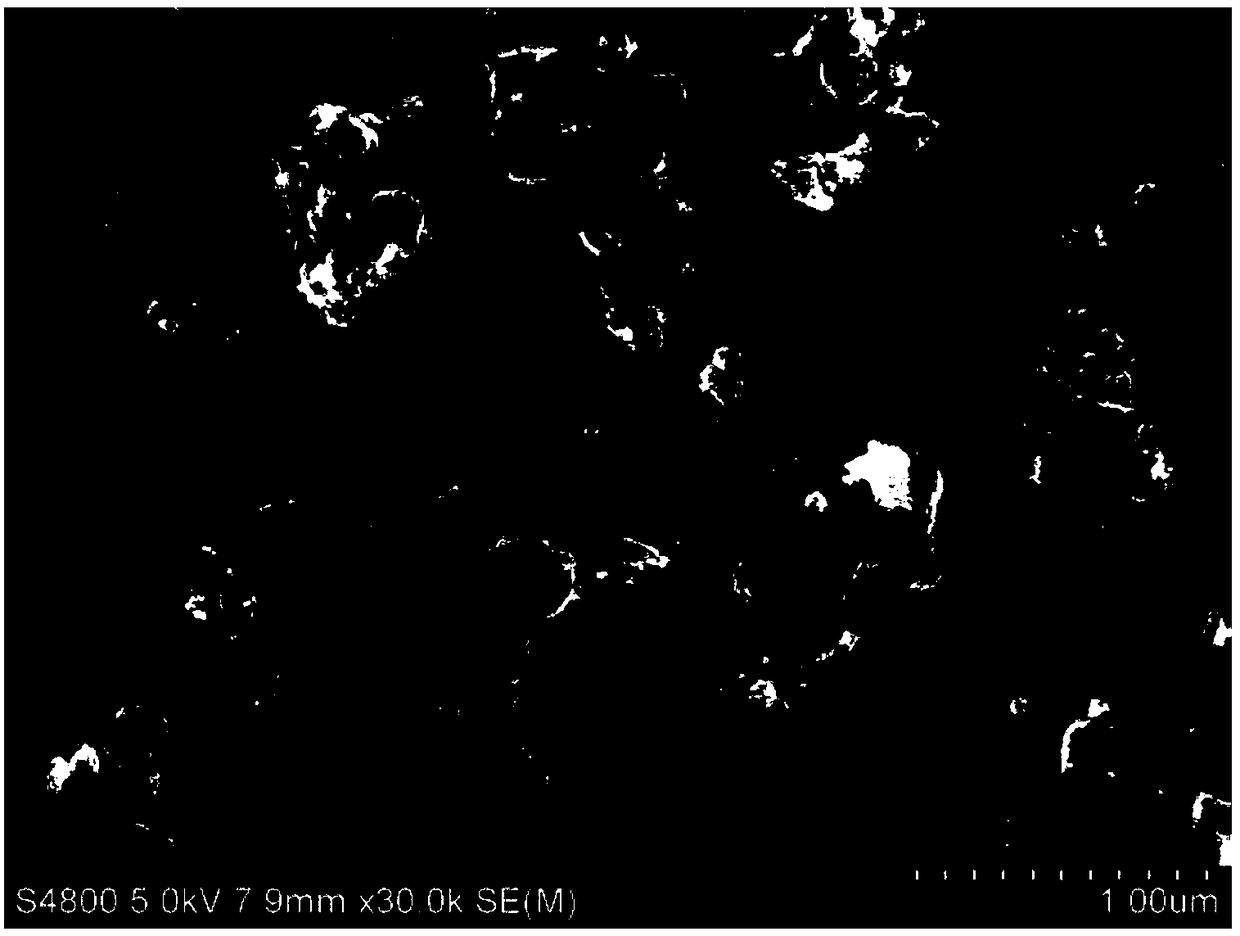

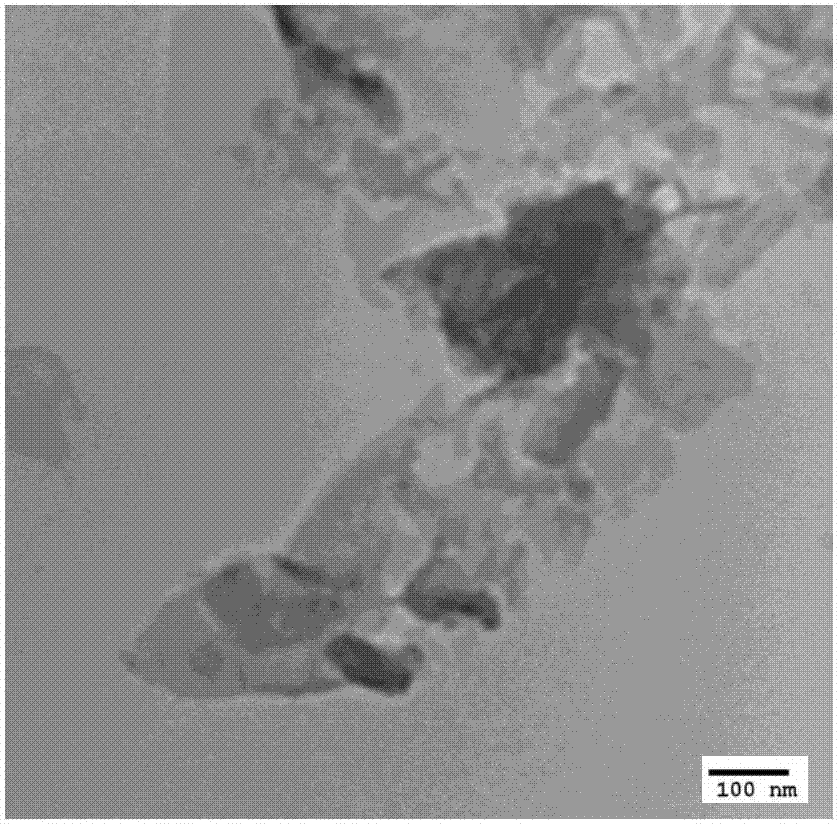

The invention discloses a borophene nanosheet and a preparation method thereof, and mainly solves the problem of preparing a two-dimensional borophene nanosheet from boron powder at present. The borophene nanosheet has a typical two-dimensional layered structure, the thickness of the borophene nanosheet ranges from 0.3 nm to 10 [mu]m, the transverse size of the borophene nanosheet ranges from 100 nm to 100 [mu]m, and the mass content of boron is larger than 90%. The preparation method comprises the following steps: providing boron powder, adding the boron powder into a solvent, carrying out ultrasonic treatment in a water bath, then adding the obtained product into concentrated acid, carrying out ultrasonic treatment, and carrying out centrifugal drying to obtain an intercalation product; performing high-temperature expansion on the intercalation product to obtain expanded boron powder; and finally, performing liquid-phase stripping on the expanded boron powder to obtain the borophene nanosheet. The invention provides a simple, green, efficient and low-cost method for preparing the borophene nanosheet, and large-scale production can also be realized.

Owner:JIANGSU XFNANO MATERIALS TECH CO LTD

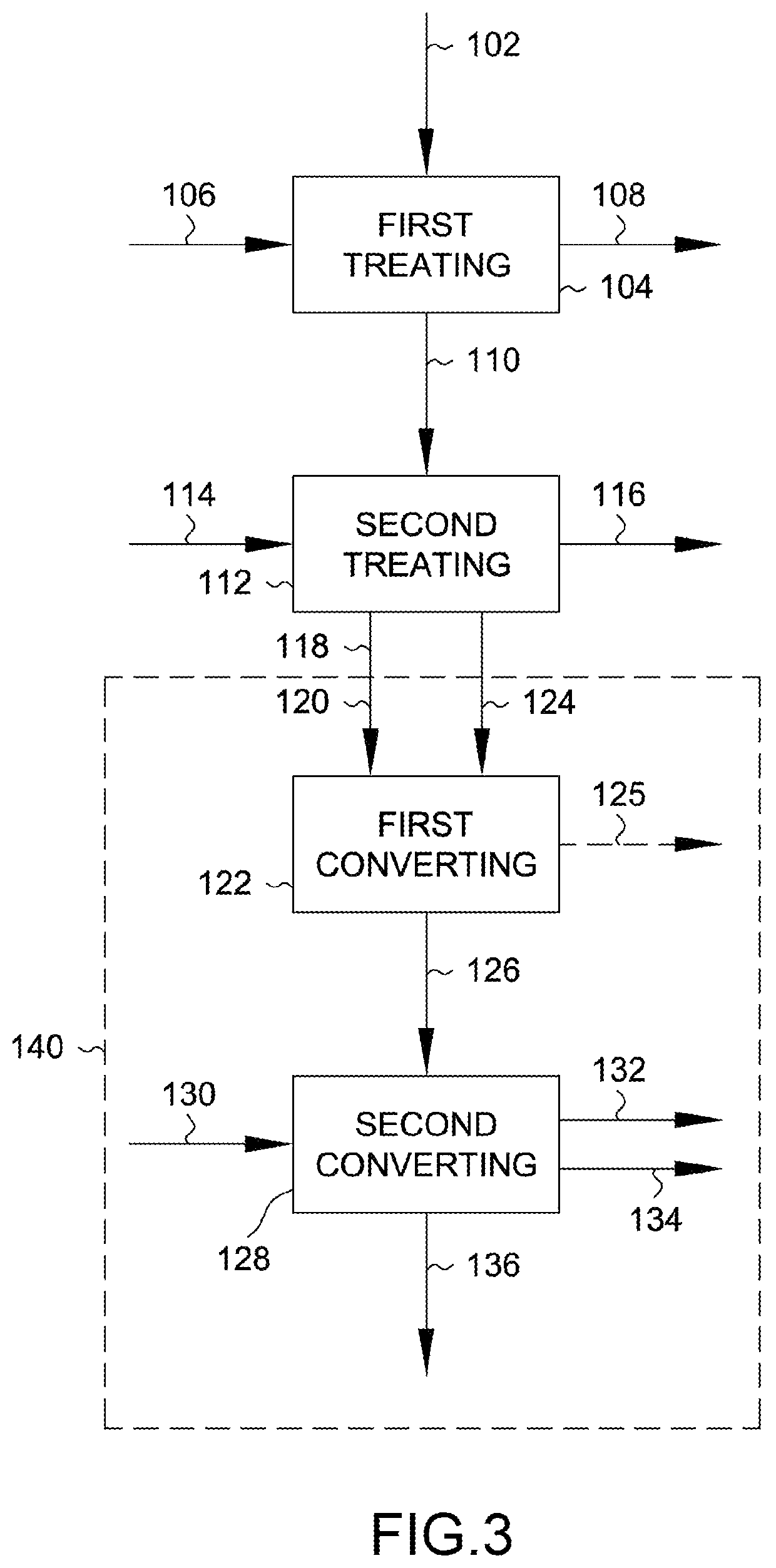

Cosolvent processing of reinforcing fiber-containing products for recycling reinforcing fibers

ActiveUS10610911B1Improving value and utilityReduce complexitySilicaArtificial filament recoveryFiberPolymer science

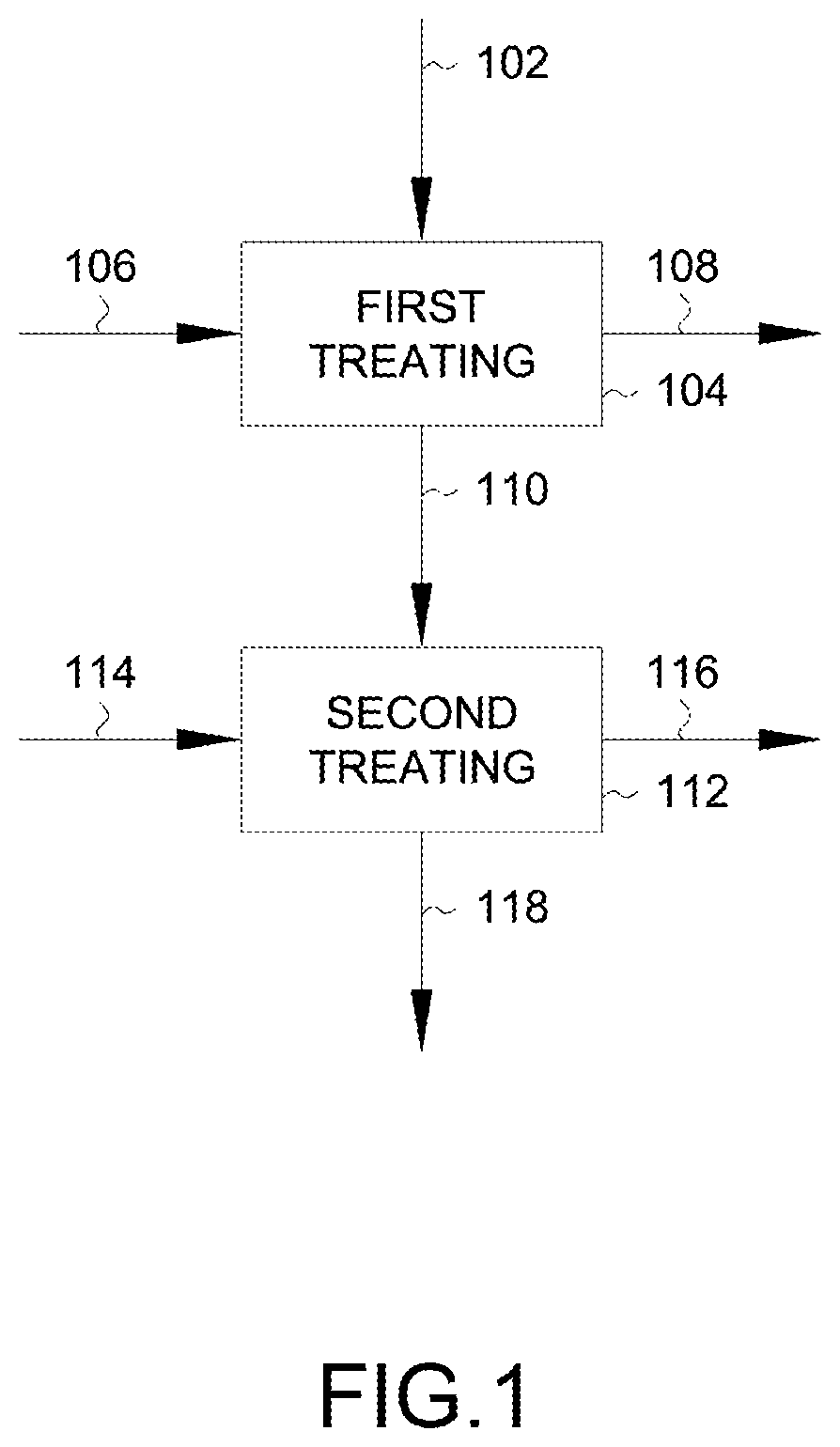

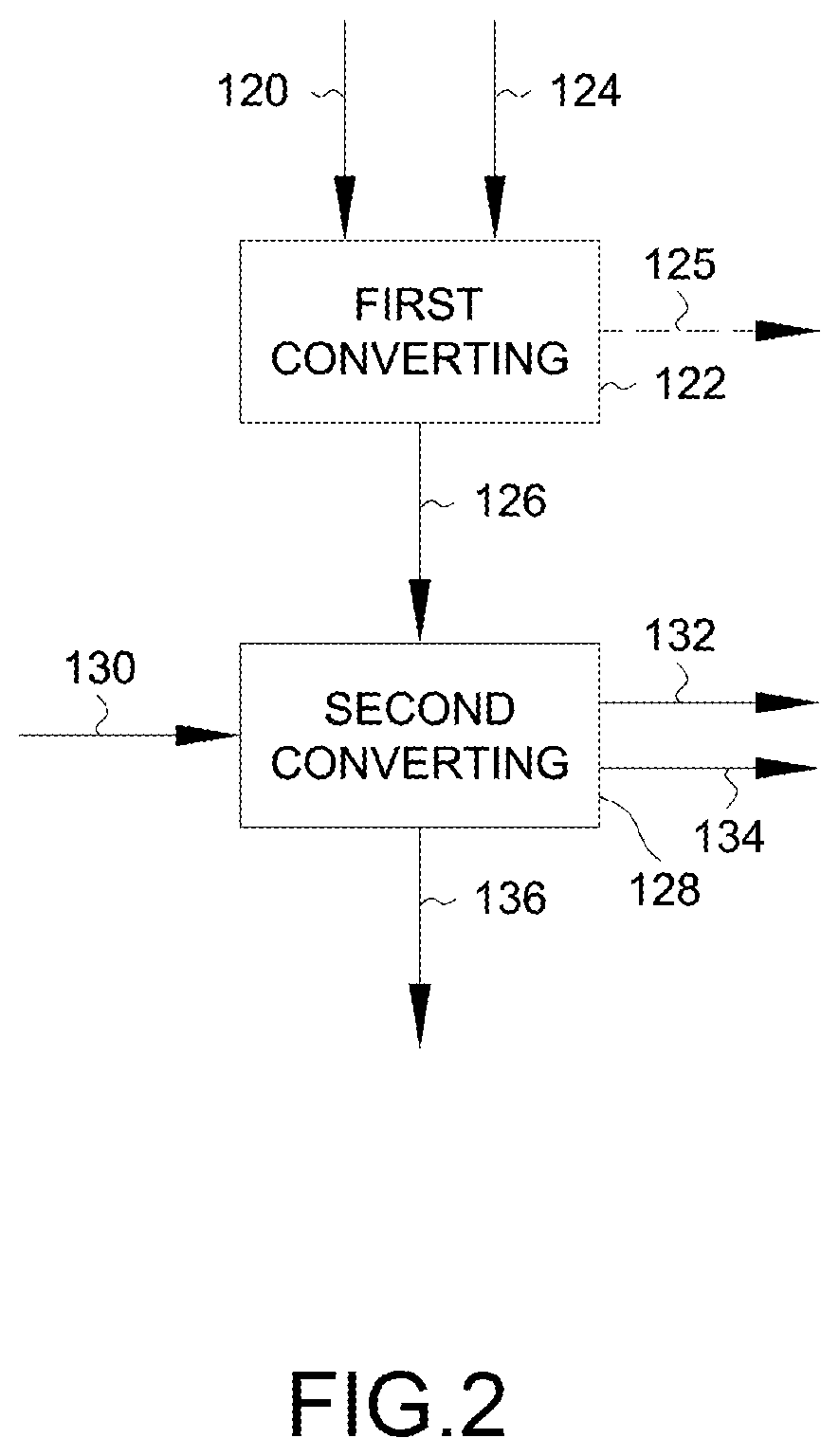

Processing reinforcing fiber products to recover reinforcing fibers by removing other material, such fiber sizing material and / or matrix material from the reinforcing fibers. The processing includes cosolvent treating the reinforcing fiber product with a cosolvent composition including a normally-liquid first solvent portion and a normally-gaseous second solvent portion under conditions of temperature and pressure at which the cosolvent composition is in the form of a single fluid phase that is a liquid or a supercritical fluid. The processing may be performed in a continuous manner to recover the continuous reinforcing fibers in a continuous form.

Owner:VARTEGA INC

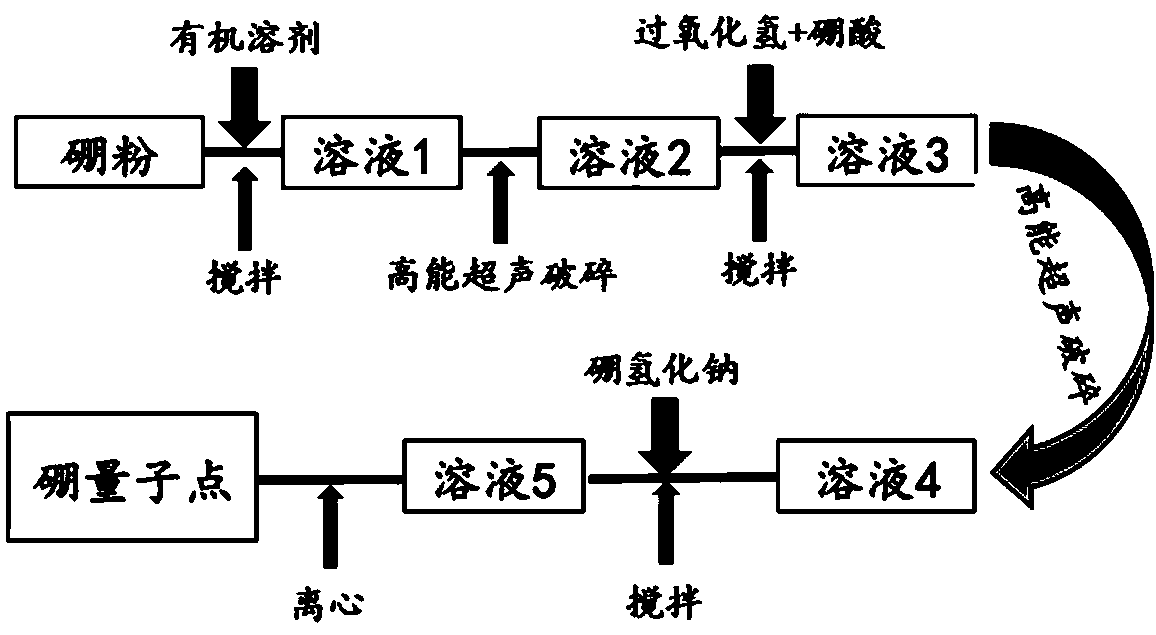

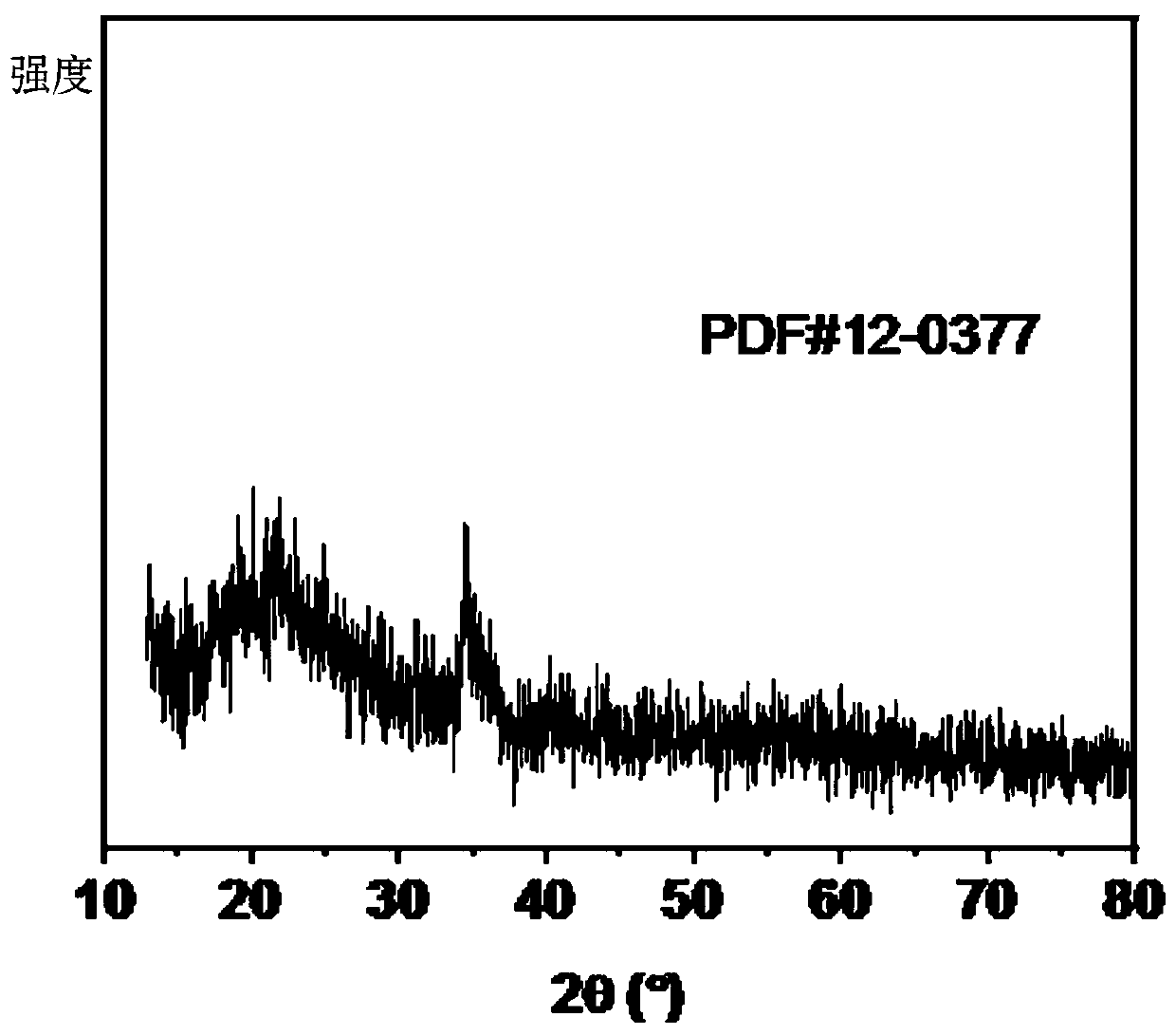

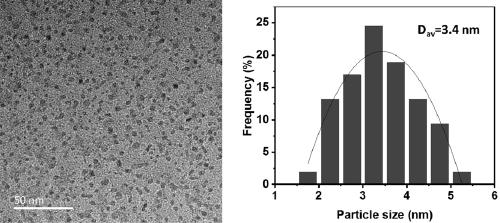

Preparation method and applications of boron quantum dots

The invention relates to a preparation method and applications of boron quantum dots, and belong to the technical field of preparation of quantum dots. The preparation method comprises: dispersing boron powder in an organic solvent, and stirring uniformly to obtain a mixed solution containing boron particles; adding a hydrogen peroxide solution and boric acid powder, and carrying out high-energy ultrasonic breaking to obtain a primary product solution; and adding sodium borohydride, and carrying out centrifugation to obtain the boron quantum dots. According to the present invention, the boronquantum dots are prepared by using the boron powder as the boron source for preparing fluorescent boron quantum dots and using the organic solvents isopropanol and tetrahydrofuran as the double-drivechemical etching agent through the high-energy ultrasonic breaking assisted liquid phase stripping method, have characteristics of uniform size and slight green fluorescence, can be used as a boron-containing drug for boron neutron capture therapy, and has large-scale production potential and broad commercial application prospects.

Owner:ZHONGBEI UNIV

Method for preparing boron alkene

The invention discloses a method for preparing boron alkene. The method includes steps of carrying out ball-milling on boron sources and catalysts according to a mass ratio of 1:3-5 under the condition of the ball-to-powder ratio of 4-10:1 for 40-60 hours and immediately cooling obtained products by the aid of liquid nitrogen for 1-2 hours; carrying out distillation separation on the products for 2-4 hours, removing remaining liquid-state borane, treating the products by the aid of a tube vacuum furnace for 2 hours and removing impurity carbon; carrying out solid-liquid extraction treatment on obtained products, drying the products by the aid of a vacuum drying tank and naturally cooling the products until the temperatures of the products reach the room temperature so as to obtain the boron alkene with the purity of 95%-98.5%. The method has the advantages that equipment is simple and is low in cost, the boron alkene obtained by the aid of the method is high in purity and product quality and contains few impurities, and accordingly the method has popularization value.

Owner:YANSHAN UNIV

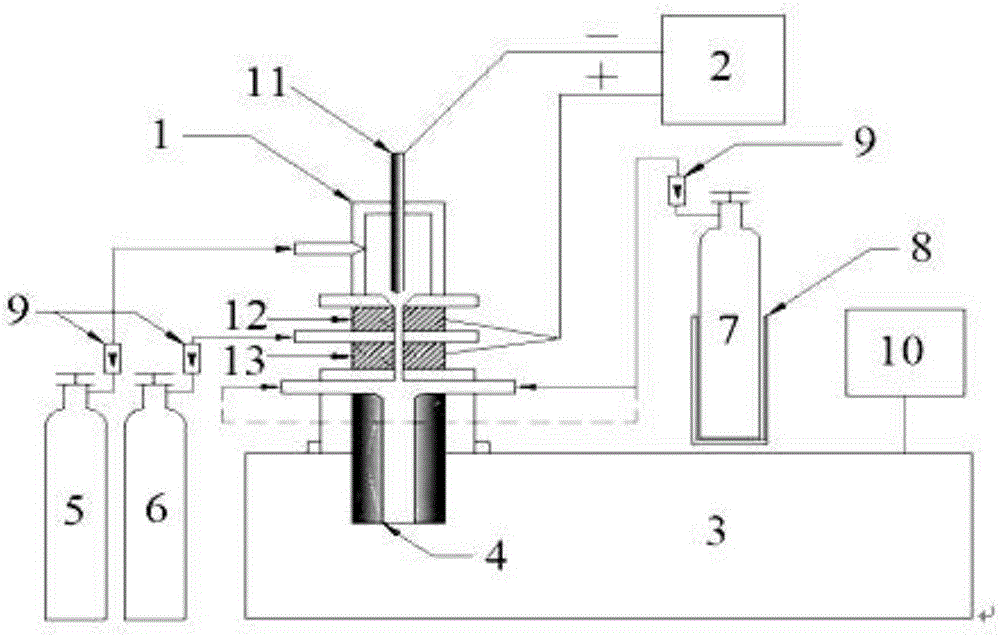

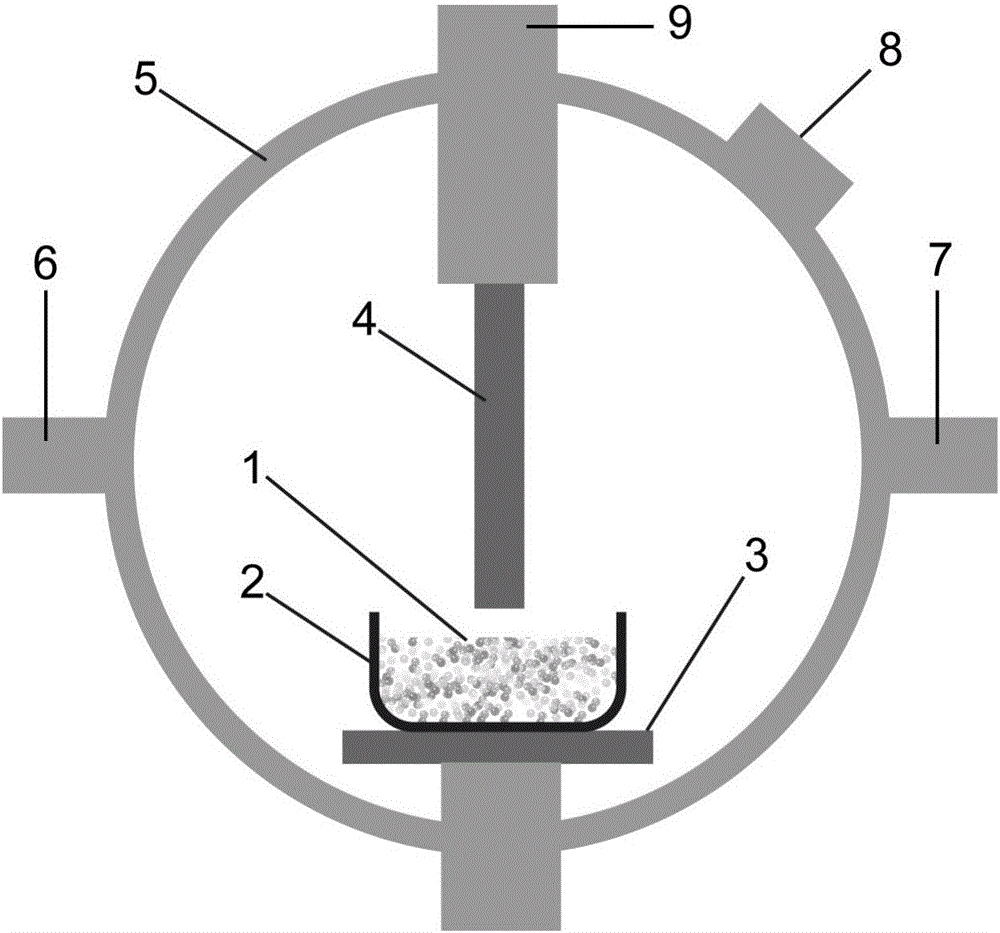

Amorphous boron powder preparation device and method of device for preparing amorphous boron powder

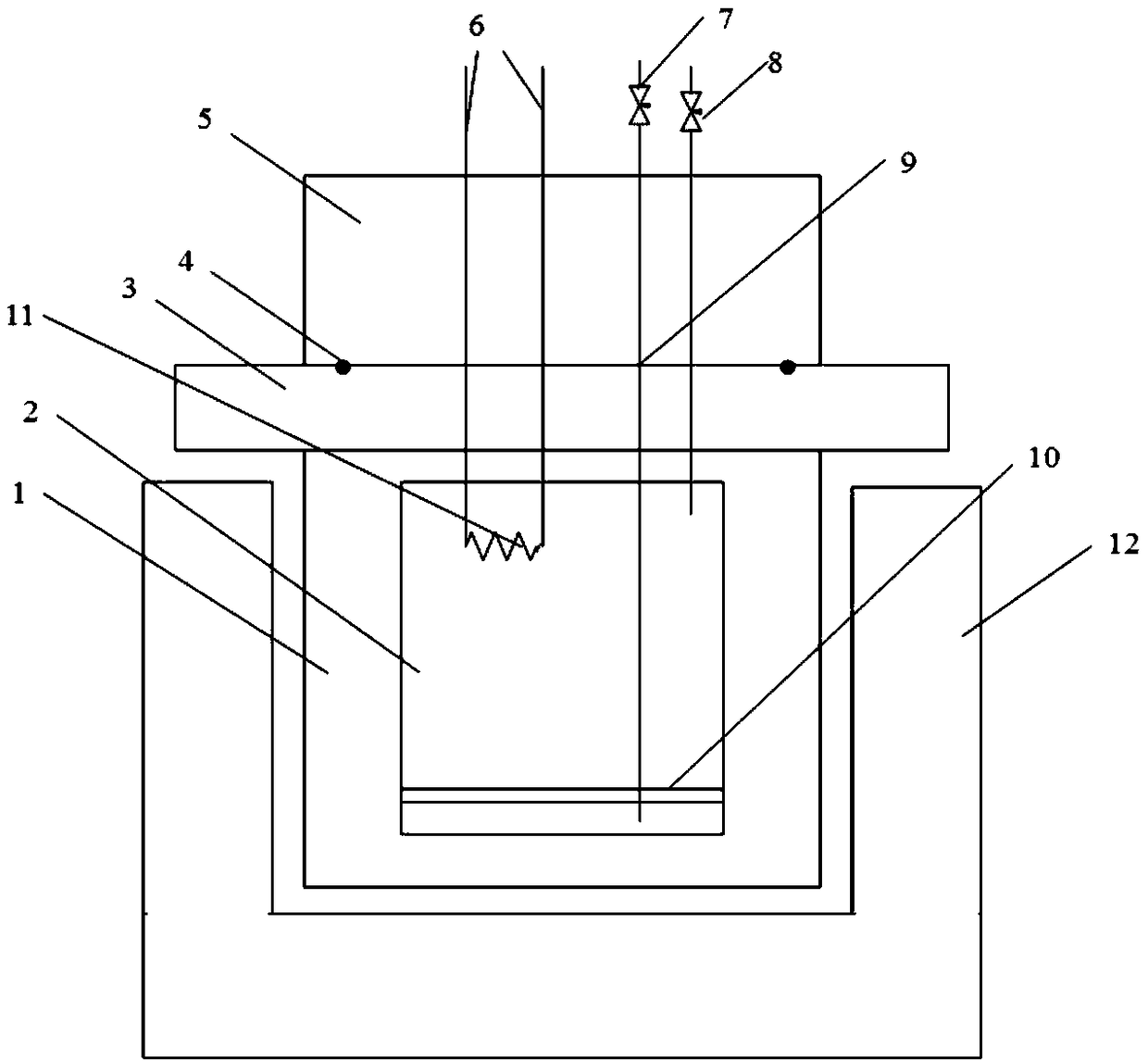

The invention relates to an amorphous boron powder preparation device. The device comprises a sealing body, a reactor (2), a self-propagating reaction initiation assembly, an air inflation valve (7),an air release valve (8), an air guide pipe (9) and a heating body (12); the reactor (2) is used for containing reaction raw materials; the sealing body is used for placing the reactor (2), and the reaction raw materials in the reactor are subjected to heat insulation from the exterior and located in a sealing space in a reaction process; the self-propagating reaction initiation assembly is used for initiating a self-propagating reaction of the reaction raw materials; two air through holes are formed in the sealing body, the air guide pipe (9) penetrates through the air through holes and is connected with the interior and the exterior of the sealing body, and the air inflation valve (7) and the air release valve (8) are arranged on the air guide pipe (9) of the exterior of the sealing body; the heating body (12) is used for heating the sealing body, and accordingly the reaction raw materials in the reactor (2) are pre-heated.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing two-dimensional material by stripping layered material with oxide semiconductor nano-powder

InactiveCN112158888ALow luminous efficiencyEfficient light emittingAmino compound purification/separationOxide/hydroxide preparationNanoparticlePhysical chemistry

The invention relates to a method for preparing a two-dimensional material by stripping a layered material with oxide semiconductor nano-powder. The method comprises the following steps: adsorbing p-type semiconductor nano-particles containing oxygen vacancies (oxygen holes) on the surface of the layered material while reactively adsorbing the semiconductor nano-particles on the surface of the layered material, and carrying out grinding in a grinder to realize inter-layer separation, carrying out stripping to prepare the two-dimensional material which is an intermediate film formed by compounding a single-layer or few-layer atom or molecular layer two-dimensional material and nanoparticles. and then separating the nanoparticles from the two-dimensional film to obtain the two-dimensional material. According to the technology, two types of practical products can be obtained, one type is an intermediate film formed by compounding a single-layer or few-layer atom or molecular layer two-dimensional material and nanoparticles; the other type is a two-dimensional material, and the two types of materials have wide and special applications.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

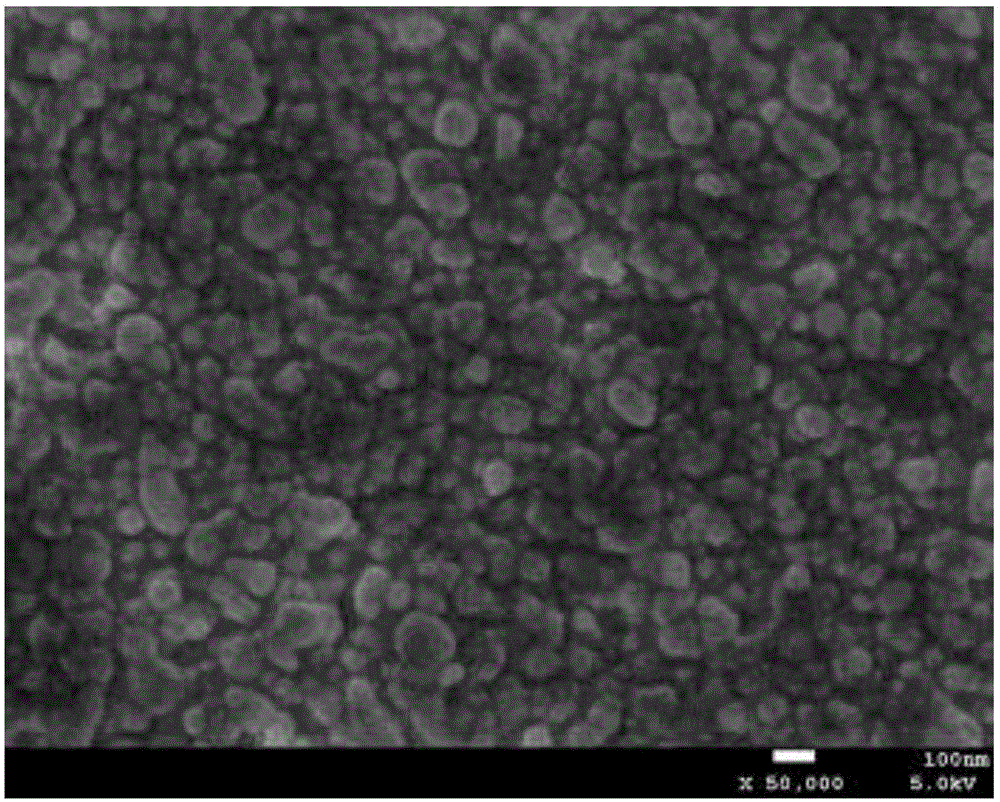

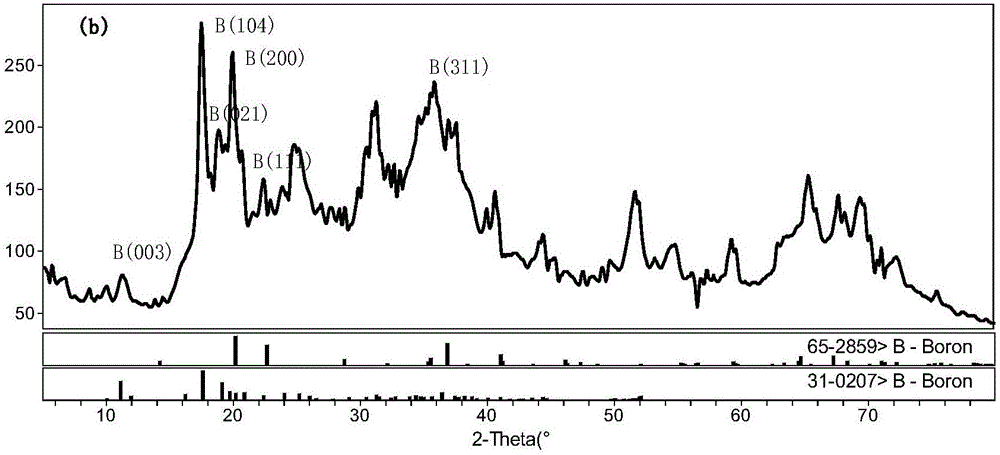

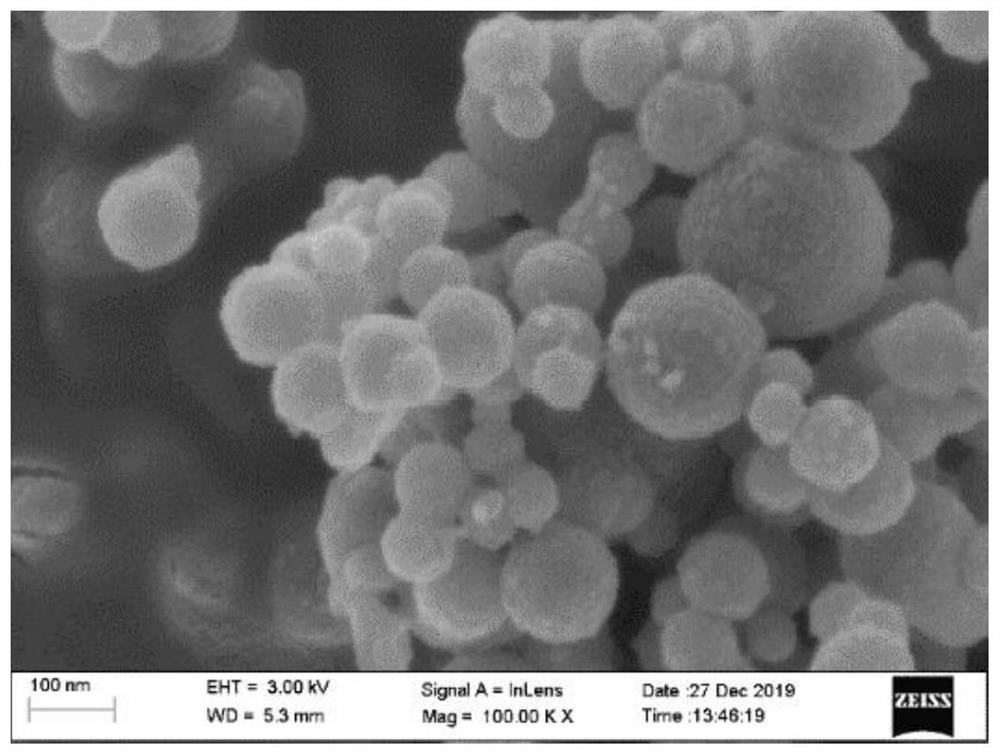

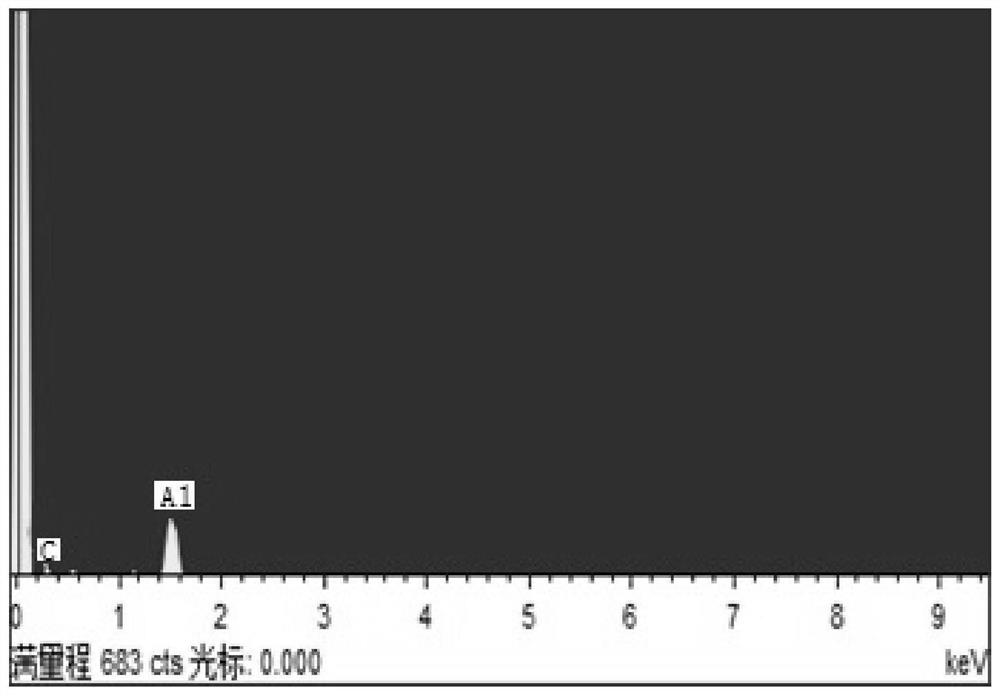

Method and device for preparing high-purity nano boron powder by argon-hydrogen hot plasma method

The invention discloses a method and device for preparing high-purity nano boron powder by an argon-hydrogen hot plasma method. The method includes the following steps: taking argon and hydrogen as arc discharge gas to generate plasma jet at the temperature of thousands of degrees centigrade; introducing the jet into a reactor, quickly mixing with gaseous BCl3 and finishing reduction reaction to generate solid boron and gaseous hydrogen chloride; and carrying out gas-solid separation to obtain solid boron powder. The yield of produced boron powder is above 60%, the obtained product does not need to be treated further and the purity of the product is above 98%, and the average particle size of the product ranges from 30 nm to 150 nm. Compared with the traditional fused salt electrolysis process and hot spreading reduction method, the method has the features that the high-purity boron powder does not need to be subjected to aftertreatment or only needs to be subjected to simple aftertreatment, and technological conditions are simple. Compared with a low-air-pressure plasma process, the method has the features that production is expanded easily, and economy is good.

Owner:SICHUAN YIJIE TECH CO LTD

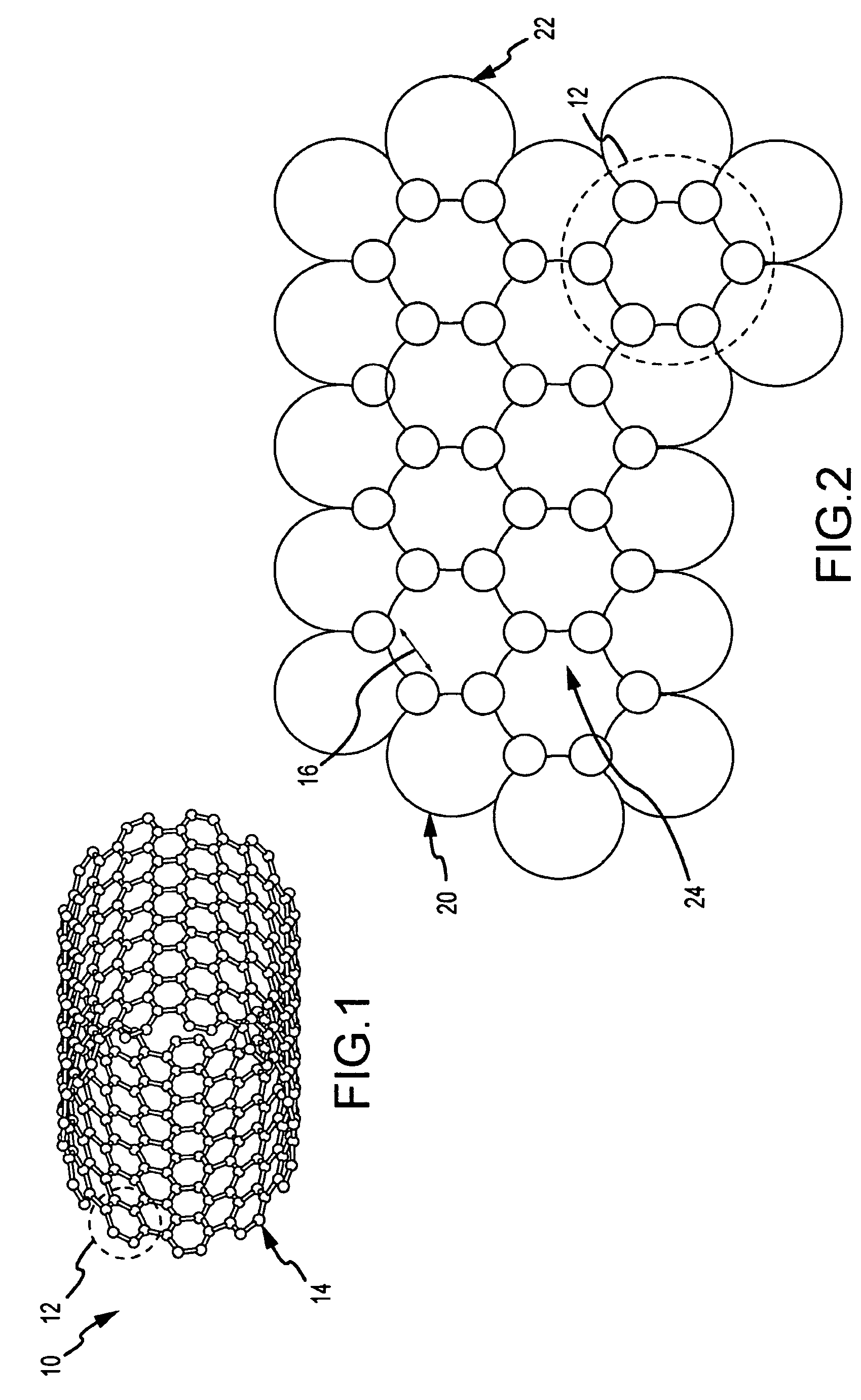

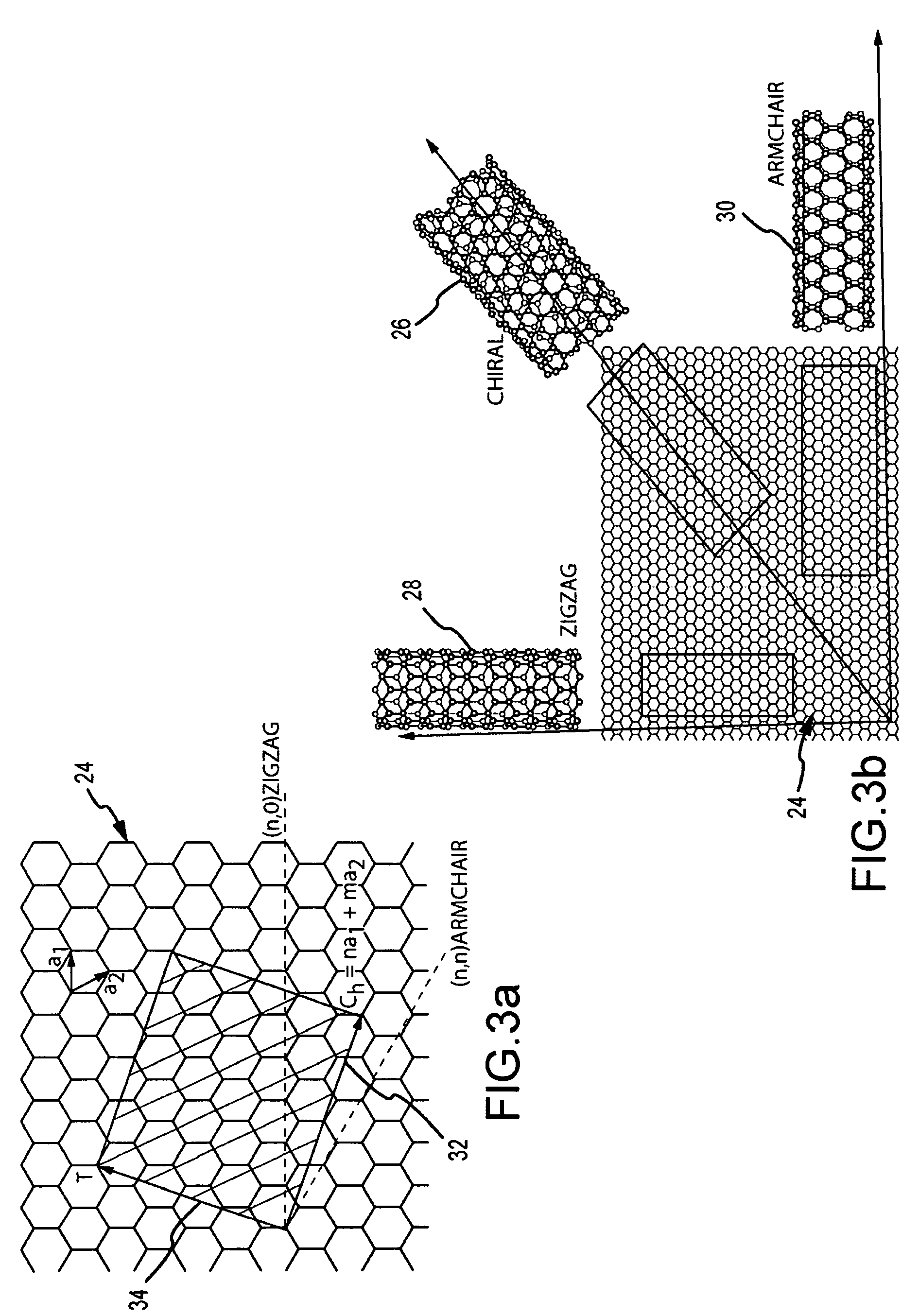

Epitaxial growth and cloning of a precursor chiral nanotube

A precursor chiral nanotube with a specified chirality is grown using an epitaxial process and then cloned. A substrate is provided of crystal material having sheet lattice properties complementary to the lattice properties of the selected material for the nanotube. A cylindrical surface(s) having a diameter of 1 to 100 nanometers are formed as a void in the substrate or as crystal material projecting from the substrate with an orientation with respect to the axes of the crystal substrate corresponding to the selected chirality. A monocrystalline film of the selected material is epitaxially grown on the cylindrical surface that takes on the sheet lattice properties and orientation of the crystal substrate to form a precursor chiral nanotube. A catalytic particle is placed on the precursor chiral nanotube and atoms of the selected material are dissolved into the catalytic particle to clone a chiral nanotube from the precursor chiral nanotube.

Owner:RAYTHEON CO

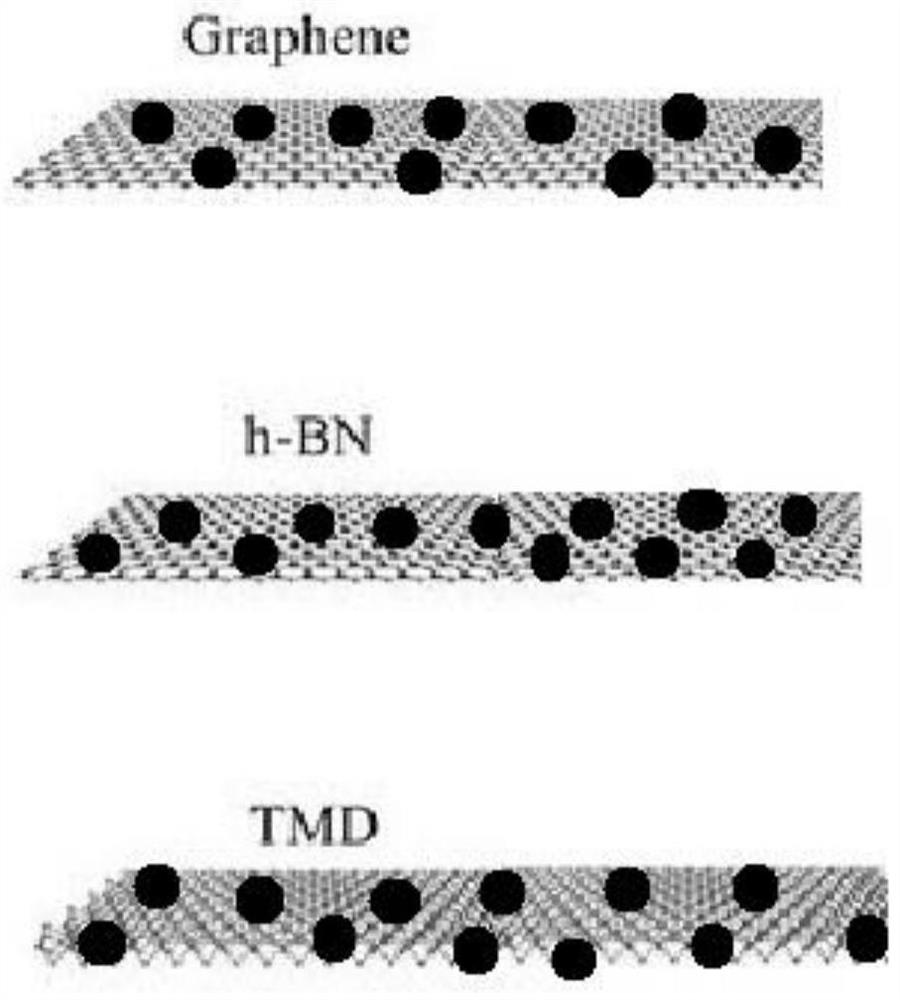

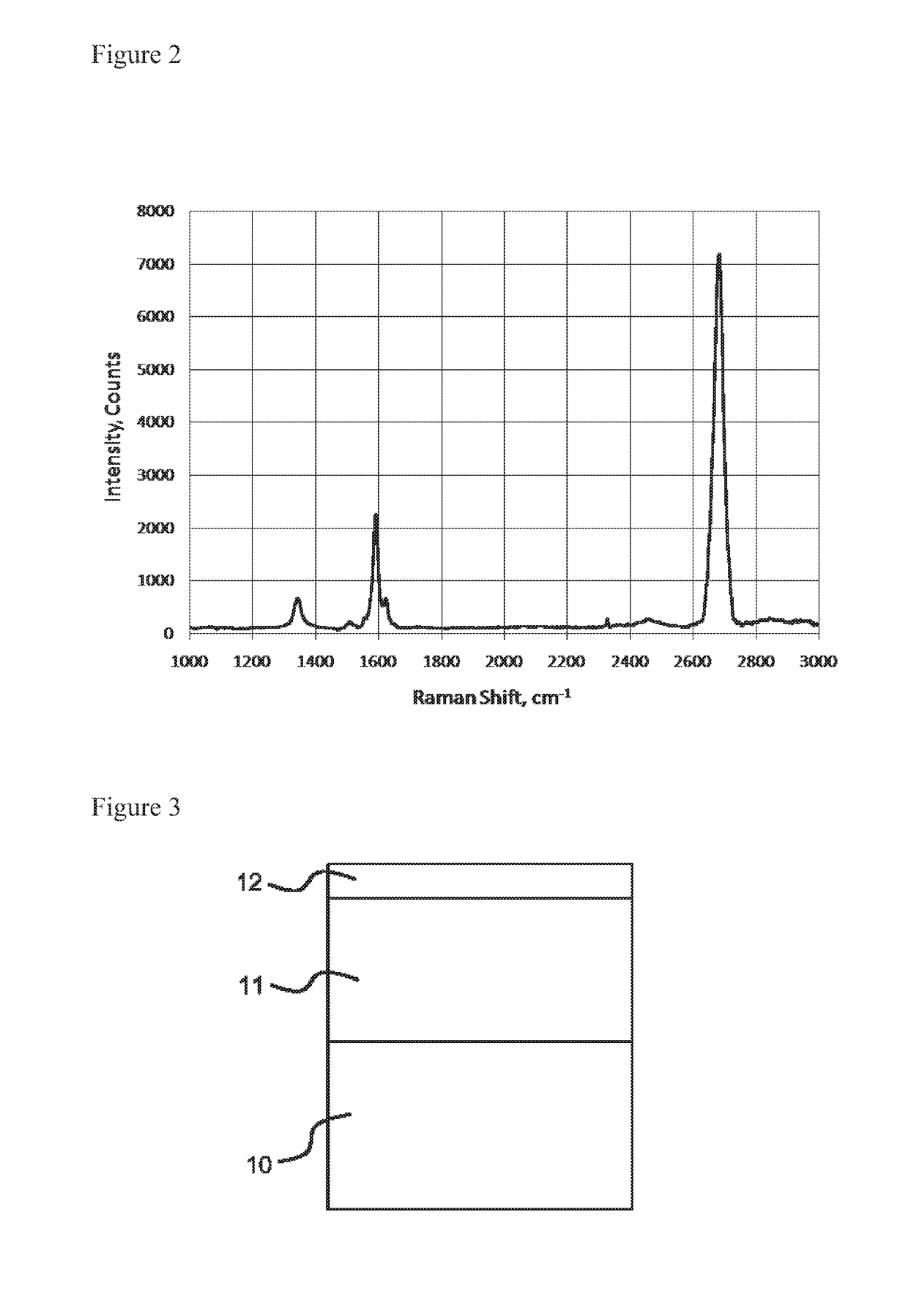

Multi-atomic layered materials

ActiveUS20190292061A1Distorted bonding characteristicDistorted structureMaterial nanotechnologyPolycrystalline material growthMaterials science

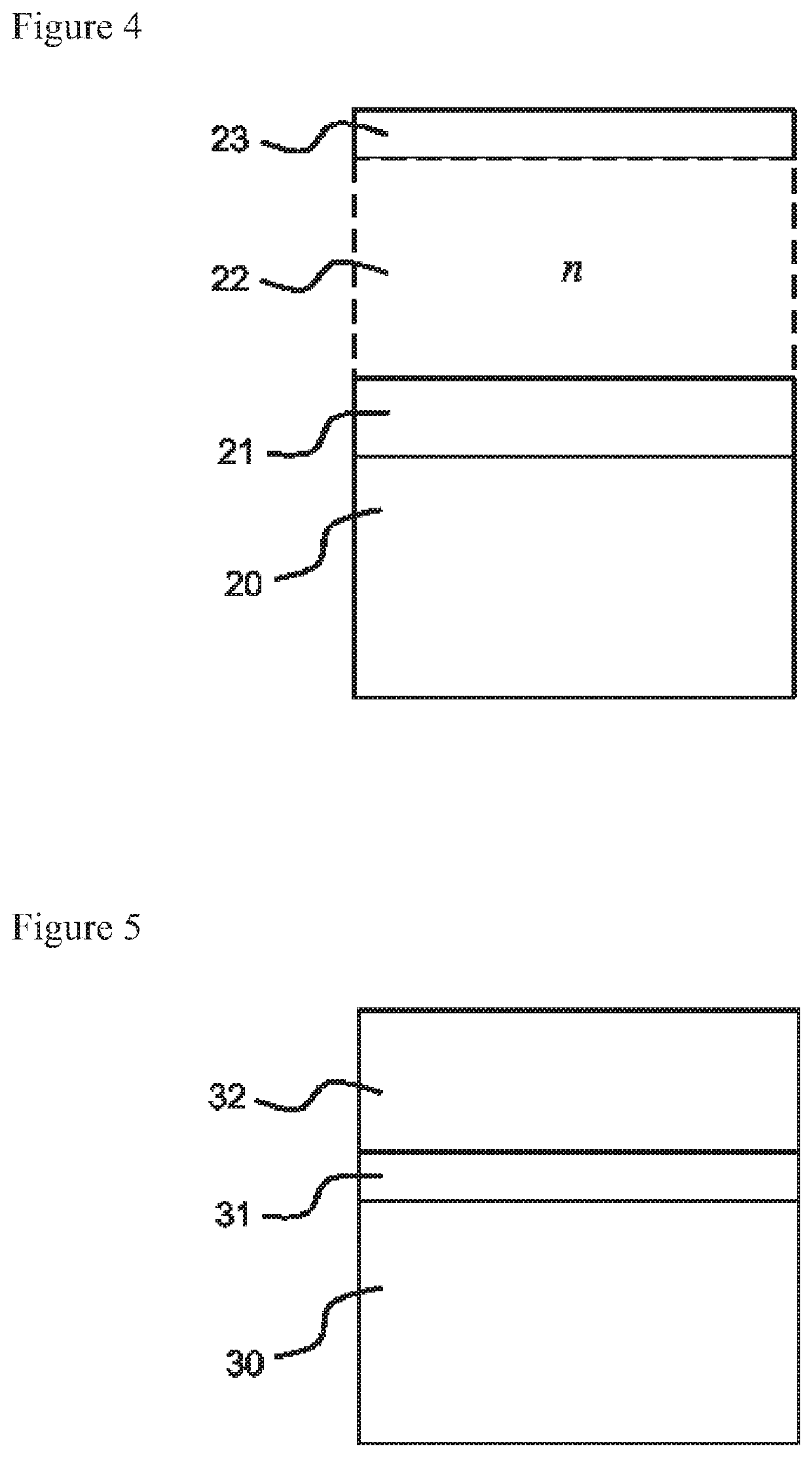

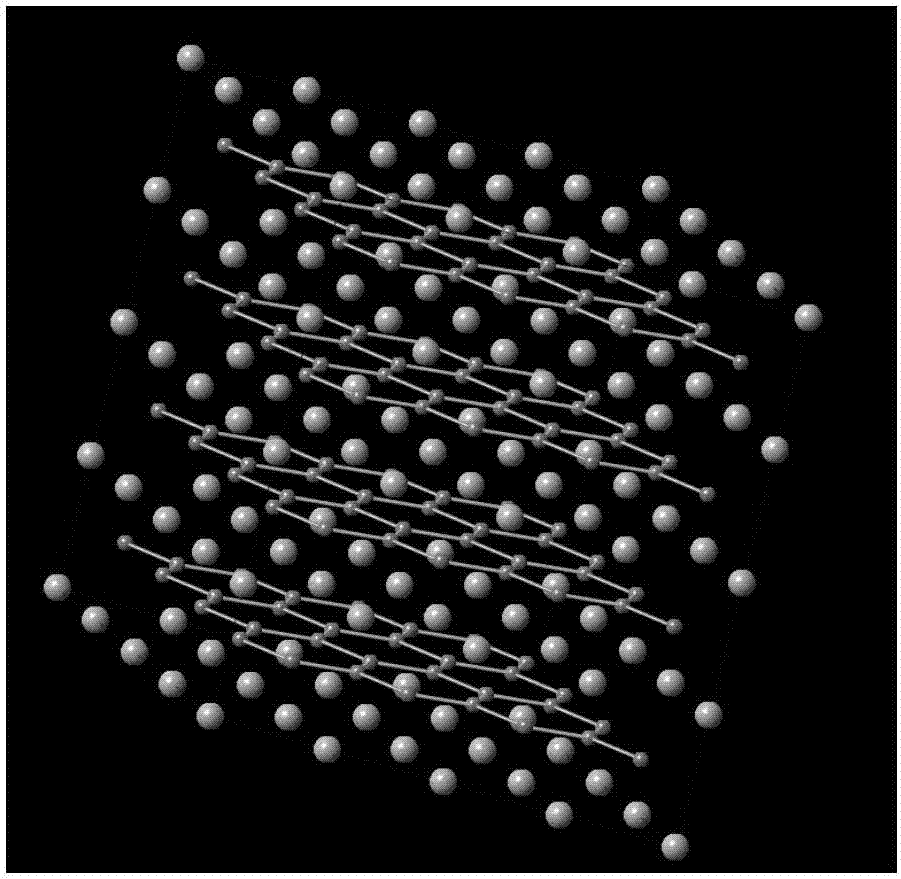

A multi-atomic layered material and methods of making and using the same are described. The material can include a first 2D non-carbon mono-element atomic layer, a second 2D non-carbon mono-element atomic layer, and intercalants positioned between the first and second atomic layers.

Owner:SABIC GLOBAL TECH BV

Fluorescent probe as well as preparation method, application and application method thereof

ActiveCN110451517AGood biocompatibilityStrong fluorescence propertiesPowder deliveryBoronHigh concentrationTriboluminescence

The invention is applicable in the technical field of detection and provides a fluorescent probe as well as a preparation method, application and an application method thereof, wherein the fluorescentprobe is a two-dimensional boroxene nanosheet. The fluorescent probe is the two-dimensional boroxene nanosheet, takes on an obvious two-dimensional layered stacking structure, is about 20 nm in thickness, has strong fluorescence luminescence characteristic, is low in development cost, is simple and convenient in preparation process and is green and pollution-free. Through a test for performing cell biocompatibility on the boroxene nanosheet, the result indicates that even if at high concentration of 400ug / mL, a HeLa cell still can maintain the survival rate to be more than 80 percent on the boroxene nanosheet, and the boroxene nanosheet has high biocompatibility and is suitable for cell bioimaging.

Owner:SHENZHEN UNIV

A method of producing a two-dimensional material

ActiveUS20180308684A1Novel structureLarge grainPolycrystalline material growthBoronDecompositionCrystalline materials

A method of producing graphene or other two-dimensional material such as graphene including heating the substrate held within a reaction chamber to a temperature that is within a decomposition range of a precursor, and that allows two-dimensional crystalline material formation from a species released from the decomposed precursor; establishing a steep temperature gradient (preferably >1000° C. per meter) that extends away from the substrate surface towards an inlet for the precursor; and introducing precursor through the relatively cool inlet and across the temperature gradient towards the substrate surface. The steep temperature gradient ensures that the precursor remains substantially cool until it is proximate the substrate surface thus minimizing decomposition or other reaction of the precursor before it is proximate the substrate surface. The separation between the precursor inlet and the substrate is less than 100 mm.

Owner:PARAGRAF LTD

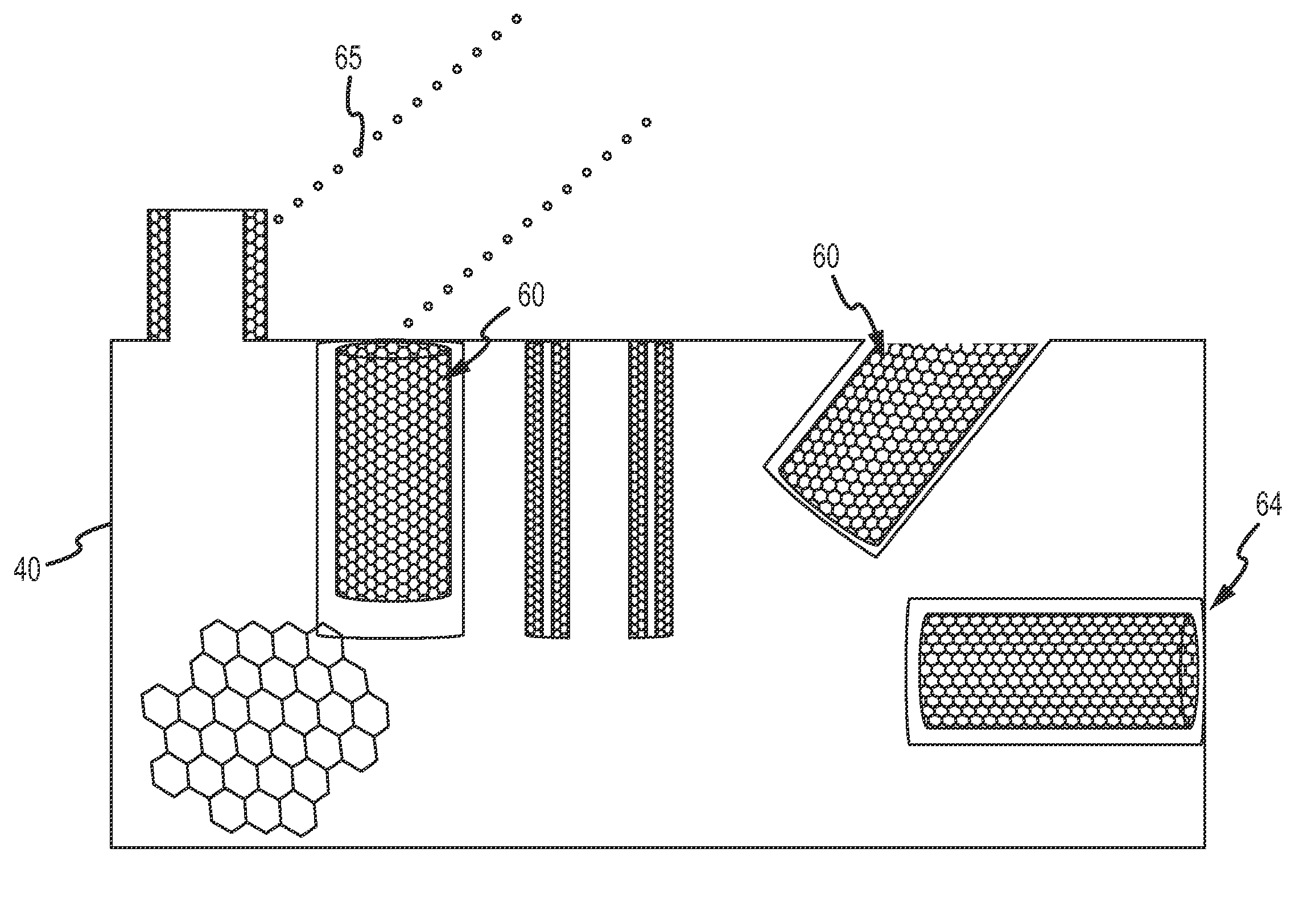

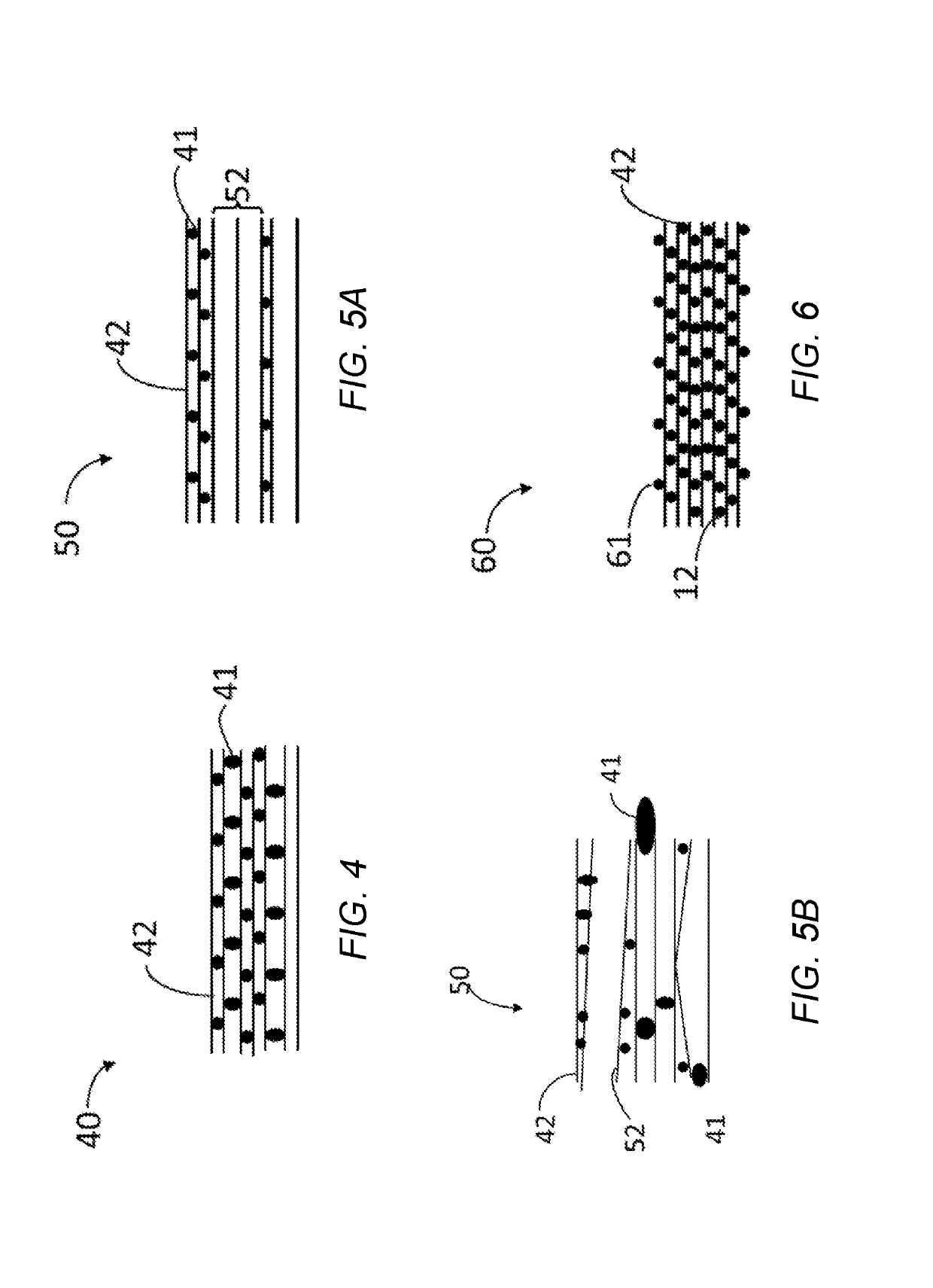

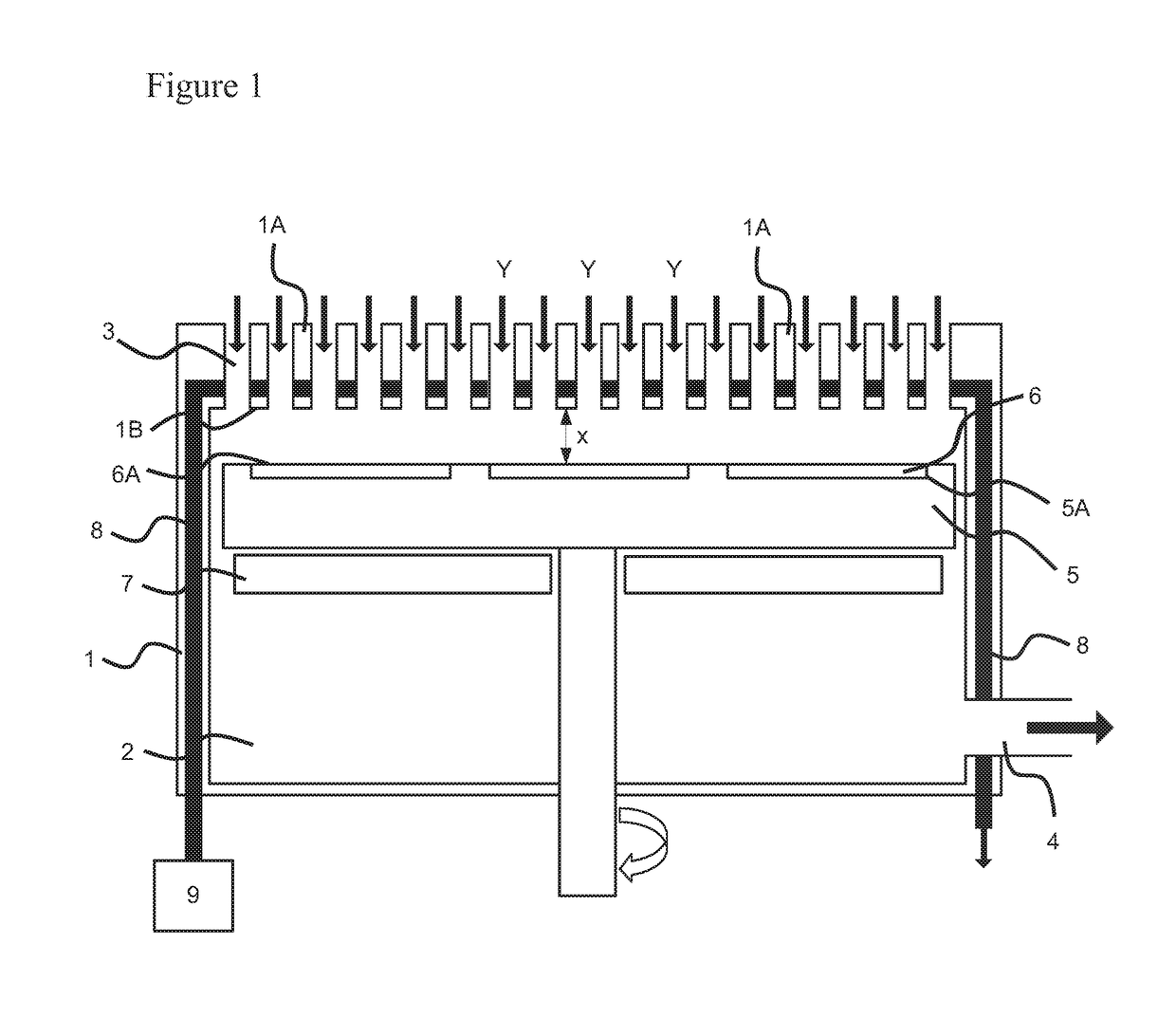

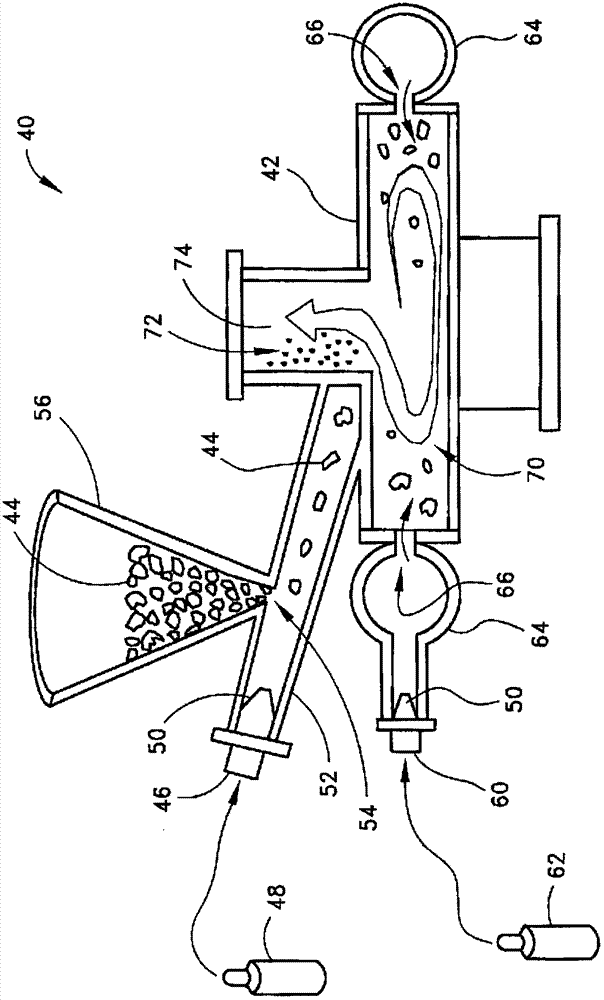

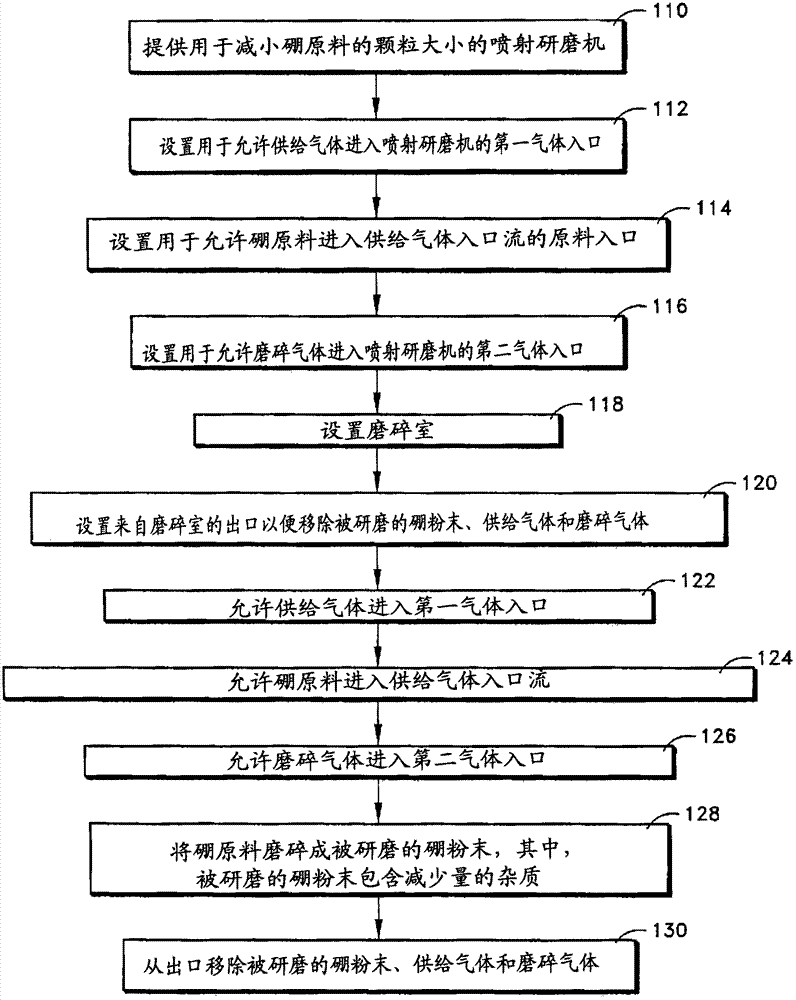

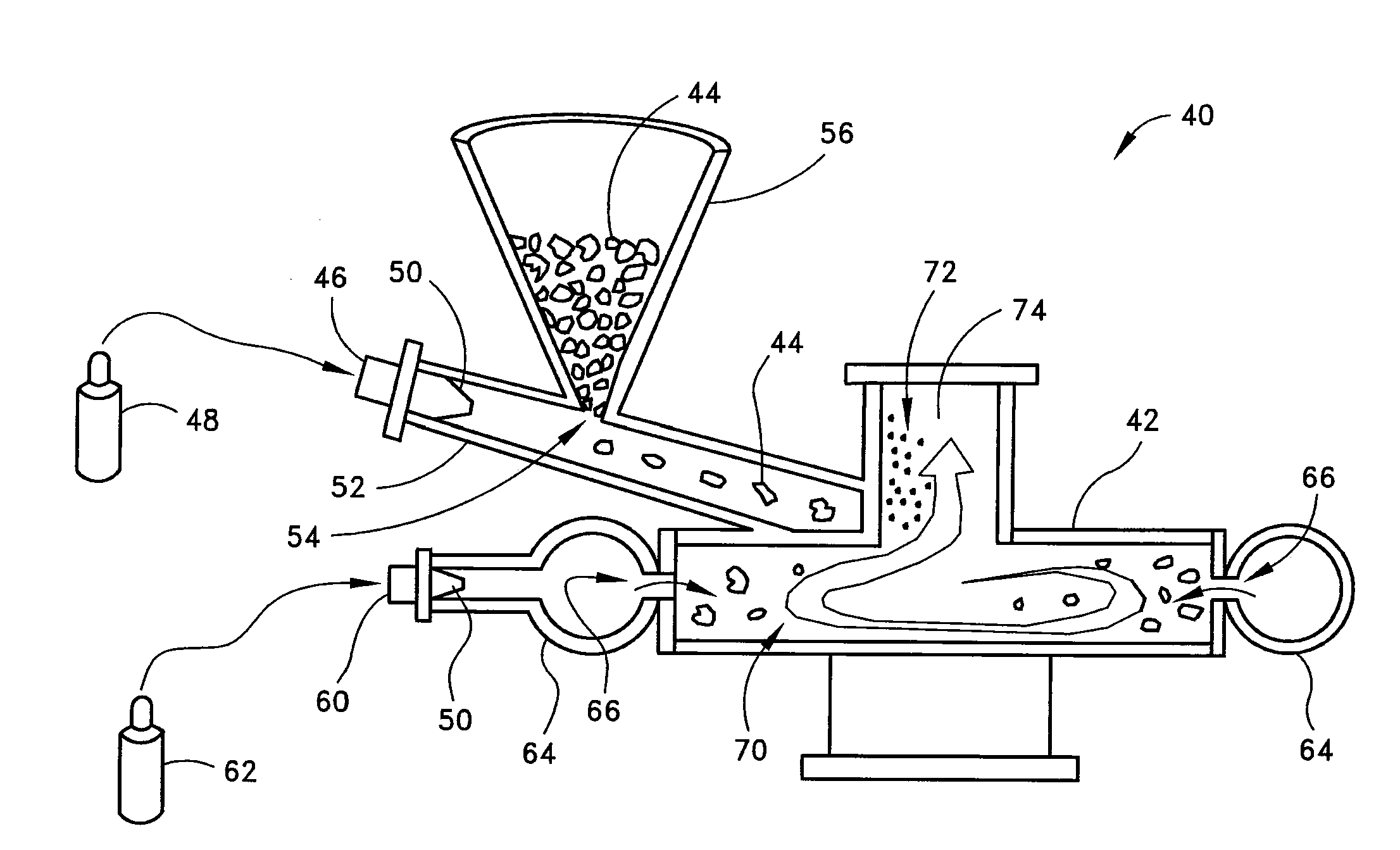

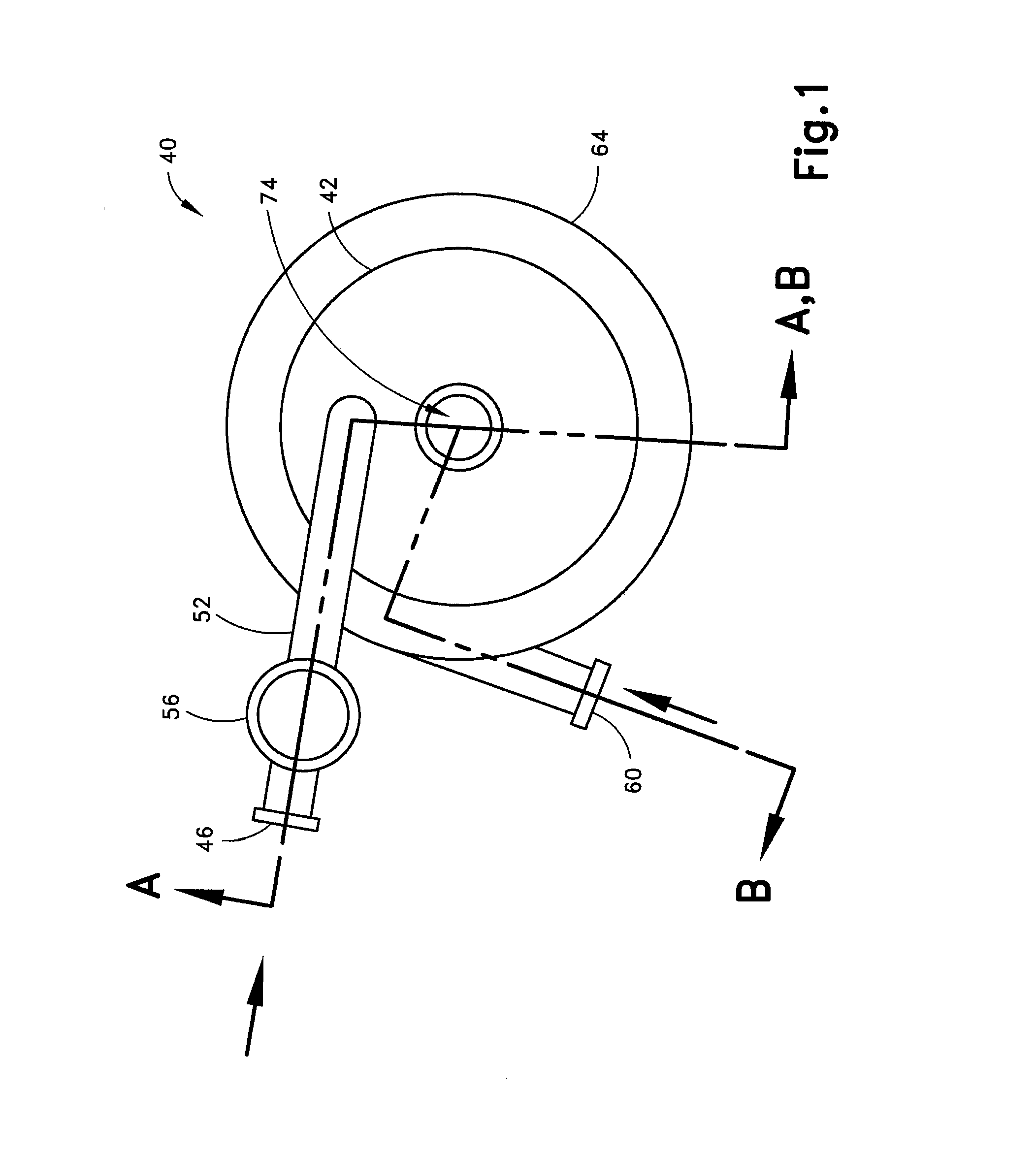

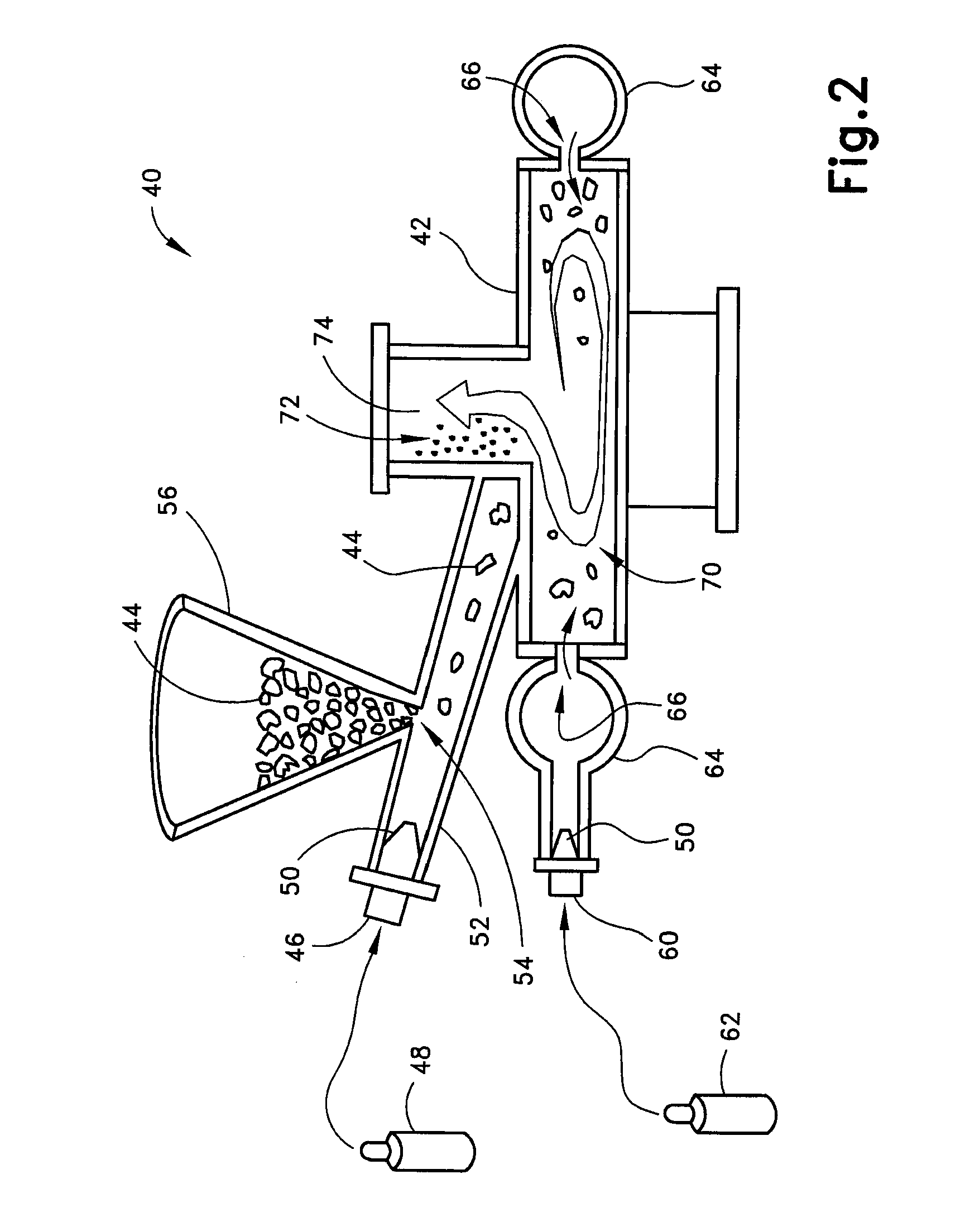

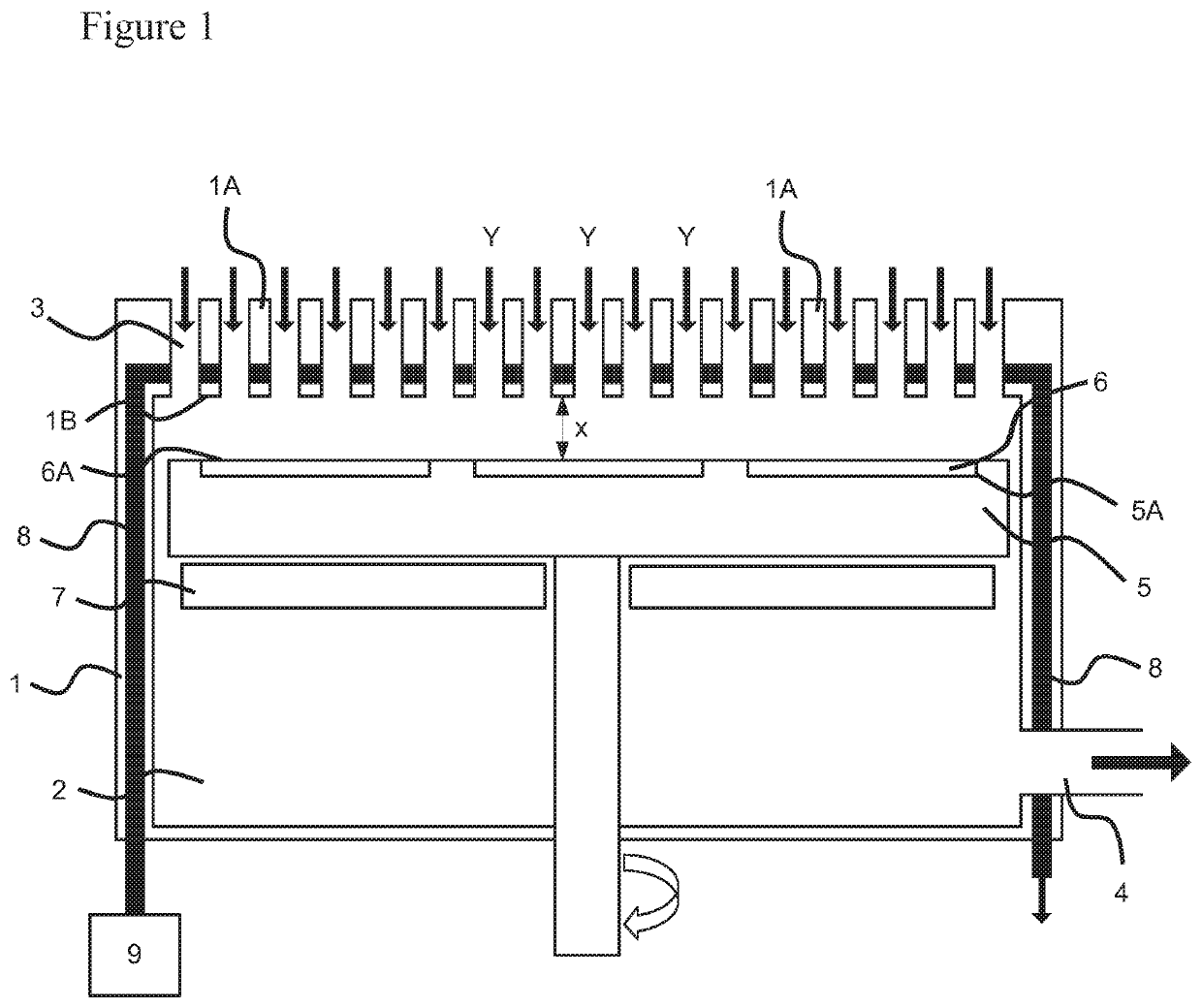

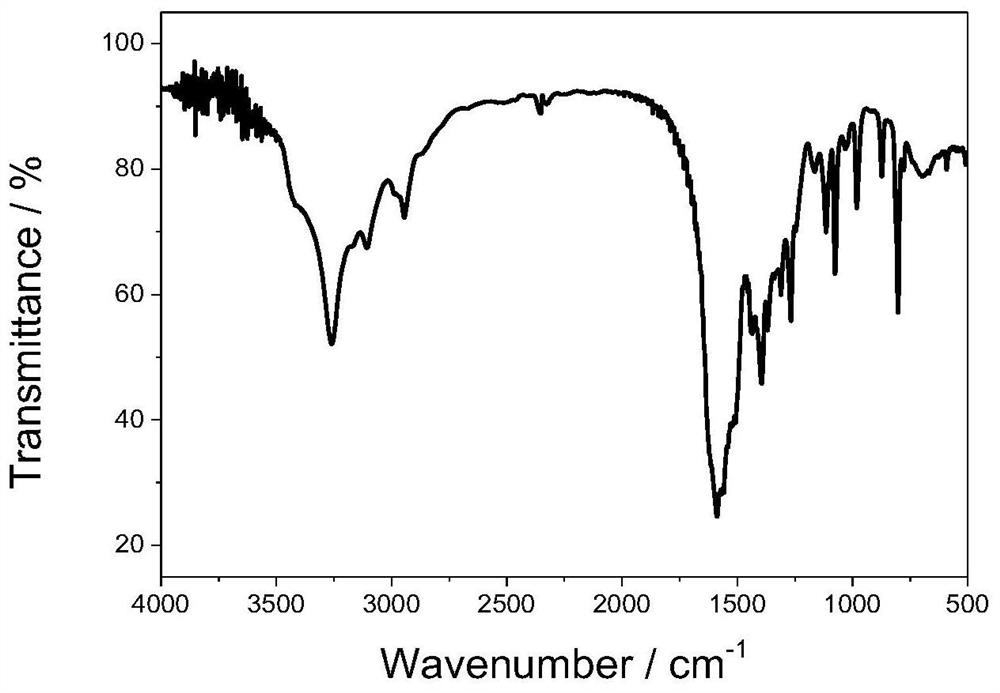

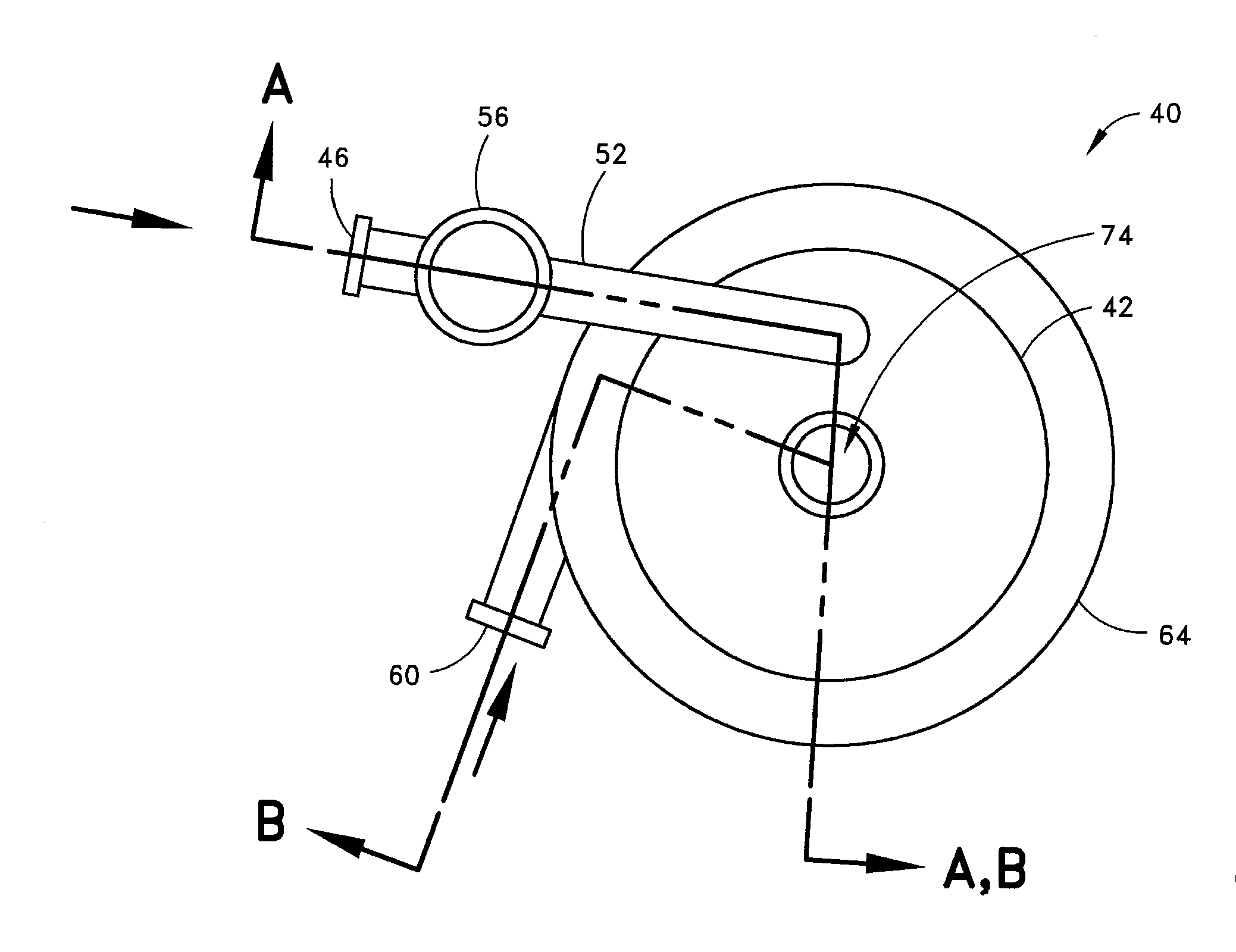

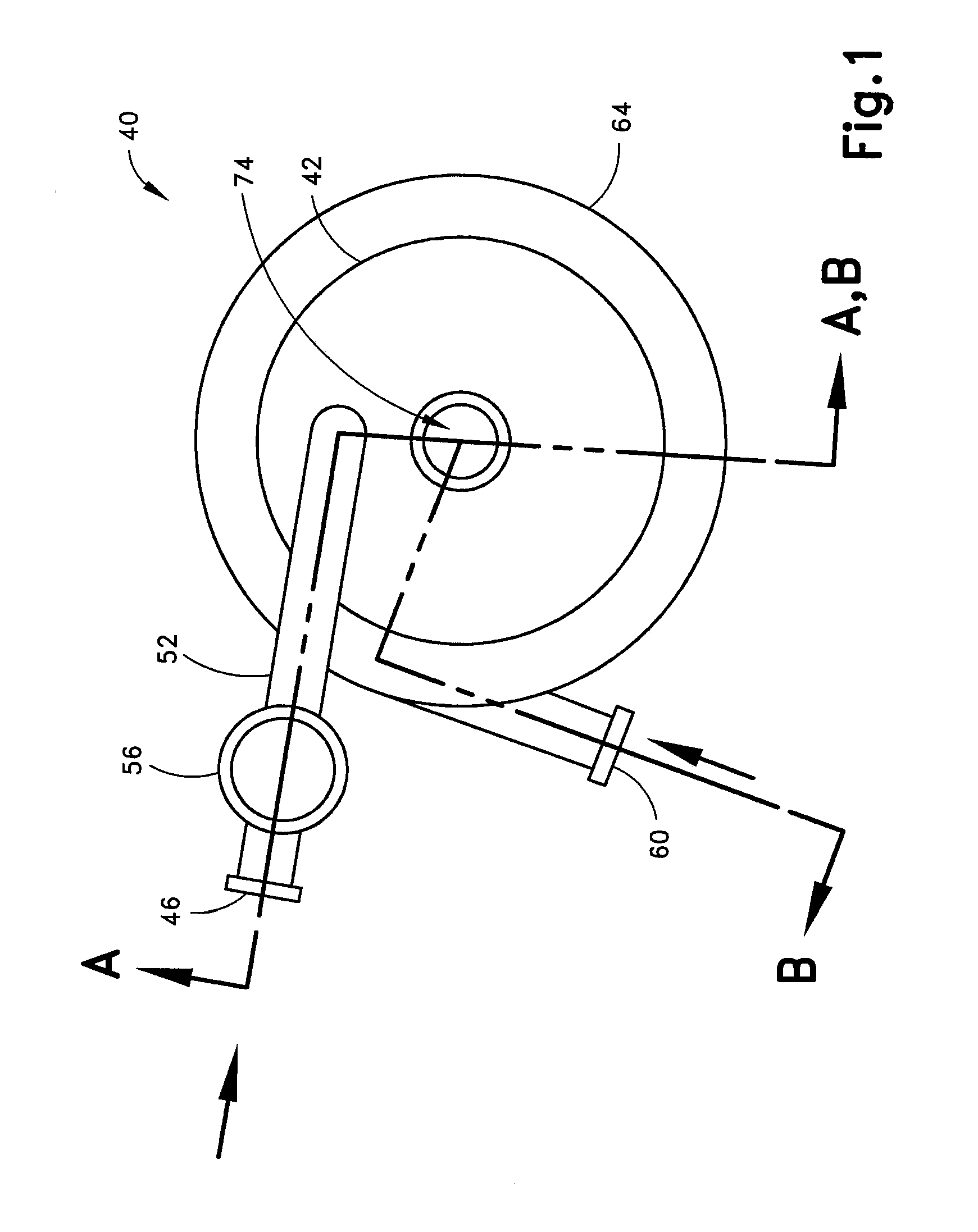

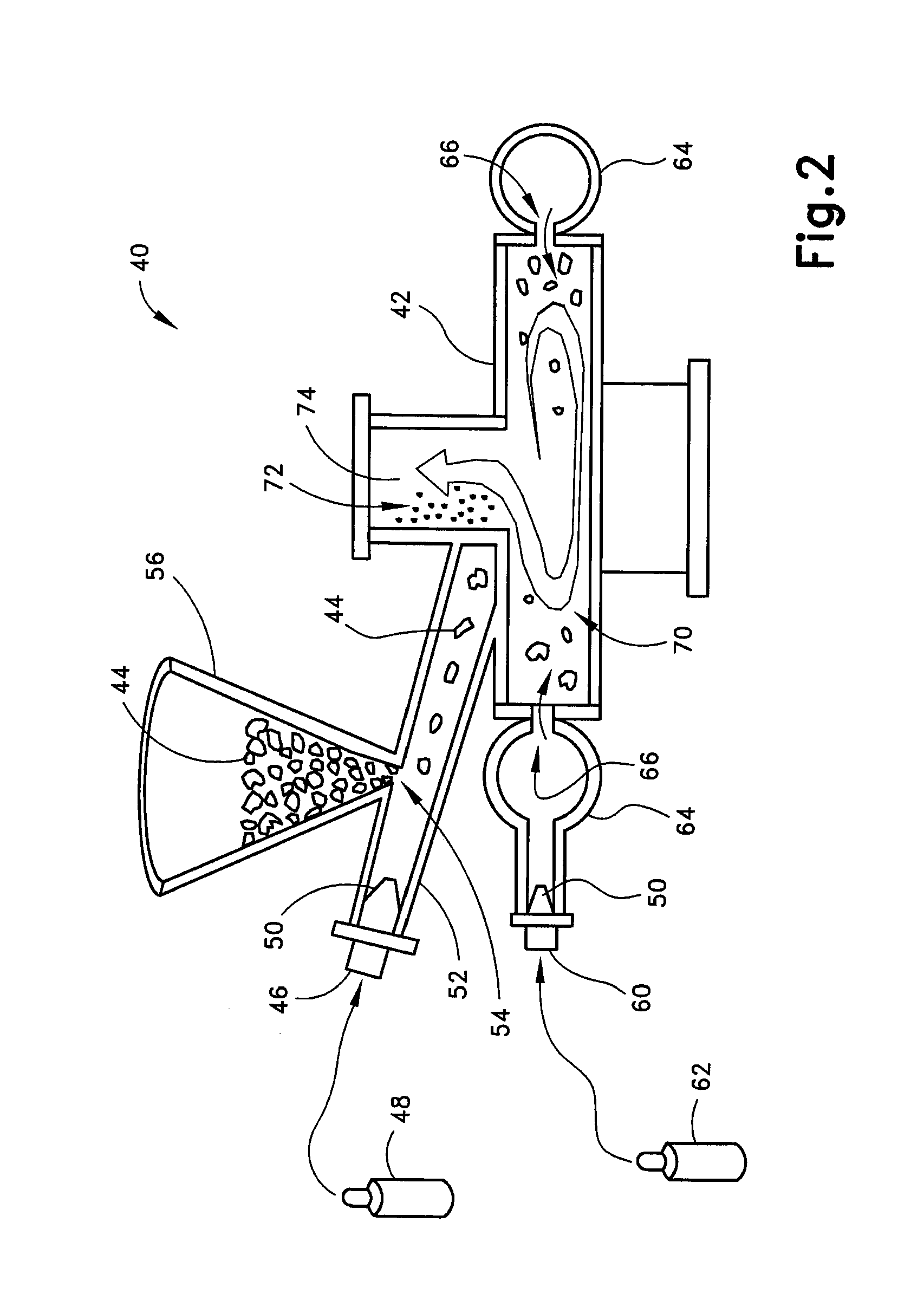

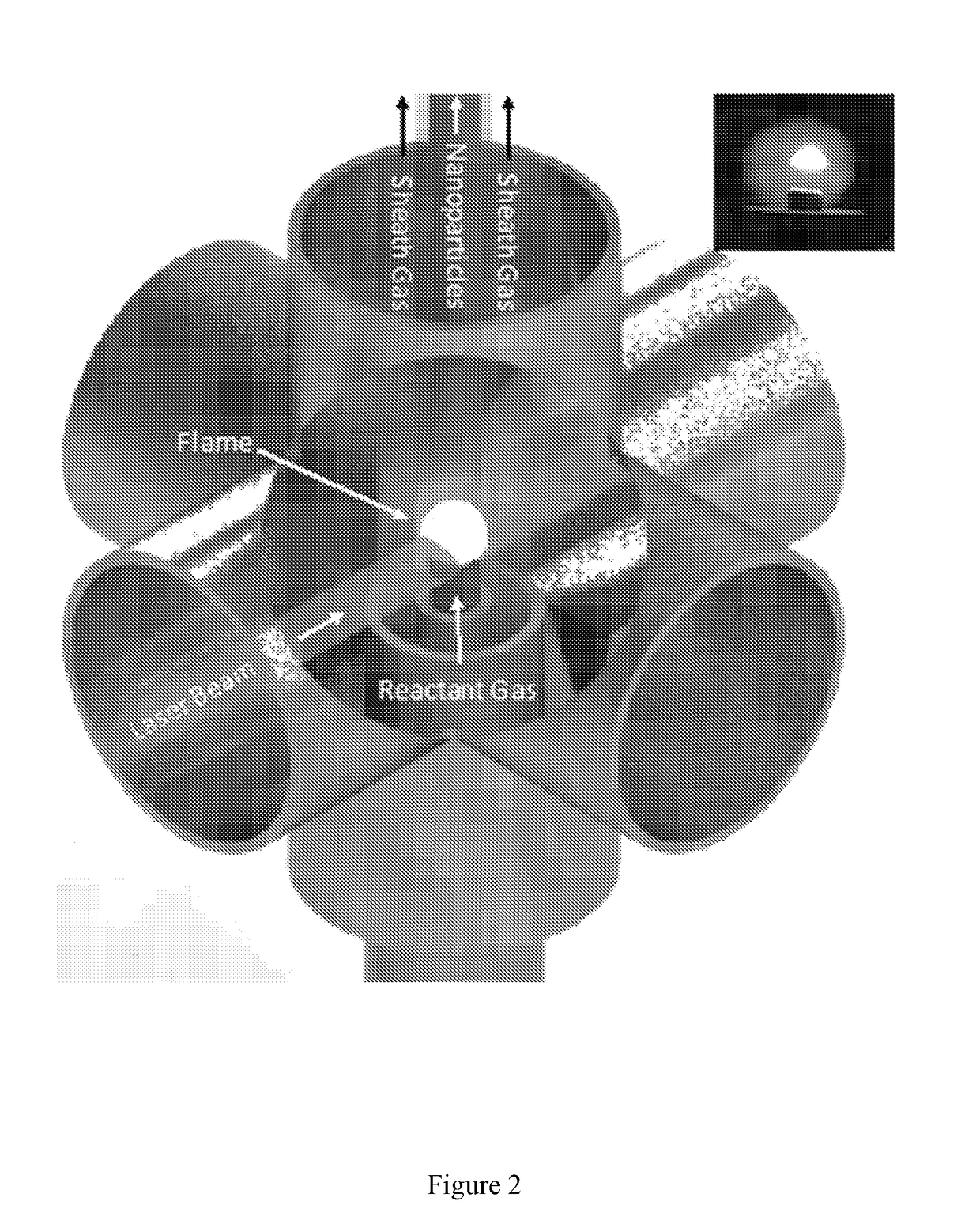

Jet milling of boron powder using inert gases to meet purity requirements

The invention relates to jet milling of boron powder using inert gases to meet purity requirements. A processing system (40) and an associated method for milling boron (44, 72) with impurity contamination avoidance are provided. The system includes a jet mill (42) for reducing the particle size of a boron feed stock (44), and a feed stock inlet (54) for delivering the boron feed stock (44) toward the jet mill (42). The system includes at least one inlet (for example, 46, 60) for delivering at least one gas (for example, 48, 62) into the jet mill (42). The gas and the boron feed stock (44) comingle within the jet mill (42) during milling reduction of boron particle size. The system includes a source of the at least one gas operatively connected to the at least one inlet (for example, 46, 60), with the at least one gas (for example, 48, 62) being a gas that avoids transferring impurity during milling reduction of boron particle size.

Owner:GENERAL ELECTRIC CO

Jet milling of boron powder using inert gases to meet purity requirements

A processing system and associated method for milling boron with impurity contamination avoidance. The system includes a jet mill for reducing the particle size of a boron feed stock, and a feed stock inlet for delivering the boron feed stock toward the jet mill. The system includes at least one inlet for delivering at least one gas into the jet mill. The gas and the boron feed stock comingle within the jet mill during milling reduction of boron particle size. The system includes a source of the at least one gas operatively connected to the at least one inlet, with the at least one gas being a gas that avoids transferring impurity during milling reduction of boron particle size.

Owner:GENERAL ELECTRIC CO

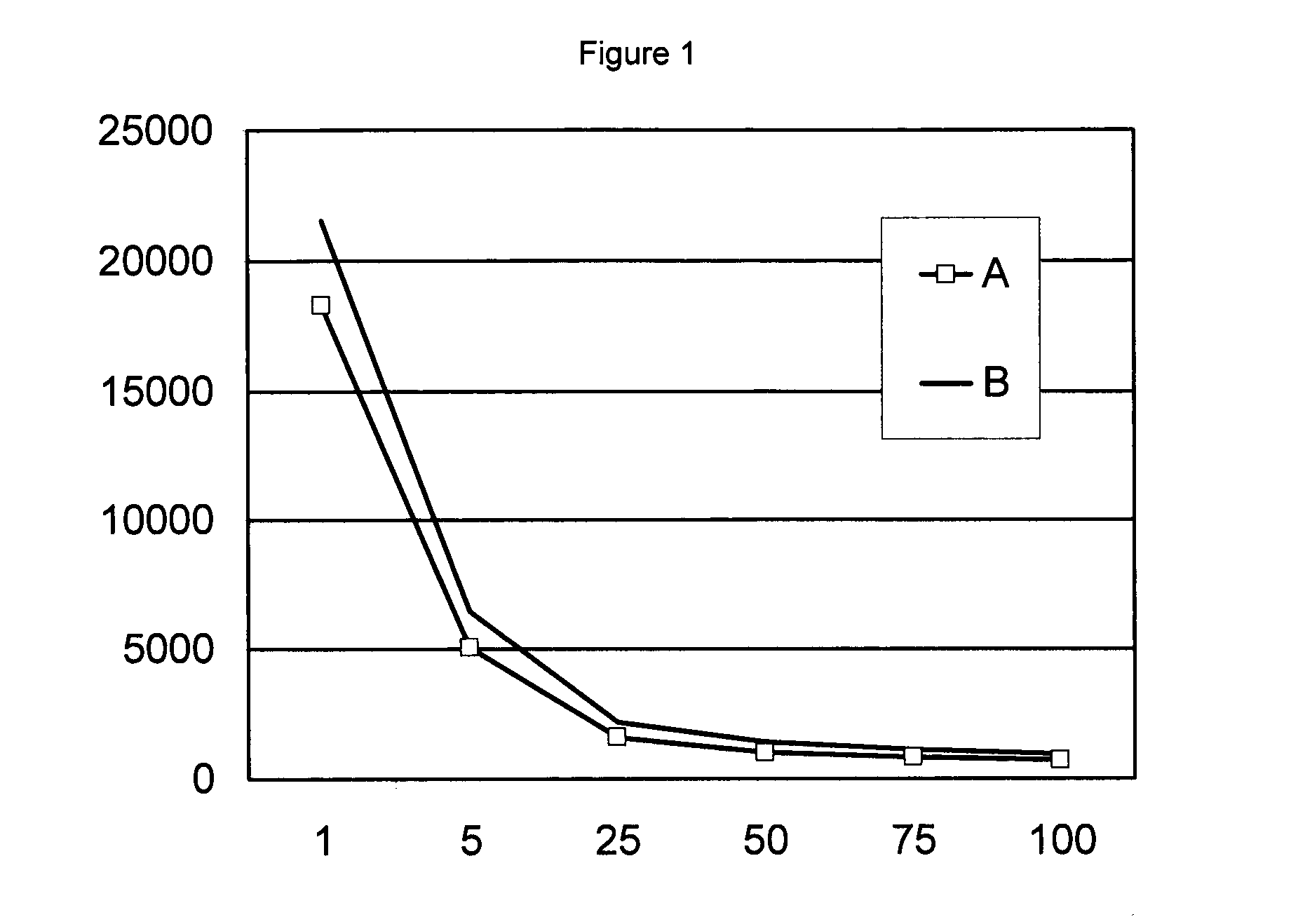

Boron Compound Suspension

ActiveUS20130230605A1Avoid cloggingImpaired movementBiocideCosmetic preparationsHigh concentrationBoron containing

A suspension of a boron containing compound in the form of crystals, powder or granulate in a solvent which contain a carbomer as dispersant. This suspension is very stable, even at high concentrations, and exhibits favourable non-Newtonian viscosity behavior, which makes it suitable in a number of applications, such as for the control of fission reactions with the generation of electric power from nuclear energy.

Owner:C IP SA

Method of producing a two-dimensional material

ActiveUS10593546B2Easy to controlHighly controllablePolycrystalline material growthBoronCrystalline materialsGraphite

A method of producing graphene or other two-dimensional material such as graphene including heating the substrate held within a reaction chamber to a temperature that is within a decomposition range of a precursor, and that allows two-dimensional crystalline material formation from a species released from the decomposed precursor; establishing a steep temperature gradient (preferably >1000° C. per meter) that extends away from the substrate surface towards an inlet for the precursor; and introducing precursor through the relatively cool inlet and across the temperature gradient towards the substrate surface. The steep temperature gradient ensures that the precursor remains substantially cool until it is proximate the substrate surface thus minimizing decomposition or other reaction of the precursor before it is proximate the substrate surface. The separation between the precursor inlet and the substrate is less than 100 mm.

Owner:PARAGRAF LTD

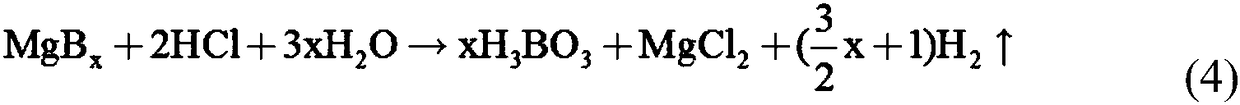

Method for preparing layered boron material through liquid phase method

The present invention relates to a method for preparing a layered boron material through a liquid phase method. The method comprises: (1) adding a metal boride into a dispersant containing an oxidizing agent at a room temperature under a normal temperature, and carrying out a reaction to obtain a layered boron material and a metal salt; and (2) washing the material obtained after the reaction in the step (1) to remove the metal salt, and drying the remaining material to obtain the layered boron material.

Owner:BEIJING UNIV OF CHEM TECH

Method for improving oxidation resistance of active Ti/2B nano powder material

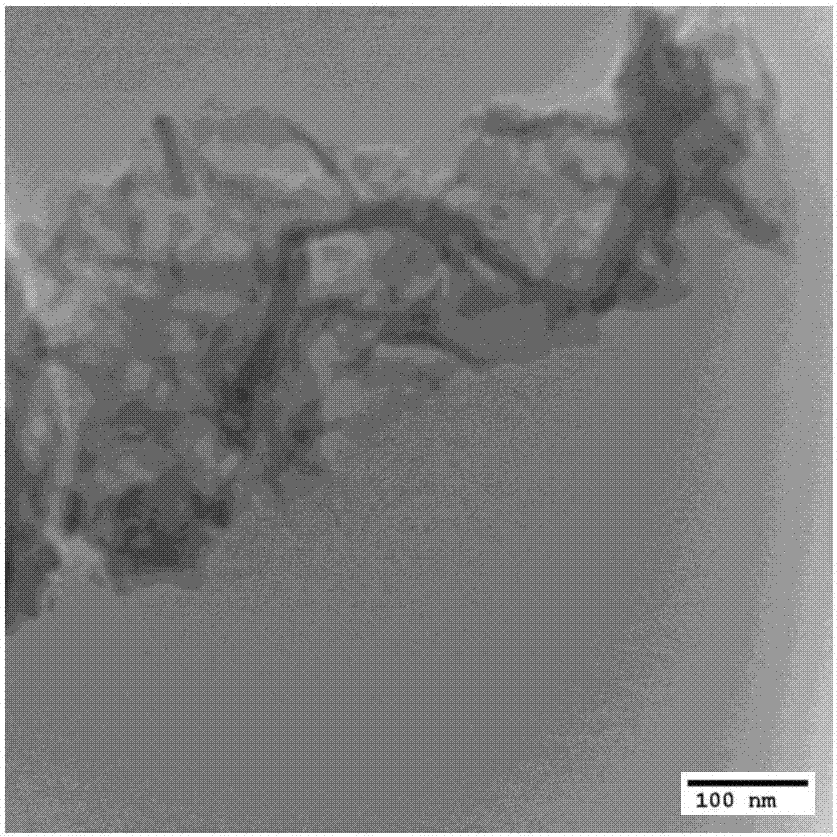

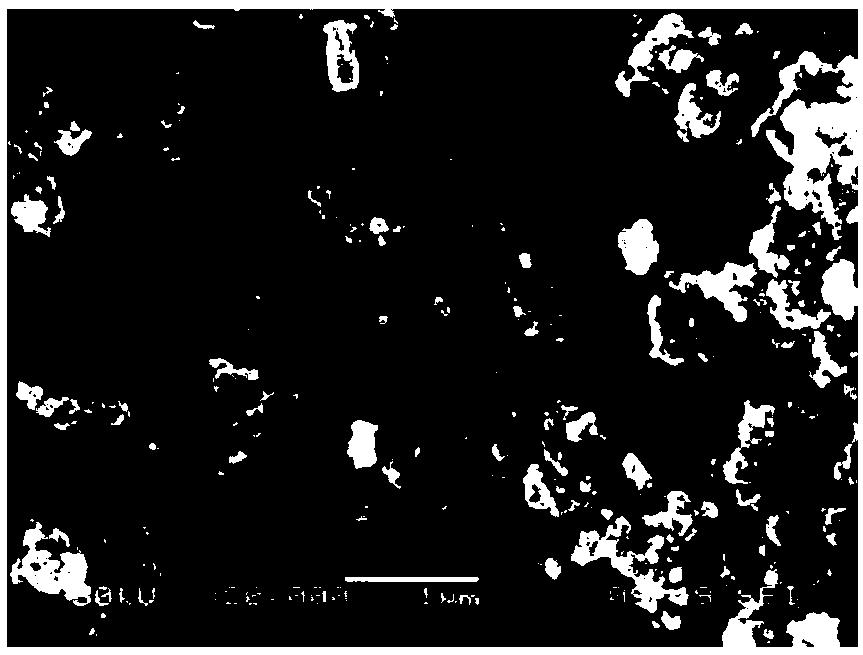

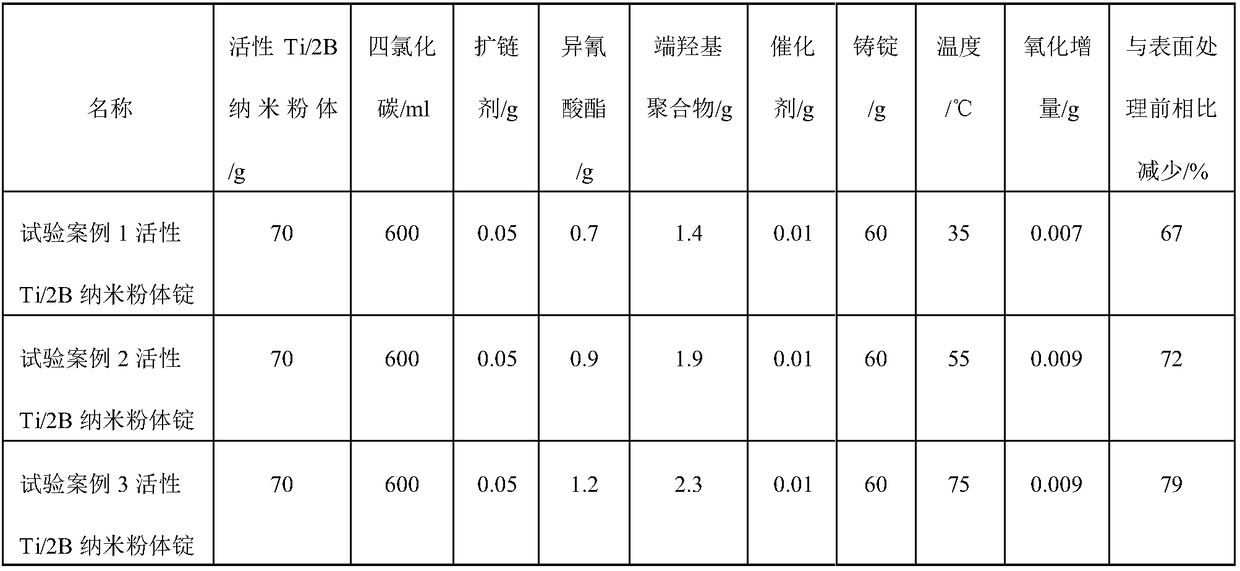

ActiveCN108640805AAvoid reunionImprove antioxidant capacityBoronNanotechnologyIn situ polymerizationOxide

The invention relates to a method for improving oxidation resistance of an active Ti / 2B nano powder material, and belongs to the technical field of surface treatment of nano energy-containing materials. In view of the oxidizing problem of active Ti / 2B nanopowder, the active Ti / 2B nanopowder is dispersed by a high temperature ball milling method in an absolutely dry and anaerobic environment underpure Ar gas, and then in-situ polymerization is carried out to form a thin polyurethane film on the surface of nanoparticles to coat the Ti / 2B nano-powder particles, so that the Ti / 2B nano-powder particles are separated from air to prevent further oxidation. The prepared active Ti / 2B nano powder material has markedly-improved oxidation resistance. The thin polyurethane film is formed on the surface of the nanoparticles to coat the Ti / 2B nano-powder particles to improve the oxidation resistance according to the preparation process. The prepared active Ti / 2B nano-powder material is measured as follows: the weight gain of a sample is measured, and the reduction of measured oxide increment reaches 79%, and indicates that the oxidation resistance is remarkably improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

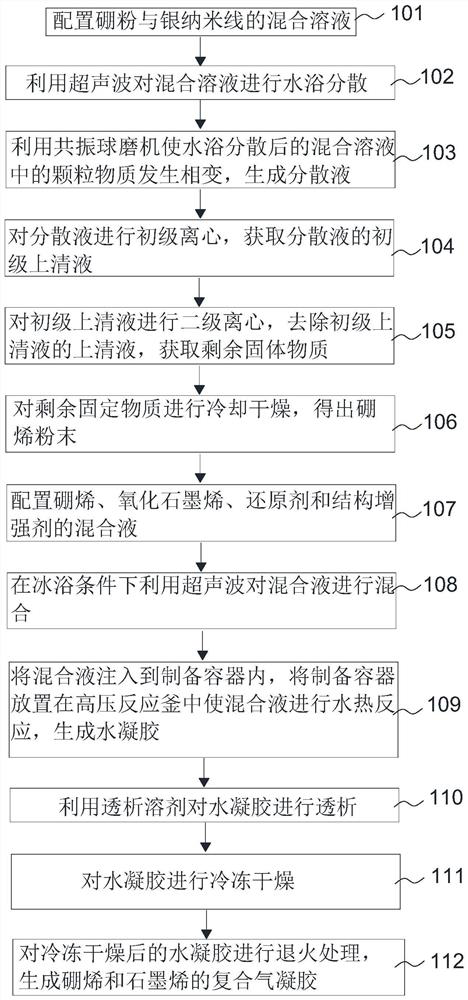

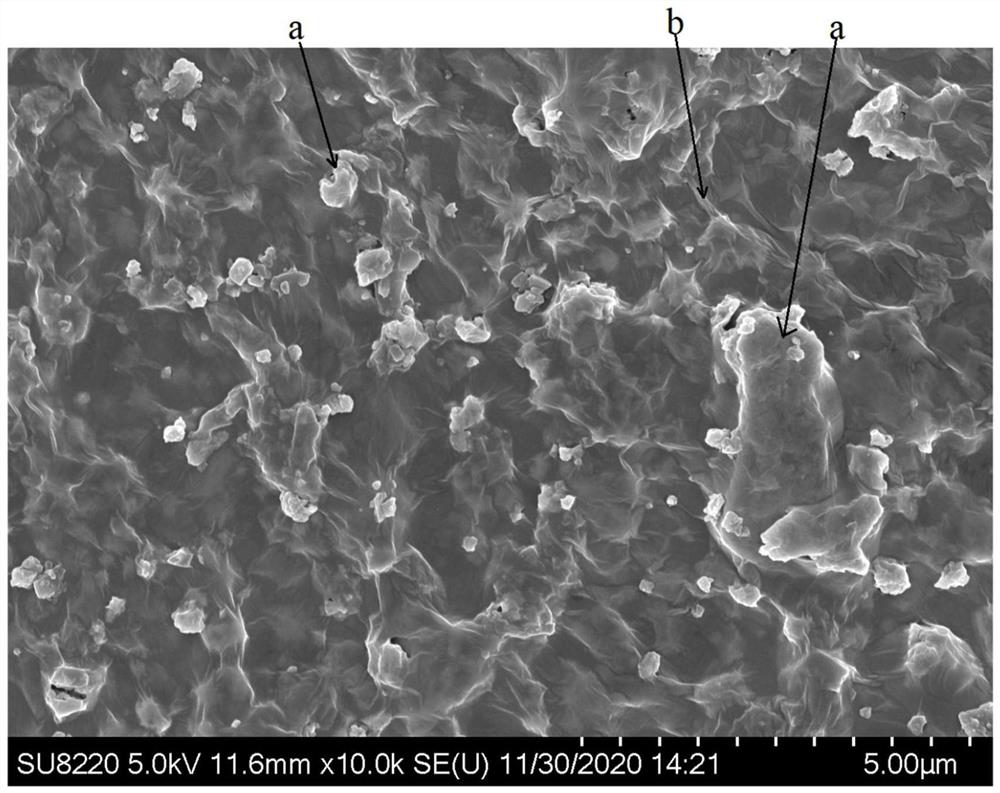

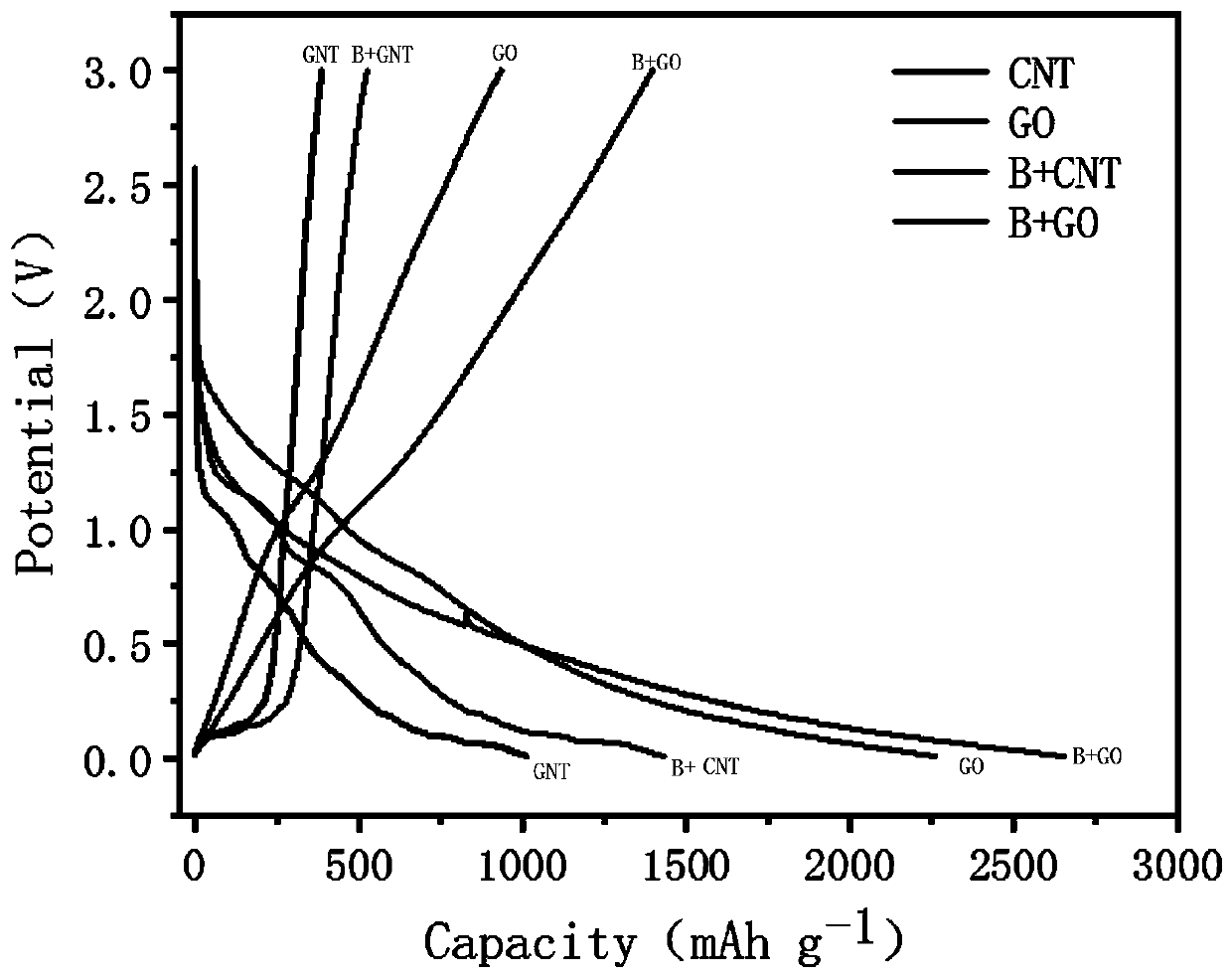

Preparation method and preparation container of boron alkene and graphene composite aerogel electrode plate

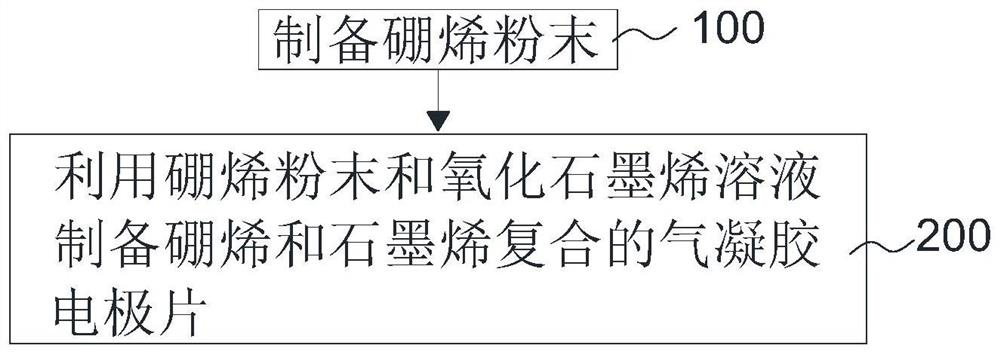

PendingCN114512656ASolve structural instability problemsImprove conductivityMaterial nanotechnologyCell electrodesHeterojunctionGel electrode

The invention provides a preparation method and a preparation container of a boron alkene and graphene composite aerogel electrode plate. The preparation method comprises the following steps: preparing boron alkene powder; and preparing the boron alkene and graphene composite aerogel electrode plate by using the boron alkene powder and the graphene oxide solution. The problem of structure instability after boron alkene loses metal substrate support is solved, the properties of boron alkene are fully utilized, boron alkene and graphene are combined to form a heterojunction, and the boron alkene / graphene heterojunction aerogel electrode plate is prepared and applied to a lithium ion battery negative electrode. The prepared aerogel electrode plate has excellent conductivity, an additional collector electrode is not needed in a battery, and the synthesized boron-alkene / graphene aerogel electrode plate has large specific capacity which is improved by 39% compared with a graphene skeleton without addition of boron-alkene. And meanwhile, the aerogel electrode plate is relatively good in high-rate charge-discharge performance.

Owner:TSINGHUA UNIV

Preparation method and application of powder material

ActiveCN112207285AEasy to manufactureHigh purityMaterial nanotechnologyTransportation and packagingMicron scaleAlloy

The invention relates to a preparation method and application of a powder material. The preparation method comprises the following steps of obtaining an initial alloy strip containing a matrix phase and a dispersed particle phase through solidification of an alloy melt, removing the matrix phase in the initial alloy strip, and retaining the dispersed particle phase at the same time, so as to obtain the powder material composed of the original dispersed particle phase. The preparation method is simple in process, can be used for preparing nano-scale, sub-micron-scale and micron-scale powder materials with various sizes, and has a good application prospect in the fields of catalytic materials, powder metallurgy, composite materials, wave-absorbing materials, sterilization materials, metal injection molding, 3D printing, coatings and the like.

Owner:赵远云

Method for preparing boron nano material through arc discharge

InactiveCN105731480AIncrease production capacityHigh purityBoronNanotechnologyPowder mixtureNanomaterials

The invention relates to a method for preparing a boron nano material through arc discharge, and belongs to a method for preparing a nano material. The invention mainly aims to solve the technical problems of poor product purity, low preparation efficiency and low production of the existing method for preparing a nano material through arc discharge. The technical scheme of the invention is that the method for preparing the boron nano material through arc discharge comprises the following steps: (1) mixing boron powder and high-boiling-point metal powder according to a volume ratio of (1-10):1 to prepare a powder mixture; (2) installing a pure tungsten negative electrode and a mixed positive electrode in a reaction cavity of an arc discharge device, wherein the mixed positive electrode and the pure tungsten negative electrode are connected with a power supply, and the mixed positive electrode is a mixed electrode prepared from a powder mixture and a tungsten crucible; (3) performing evacuation on the reaction cavity, and then introducing a working gas; (4) switching on a power supply to perform arc discharge, and keeping the discharge current and the voltage stable during discharge; and (5) after discharge, collecting a product in the reaction cavity under the protection of argon gas.

Owner:SHANXI UNIV

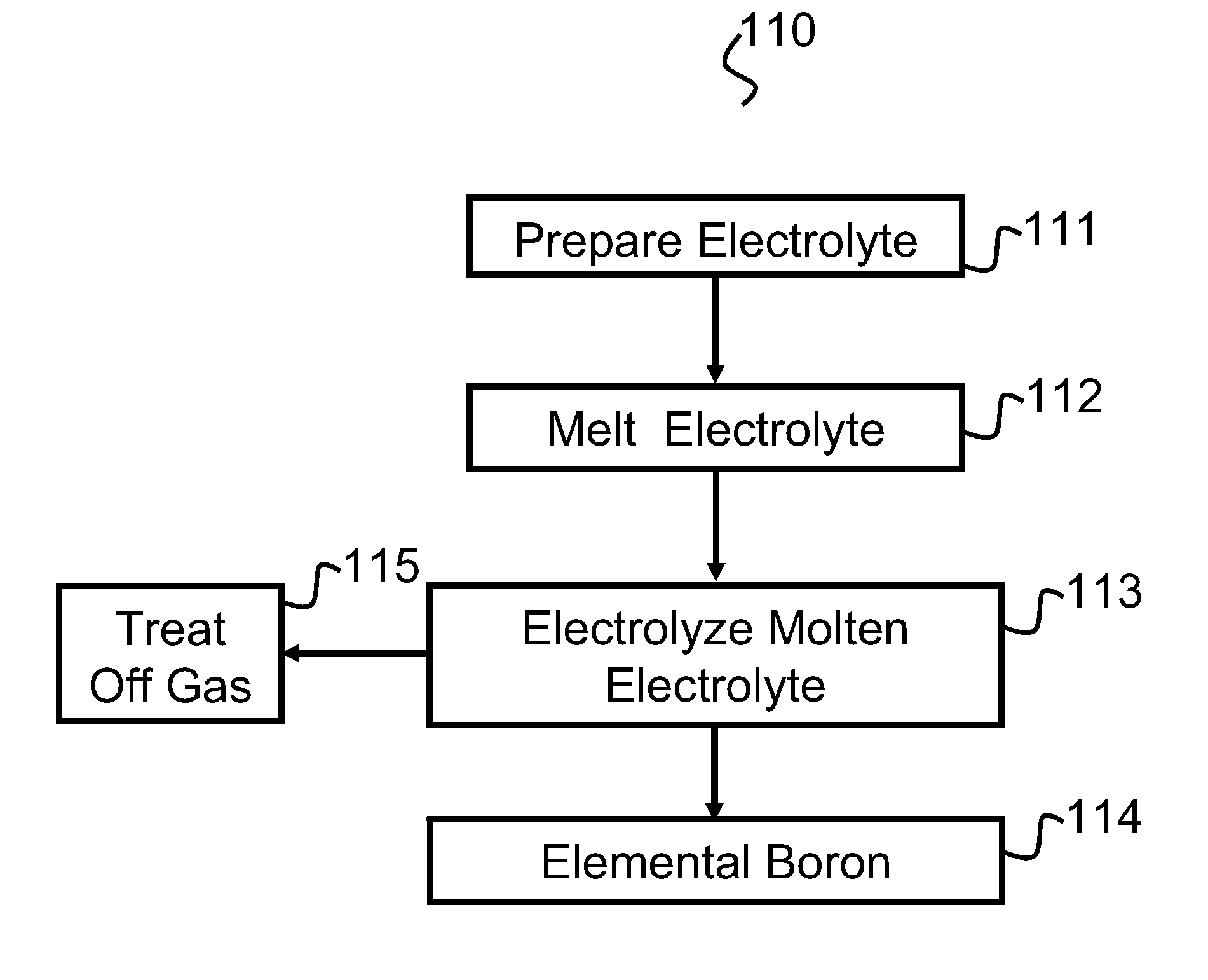

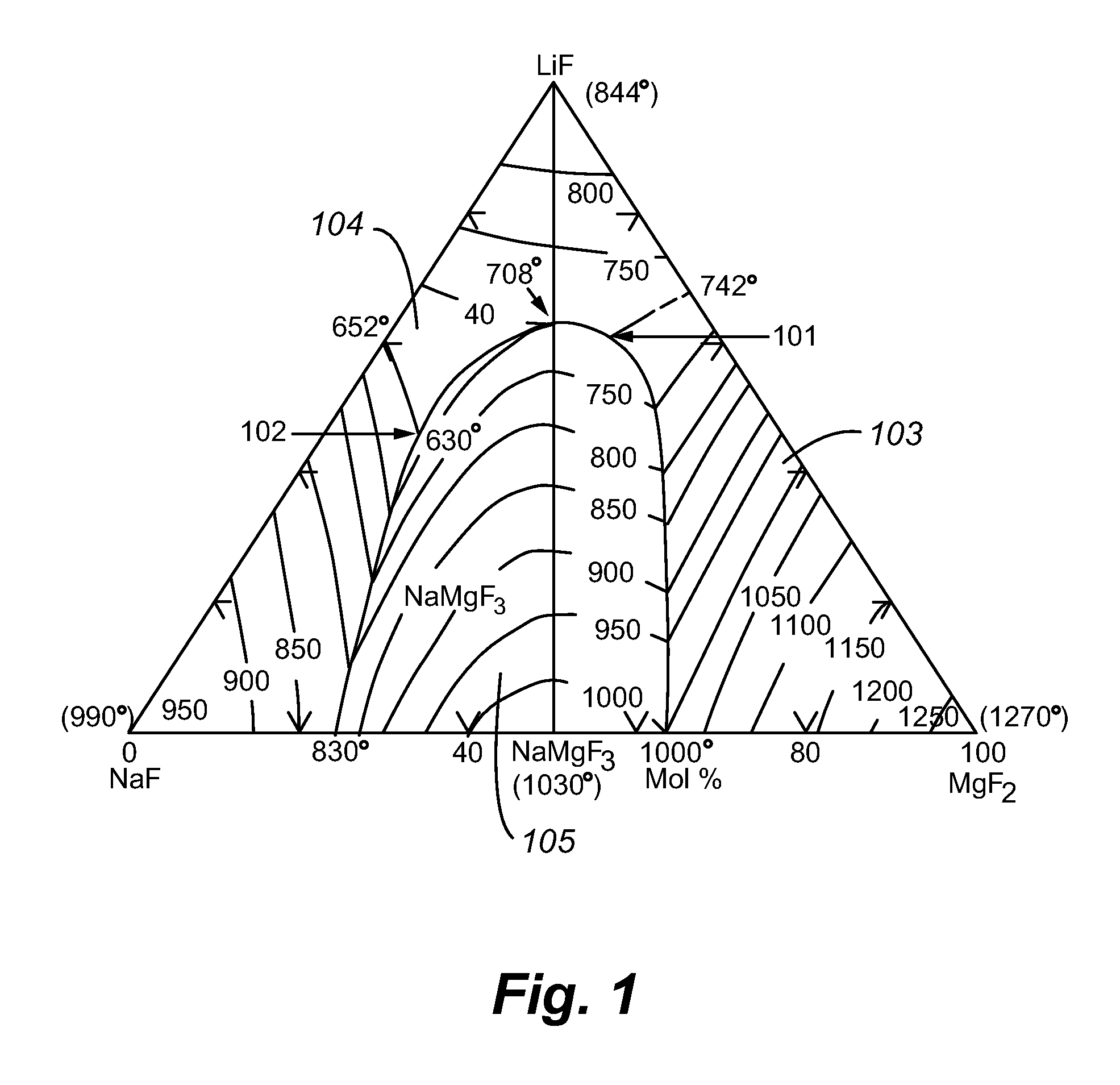

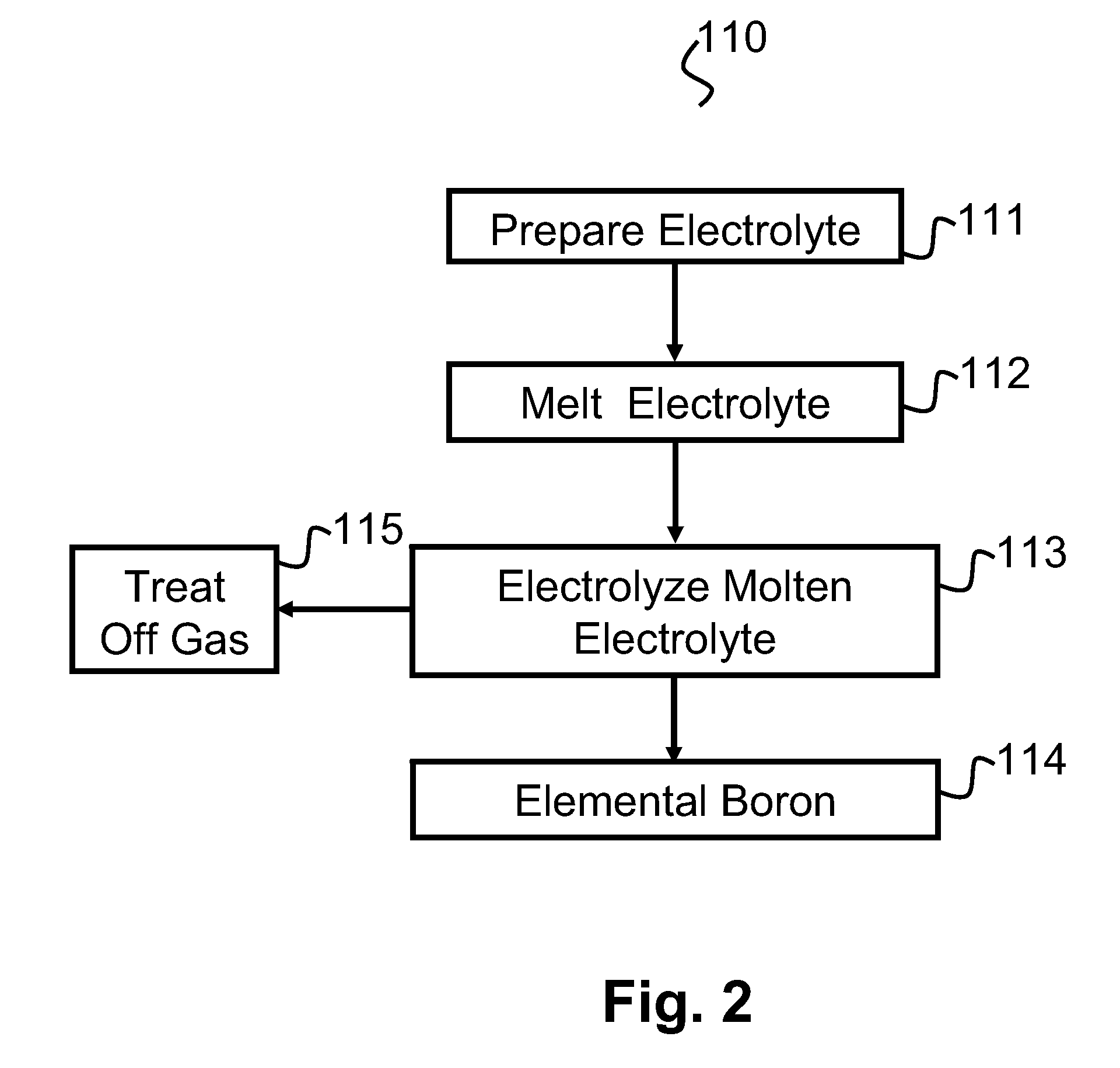

Synthesis of boron using molten salt electrolysis

The invention relates generally to elemental boron, particularly to elemental boron having a high purity level and to a method of recovering elemental boron by the electrolysis of a molten boron-containing electrolyte.

Owner:COLORADO SCHOOL OF MINES

Insoluble energetic organic polymer coated micro-nano particles and preparation method thereof

ActiveCN112079677APrevent oxidationSolve easy oxidationTransportation and packagingBoronMicro nanoOrganosolv

The invention discloses insoluble energetic organic polymer coated micro-nano particles and a preparation method thereof. The preparation method comprises the following steps: soaking micro-nano aluminum powder or boron powder in a solvent at low temperature, adding a first monomer and a second monomer at 0-25 DEG C, reacting for 0.5-2 hours at 0-5 DEG C in a protective gas atmosphere, reacting at50-120 DEG C to obtain a reaction solution, and carrying out nucleophilic substitution reaction on halogen and the second monomer; carrying out condensation polymerization on the aldehyde group and the second monomer, carrying out catalytic coupling reaction on the amino group and the second monomer, separating the product in the reaction solution, and performing drying to obtain the insoluble energetic organic polymer coated micro-nano particles. The energetic organic polymer coated micro-nano particles are insoluble in water and an organic solvent, so the problems of slow decomposition andpoor stability after soaking are avoided, the dispersity is good, and the problems that the surfaces of micro-nano aluminum and boron particles are easy to oxidize and the temperature required by a combustion reaction is high are solved.

Owner:NORTHWEST UNIV

Layer cast molding graphene-nonmetallic composite material and preparation method

ActiveCN106829945AHigh hardnessHigh strengthSiliconCarbon compoundsMaterials processingSensor materials

The invention relates to a layer cast molding graphene-nonmetallic composite material and a preparation method. The method for preparing the layer cast molding graphene-nonmetallic composite material comprises the following steps: mixing, grinding and shearing graphene quantum dots and / or micro-chips and nonmetallic substances under the ultrasonic action, drying, performing laser treatment, quenching and refining, so that molecular rearrangement and grafting fusion can be promoted. The layer cast molding graphene-nonmetallic composite material prepared by the invention has excellent performances of high hardness, high strength and low electrical resistivity, is easy to produce and can be widely applied to the processing fields of dental implant, super electric drills and other materials, the field of super-capacitor energy storage materials, the field of catalyst materials, the field of heat dissipation materials, the field of medicines, the field of coating materials, the fields of conductive ink and photoelectric sensor materials, the bio-relevant field and the like.

Owner:GUANGZHOU FENGSHANG ELECTRIC APPLIANCE

Jet milling of boron powder using inert gases to meet purity requirements

InactiveUS20120325942A1Small particle sizeAvoid impurity contaminationGas current separationBoronProcess engineeringBoron

A processing system and associated method for milling boron with impurity contamination avoidance. The system includes a jet mill for reducing the particle size of a boron feed stock, and a feed stock inlet for delivering the boron feed stock toward the jet mill. The system includes at least one inlet for delivering at least one gas into the jet mill. The gas and the boron feed stock comingle within the jet mill during milling reduction of boron particle size. The system includes a source of the at least one gas operatively connected to the at least one inlet, with the at least one gas being a gas that avoids transferring impurity during milling reduction of boron particle size.

Owner:GENERAL ELECTRIC CO

Process for rapidly synthesizing high-purity amorphous boron powder

The invention discloses a process for rapidly synthesizing high-purity amorphous boron powder and belongs to the field of inorganic chemical synthesis. The amorphous boron powder product with purity being 95% or higher is prepared from magnesium powder and boron trioxide as raw materials through steps of high-temperature self-propagating reaction, heat treatment, acid washing, water washing and drying, and the content of the amorphous boron powder is higher as compared with boron powder obtained with the traditional self-propagating method. The purification process is simple to operate, complicated operation for intermediate synthesis of level-90 boron powder is omitted as compared with other 95 boron powder processes, energy consumption is low, and the process is suitable for industrial production.

Owner:王婉婷

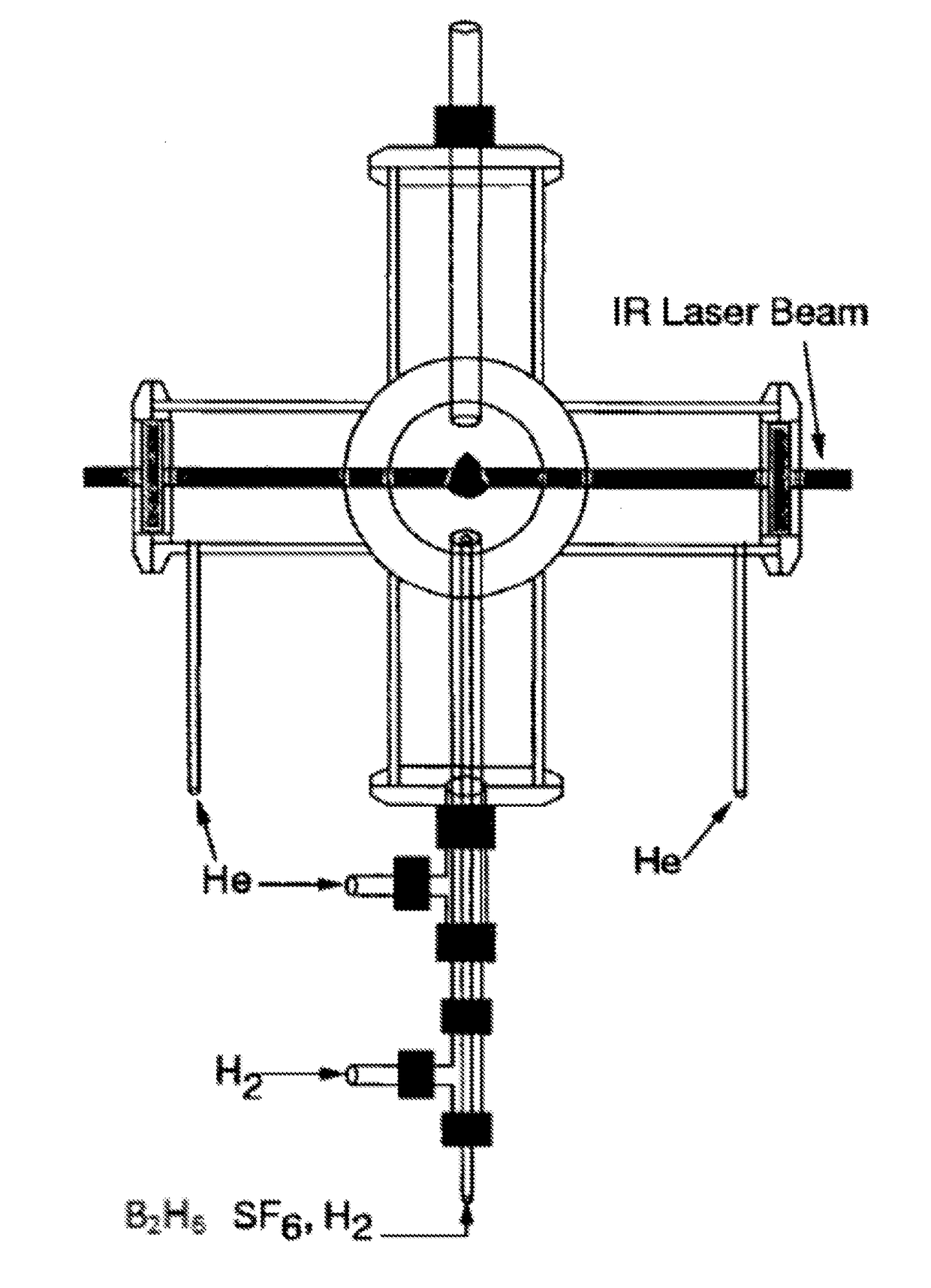

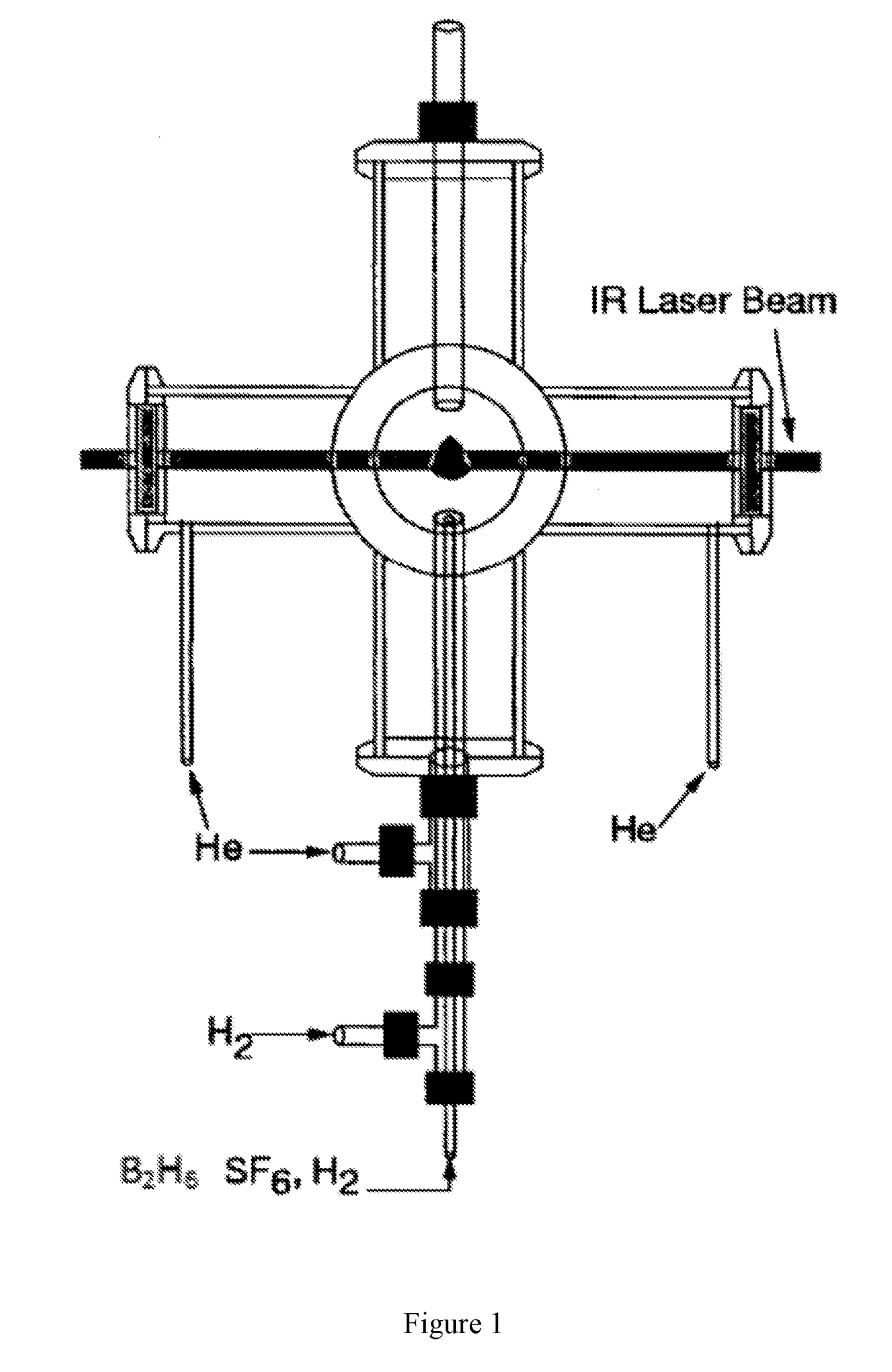

Boron nanoparticle compositions and methods for making and using the same

Provided are boron nanoparticles. The boron nanoparticles can be made by pyrolysis of a boron precursor (e.g., a boron hydride such as, for example, diborane) using a photosensitizer and electromagnetic radiation of an appropriate wavelength. The boron nanoparticles can be functionalized. The boron nanoparticles can be hydrogen-containing boron nanoparticles (e.g., hydrogen-terminated boron nanoparticles). Also provided are methods of hydrogen generation using boron nanoparticles, an activator, and water. Examples of activators include, but are not limited to, Li, Na, K, LiH, NaH, and combinations thereof.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Boron extracting device and method

The invention belongs to the field of chemical engineering, and discloses a boron extracting device which comprises a reaction container, a heat insulation layer, a heating coil, a sealed bin and a heating control system. The heat insulation layer wraps the reaction container. The heating coil wraps the heat insulation layer. An inner cavity of the sealed bin contains the reaction container, the heat insulation layer and the heating coil. The heating control system is electrically connected with the heating coil. The invention further discloses a boron extracting method. The method includes the steps of heating brown amorphous boron with purity of 92-98% in a vacuum environment to 1600-1700 DEG C, keeping the temperature for 60-120 minutes, injecting inert protection gas till the vacuum environment restores the normal pressure, and taking out obtained boron powder when the temperature is lowered to 100 DEG C or below. By introducing the vacuum technology and the super-high-temperature technology into the boron purification process, the method has the advantages of being low in purification cost and high in product purity.

Owner:SHENZHEN SAPP DIAMOND TECH CO LTD

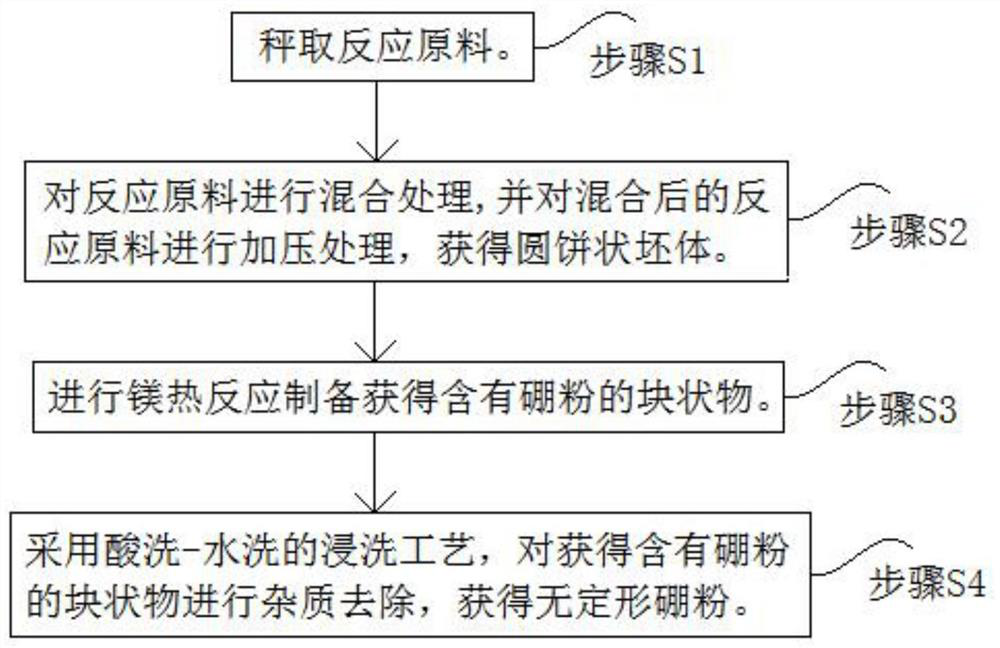

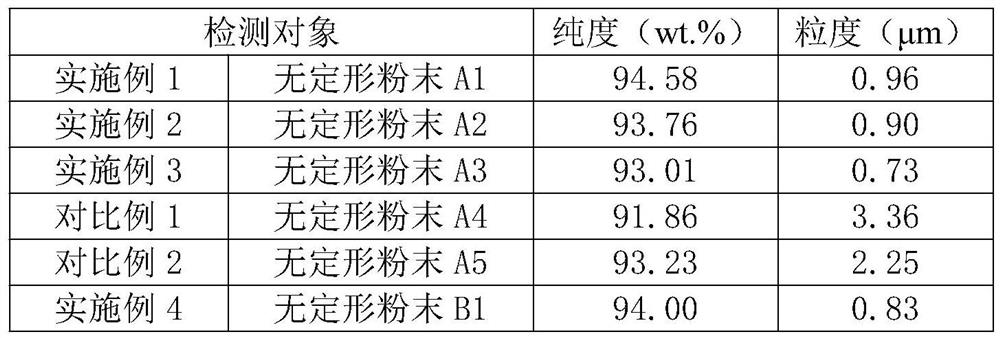

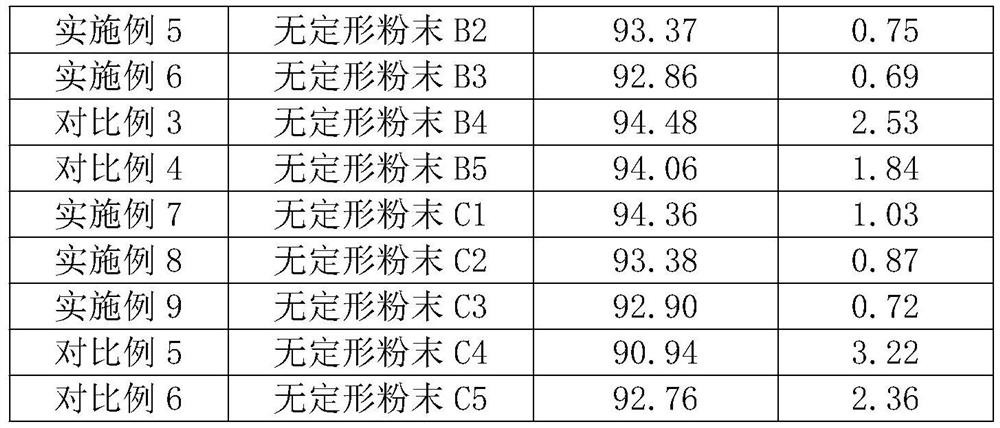

Preparation method of ultrafine amorphous boron powder

The invention belongs to the technical field of boron powder preparation. In order to obtain superfine amorphous boron powder with high purity and low particle size, the invention discloses a preparation method of the superfine amorphous boron powder. The preparation method of the superfine amorphous boron powder specifically comprises the following steps: S1, weighing reaction raw materials, wherein the reaction raw materials comprise the following components in percentage by mass: 40-48% of Mg powder, 35-42% of B2O3 powder and 10-24% of diluent powder, S2, mixing the reaction raw materials,and pressurizing the mixed reaction raw materials to obtain a cake-shaped green body, S3, carrying out a magnesiothermic reaction to prepare a block containing boron powder, and S4, by an acid pickling-water washing immersion cleaning process, carrying out impurity removal on the obtained blocky matter containing the boron powder, so that the high-purity and low-particle-size ultrafine amorphous boron powder is obtained. By adopting the method disclosed by the invention, the ultrafine amorphous boron powder with high purity and low particle size can be obtained, the manufacturing cost can be reduced, and the production efficiency can be improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

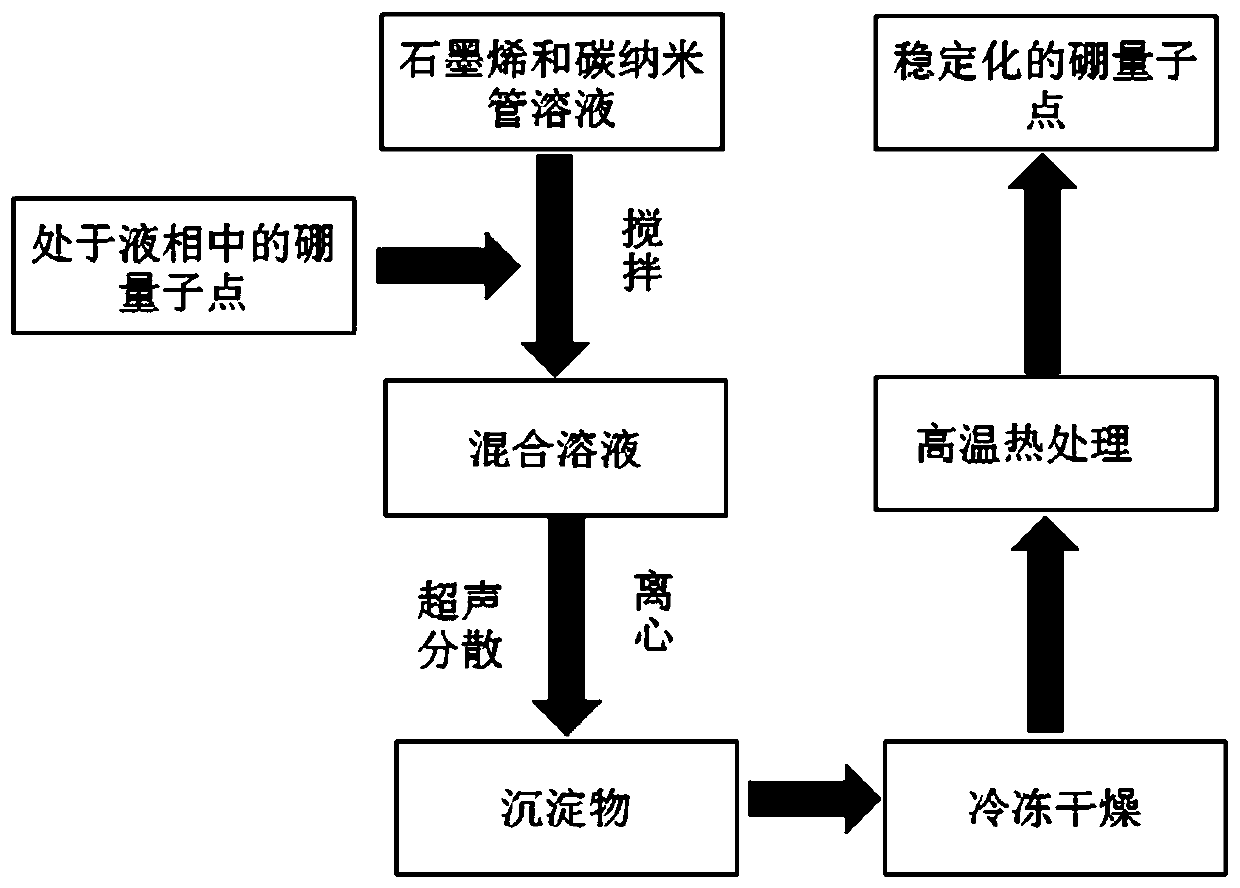

Boron quantum dot, and stabilizing treatment method and application thereof

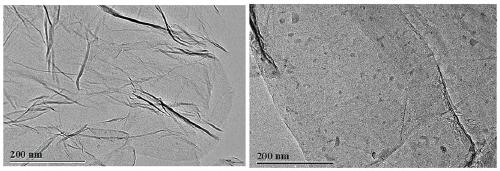

ActiveCN111217375ASolve the problem that it is difficult to exist stably in the airImprove lithium storage performanceSingle layer grapheneBoronFreeze-dryingCarbon nanotube

The invention discloses a boron quantum dot, and a stabilizing treatment method and an application thereof, belongs to the technical field of functional materials, and relates to a boron quantum dot technology. The technical problem that the boron quantum dot is difficult to stably exist in air is solved. The boron quantum dot stabilizing treatment method comprises the following steps: (1) addinga boron quantum dot solution dispersed in a liquid phase into a carbon nanotube and graphene solution to prepare a mixed solution; (2) stirring the mixed solution, ultrasonically crushing, centrifuging, and collecting the obtained precipitate; (3) freeze-drying the precipitate to obtain a composite boron quantum dot sample; and (4) carrying out high-temperature treatment on the sample subjected tofreeze drying in step (3) in an inert environment to make the boron quantum dot stably exist in the carbon nanotubes and the graphene. Compared with the prior art, the method makes a stable boron quantum dot composite material obtained, and enables the boron quantum dots to stably exist in the carbon nanotubes and graphene.

Owner:ZHONGBEI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com