Boron alkene and preparation method thereof

A boronene and boron source technology, applied in the field of two-dimensional nanomaterial preparation, can solve problems such as complex process, high requirements for production equipment, and low output of target products, and achieve the effect of simple and safe equipment, high commercial value, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

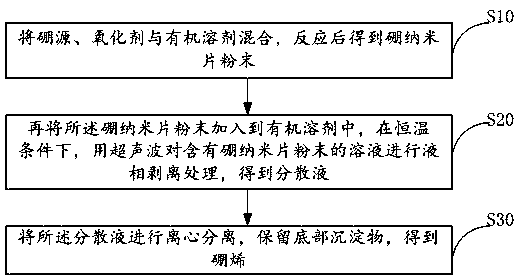

[0036] see figure 1 , which is a flow chart of a preferred embodiment of the preparation method of boron in the present invention. Described preparation method specifically comprises:

[0037] S10, mixing a boron source, an oxidizing agent and an organic solvent, and obtaining boron nanosheet powder after the reaction;

[0038] S20, adding the boron nanosheet powder into an organic solvent, and performing liquid phase exfoliation on the solution containing the boron nanosheet powder under constant temperature conditions to obtain a dispersion;

[0039] S30. Centrifuge the dispersion, keep the bottom precipitate, and obtain boronene.

[0040] Aiming at the complex preparation method of boron in the prior art, relying on expensive equipment, and low yield, the present invention adds boron source and oxidizing agent to the polar organic solvent, under sealed condition, after long-term stirring process , the reaction product was obtained, the obtained reaction product was sucti...

Embodiment 1

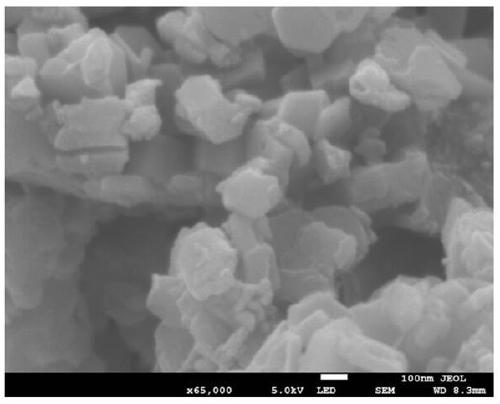

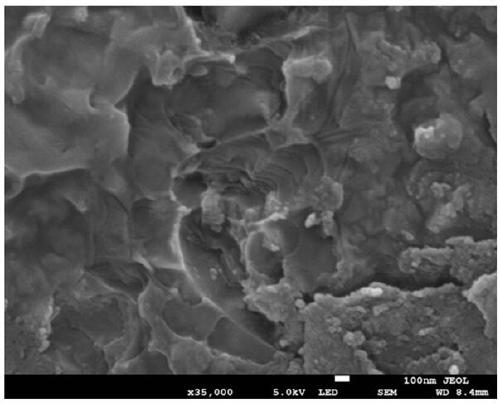

[0057] Weigh a certain mass of MgB according to the molar ratio of 1:1 2 Add iodine and simple substance into a plastic bottle containing 200 ml of acetonitrile, and then stir at a speed of 100 r / min for 1 day under sealed conditions; after the stirring, the product in the bottle is subjected to suction filtration, and The powder was repeatedly rinsed with acetonitrile, ultrasonically dispersed, and filtered five times to remove by-products; the cleaned powder was vacuum-dried at 40°C for 1 hour; the powder was added to 250ml of NMP solvent, and the liquid Phase stripping treatment: power at 500 W, water bath temperature at 5°C, ultrasonic treatment for 1 hour; centrifuge the dispersion obtained after ultrasonic treatment: centrifuge at 3000 r / min for 1 minute, and take the supernatant; Then it was centrifuged at 14000 r / min for 20 minutes, and the sediment at the bottom was collected. The remaining NMP solvent in the precipitate was converted with ethanol, and vacuum-dried a...

Embodiment 2

[0059] Weigh a certain mass of TiB according to the molar ratio of 1:5 2 and bromine simple substance were added to a bottle containing 200 ml of acetonitrile, and then stirred at a speed of 300 r / min for 35 days under sealed conditions; after the stirring was completed, the product in the bottle was subjected to suction filtration, and the filtered The powder was repeatedly rinsed with acetonitrile, ultrasonically dispersed, and suction filtered five times to remove by-products; the cleaned powder was vacuum-dried at 60°C for 4 hours; the powder was added to 250ml of DMF solvent, and the liquid Phase stripping treatment: power 600 W, water bath temperature 10°C, ultrasonic treatment for 5 hours; centrifuge the dispersion obtained after ultrasonic treatment: after centrifugation at 3000 r / min for 15 minutes, take the supernatant; Then centrifuge at 15000 r / min for 20 minutes, and take the bottom sediment. The remaining DMF solvent in the precipitate was converted with ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com