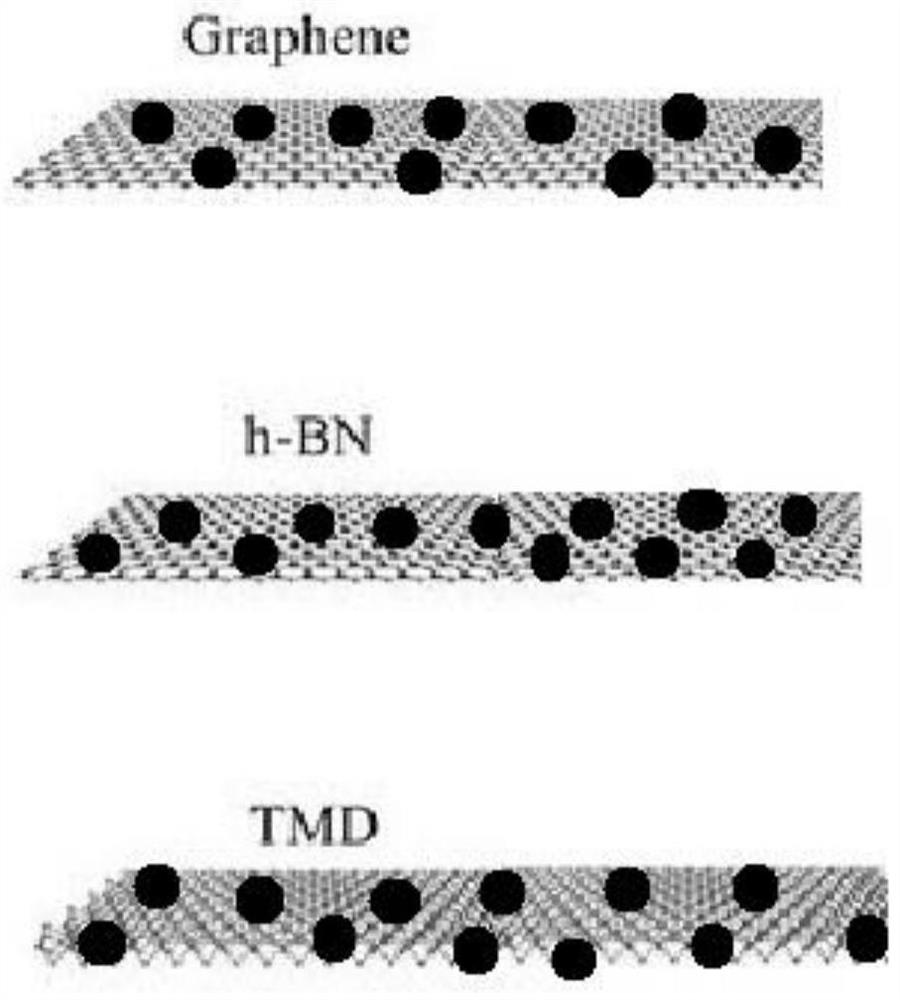

Method for preparing two-dimensional material by stripping layered material with oxide semiconductor nano-powder

A technology of oxide semiconductors and nanopowders, which is applied in the direction of oxide/hydroxide preparation, sulfide/polysulfide preparation, chemical instruments and methods, etc., which can solve the randomness of the stripping method and the fluctuation of process parameters Problems such as chemical vapor deposition and small molecule synthesis preparation, to achieve the effect of low light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Example 1: Manganese nitrate, ferric nitrate and nickel nitrate solutions are mixed according to the atomic equivalent of the three metal elements 3:1:1, then precipitated with ammonia water, sintered and decomposed at high temperature in the air to form p-type semiconductor nanopowder of oxide solid solution The specific preparation of p-type semiconductor powder does not belong to the scope of protection of this patent. This is just an example, and the specific preparation method is not limited, as long as it is a semiconductor nanoparticle smaller than 100nm and forms an oxygen-deficient p-type semiconductor powder. Conductivity is enough. The work function of this semiconductor is about 4.7eV, which is greater than the work function of the two-dimensional material molybdenum disulfide, which is about 1.9eV. The specific proportion of transition metal manganese-iron-nickel oxide nanoparticles is 50 grams, mixed with 0.5 grams of few-layer molybdenum disulfide , the m...

Embodiment 2

[0110]Embodiment 2: The NiO oxide solid solution is a p-type semiconductor nanopowder. The work function of this nickel oxide semiconductor is greater than the work function of the two-dimensional material graphite, and 100 grams of nickel oxide nanoparticles with a specific ratio of about 30 nm particle size are mixed with 0.5 grams of graphite powder, and the mass ratio of the two (1:130 ) is greater than 1:25, then in a grinder, grind for 16 hours in an inert gas argon protective atmosphere, observe with an electron microscope, the nanoparticles have absorbed more than 99% of single-layer or few-layer graphene, and the grinding is over; if the observation does not reach the nanometer The particles adsorb more than 90% of single-layer or few-layer graphene, and continue to grind until reaching. Taking out the composite intermediate structure with nanoparticles adsorbed on the surface of graphene can be used for specific purposes. Then add the composite intermediate to an aq...

Embodiment 3

[0111] Embodiment 3: Manganese oxide, copper oxide and cobalt oxide powders are ground according to the atomic equivalent of three metal elements 3:1:3 mixed ball mill, and then the solid solution oxide p-type semiconductor nano-powder made by sintering at high temperature is specifically prepared. Powder does not belong to the protection scope of this patent, and it is just an example here. The work function of this oxide solid solution semiconductor is about 4.6eV, which is greater than that of MXene (titanium carbide) at about 1.7-1.9eV. The specific ratio of transition metal manganese-iron-nickel oxide nanoparticles is 20 grams, and the few-layer molybdenum disulfide Mix 0.25 grams, the mass ratio (1:80) of the two is greater than 1:25, and then grind for 8 hours in an inert gas argon protective atmosphere in a planetary grinder, and observe with an electron microscope, the nanoparticles have adsorbed more than 99% of the monolayer or Few layers of MXene (titanium carbide)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com