Fluorescent probe as well as preparation method, application and application method thereof

The technology of a fluorescent probe and an application method, which is applied in the detection field, can solve the problems of complex preparation process of the fluorescent probe, difficult mass production and preparation, high development cost, etc., and achieves low development cost, strong fluorescent luminescence characteristics, high biological phase and the like. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In an embodiment of the present invention, the preparation method of the fluorescent probe includes:

[0031] Dispersing boron powder in isopropanol to prepare a first dispersion with a concentration of 0.1-10 mg / mL;

[0032] subjecting the first dispersion to ultrasonic stripping of the probe to obtain a second dispersion;

[0033] The second dispersion liquid is subjected to a water-bath ultrasonic stripping treatment to obtain a third dispersion liquid;

[0034] The third dispersion liquid is subjected to fractional-speed centrifugation, and the resulting precipitate is made into boronene nanosheets, to obtain.

[0035] In a preferred embodiment of the present invention, the above-mentioned boron powder is dispersed in isopropanol to prepare the first dispersion liquid with a concentration of 0.1-10 mg / mL, which specifically includes:

[0036] The boron powder was dispersed in isopropanol to prepare a first dispersion with a concentration of 1 mg / mL.

[0037] In a...

Embodiment 1

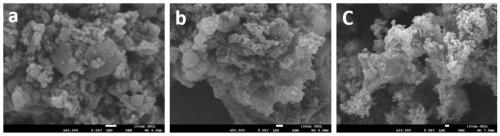

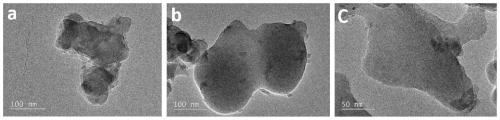

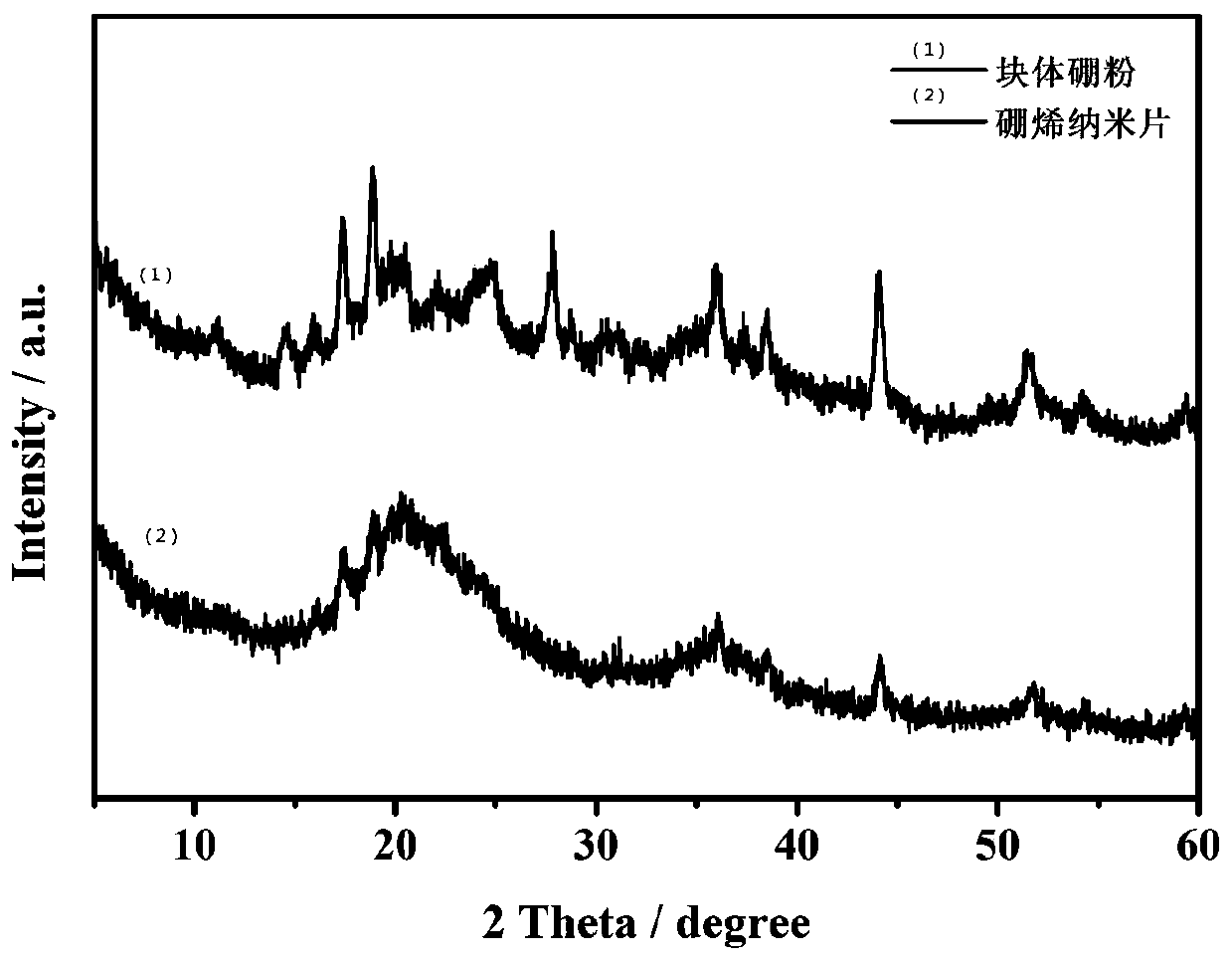

[0054] The bulk boron powder was dispersed in isopropanol (IPA) to prepare a dispersion liquid with a concentration of 0.1 mg / mL, and then the dispersion liquid was subjected to ultrasonic peeling treatment of the probe (specific parameters: 900W ultrasonic power, total time 0.5 hours, ultrasonic 1s, pause for 5s, constant temperature at 5°C), and then perform ultrasonic peeling treatment in a water bath on the dispersion obtained after ultrasonication of the probe (specific parameters: 1200W ultrasonic power, total time of 1 hour, constant temperature at 5°C), and finally the stripped dispersion Perform split-speed centrifugation (specific parameters: centrifuge at 10,000 rpm for 10 minutes, take the upper layer liquid, then centrifuge at 13,000 rpm for 10 minutes, remove the sediment in the lower layer, and keep the temperature at 5°C) to obtain boronene nanosheets with uniform particle size and thin thickness.

Embodiment 2

[0056] Disperse the bulk boron powder in isopropanol (IPA) to prepare a dispersion liquid with a concentration of 10 mg / mL, and then subject the dispersion liquid to ultrasonic peeling treatment of the probe (specific parameters: 500W ultrasonic power, total time 2 hours, ultrasonic 5s , pause for 10s, constant temperature at 20°C), and then, the dispersion liquid obtained after the ultrasonic probe was subjected to water-bath ultrasonic stripping treatment (specific parameters: 500W ultrasonic power, total time 5 hours, constant temperature 20°C), and finally the stripped dispersion liquid Split speed centrifugation (specific parameters: centrifuge at 8000rpm for 20 minutes, take the upper liquid, then centrifuge at 11000rpm for 10 minutes, take the lower layer of sediment, keep the temperature at 15°C), and obtain boron nanosheets with uniform particle size and thin thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com