Patents

Literature

47results about How to "Crystal phase stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

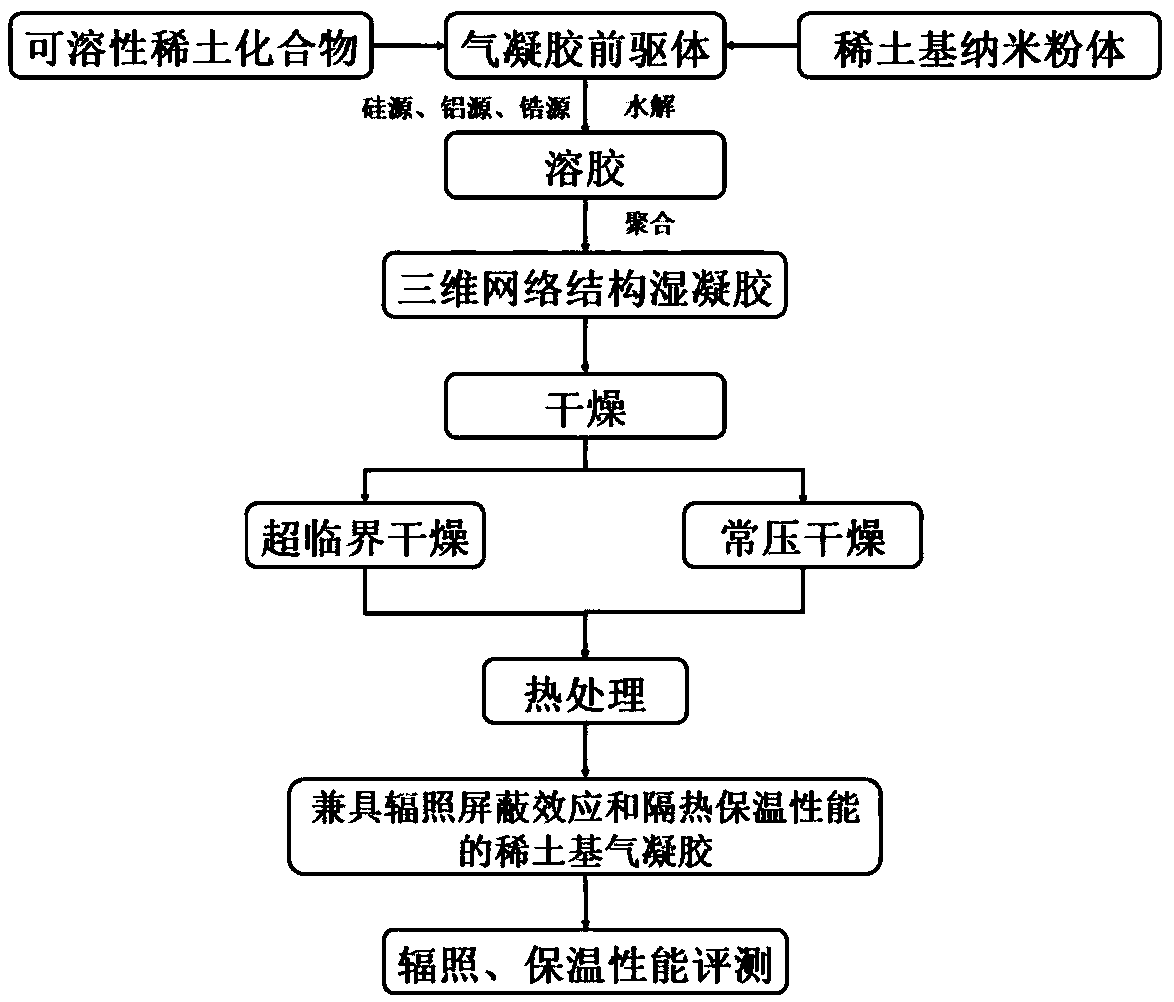

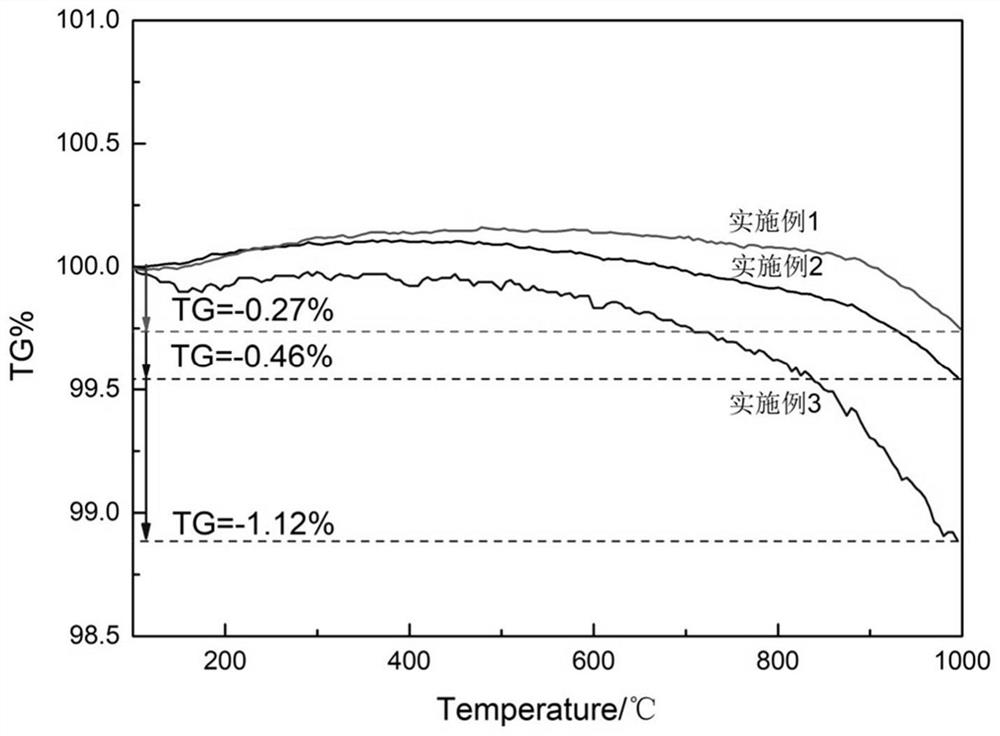

Rare-earth-based aerogel material with radiation shielding effect and heat insulation property as well as preparation and application of rare-earth-based aerogel material

The invention provides a rare-earth-based aerogel material with a radiation shielding effect and heat insulation property and preparation and application of the rare-earth-based aerogel material. Thematerial comprises an aerogel matrix material and a rare-earth-based material, wherein the rare-earth-based material is compounded with the aerogel matrix material; the rare-earth-based material is selected from one or more of rare earth zirconate, rare earth titanate, rare earth tungstate and rare earth cerate; and the content of the rare-earth-based material ranges from 1wt% to 45wt%. The radiation shielding property and the fireproof heat insulation property are effectively combined by compounding the rare-earth-based material in aerogel, and the prepared material particularly meets the requirements of radiation shielding and fireproof heat insulation in the field of nuclear engineering.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

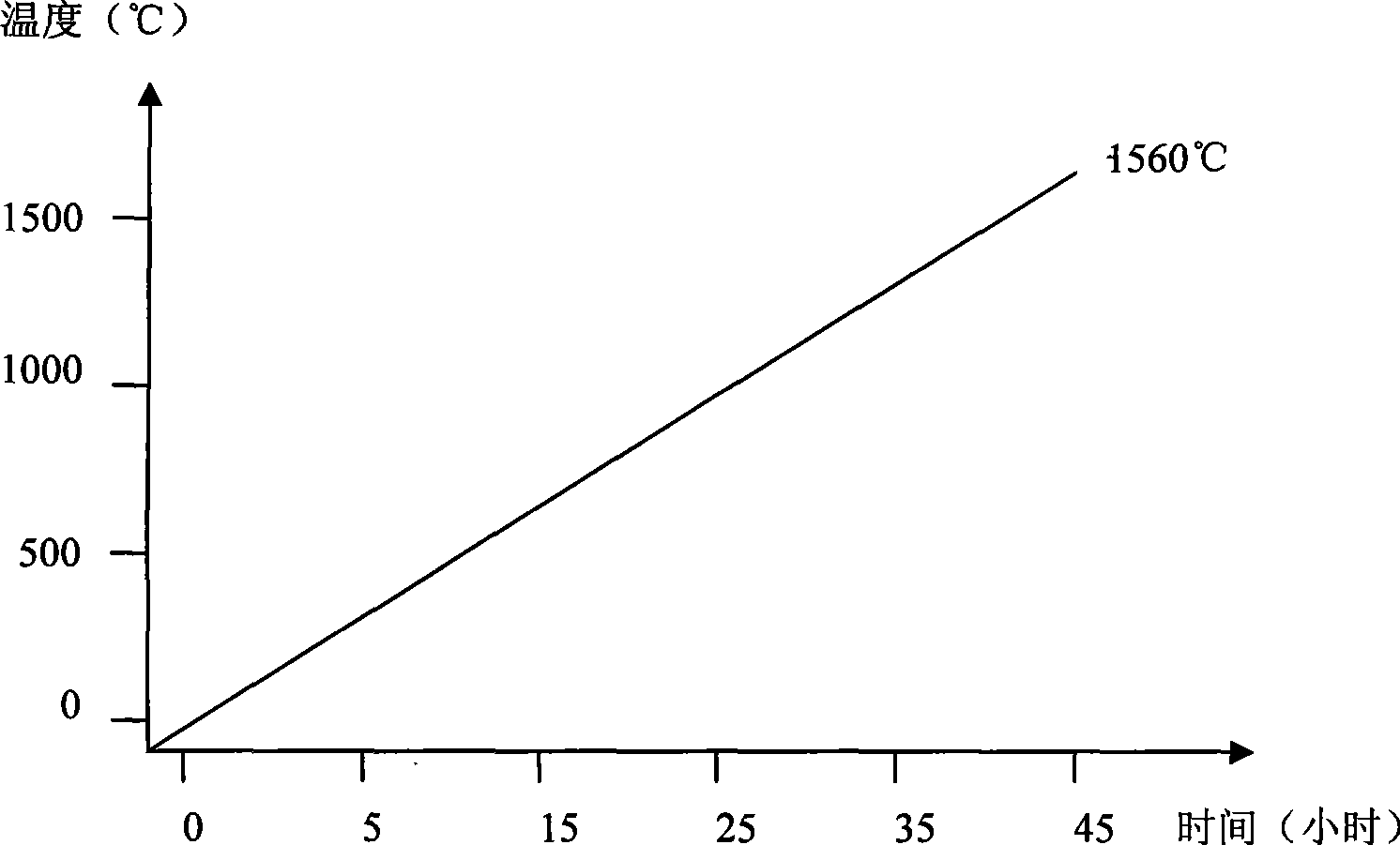

Method for preparing zirconia ceramic product

The present invention provides a method for preparing zirconia ceramic products. The raw material includes 84-97% of monoclinic zirconia, 0-15% of yttrium oxide, and 0-3% of magnesium oxide. The raw material is pulverized to a particle size of no more than 20 microns. Isostatic pressing or hot die casting is used. The isostatic pressing green body or hot die casting green body after de-waxing is cleaned, and loaded into a high-temperature furnace for calcination, wherein the calcination temperature is 1600-1700 DEG C, and the temperature is kept for 3-6 h to obtain the product. The present invention uses the simplest process to obtain indicators surpassing that of the zirconia products produced by conventional processes. The pre-high-temperature stabilization is not needed, therefore the energy can be saved by about 50%. The chemical composition of the products and crystalline phase composition are highly consistent. The quality stability of the products is high. Other impurities will not be brought during the preparation process. The production cost is low, is 50% of conventional craft products, and 30% of novel fine ceramic products.

Owner:LUOYANG BEIYUAN SPECIAL CERAMICS

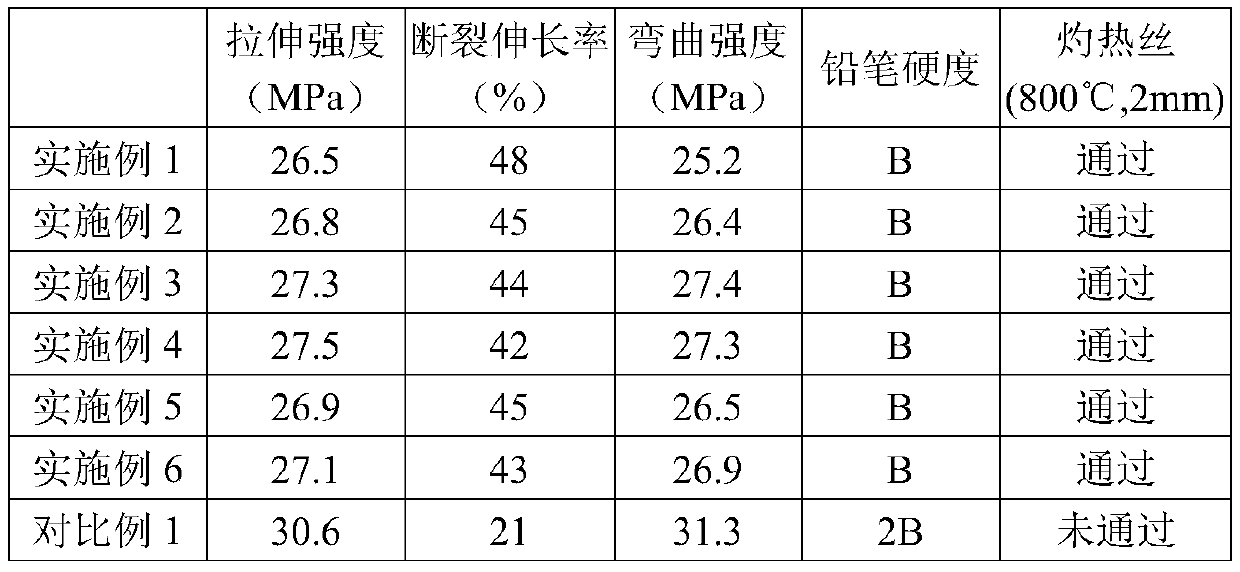

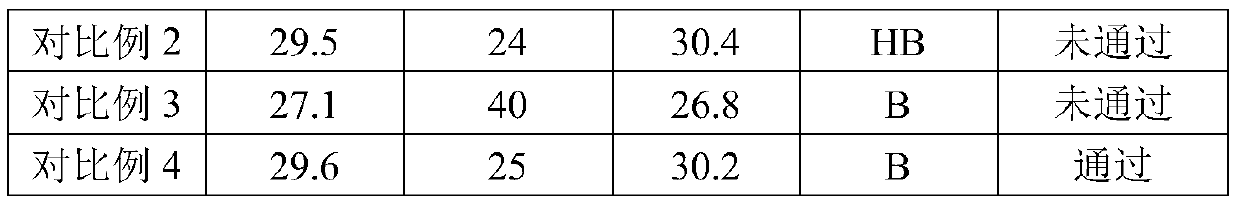

Scratch-resistant flame-retardant PP modified material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and especially, relates to a scratch-resistant flame-retardant PP modified material. The scratch-resistant flame-retardant PP modified material is composed of the following components in parts by mass: 35 to 60 parts of block co-polypropylene, 10 to 20 parts of random co-polypropylene, 3 to 8 parts of a scratch-resistant additive, 1 to 5 parts of a toughening modifier, 2 to 7 parts of a halogen-free flame retardant, 1 to 2 parts of a flame-retardant synergist, 1 to 3 parts of a lubricant and 1 to 2 parts of an antioxidant,wherein the scratch-resistant additive is nano aluminum oxide and polypropylene grafted high-molecular-weight polyorganosiloxane, and the toughening modifier is an acrylic acid-polysiloxane rubber-methyl methacrylate multipolymer and / or an acrylic acid-ethylene propylene rubber-methyl methacrylate multipolymer. Compared with the prior art, the PP modified material disclosed by the invention has scratch resistance, and the toughness and flame retardancy of the PP modified material are correspondingly improved.

Owner:东莞毅工工程塑料有限公司

Fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder, and preparation method thereof

InactiveCN107722982AHigh luminous intensityHigh reactivityLuminescent compositionsFluorescenceNitrogen oxide

The invention discloses a fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder, and a preparation method thereof, and belongs to the technical field of luminescent material. Thepreparation method is used for solving a problem in the prior art that the fluorescent brightness of BaSi<2>O<2>N<2>:Eu<2+> nitrogen oxide is low. The chemical formula of the fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder is (Ba<1-x-y-z-m>M<x>R<y>A<z>)O*0.5SiO<2>*0.5Si<3>N<4>:mEu<2+>, wherein 0.01<=m<=0.05, 0<=x<=0.2, 0.005<=y<=0.2, 0.5<=y / z<=1, 0<x+y+z<0.5, R is used for representing at least one element selected from La, Y, Tb, Dy, Ho, Er, Tm, Yb, Lu, Bi, Pr, and Mn, M is used for representing at least one element selected from Ca, Sr, and Mg, A is used for representing at least one element selected from K, Na, and Li. The fluorescent brightness of the fluorescence-enhanced silicon-based nitrogen oxide cyan fluorescent powder is high, and the excitation peak value is stabilized at 490 to 500nm under blue light excitation.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

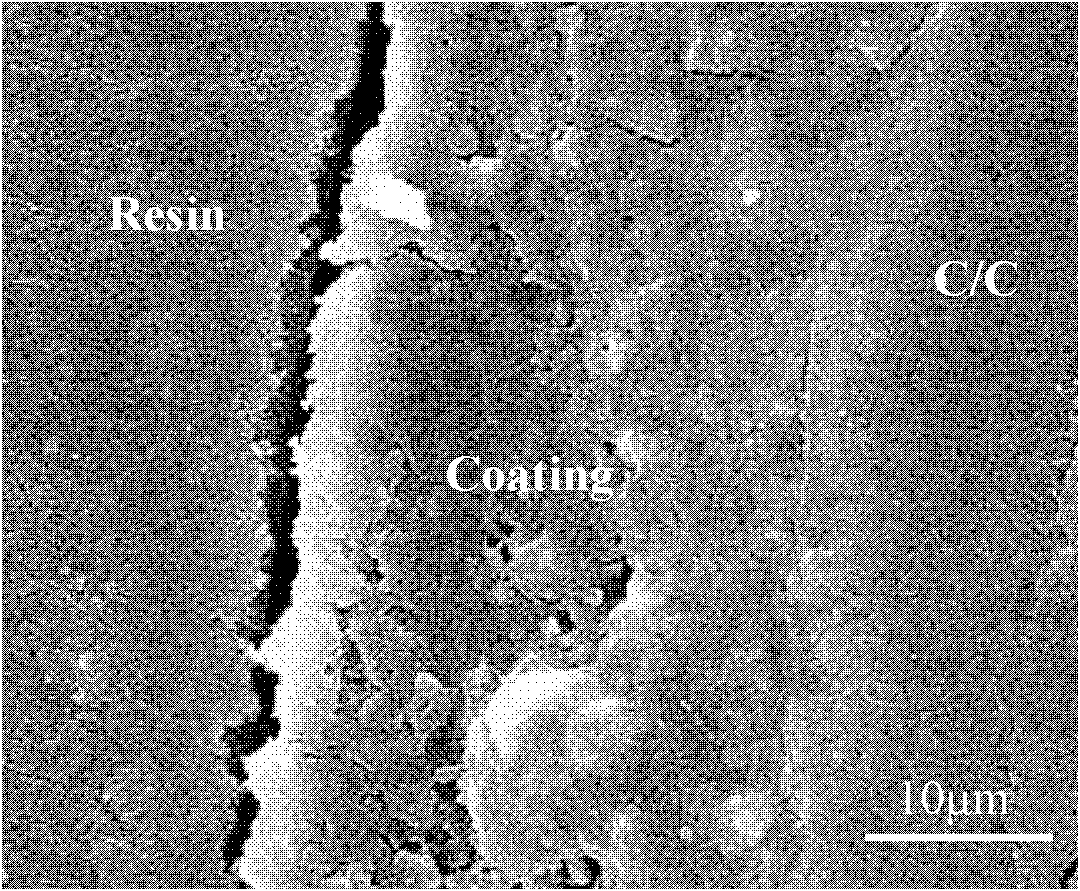

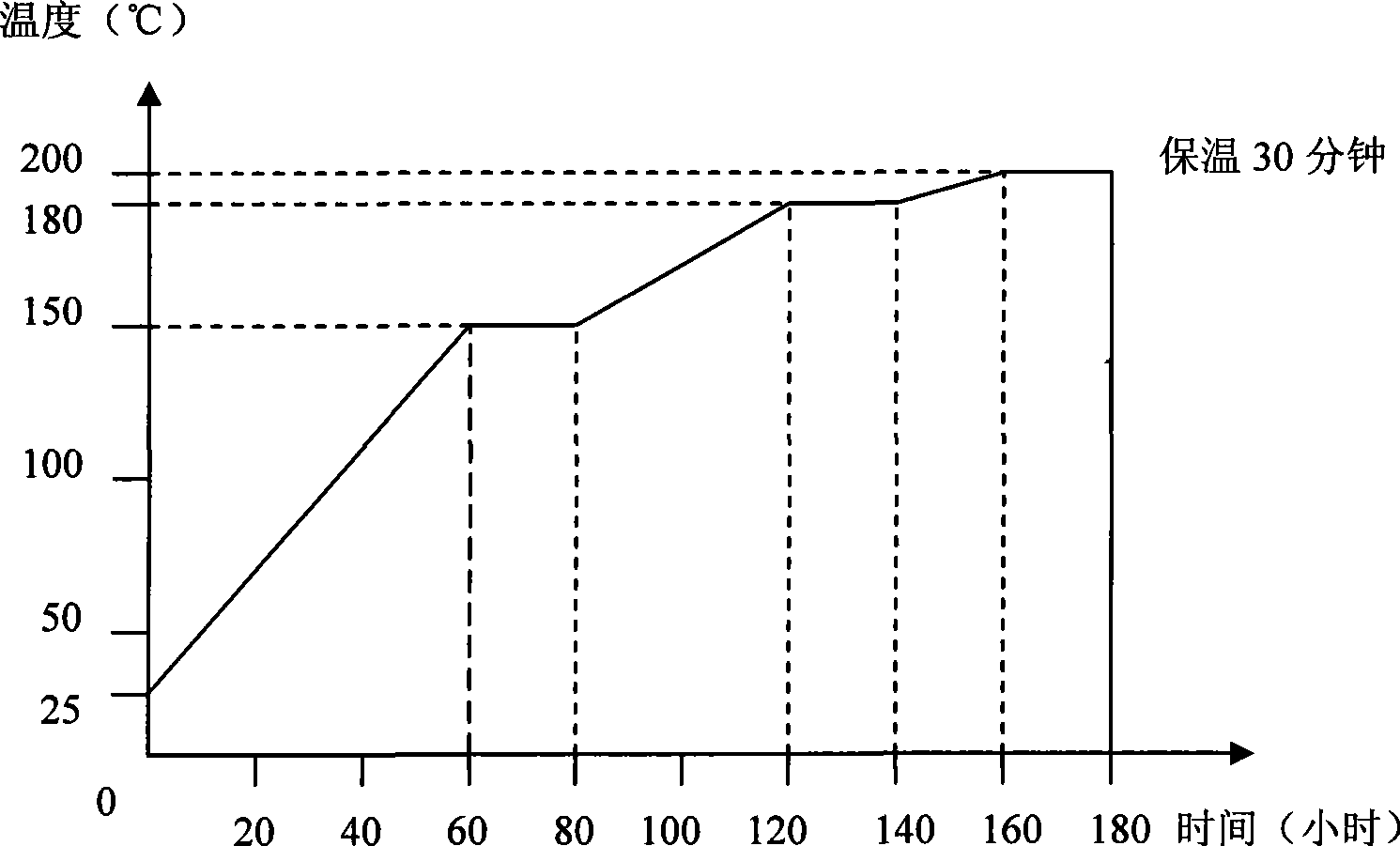

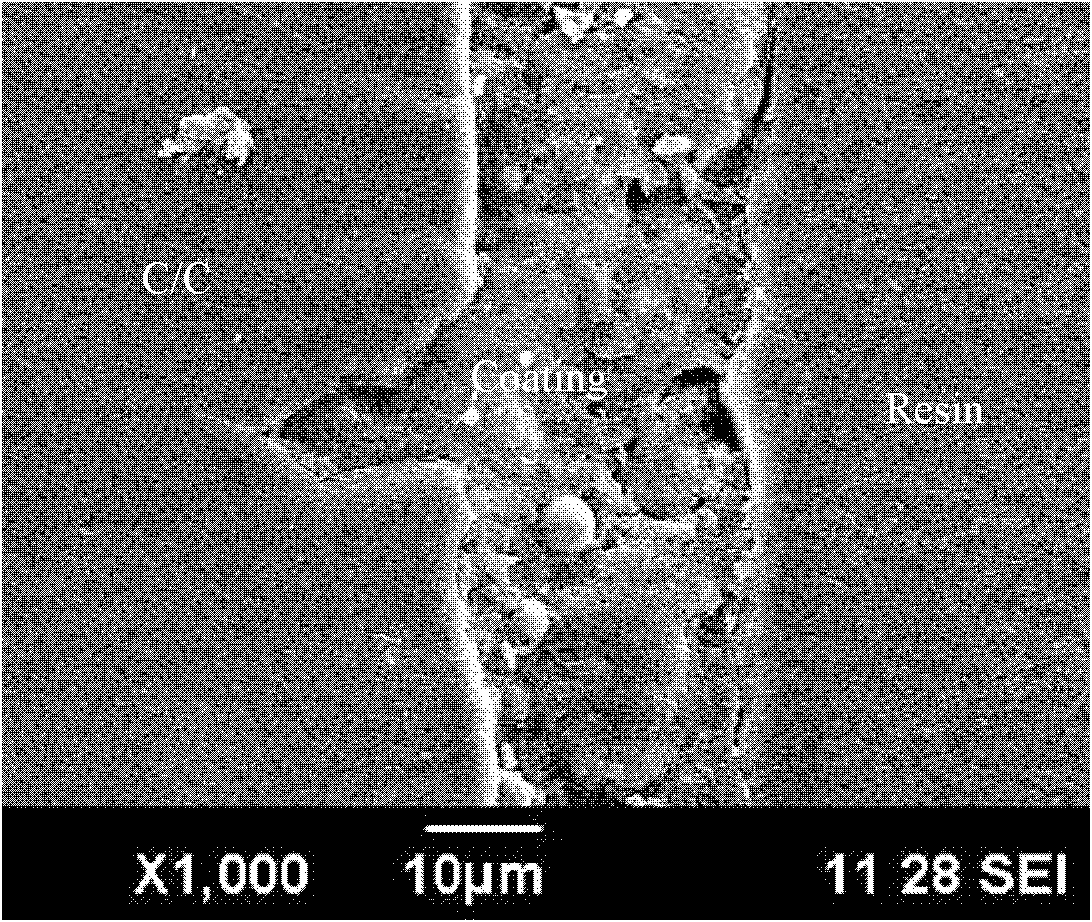

Method for preparing Hap-PAM biological gradient compound coating by impulse hydrothermal electrophoretic polymerization method

InactiveCN101838837AGuaranteed biocompatibilityGuaranteed biological activityElectrophoretic coatingsDeposition temperatureConcentration ratio

The invention provides a method for preparing a Hap-PAM biological gradient compound coating. The method comprises the following steps of: preparing aqueous solution of acrylamide and suspension of hydroxyapatite isopropyl alcohol respectively from hydroxyapatite, acrylamide monomers, isopropyl alcohol and the like serving as raw materials in a certain concentration ratio, performing DC electrodeposition processing on a carbon / carbon matrix in the aqueous solution of acrylamide for some time, and placing the carbon / carbon matrix in the suspension of hydroxyapatite for hydrothermal electrophoretic polymerization; and preparing the Hap-PAM gradient compound coating which has the advantages of uniform and compact surface, complete crystal orientation and close bonding of the coating and the matrix at different deposition temperatures and voltages. Due to the advantages, particularly higher bonding force, the Hap-PAM biological gradient compound coating has a quite good development prospect in clinical application.

Owner:SHAANXI UNIV OF SCI & TECH

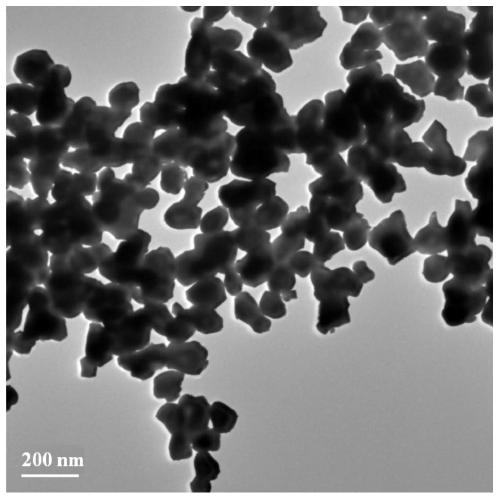

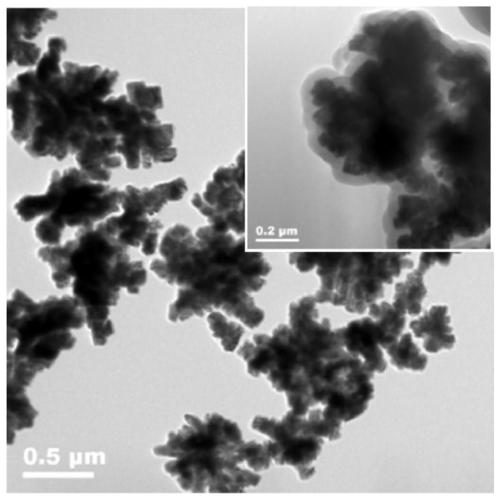

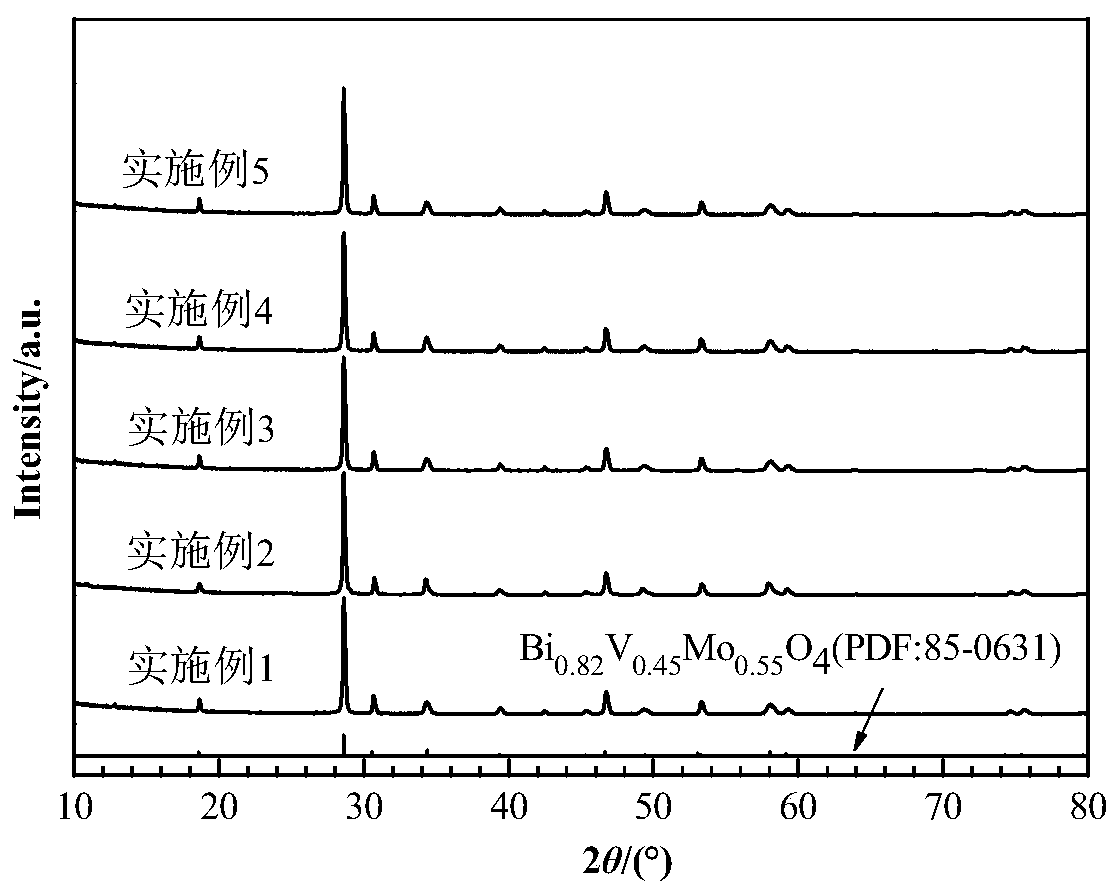

Silica-encapsulated ultra-fine bismuth vanadomolybdate yellow pigment and preparation method thereof

ActiveCN109705621AImprove high temperature stabilityReduce volatilityPigment physical treatmentUltra fineSilicon dioxide

The present invention discloses a silica-encapsulated ultra-fine bismuth vanadomolybdate yellow pigment which is composed of a transparent SiO2 shell encapsulating layer and powder particles of a bismuth vanadomolybdate yellow pigment encapsulated therein. In addition, a preparation method of the silica-encapsulated ultra-fine bismuth vanadomolybdate yellow pigment is also disclosed. The silica-encapsulated ultra-fine bismuth vanadomolybdate yellow pigment disclosed by the present invention, with silica as a transparent encapsulating shell to encapsulate the ultra-fine bismuth vanadomolybdateyellow pigment, has significant improvements in high temperature resistance and acid resistance and can meet higher use requirements. According to the present invention, the ultra-fine bismuth vanadomolybdate particles prepared by a wet-chemical process under a liquid phase condition are encapsulated with silica after being dried and calcined, thus avoiding agglomeration and caking of the pigmentpowder and resulting in a fine and uniform particle size and good dispersibility of the pigment particles; and with no need for expensive equipment and because of a simple easy-to-operate process andlow production cost, promotion and application are facilitated.

Owner:JINGDEZHEN CERAMIC INSTITUTE

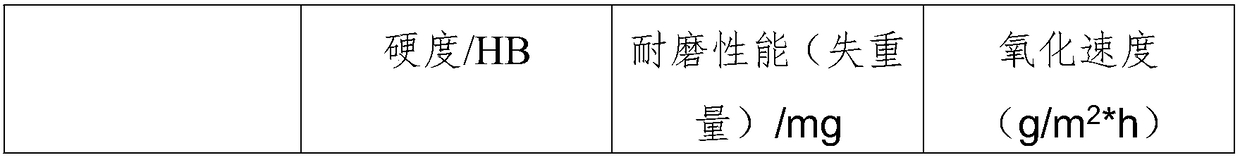

Low-voltage apparatus electrical contact material and preparation method thereof

InactiveCN103700518AReduce focused ablationDiffusion strengtheningContactsLow voltageHeat conducting

The invention discloses a low-voltage apparatus electrical contact material and a preparation method thereof. The preparation method is characterized in that nano-diamond and an aqueous solution of Ce3<+> cerium salt are uniformly mixed into a precursor by ultrasonic wave; the precursor is dried for 4h at the temperature of 90-100 DEC G, is loaded in a porcelain crucible, and is roasted for 1-2h under the temperature of 600-850 DEG C in a vacuum sintering furnace; a roasted product is smashed by a ball mill or a jet mill; after a wetting agent is added into and mixed with the smashed product, the mixed product and copper tungsten alloy powder are added into and uniformly mixed in a three-dimensional blender mixer in proportion; the mixed product is added into a mold for hot press molding and is sintered for 1.5-4h in the vacuum sintering furnace with the temperature of 1000 DEG C. The low-voltage apparatus electrical contact material has the advantages that the electrical contact material contains the nano-diamond, the dispersion strengthening function is realized, and the super-strong hardness and the wear-resisting property are realized; the diamond is super-strong in heat-conducting property, the surface temperature can be reduced, and the fusion welding and the electric ablation are resisted; the diamond is covered by cerium oxide, the electron work function is lower, the movement of an electric arc is dispersed, and the concentrated ablation on the contact material by the electric arc is reduced; the cost is greatly reduced as copper replaces silver.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

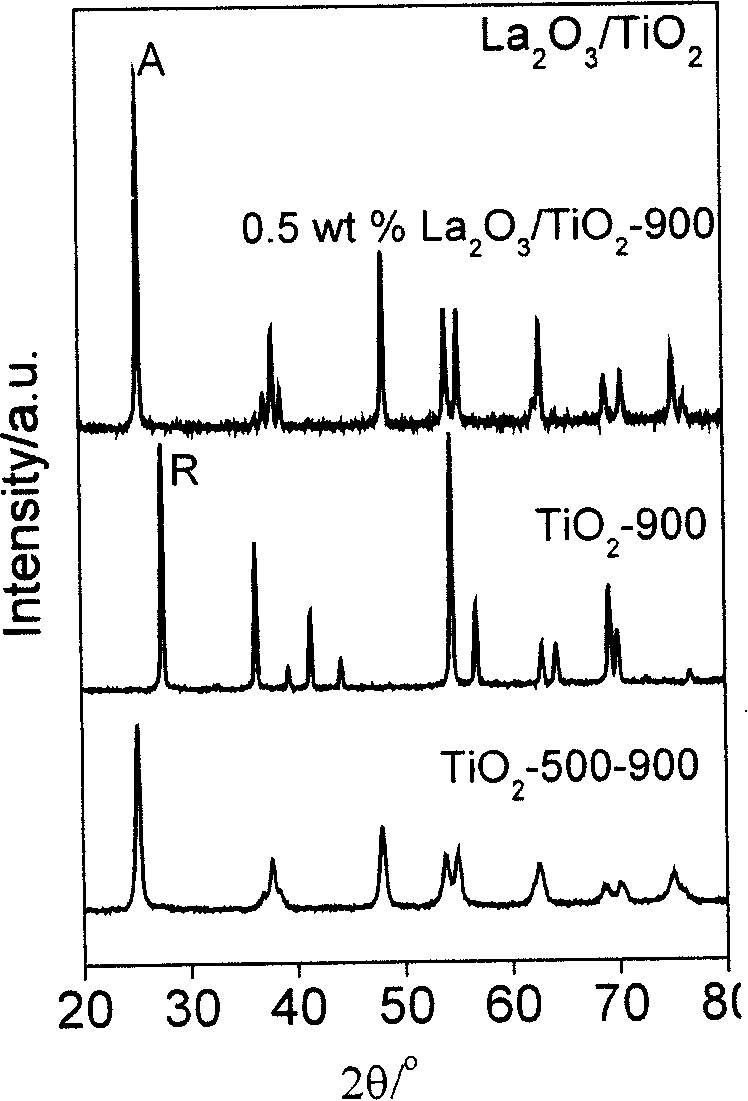

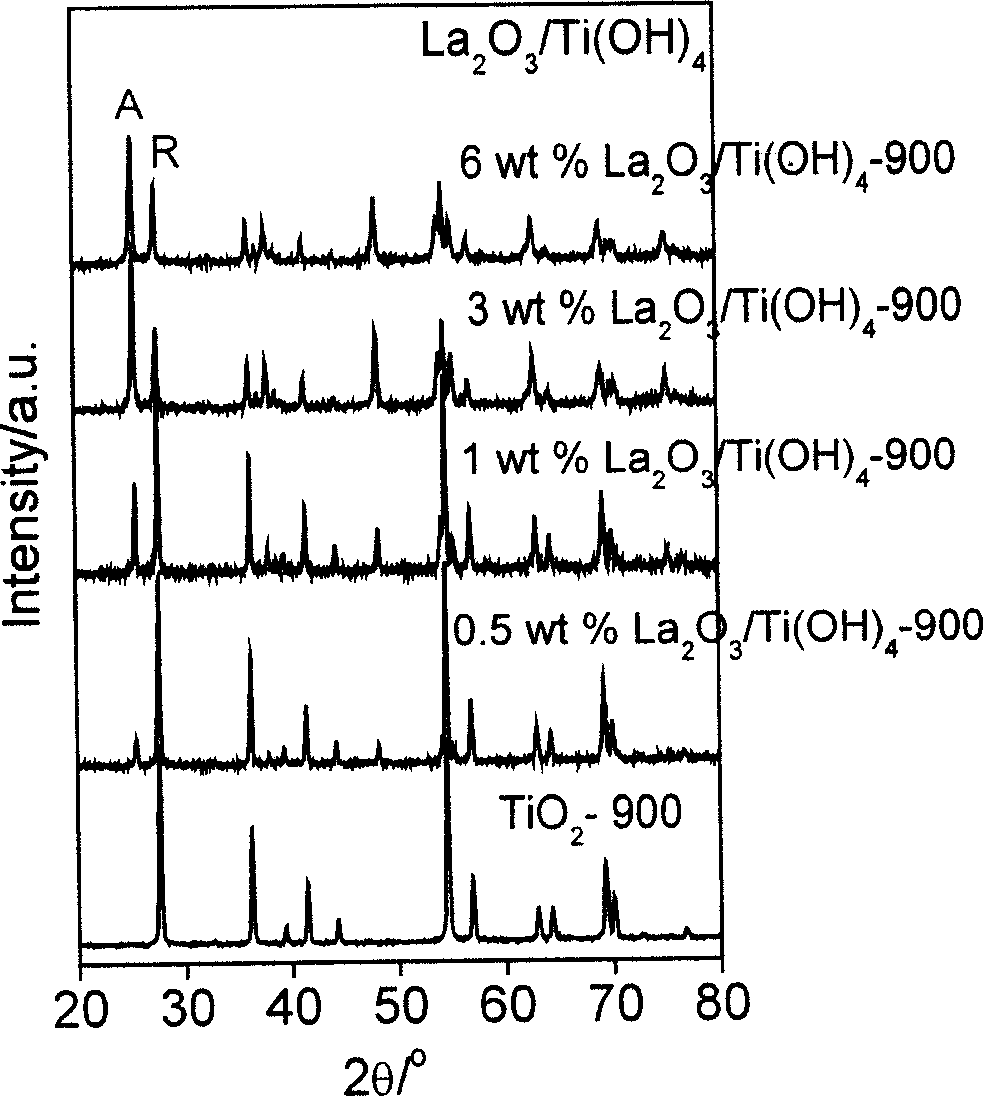

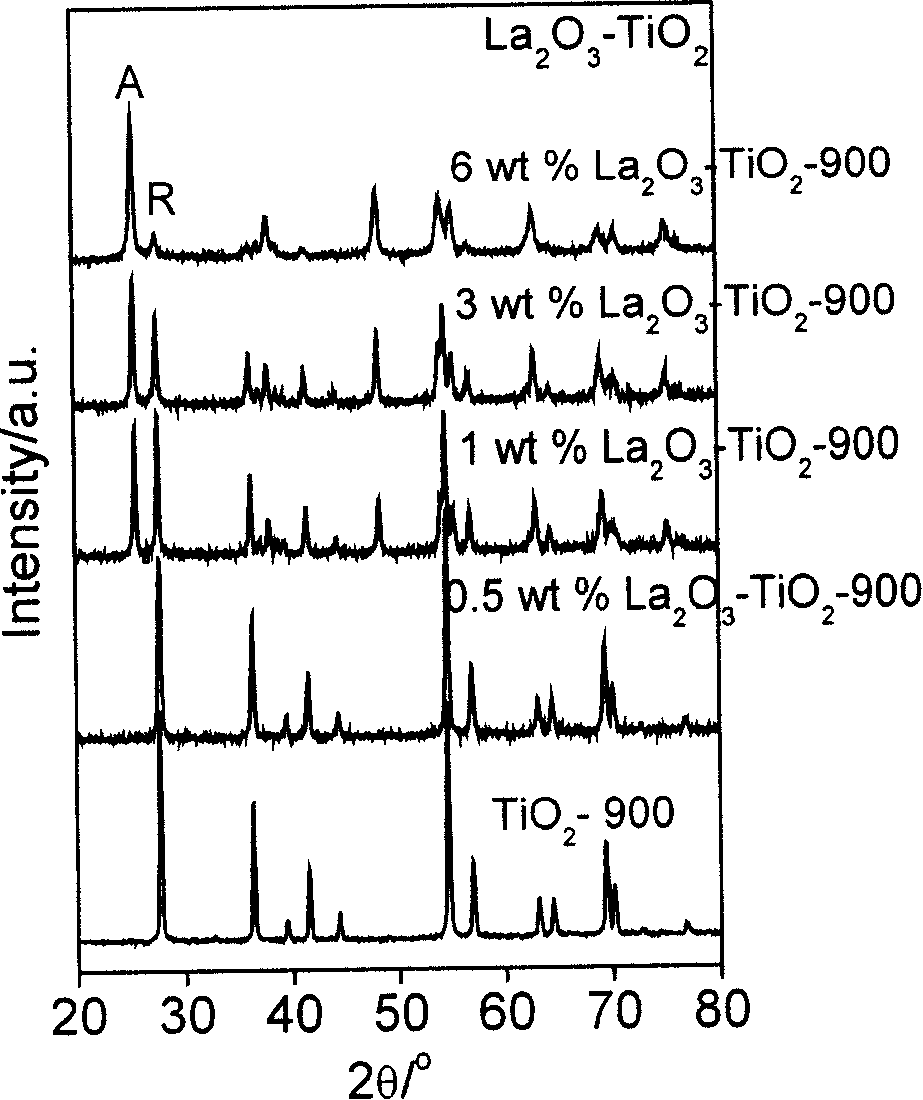

Method for stabilizing anatase phase nano titanium oxide and cubic phase nano zirconium oxide

InactiveCN101164896AReduce contentEasy to operateTitanium dioxideZirconium oxidesTitanium oxideLanthanum nitrate

This invention relates to a method for stabilizing, under high temperature, anatase phase nanometer titanium oxide (TO) or tetragonal phase nanometer zirconium oxide (ZO). The substantive feature is that: the obove-mentioned TO or ZO is treated, under particular temperature, by impregnation in solution containing lanthanum nitrate as stabilizator, and then being dried, sintered to obtain the final product powder. This invention is characterized by: (1), very low content of stabilizator in said powders, calculated as lanthanum oxide, being respectively 3% and 0.3% of the single layer dispersion on the TO and ZO; (2), this inventive products can be stabilized under at least 900deg.C; (3) said lanthanum oxide dispersed on the TO and ZO can effectively eliminate the growth of the particles of the TO and ZO, and eliminate agglutination, and decrease in the specific surface area.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

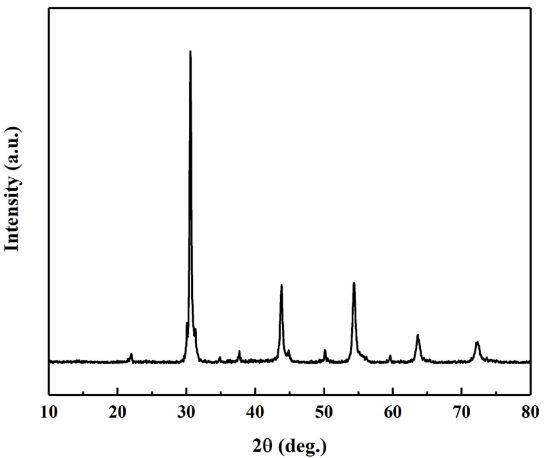

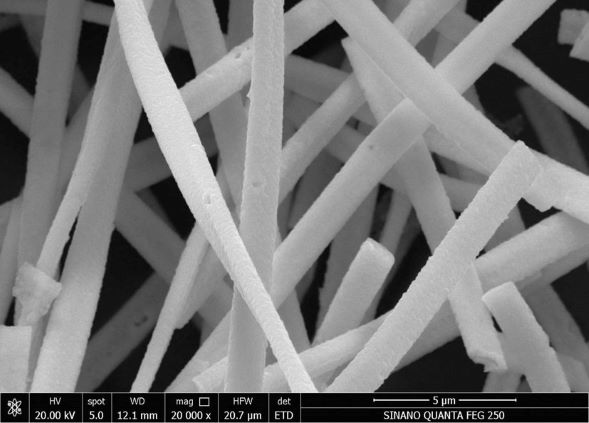

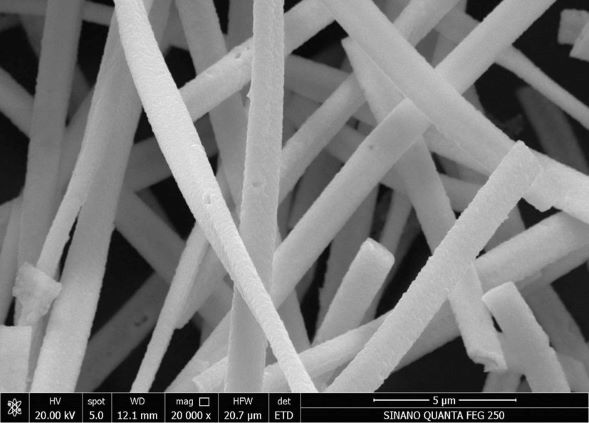

High-entropy zirconate inorganic fiber and preparation method thereof

The invention relates to a high-entropy zirconate inorganic fiber and a preparation method thereof. The preparation method comprises the following steps that basic zirconium carbonate, a calcium source, a strontium source, a barium source, glacial acetic acid and a spinning aid are heated and dissolved in a certain proportion in an aqueous solution to prepare high-entropy zirconate precursor sol; electrostatic spinning is carried out on the high-entropy zirconate precursor sol to obtain high-entropy zirconate precursor fibers; and heat treatment is carried out on the high-entropy zirconate precursor fiber to obtain the high-entropy zirconate inorganic fiber. The obtained sol is stable and good in spinnability, the obtained high-entropy zirconate fiber is a single-phase solid solution, the diameter of the fiber is 0.5-1.5 [mu]m, and the crystal phase and the fiber form are kept stable under the condition of the high temperature ranging from the room temperature to 1400 DEG C.

Owner:QILU UNIV OF TECH

Preparation method of dielectric film with ultrahigh dielectric constant

ActiveCN111430228AKey lengthReduce distortionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricPhysical chemistry

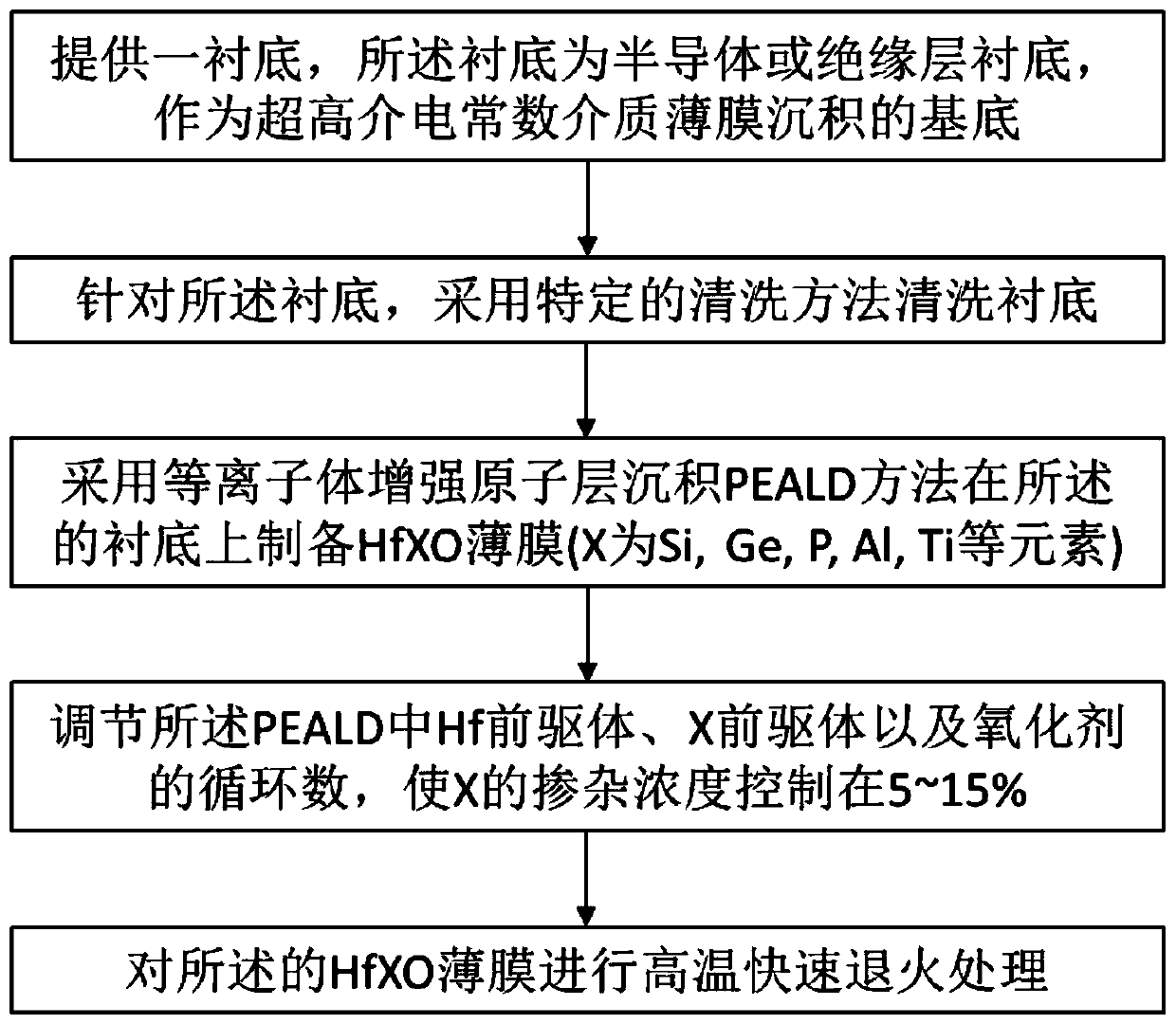

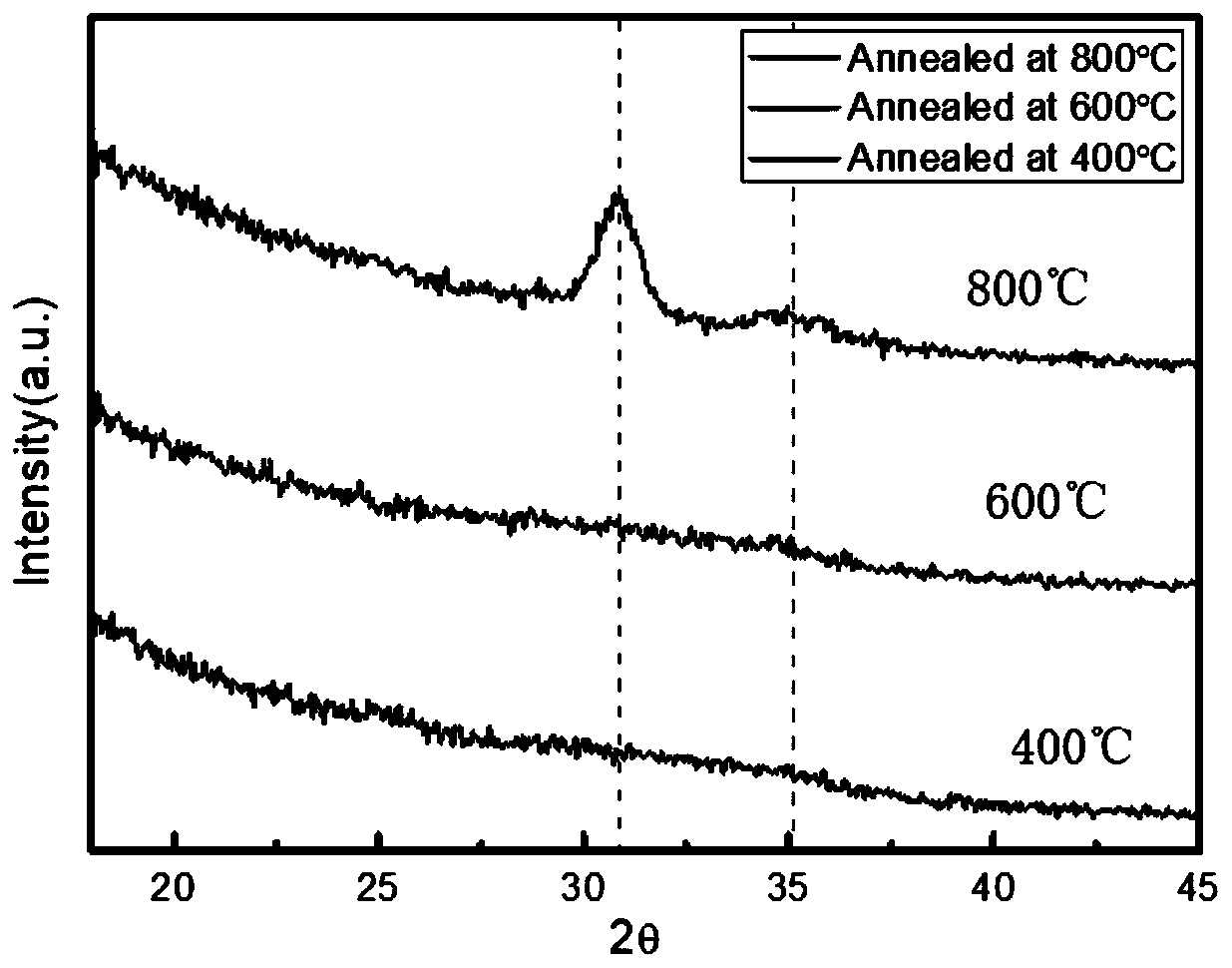

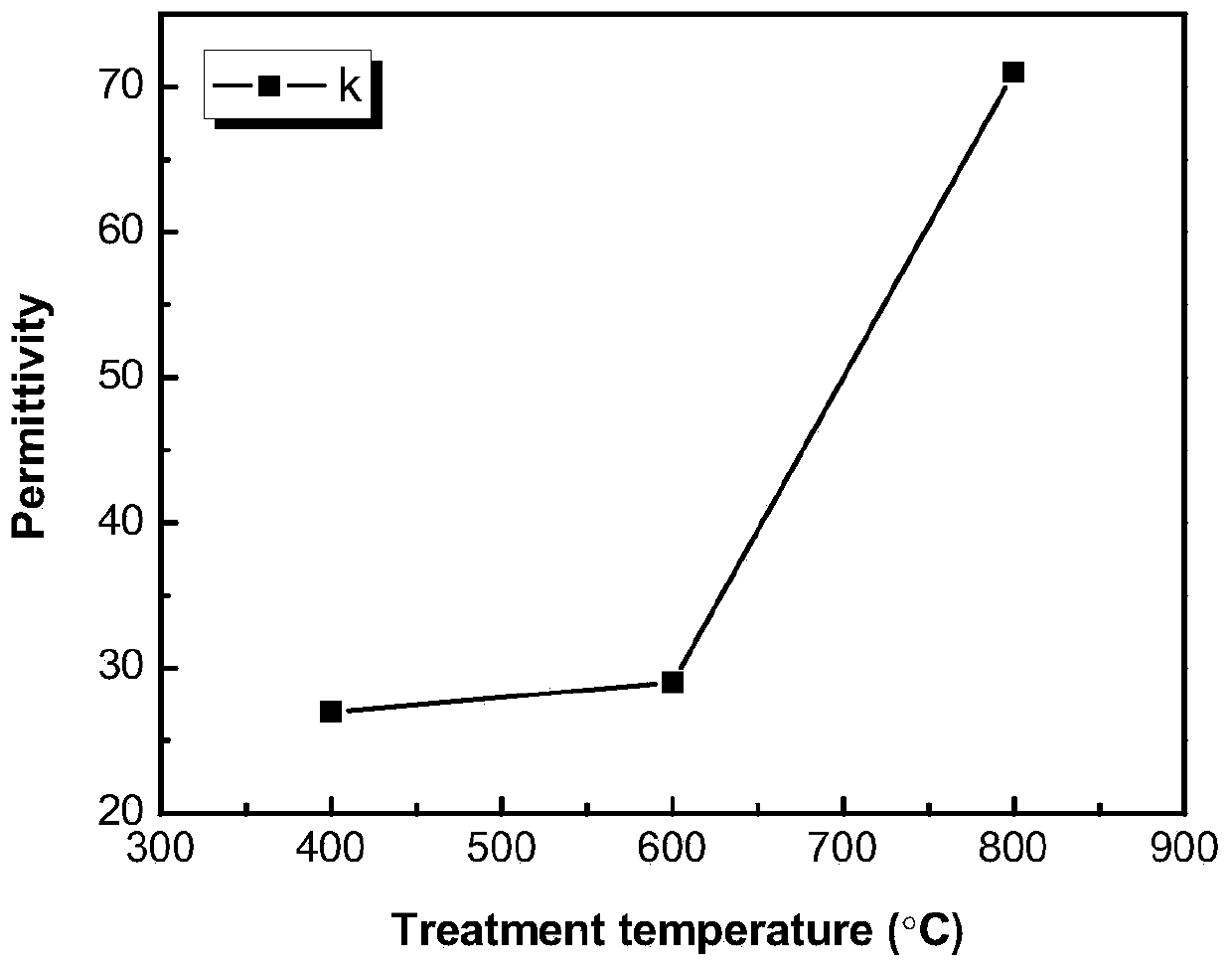

The invention discloses a preparation method of a dielectric film with an ultrahigh dielectric constant. The method comprises the following steps: (1) providing a substrate and cleaning the substrateto serve as a substrate for depositing the dielectric film; (2) preparing an HfXO thin film on the substrate by adopting a plasma enhanced atomic layer deposition method, wherein X is Si, Ge, P, Al orTi, and the number of atoms of X doped in HfXO accounts for 5-15%; and (3) carrying out high-temperature rapid annealing treatment on the HfXO film. By forming a crystalline phase structure with an ultrahigh dielectric constant, the preparation of the dielectric film with the ultrahigh dielectric constant is realized. According to the preparation method, the dielectric film with low equivalent gate-oxide thickness, ultrahigh dielectric constant, wide energy gap and high reliability can be prepared, and a feasible path is provided for selection of gate-oxide media in a semiconductor process technology which is rapidly developed along with the Moore law at present.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of nanometer alumina doped polyimide film

The invention discloses a preparation method of a nanometer alumina doped polyimide film. The method specifically comprises: 1) selecting a proper amount of pyromellitic dianhydride (PMDA) and 4,4'-diamine diphenyl ether (ODA); and 2) mixing the selected materials, weighing a certain amount of the pre-prepared nanometer oxide dispersion of aluminum, adding a required solvent according to a certain solid content, diluting, carrying out high-speed stirring, adding to a three-necked flask filled with ODA, and stirring until completely dissolving. According to the present invention, the nanometer alumina particle solution is added during the solution mixing, such that the polyimide film can be reinforced and toughened, and the wear resistance of the polyimide film can be significantly improved.

Owner:刘庆祝

Low-temperature curing ceramic powder and method for producing the same

The invention relates to low temperature curing ceramic powder and a method for preparing the same, which belongs to the technical field of material. The ceramic powder comprises the following compositions in weight percentage: 42 to 50 percent of Al2O3, 15 to 18 percent of SiO2, 3.5 to 6.5 percent of MgO, 28 to 35 percent of thermosetting plastic PA, and 0.5 to 1 percent of thermosetting plastic PC. The method for preparing the low temperature curing ceramic powder comprises the following steps: performing high temperature pre-sintering and ball milling on the Al2O3, the SiO2 and the MgO respectively, and then removing the water through drying; performing low temperature presintering and water vapor heating on the thermosetting plastic PA and the thermosetting plastic PC, and then screening out the part of which the fineness is between 250 and 300 meshes; and mixing inorganic materials and organic materials after the treatment, stirring the materials evenly to preparing the low temperature curing ceramic powder. Through a test under the condition that the temperature is between 40 DEG C below zero and 1,500 DEG C, the air velocity is 200 meters per second, the airflow pressure is 2 MPa and the vibration frequency is 2,500 Hz, the low temperature curing ceramic powder is proved to have stable material performance and excellent comprehensive effect, and can be a filling insulating material for various types of thermocouples.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

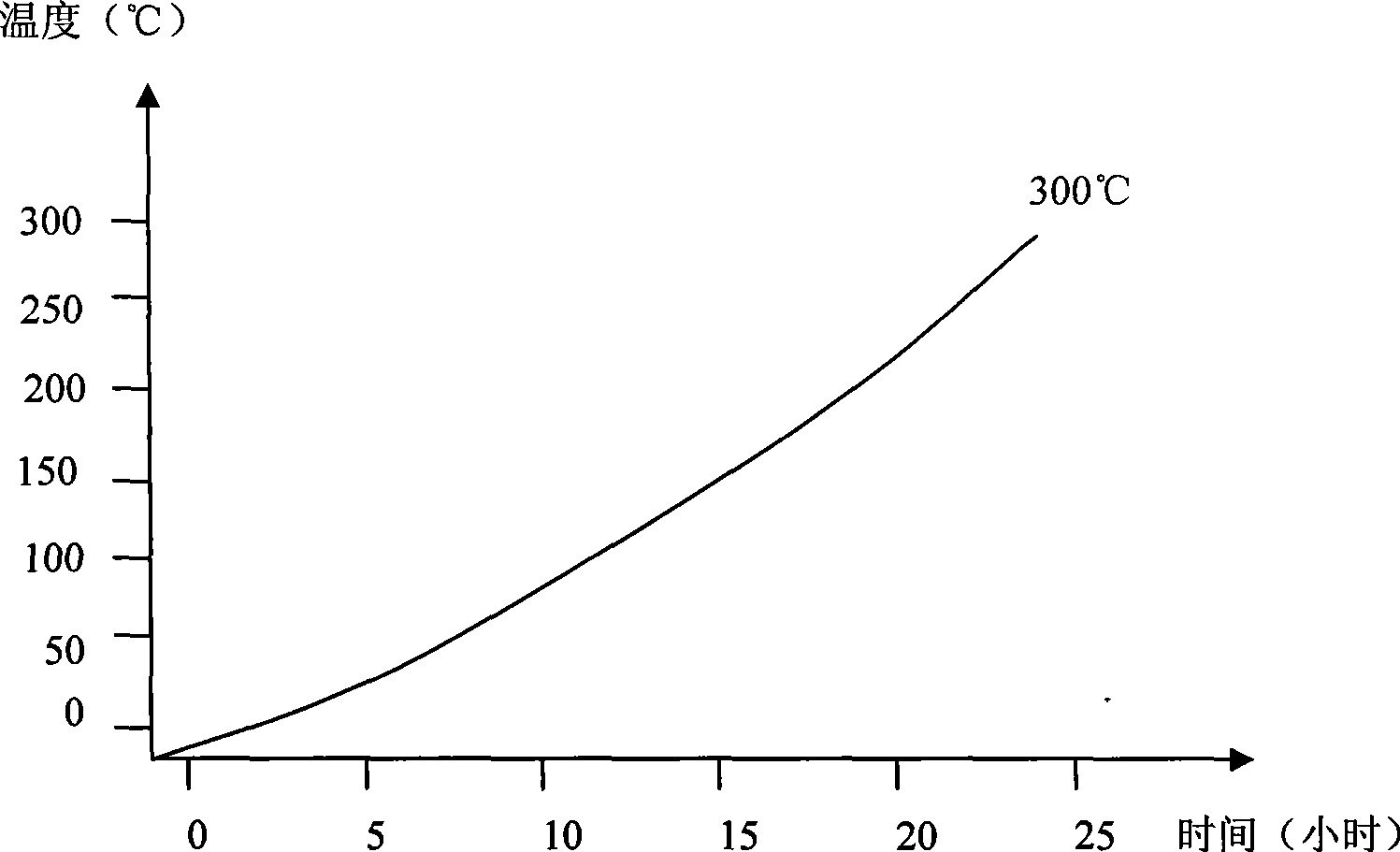

Antioxidant wear-resistant spheroidal graphite cast iron and preparation method thereof

InactiveCN108642370AHigh surface hardnessHigh strengthProcess efficiency improvementWear resistantOxygen ions

The invention relates to the technical field of spheroidal graphite cast iron, in particular to antioxidant wear-resistant spheroidal graphite cast iron and a preparation method thereof. The antioxidant wear-resistant spheroidal graphite cast iron is prepared from raw materials as follows: steel scrap, pig iron, a graphite carburant, a nucleating agent and a rare earth magnesium alloy spheroidizing agent. The preparation method comprises the following steps: melting the steel scrap and pig iron in a medium-frequency induction furnace at a certain temperature, and melting the steel scrap and pig iron to obtain molten iron and carrying out desulfurization and the like. The inner tissues and the surface tissues of the spheroidal graphite cast iron provided by the invention are uniformly and compactly distributed, the spheroidal graphite cast iron is high in the surface hardness and strength and good in toughness, oxidization resistance and wear resistance. The nucleating agent contains silicon, and can promote the cast iron to form a compact silicon dioxide oxidation film layer at a high temperature to prevent permeation and invasion of oxygen ions to a casting effectively to preventfurther oxidization, so that the anti-oxidant growth performance of the casting is improved greatly; by adding tungsten and chromium into the nucleating agent, the strength and plasticity of the spheroidal graphite cast iron can be improved; and by adding proper antimony, the quantity and the rate of spheroidization of spherulitic graphite can be increased.

Owner:HANSHAN DONGSHAN DEYU SPHERULITIC GRAPHITE CASTING FACTORY

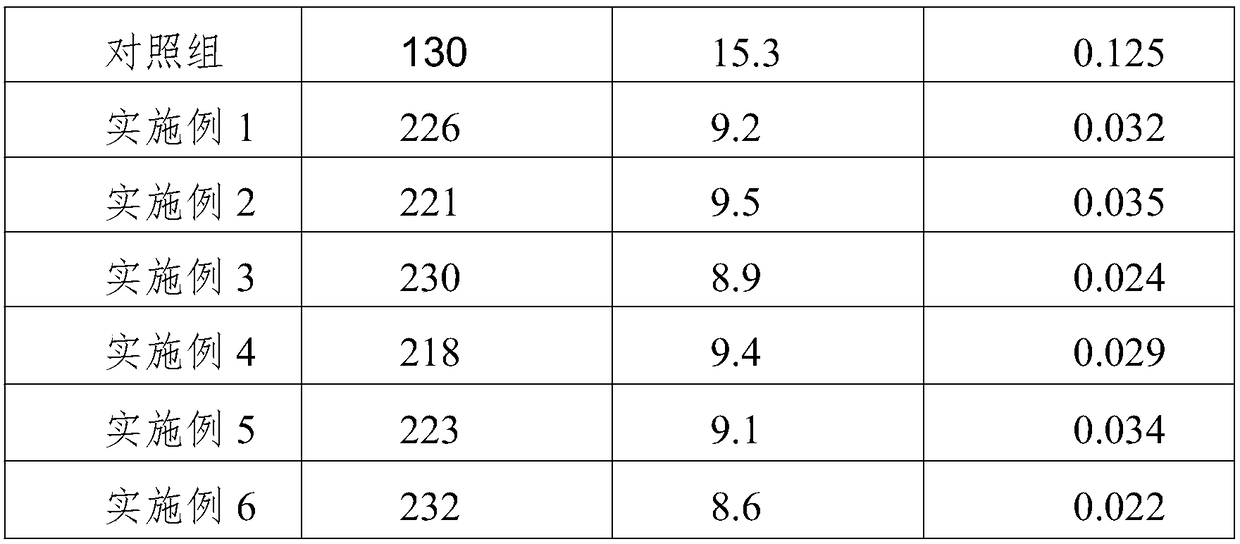

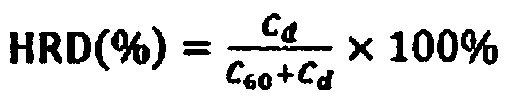

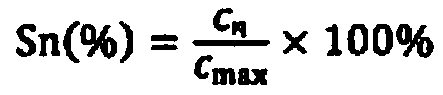

Preparation method for hydrogen storage alloy material

ActiveCN110157951AShorten process timeReduce the number of process cyclesHydrogen separation using solid contactCeriumManganese

The invention relates to a production technology for a nickel-hydrogen battery electrode material, and particularly discloses a preparation method for a hydrogen storage alloy material; the preparation method comprises the following steps of: a, measuring raw materials according to a proportion; b, sequentially inputting the raw materials into a smelting furnace with argon gas protection accordingto the feeding order of yttrium, lnthanum, cerium, manganese, samarium and nickel; c. removing moisture in the materials; d, removing low boiling point volatiles; e. fully melting the raw materials;f, repeatedly crushing and melting; g, inputting a product into the smelting furnace, wherein the temperature is raised to 850-920 DEG C, the temperature is kept for 5-10min, and then the temperatureis cooled to the normal temperature at a rate of 20-50 DEG C / min. The advantages are as follows: 1) solving the problem of Mg volatilization during alloy smelting; 2) greatly reducing the effect ofimpurities on the alloy; 3) making the internal crystal phase of the alloy more stable and increasing the number of cycles of the alloy; 4) improving the capacity of the alloy hydrogen storage material; expanding the applicable temperature of the alloy hydrogen storage material; reducing the hydrogen absorption and desorption pressure, and 5) making the alloy crystal phase more uniform.

Owner:YIBIN TIANYUAN GRP CO LTD

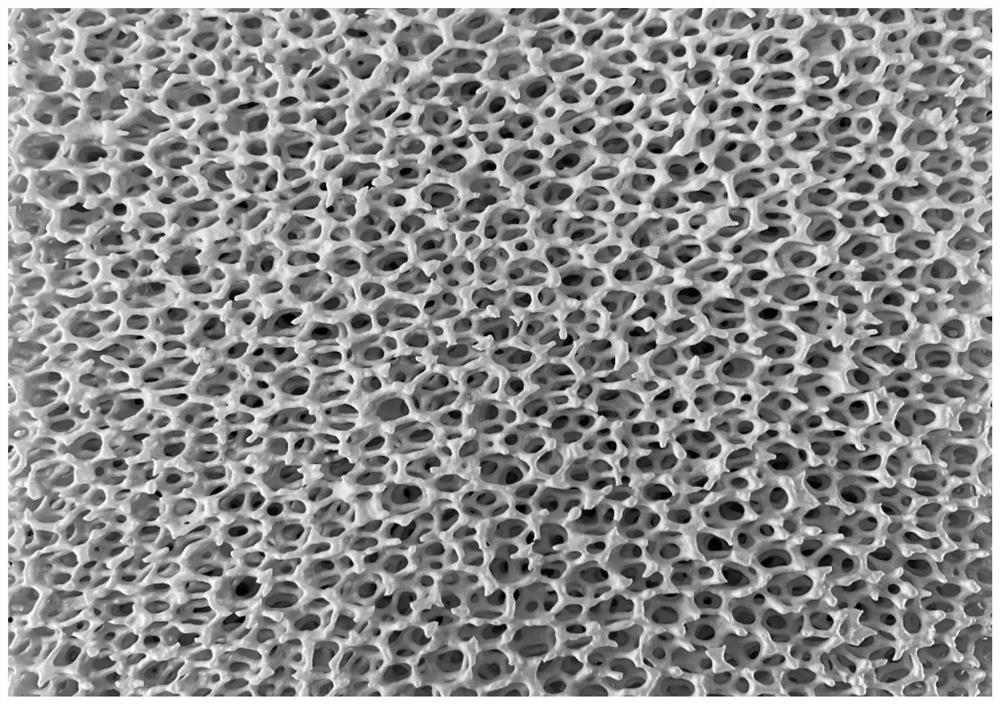

Aluminum titanate porous ceramic, preparation method thereof and porous medium burner

InactiveCN112778008AModerate viscosityAppropriate ratioGaseous fuel burnerCeramicwareAdhesivePorous medium

The invention discloses aluminum titanate porous ceramic, a preparation method thereof and a porous medium burner, and belongs to the technical field of ceramic. The aluminum titanate porous ceramic is prepared from slurry of raw materials through pyrolysis and sintering molding, and the raw materials comprise Al2O3, TiO2, a stabilizer, an adhesive, a dispersing agent and a solvent used for dissolving the adhesive, wherein the weight ratio of the Al2O3 to the TiO2 to the stabilizer is (50-70): (30-50): (1-10), and the stabilizer is at least one selected from the group consisting of magnesium oxide, magnesium carbonate, silicon dioxide, ferric oxide, cerium oxide, lanthanum oxide and yttrium oxide. The preparation method comprises the following steps of: immersing foamed plastic with pores into slurry of raw materials, coating the surface of the foamed plastic with slurry, drying and curing after coating, and sintering and molding after pyrolysis. The problem that existing aluminum titanate porous ceramic is poor in thermal shock resistance can be solved.

Owner:SONGSHAN LAKE MATERIALS LAB +1

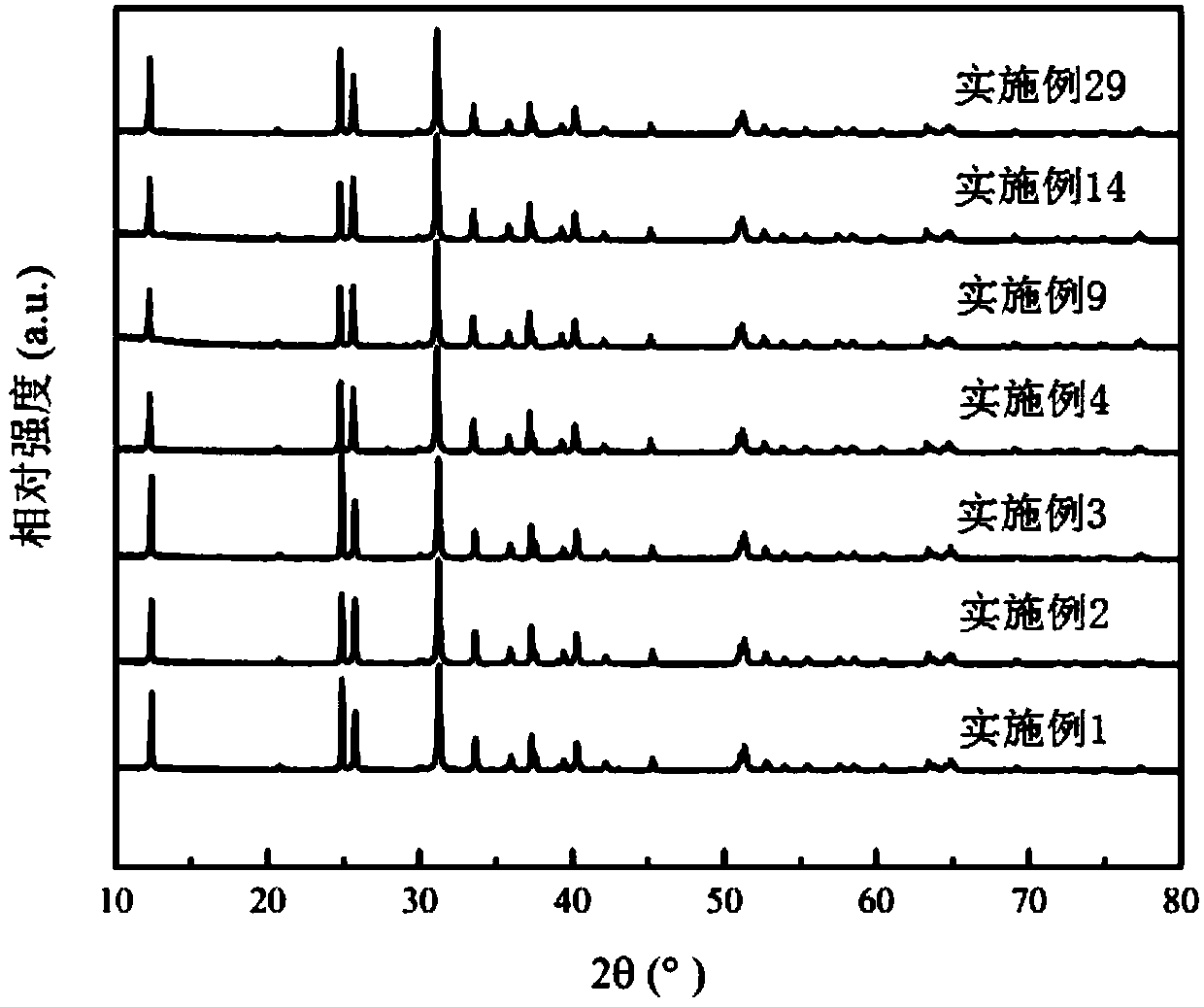

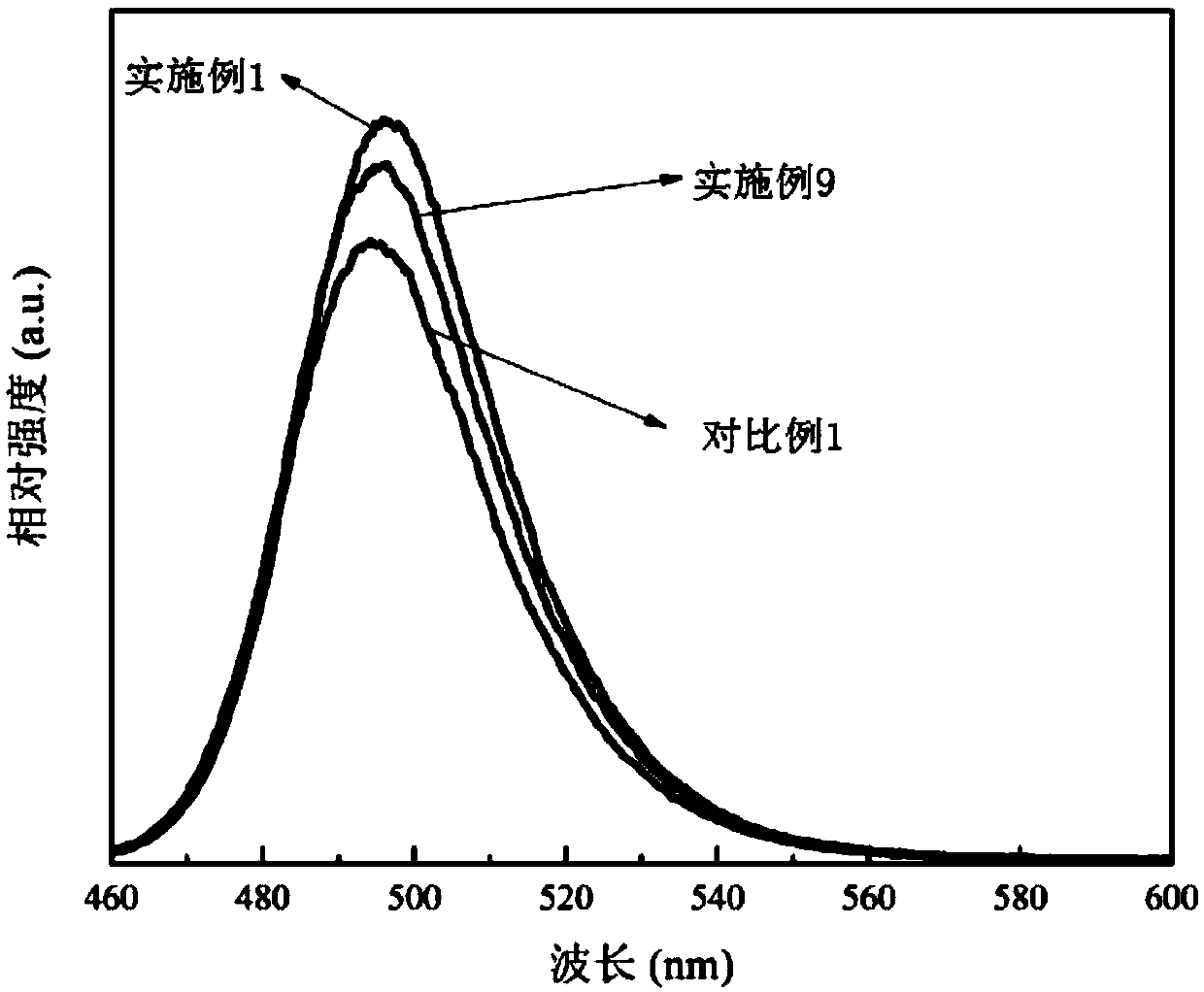

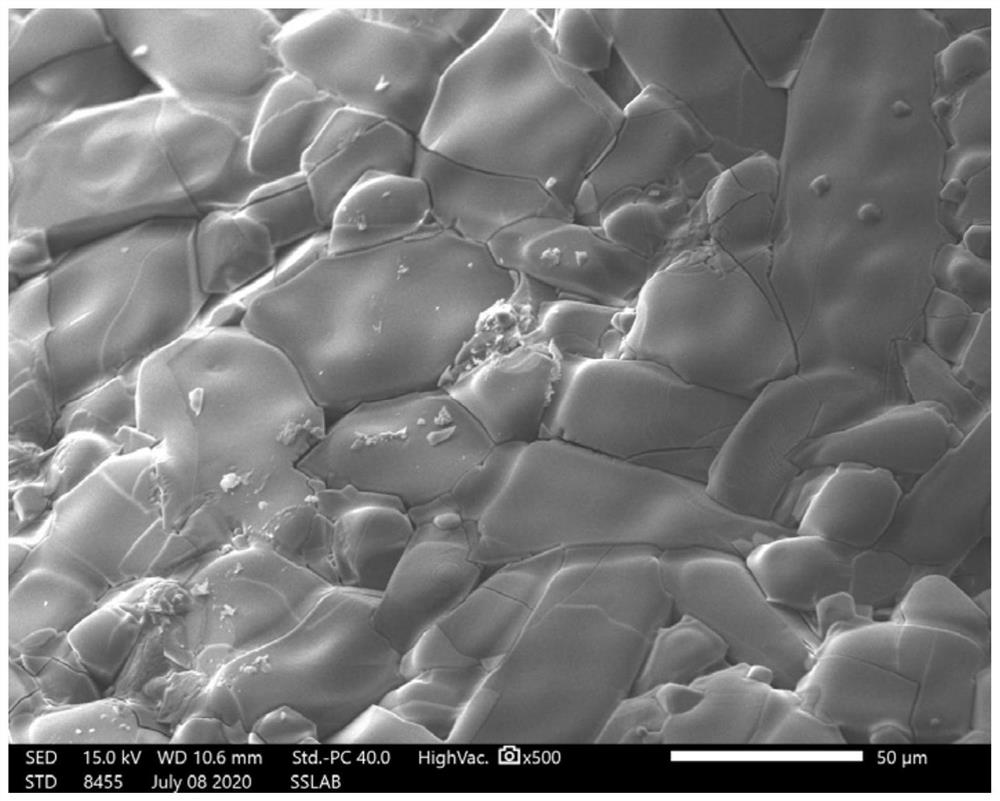

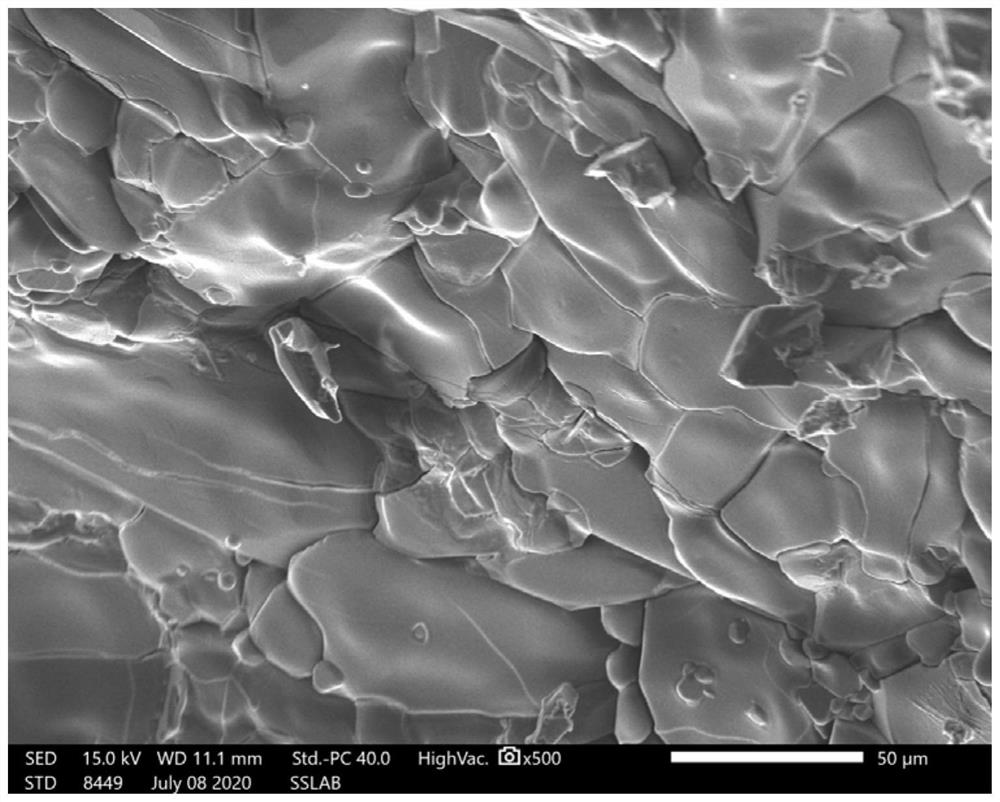

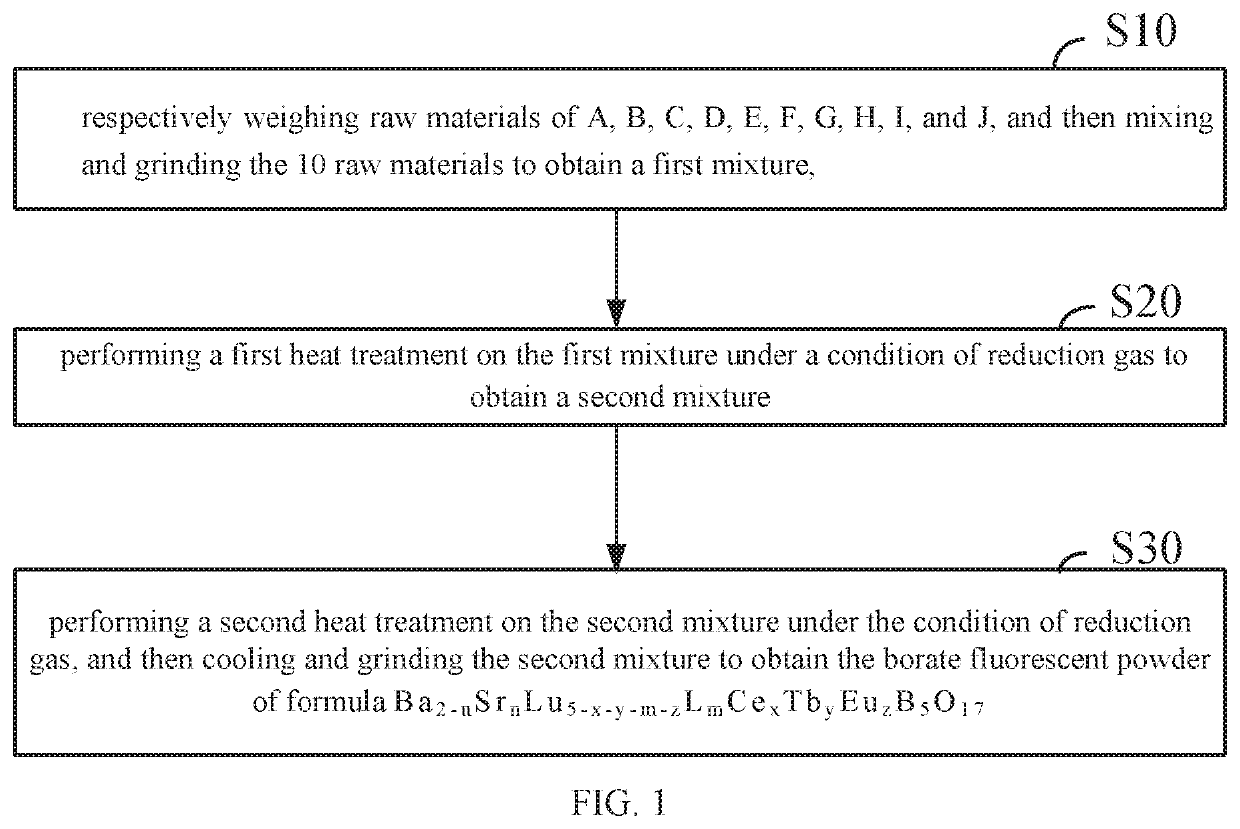

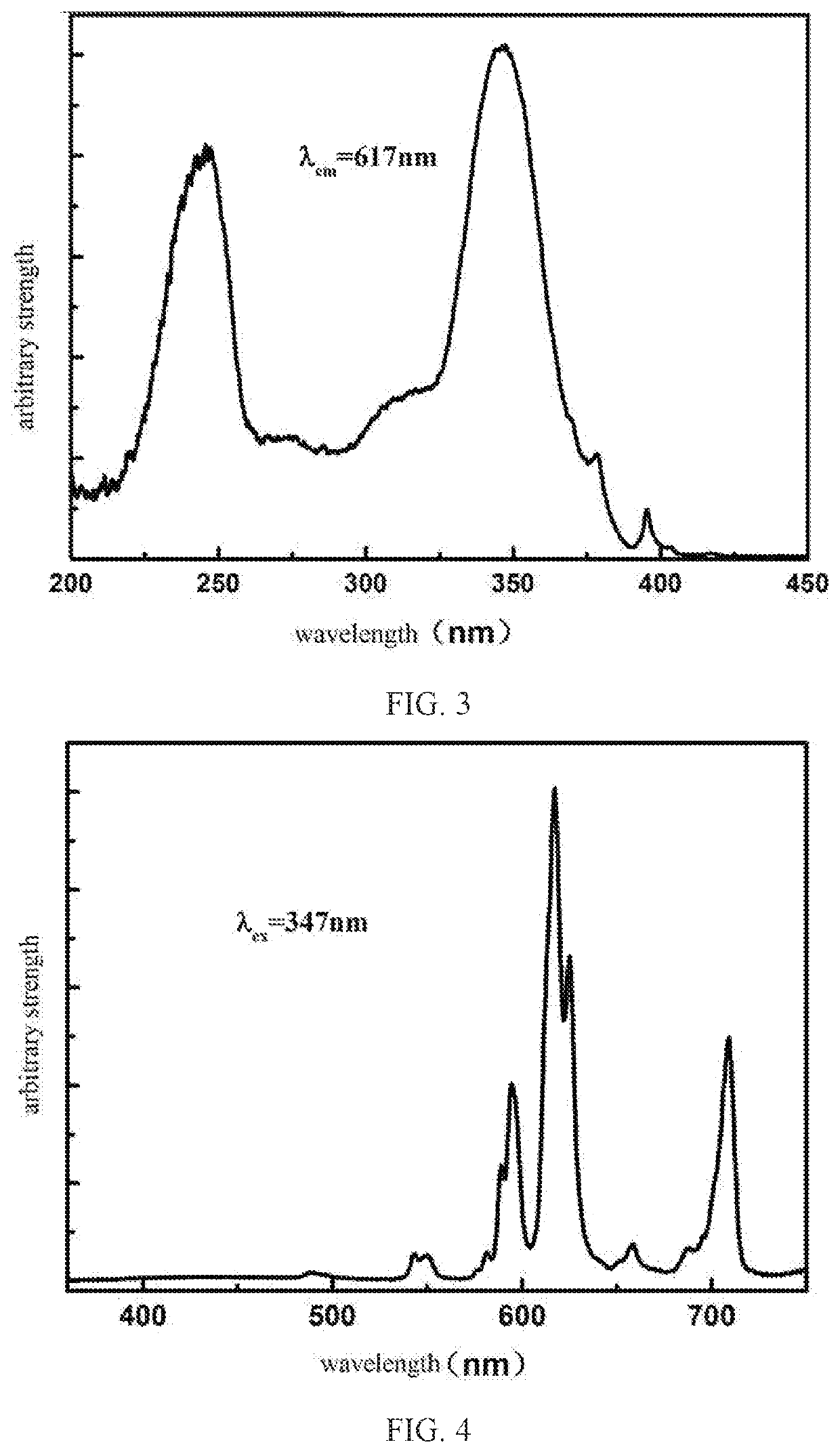

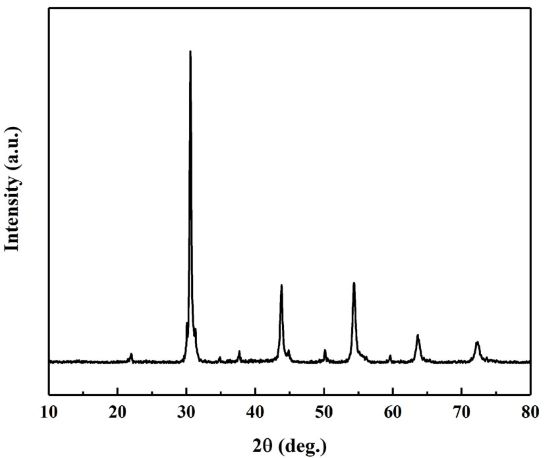

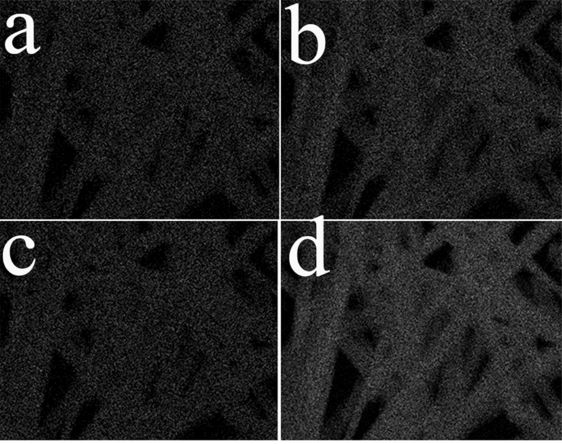

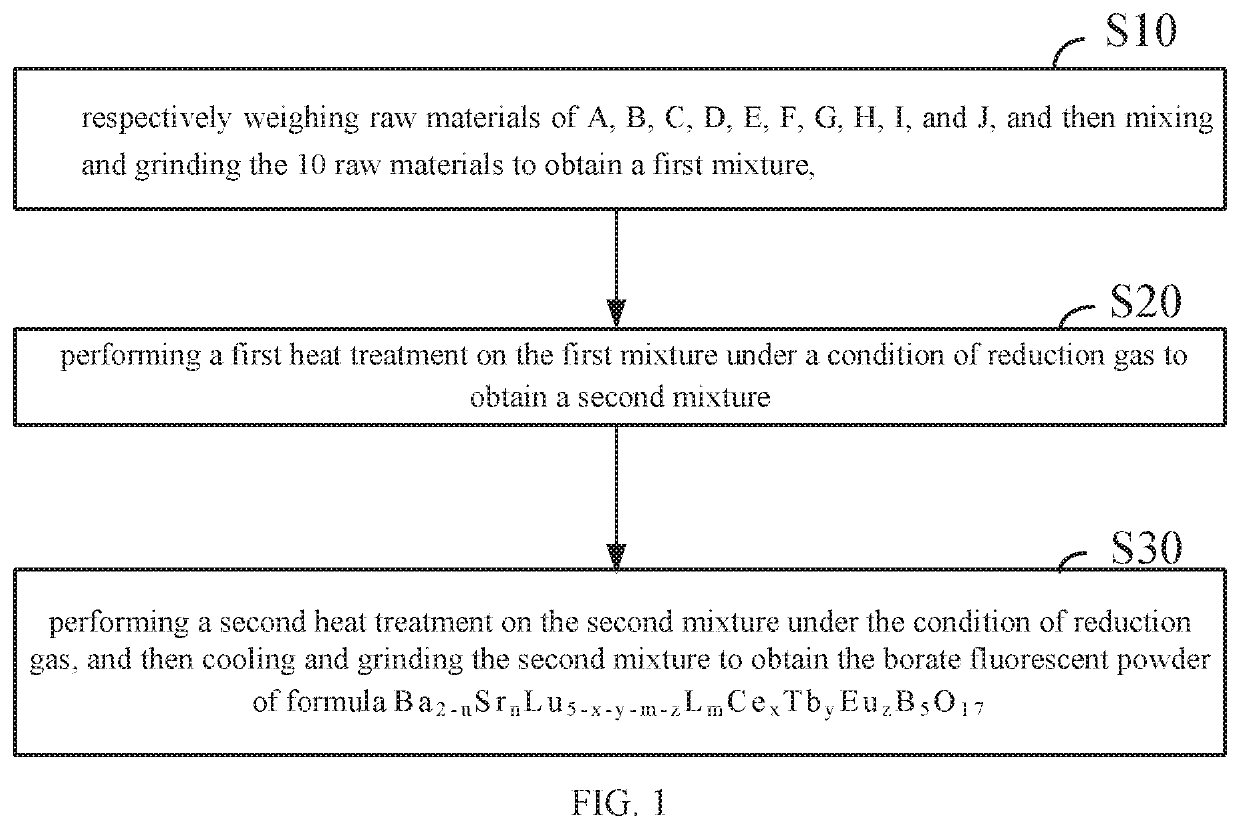

Borate fluorescent powder and preparing method thereof

ActiveUS20210301204A1Low luminous efficiencyCrystal phase stabilityEnergy efficient lightingLuminescent compositionsPhysical chemistryUltraviolet

A borate fluorescent powder and a preparing method thereof are provided. The formula of the borate fluorescent powder is Ba2-nSrnLu5-x-y-m-zLmCexTbyEuzB5O17. L is one or any combination of the elements Gd, La, and Sc. Ranges of x, y, z, m, and n are respectively 0<x≤0.6, 0<y≤3, 0<z≤0.4, 0≤m≤1, and 0≤n≤0.5. The borate fluorescent powder provided has a stable crystalline phase, high luminous efficiency, and decent thermal stability, and can be applied to ultraviolet LEDs or near-ultraviolet LEDs to construct white LEDs.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

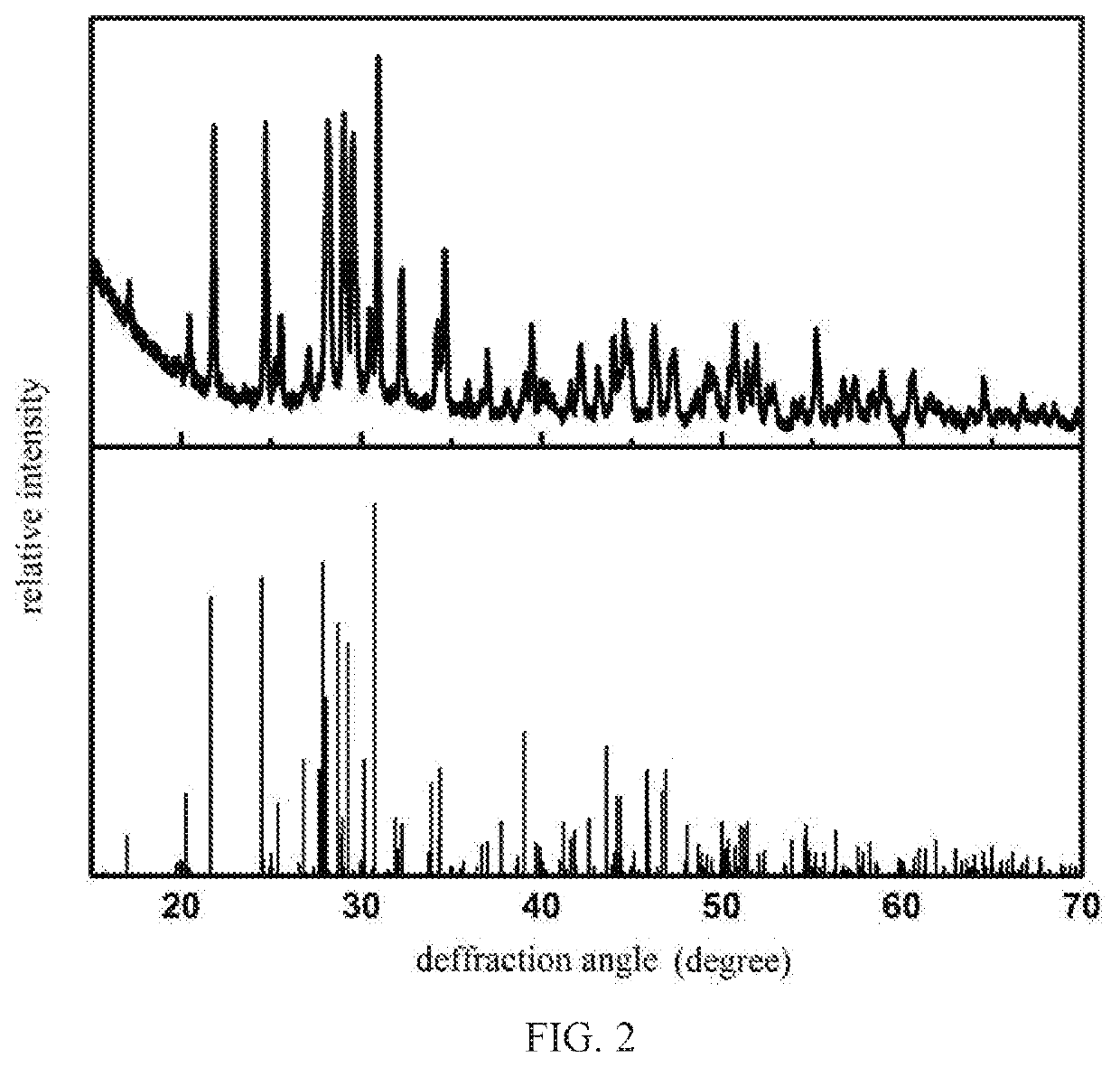

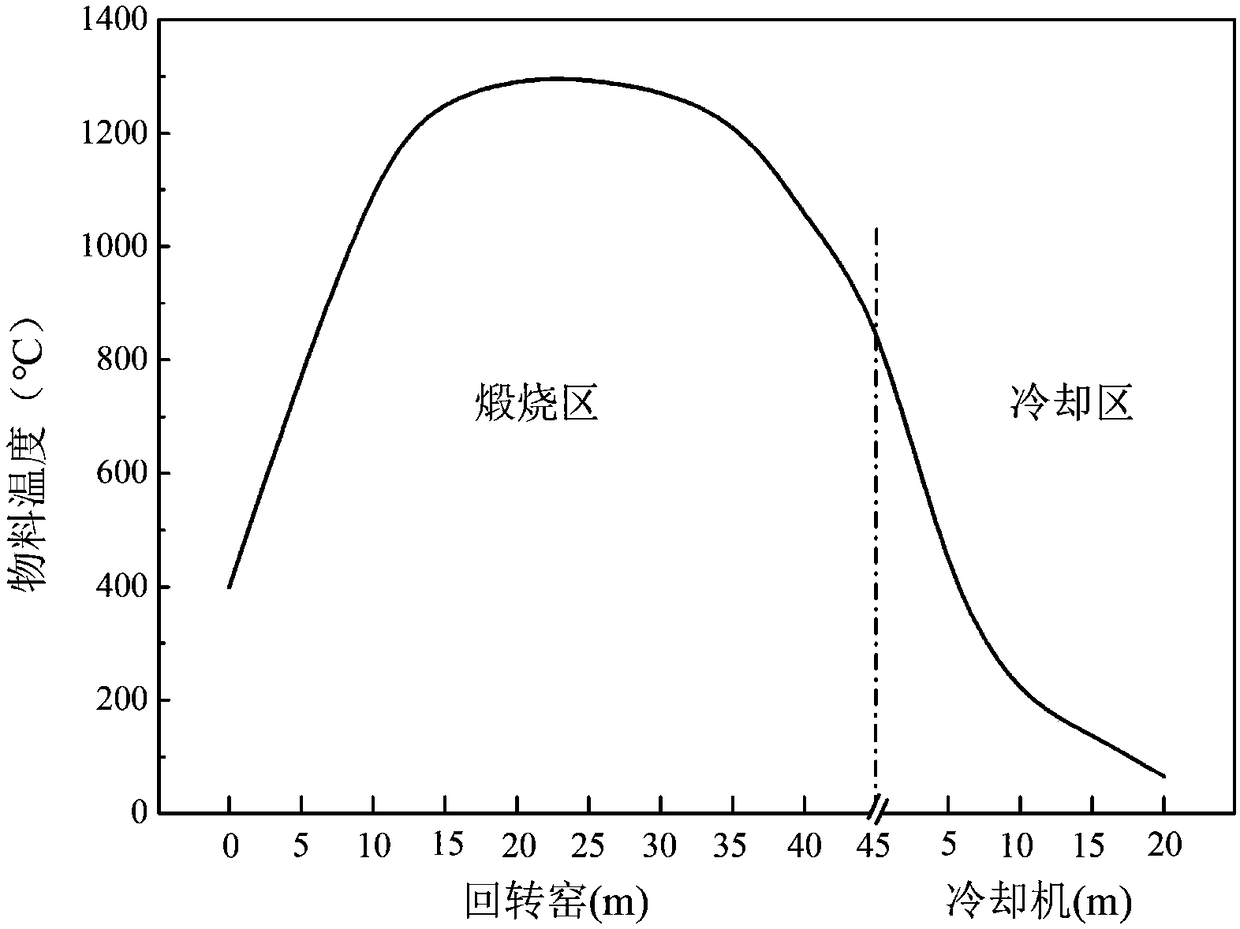

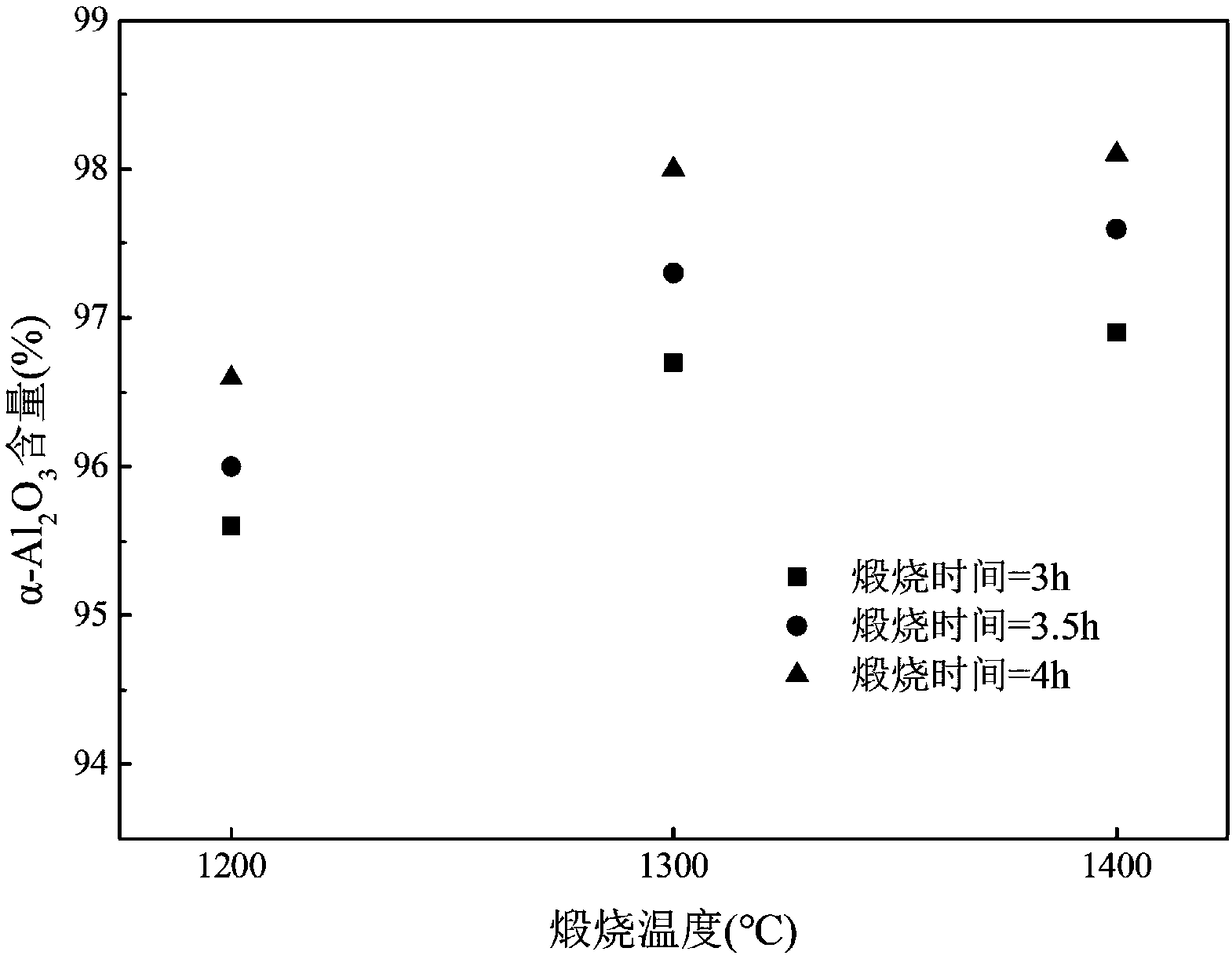

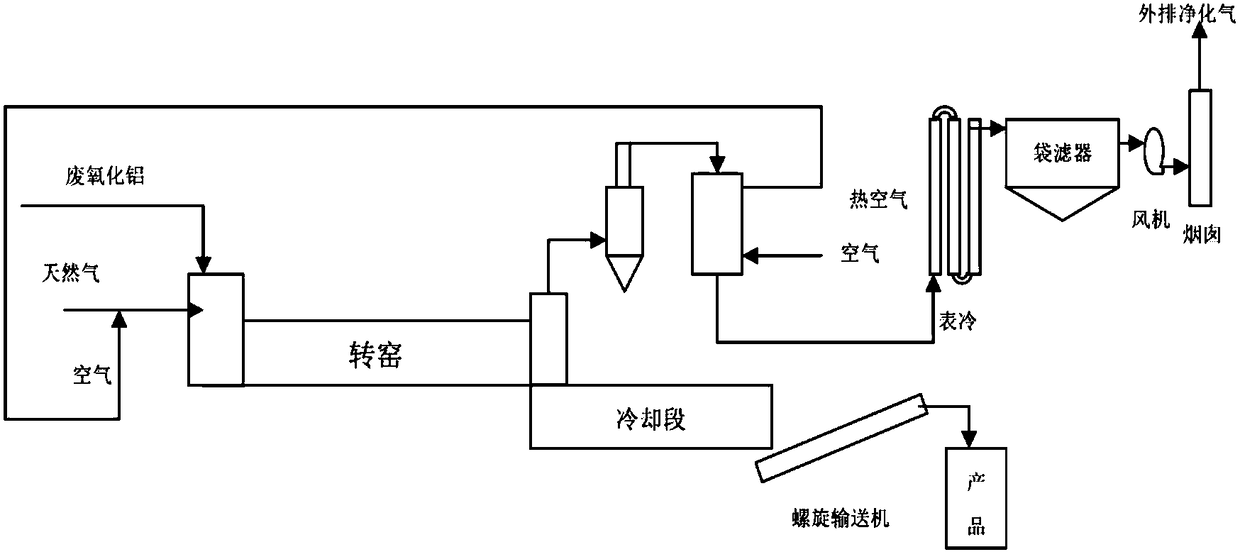

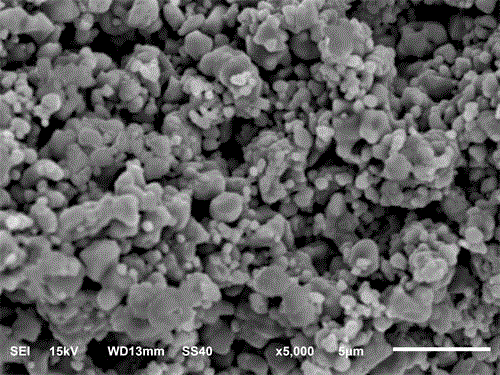

Method for preparing high-purity alpha-aluminium oxide by means of waste activated aluminium oxide

InactiveCN108585010ASmall specific surface areaStrong heat resistanceAluminates/aluminium-oxide/aluminium-hydroxide purificationMixed materialsSeed crystal

The invention discloses a method for preparing high-purity alpha-Al2O3 by means of waste activated aluminium oxide. According to the method, after the waste activated aluminium oxide and alpha-Al2O3 seed crystal powder are mixed, the mixture enters a rotary kiln preheating tower for drying and preheating first, the preheated and mixed material enters a reaction area of a rotary kiln to complete acalcination process, the calcinated material is unloaded into a cooler for cooling, and the cooled material is screened to obtain the alpha-Al2O3. According to the method, the waste activated aluminium oxide (gamma-type activated aluminium oxide) which contains organic anthraquinone, impurities including inorganic base and the like in a process of producing hydrogen peroxide (hydrogen peroxide) through an anthraquinone method is used for preparing a high-purity alpha-Al2O3 material through a solid phase method, so that resourceful utilization of the waste activated aluminium oxide is achieved,the problems are solved that the recovery and utilization rate of the waste aluminium oxide generated in the existing hydrogen peroxide production process is low, the treatment mode is unreasonable,and resources are waste.

Owner:CENT SOUTH UNIV +1

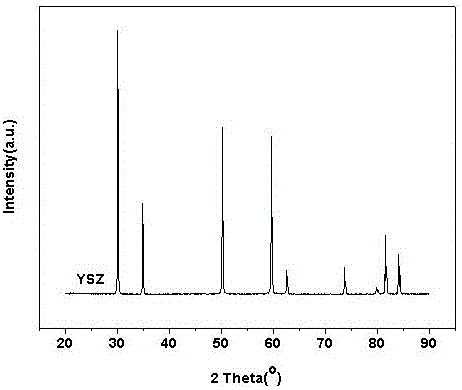

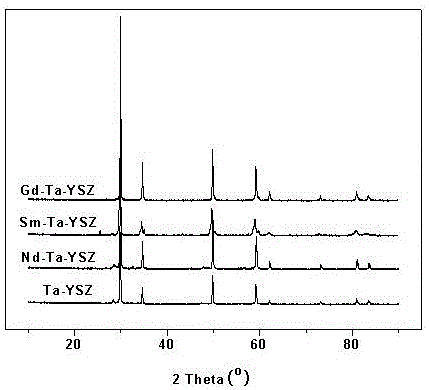

A stable zirconia ceramic target material for electron beam physical vapor deposition and its preparation method

ActiveCN103936415BCrystal phase stabilityChemically stableElectron beam physical vapor depositionGas phase

Owner:INNER MONGOLIA UNIV OF SCI & TECH

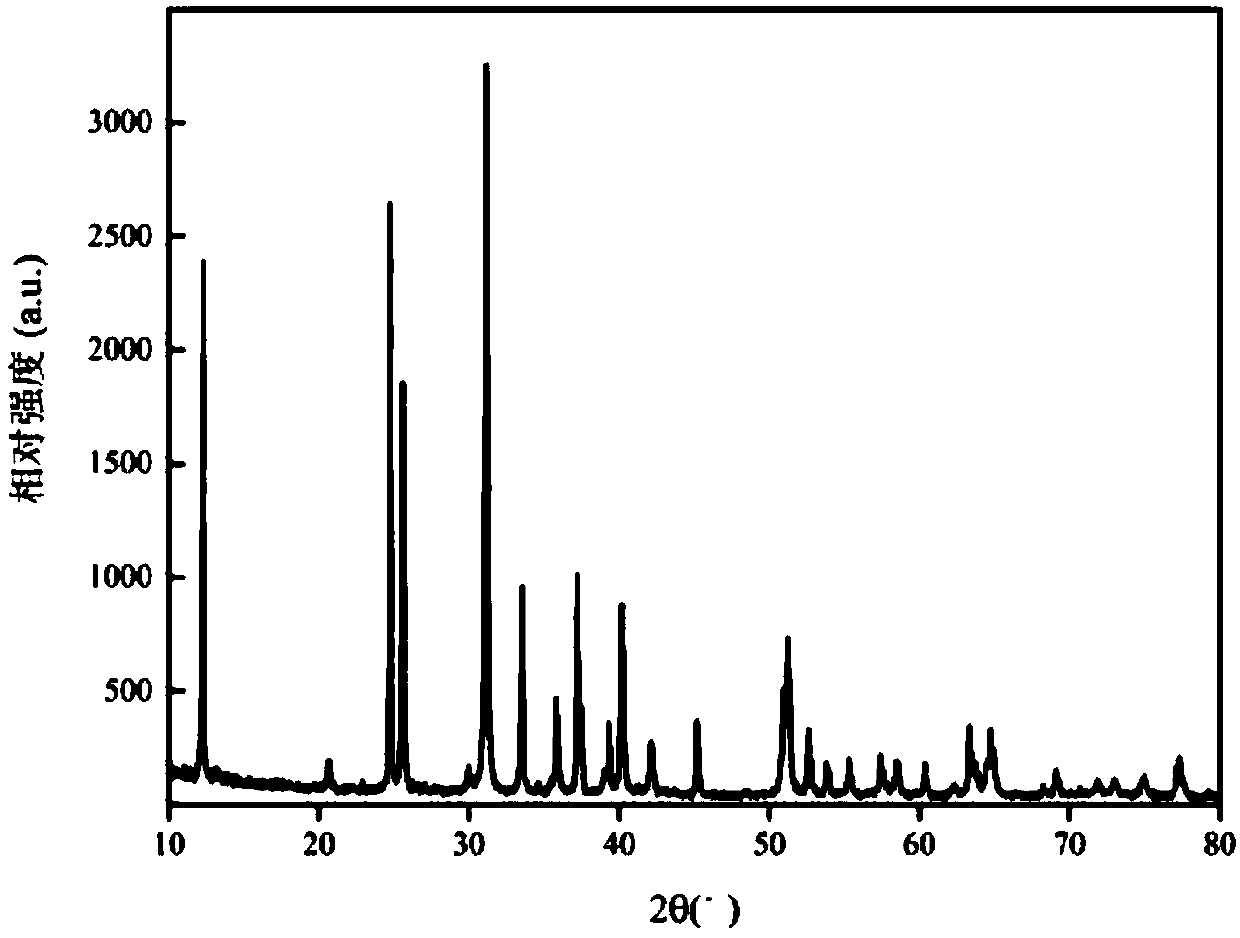

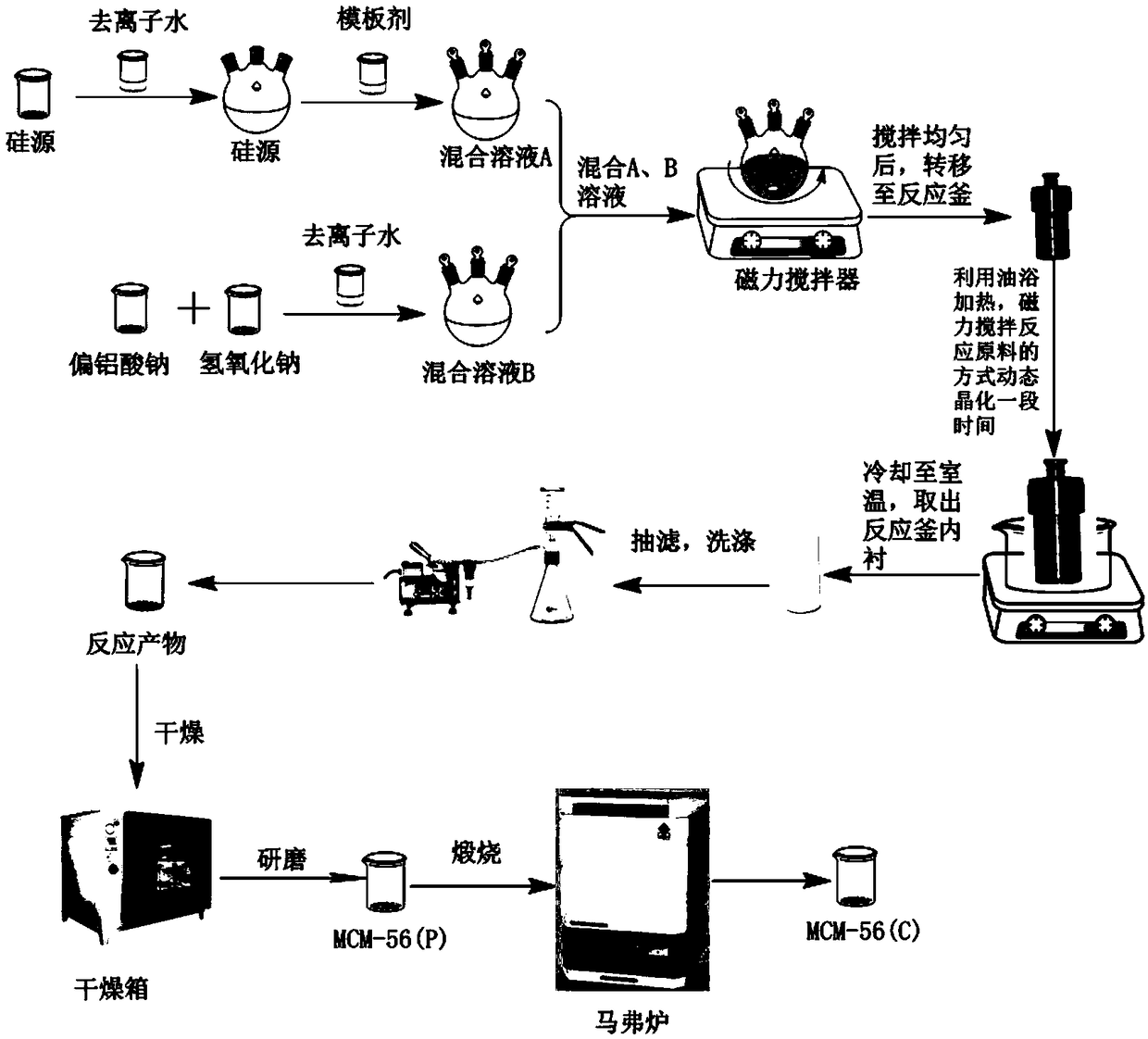

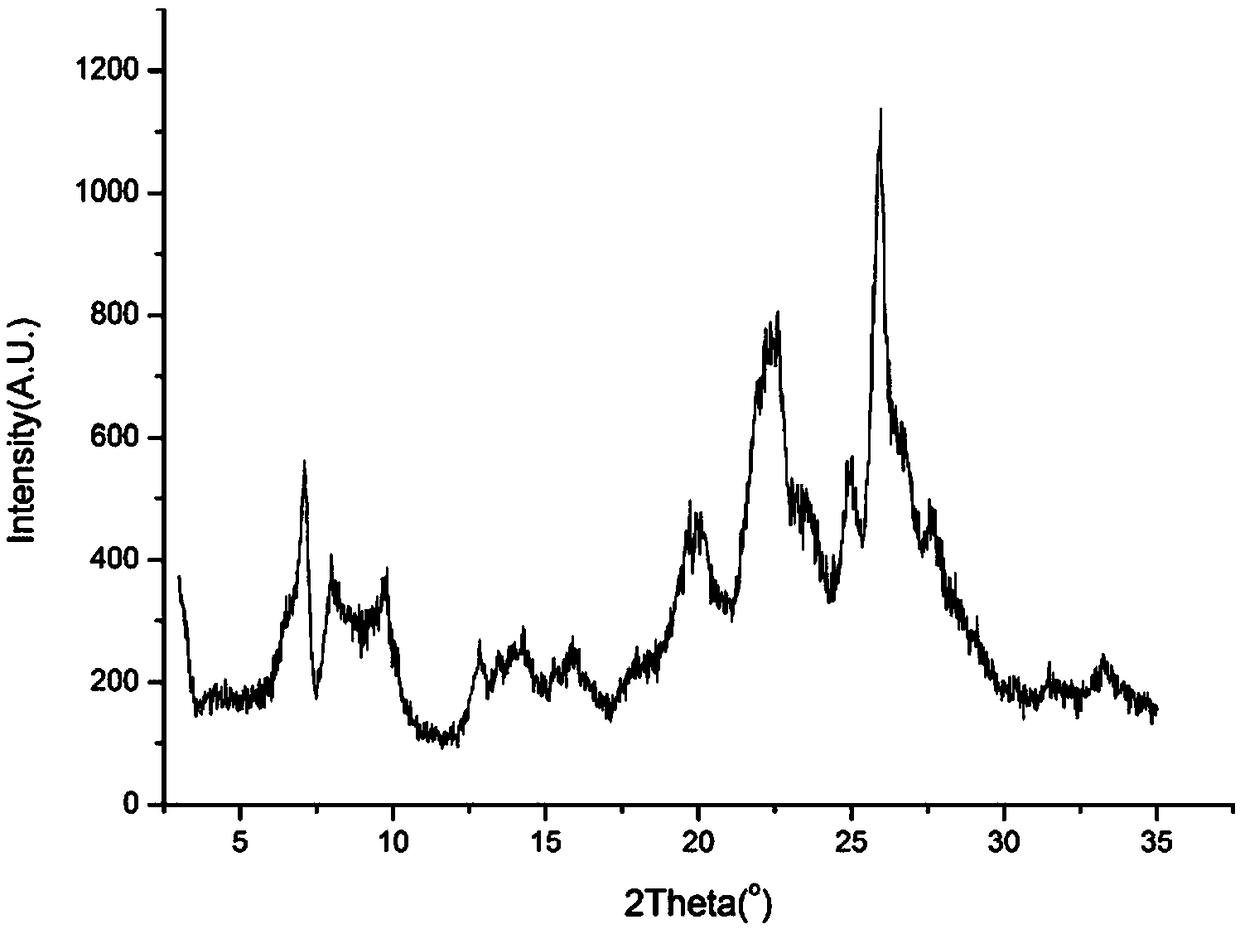

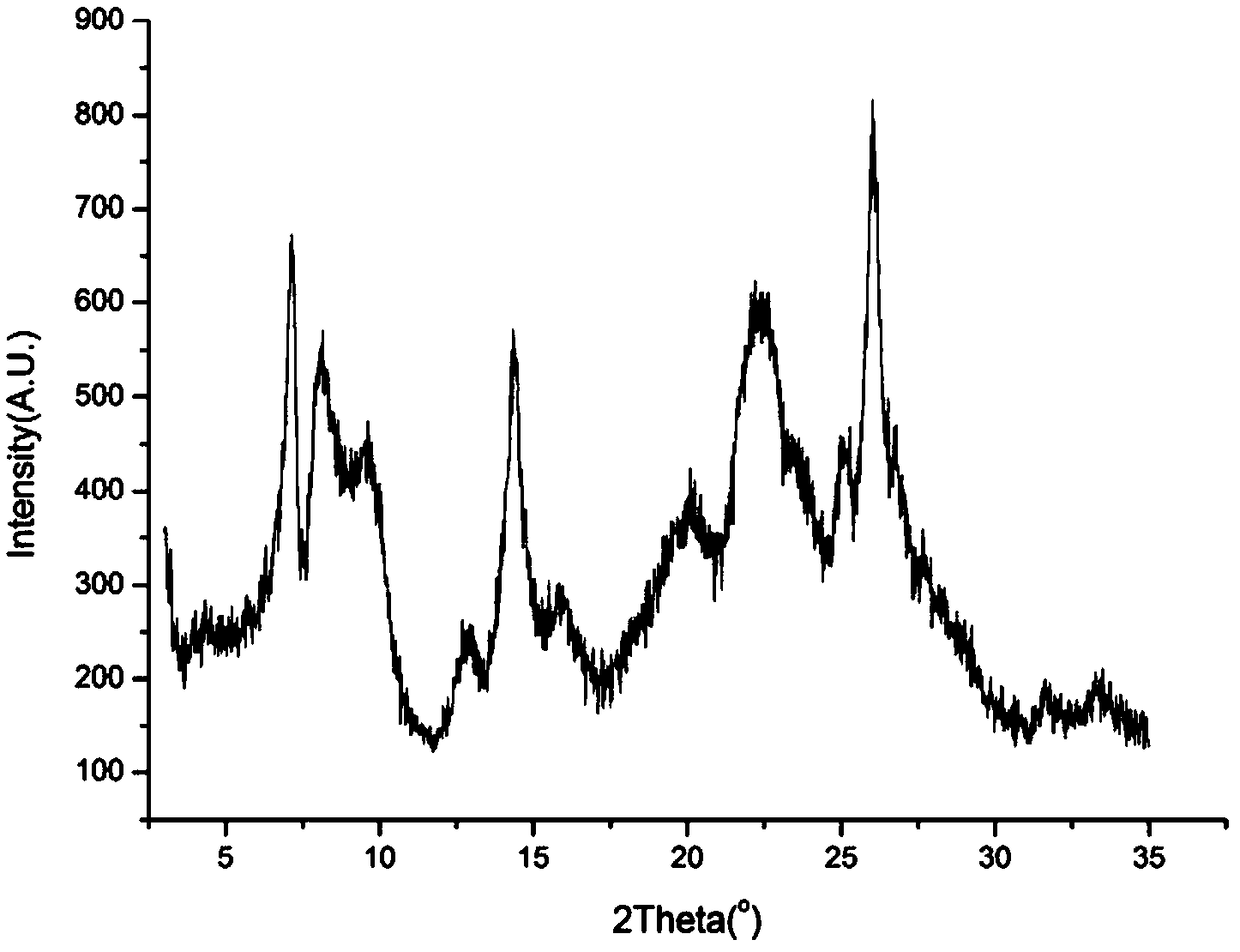

Method for synthesizing MCM-56 molecular sieve by HMI (hexamethylene imine)/PI (piperidine) composite template

ActiveCN108862313ACrystal phase stabilityEasy to operateCrystalline aluminosilicate zeolitesMolecular sieveSilica gel

The invention belongs to the technical field of MCM-56 molecular sieve synthesis, and specifically discloses a method for synthesizing an MCM-56 molecular sieve by HMI (hexamethylene imine) / PI (piperidine) composite templates. According to the invention, HMI and PI are taken as the composite template, solid silica gel is selected as a silicon source, and the MCM-56 molecular sieve is synthesized under dynamic hydrothermal crystallization conditions. The dynamic hydrothermal crystallization method is realized by the manner of heating in an oil bath and magnetically stirring the reaction material. The method is simple in operation, mild in condition, and reduces the synthesis cost of the MCM-56 molecular sieve. The crystal phase of the synthesized MCM-56 molecular sieve is stable, and the synthesized MCM-56 molecular sieve is not subjected to phase transformation to form an MCM-49 molecular sieve with the prolongation of crystallization time, which enriches the species of templates for synthesizing the MCM-56 molecular sieve and provides a new method for synthesizing the MCM-56 molecular sieve.

Owner:合肥龙智机电科技有限公司

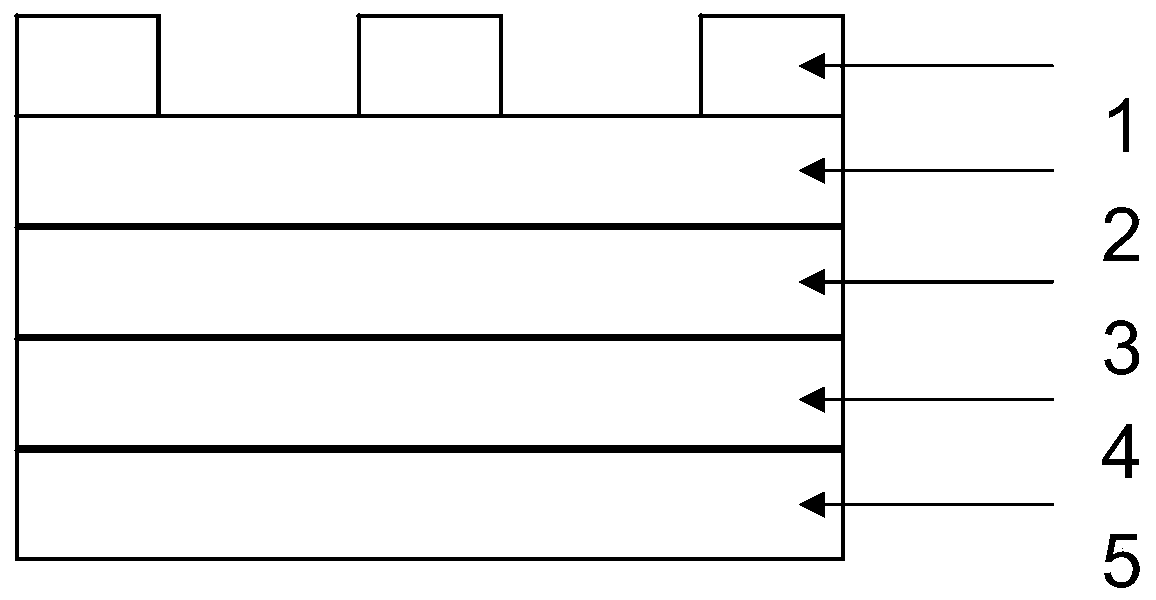

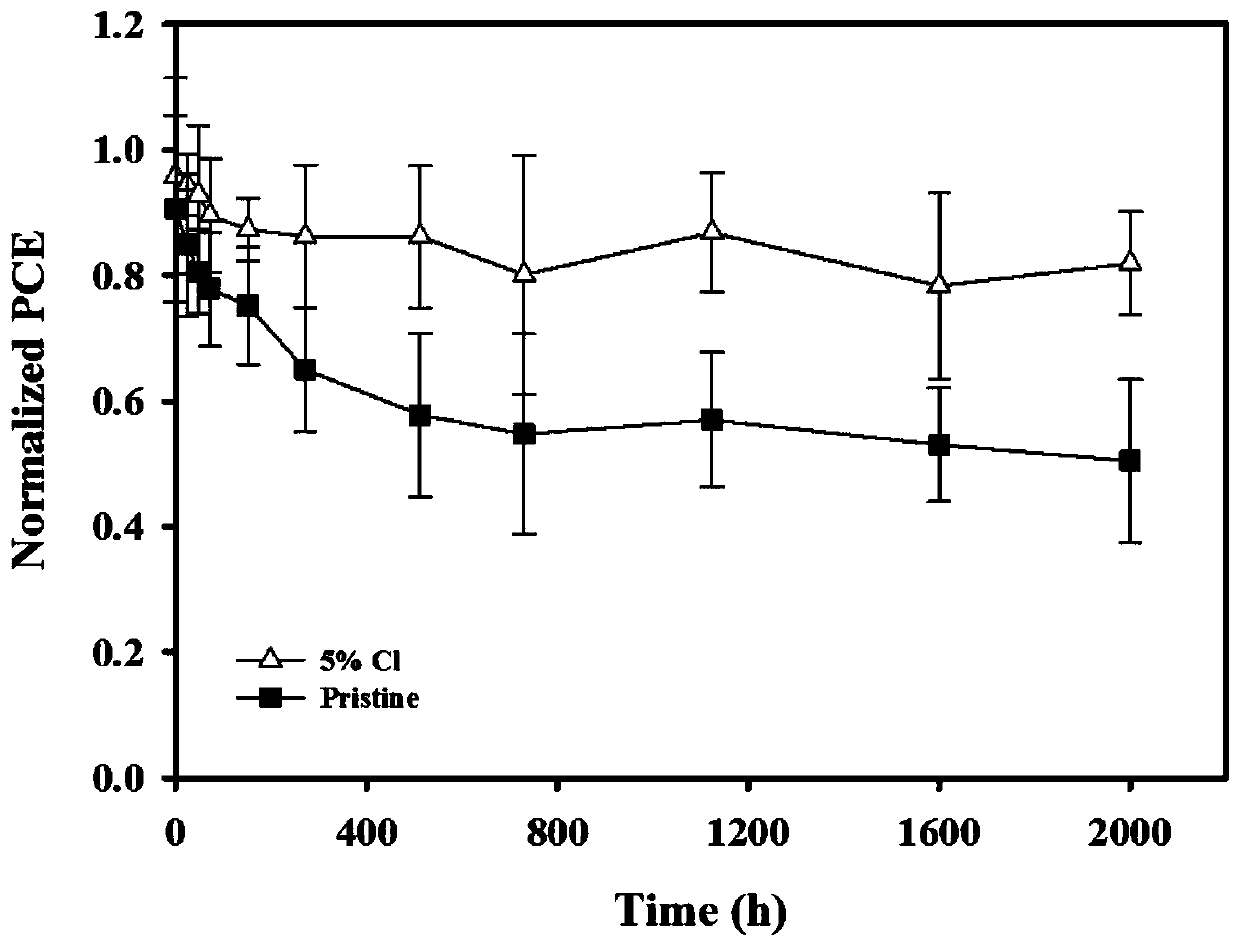

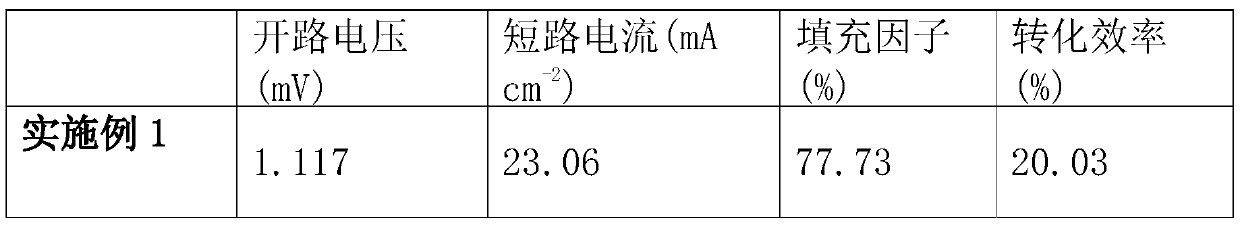

High-stability perovskite solar cell and preparation method thereof

ActiveCN110854271AIncrease the open circuit voltageSuppression of non-radiative recombinationSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrical battery

The invention belongs to the photovoltaic field, and specifically discloses a high-stability perovskite solar cell and a preparation method therefor. The solar cell sequentially comprises a conductiveglass layer, a compact electron transmission layer, a perovskite light absorption layer, a hole transmission layer and a counter electrode layer from the bottom to the top. According to the invention, DPSI (3-(decyldimethylammonium)-propanesulfonic acid inner salt) and PbCl2 are added into the light absorption layer of the perovskite cell, and under the synergistic cooperation of the two additives, a device with high open-circuit voltage is obtained. Through element regulation and control and additive defect passivation, the key problem that perovskite commercialization is hindered due to lowstability is solved, and meanwhile, the problem that the photoelectric conversion efficiency of a binary perovskite solar cell is relatively low relative to a ternary perovskite cell is also solved.

Owner:CHANGZHOU UNIV +1

Preparation method of PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating

The invention relates to a preparation method of a PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating, comprising the following steps of firstly, dissolving Ca(NO3)2.4H2O and (NH2)2HPO4 into distilled water and preparing mixed liquor by putting a urea powder into the distilled water and uniformly stirring; secondly, filtering upper layer liquid after treating the mixed liquor by phonochemistrical synthesis and obtaining a nano-hydroxyapatite powder by vacuum drying; thirdly, obtaining a nano-hydroxyapatite suspension by scattering the nano-hydroxyapatite powder into isopropanol; fourthly, dissolving acrylamide into water and preparing AM solution by adding sodium sulfite and ammonium persulfate; and fifthly, treating a C / C substrate by ultrasonic waves after being put into the AM solution, fixing the treated C / C substrate on a cathode of a hydrothermal electrophoresis reactor, soaking the cathode into the nano-hydroxyapatite suspension, sealing the reactor, and obtaining the PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating by electrophoretic deposition-heat treatment. The invention has the advantages of compact and uniform prepared composite coating and stable coating crystalline phase, can greatly enhance the bonding strength and has the expected bonding strength of 60-100MPa.

Owner:SHAANXI UNIV OF SCI & TECH

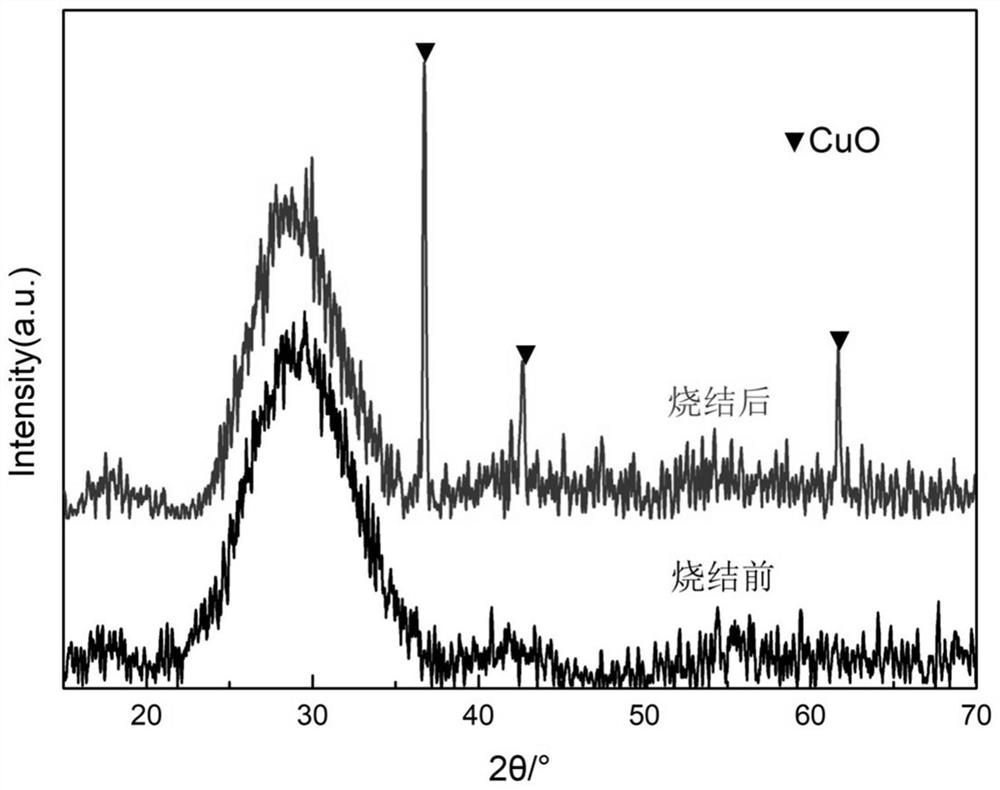

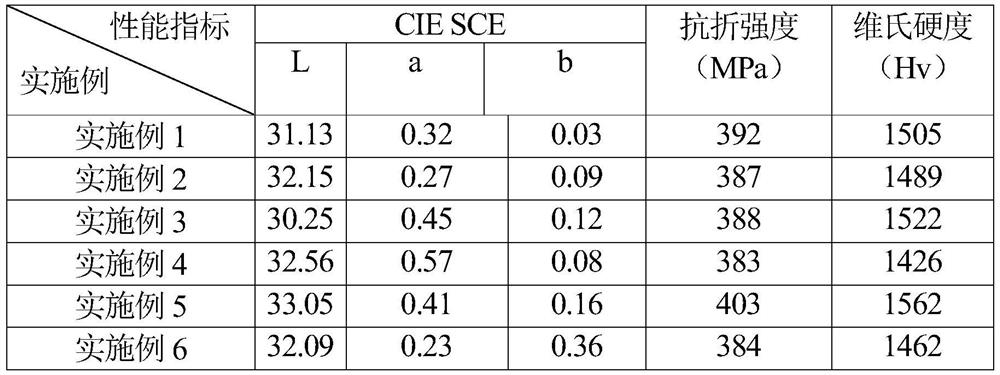

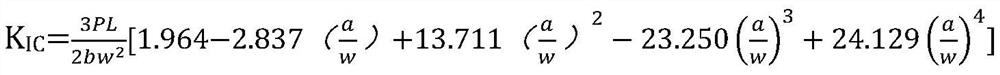

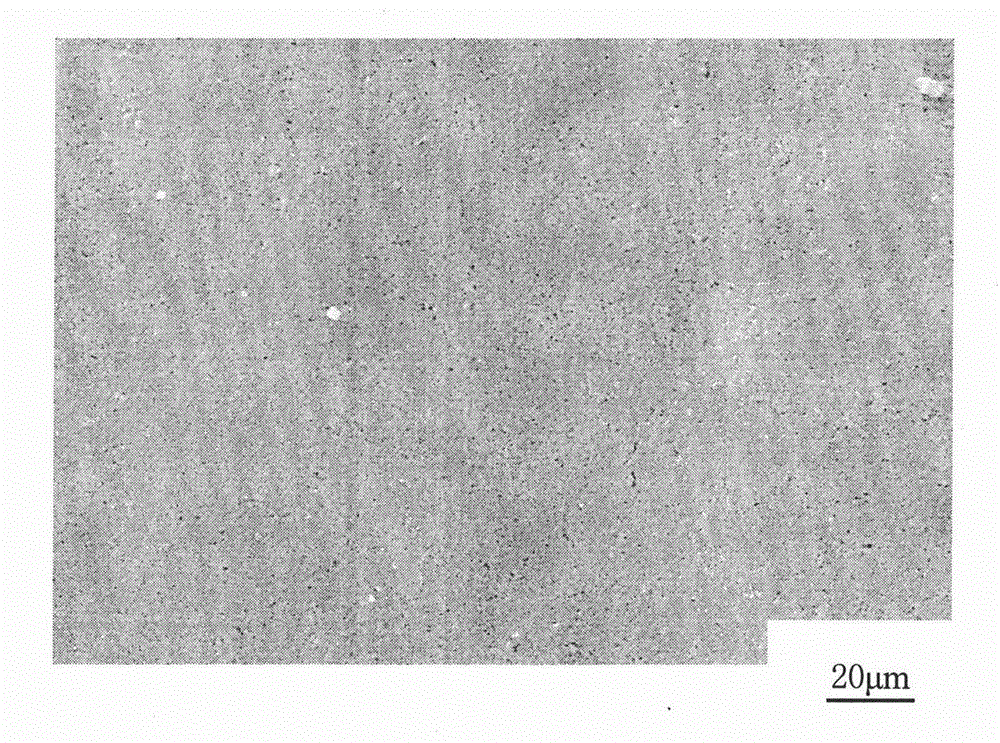

Black alumina ceramic and preparation method thereof

InactiveCN112552077ALower melting temperatureDoes not affect high temperature structurePigmenting treatmentKaolin clayCopper oxide

The invention discloses black alumina ceramic and a preparation method thereof. The preparation method comprises the steps: 1) taking, by mass, 4%-6% of diboron trioxide, 13%-15% of silicon dioxide, 55%-59% of bismuth trioxide, 0.5%-2% of manganese dioxide, 16%-19% of copper oxide, 0.8%-1.5% of tungsten trioxide, 1%-1.5% of antimony trioxide and 0.8%-2% of germanium dioxide, and mixing to obtain amixture, 2) heating and melting the mixture at 950-1100 DEG C, performing water quenching, and drying the water-quenched material to obtain black granules, 3) taking 43-55% by mass of black granules,1-5% by mass of calcined kaolin, 0.5-1% by mass of titanium dioxide and 43-55% by mass of distilled water, and carrying out ball milling to obtain black slurry, and 4) immersing the alumina ceramic in the black slurry, taking out, drying, heating at 830-850 DEG C, and cooling to obtain the black alumina ceramic.

Owner:SHAANXI UNIV OF SCI & TECH

Silicon nitride-based ceramic welding sealing component and preparation method thereof

The invention discloses a silicon nitride-based ceramic welding sealing component and a preparation method thereof, and relates to the technical field of metallized ceramic processing. The invention discloses a silicon nitride-based ceramic welding sealing component which comprises a silicon nitride ceramic matrix and a metallization layer, the silicon nitride ceramic matrix is prepared from modified silicon nitride, mullite fiber, aluminum nitride, calcium oxide, titanium oxide, a binder and a dispersing agent through the steps of modified silicon nitride preparation, mixing, granulation, primary sintering, secondary sintering and the like; raw materials of the metallization layer comprise copper powder, tungsten powder, copper oxide, yttrium oxide, zinc oxide and an organic binding agent. The invention further discloses a preparation method of the silicon nitride-based ceramic welding sealing component composed of the metallization layer and the silicon nitride ceramic matrix. According to the silicon nitride-based ceramic welding sealing component, the density of the silicon nitride ceramic matrix is improved, the silicon nitride-based ceramic welding sealing component has excellent strength, hardness and fracture toughness, the tensile strength of the sealing component is improved, and the silicon nitride-based ceramic welding sealing component has excellent high-temperature resistance.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

Method for preparing glass microfibre reinforcement nano-hydroxyapatite biological composite coating

The invention relates to a method for preparing a glass microfibre reinforcement nano-hydroxyapatite biological composite coating, comprising the following steps of: firstly, mixing Ca(NO3)2.4H2O and (NH2)2HPO4 and adding distilled water to dissolve; then adding urea powder to make the mixture into mixed liquor; putting a generating head of a multi-frequency phonochemistry generator into the mixed liquor, filtering and drying after phonochemistry synthesis, then obtaining nano-HAp powder; dispersing the nano-HAp powder, analytically pure chitosan and glass microfibre in isopropanol, then obtaining suspending liquid; pouring the suspending liquid into a hydrothermal electrophoresis reaction kettle; putting the reaction kettle in a precise constant temperature oven, galvanizing and depositing; then drying and finally obtaining the composite coating. Nano-hydroxyapatite powder is prepared by using a phonochemistry synthesis method, and therefore, the prepared composite coating is compactand even, the crystalline phase of the coating is stable, the bonding strength can be greatly increased; and the expected bonding strength reaches 20-40MPa.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of high-entropy zirconate inorganic fiber and preparation method thereof

The present invention involves a high -entropy acid saline inorganic fiber and its preparation methods.The preparation method includes alkaline carbonate, calcium source, 锶 source, 钡 source, methamphetamine, and spinning agent in accordance with a certain proportion to heated and dissolved in the aqueous solution to make high -entropiic acid precursor anterior drivers;The precursor of the salt front drive body is obtained by the electrostatic spinning method to obtain a high -entropyed pyrine before the fiber fiber;The solution is stable and the spinning is good. The high -entropyed pyrine fiber is single -phase solid -soluble, the diameter of the fiber is 0.5‑1.5 μm, and the crystal and fiber form are kept stable at room temperature to 1400 ° C.

Owner:QILU UNIV OF TECH

A kind of production method of iron-based desulfurizer with high sulfur capacity

ActiveCN101590396BEliminate the drying procedureRealize large-scale industrial productionOther chemical processesFerrous saltsCentrifugation

The invention relates to a production method of a high-sulfur capacity iron-based desulfurizer. The iron-based desulfurizer is composed of cubic crystal phase Fe3O4, amorphous Fe2O3 and amorphous Fe2O3·H2O, which comprises the following steps: (a) The solid soluble ferrous salt and soluble carbonate are placed in the mixing reactor, and an appropriate amount of water is added, and then the stirring is started, and the above-mentioned reaction materials are further mixed and reacted during the stirring process; (b) the obtained in step (a) The product is sent to a water washing tank, and the above product is washed with water dissolved in oxygen; (c) the slurry obtained after washing is sent to a buffer tank, and then centrifuged; (d) the separated solid Leave to air dry or tumble dry. The process can realize the mass industrial production of the above-mentioned high-sulfur-capacity iron-based desulfurizer with high efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A metal bonded diamond grinding wheel

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Borate fluorescent powder and preparing method thereof

ActiveUS11306247B2Low luminous efficiencyCrystal phase stabilityEnergy efficient lightingLuminescent compositionsPhysical chemistryUltraviolet

A borate fluorescent powder and a preparing method thereof are provided. The formula of the borate fluorescent powder is Ba2-nSrnLu5-x-y-m-zLmCexTbyEuzB5O17. L is one or any combination of the elements Gd, La, and Sc. Ranges of x, y, z, m, and n are respectively 0<x≤0.6, 0<y≤3, 0<z≤0.4, 0≤m≤1, and 0≤n≤0.5. The borate fluorescent powder provided has a stable crystalline phase, high luminous efficiency, and decent thermal stability, and can be applied to ultraviolet LEDs or near-ultraviolet LEDs to construct white LEDs.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

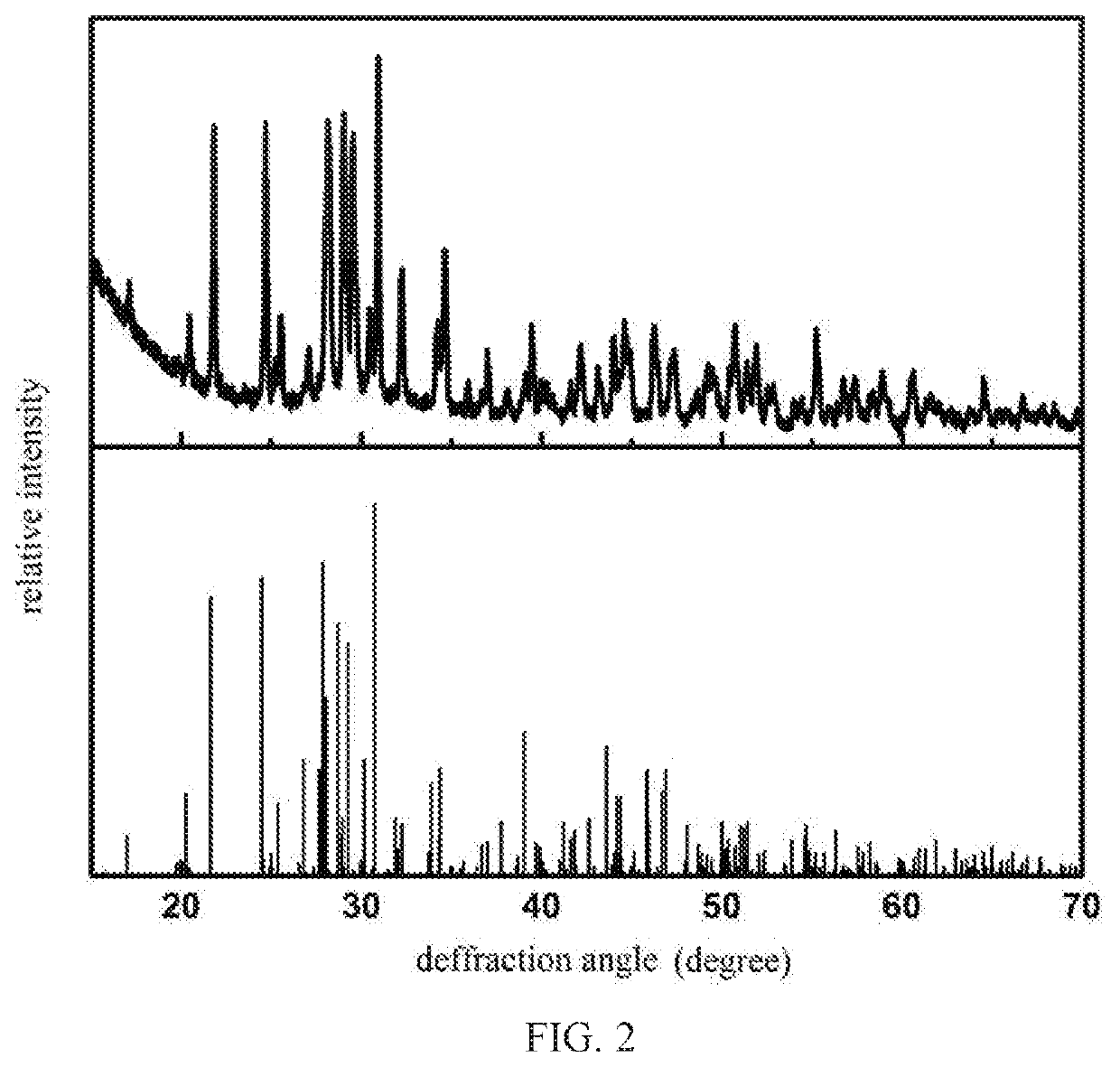

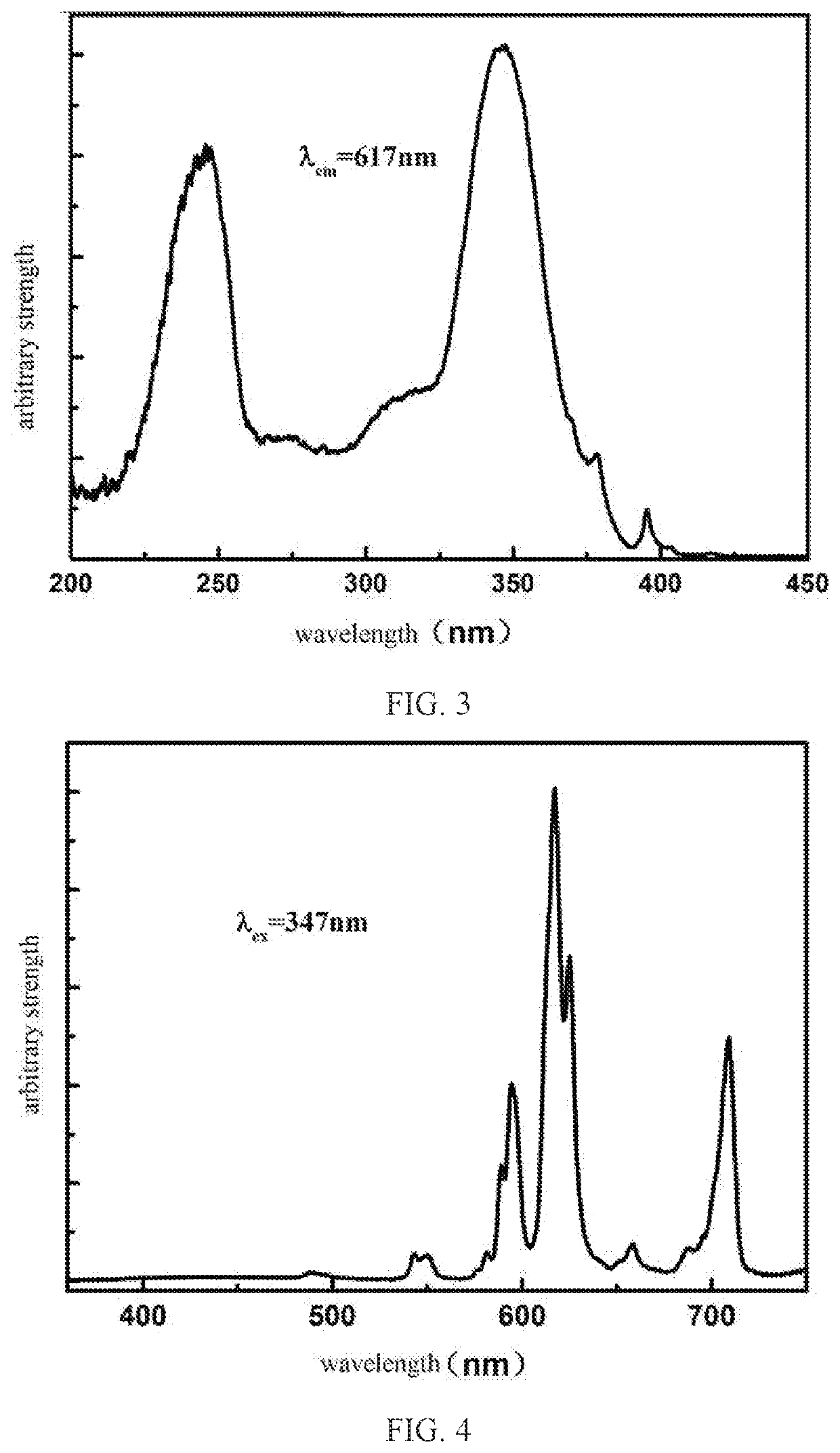

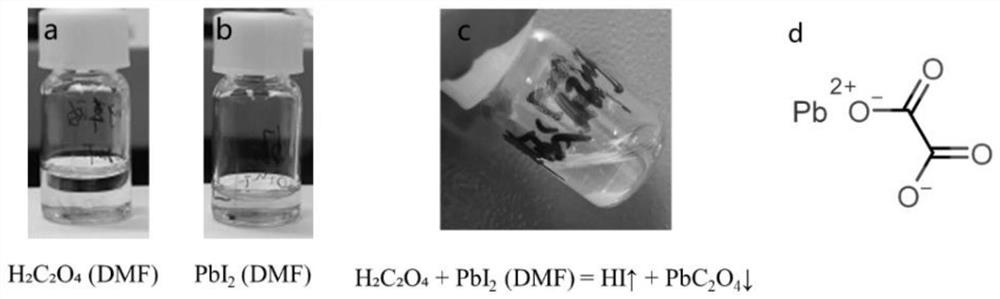

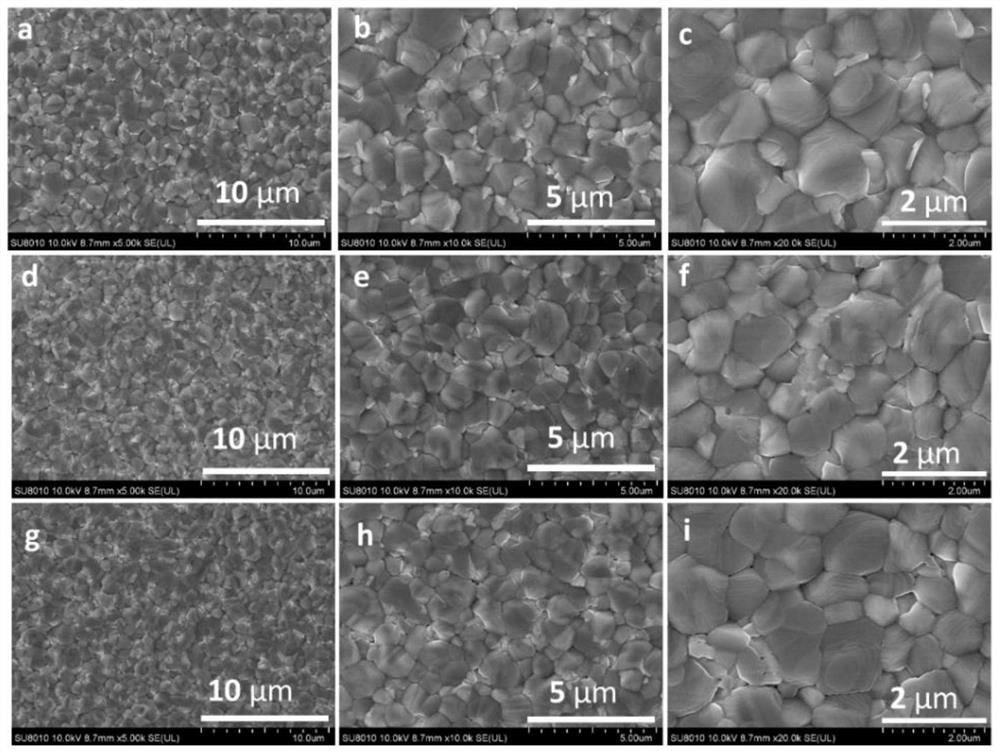

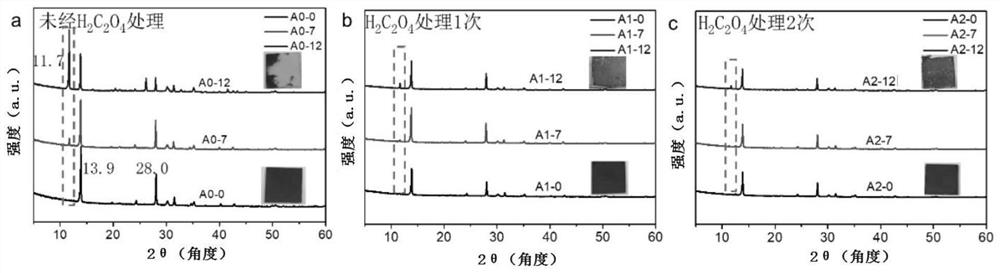

High-stability perovskite solar cell based on oxalic acid passivation and preparation method thereof

PendingCN113809241ACrystal phase stabilityImprove humidity stabilitySolid-state devicesSemiconductor/solid-state device manufacturingOXALIC ACID DIHYDRATEMetallic electrode

The invention belongs to the technical field of perovskite solar cells, and particularly relates to a high-stability perovskite solar cell based on oxalic acid passivation and a preparation method thereof. The perovskite solar cell comprises an ITO conductive substrate layer, an electron transport layer, a perovskite light absorption layer, a hole transport layer and a metal electrode from bottom to top. The perovskite light absorption layer is a perovskite light absorption layer which is subjected to H2C2O4 passivation treatment. When the perovskite light absorption layer is passivated, C2O4<2-> is introduced in the film forming process of the perovskite, so that the C2O4< 2-> and Pb suspended in the perovskite form a PbC2O4 compact layer with higher moisture resistance, the humidity stability of the perovskite light absorption layer is greatly improved, and the crystalline phase of the prepared perovskite cell is more stable; and moreover, defects on the surface of the perovskite are passivated, and meanwhile, the photoelectric property of the perovskite cell is also improved.

Owner:SUN YAT SEN UNIV

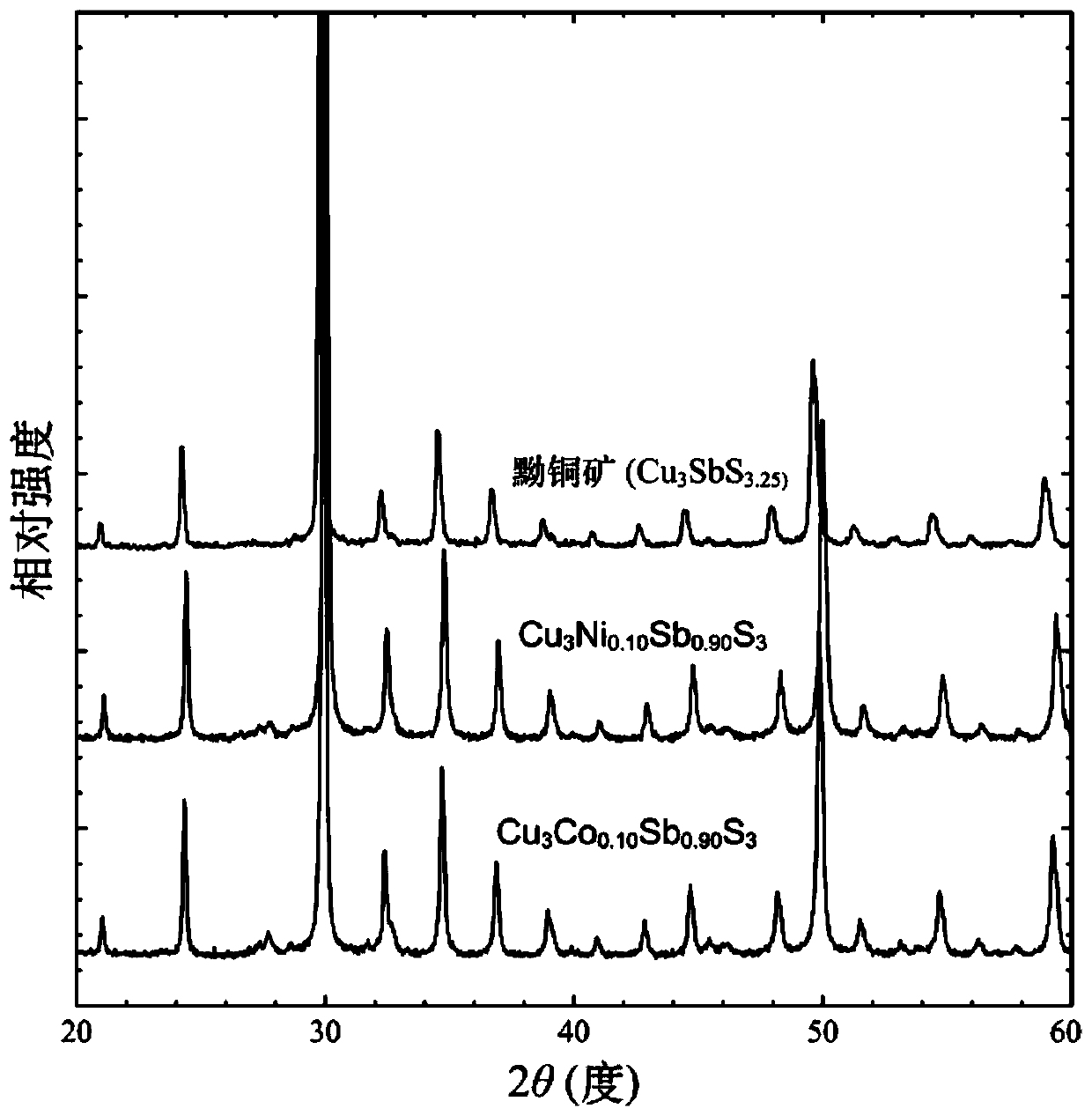

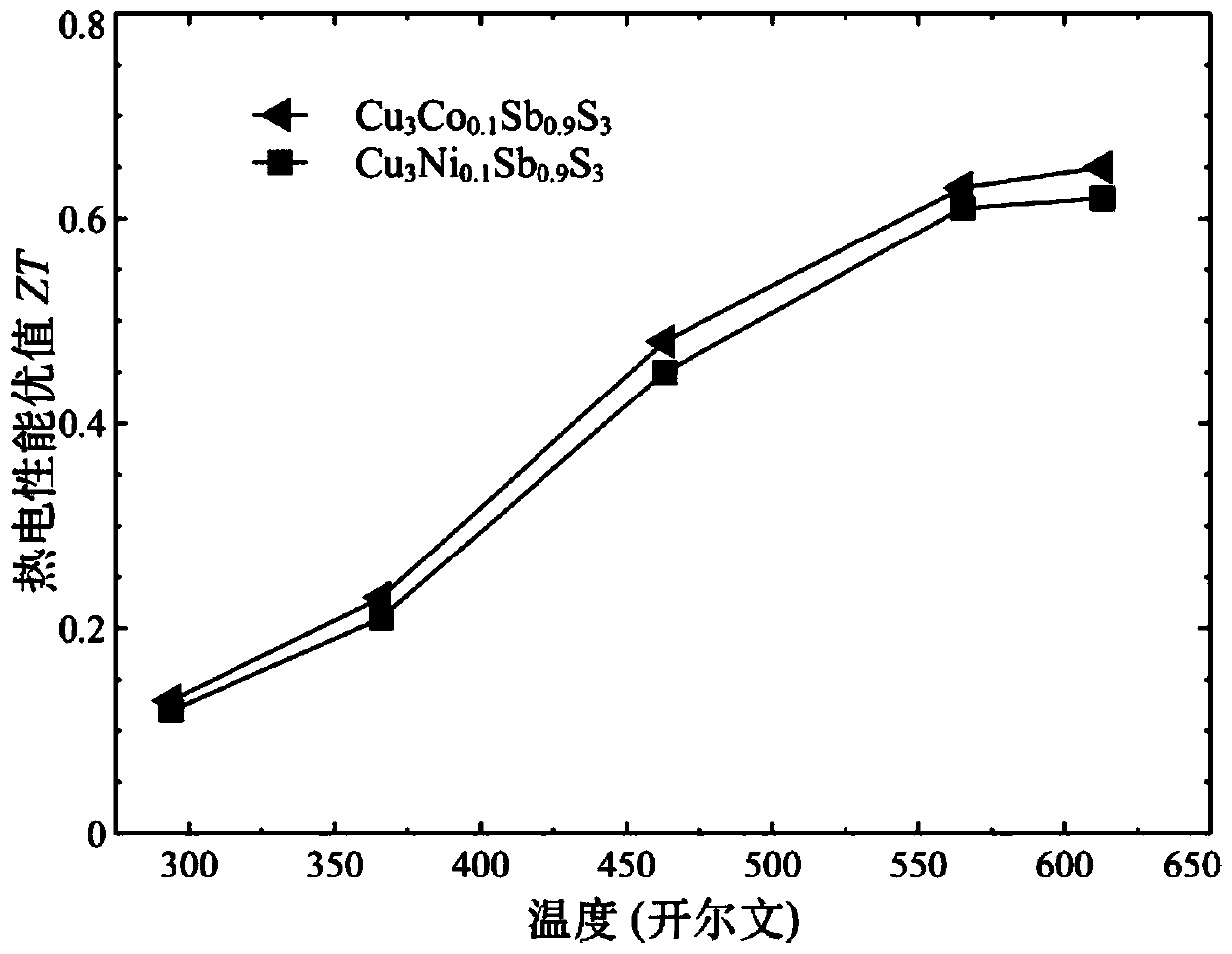

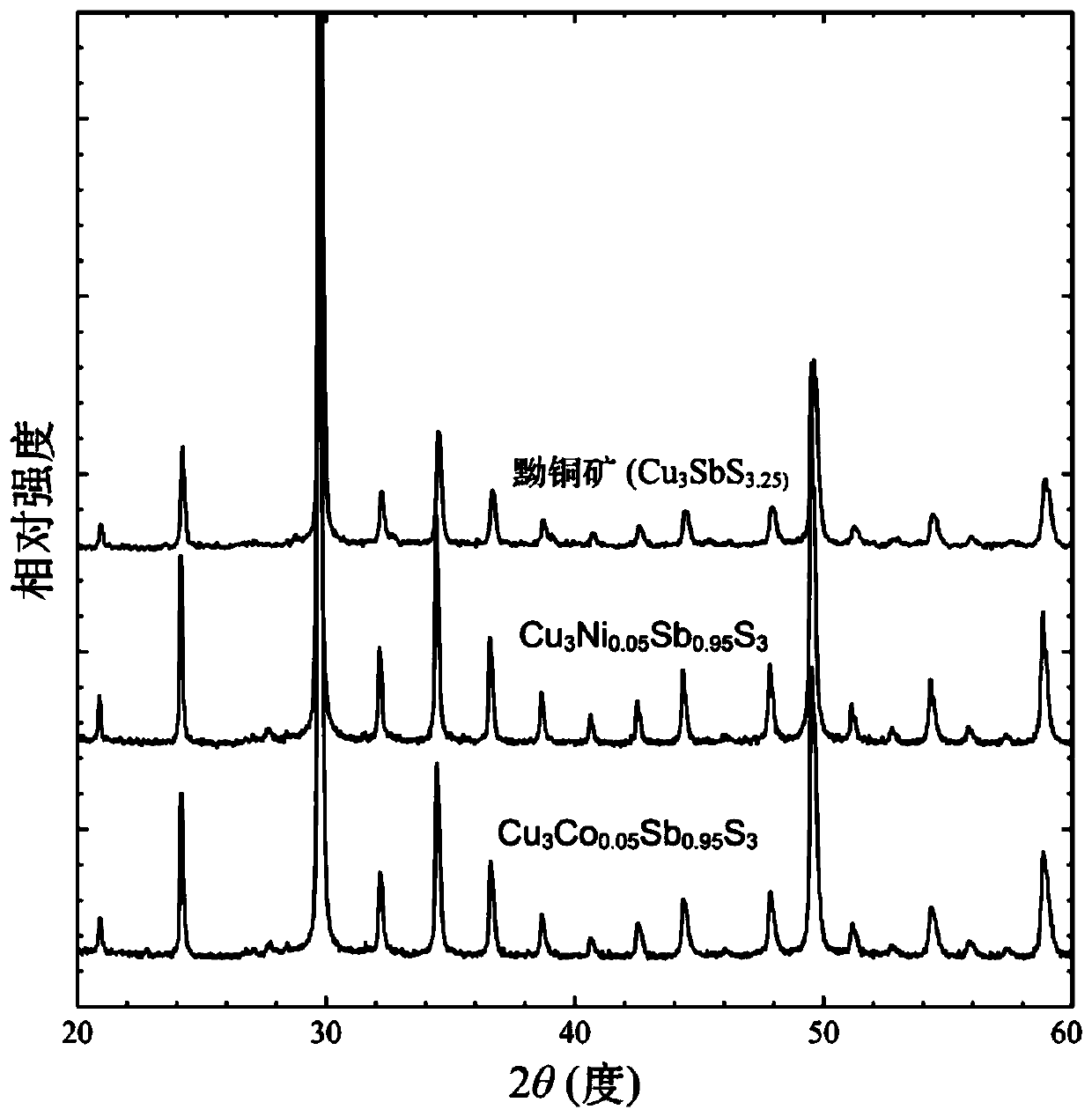

a cubic phase cu 3 sbs 3 Based thermoelectric material and method for preparing the thermoelectric material by element replacement

InactiveCN107359232BCrystal phase stabilityChanging the valence bond featureThermoelectric device manufacture/treatmentThermoelectric device junction materialsCobaltElectric properties

The invention provides a cubic phase Cu 3 Sb 3 Based thermoelectric materials, the general chemical formula is Cu 3 Sb 1‑x A x S 3 , where A is cobalt and / or nickel, and x is 0.025-0.200. By replacing Sb elements with Ni, Co and other elements, a Cu with stable structure and thermodynamic properties is synthesized. 3 Sb 1‑ x A x S 3 Cubic crystal structure. Its preparation method mainly comprises the following steps: 1) batching: according to Cu 3 Sb 1‑x A x S 3 The ratio of each element in the method takes copper, antimony, cobalt (nickel) and sulfur as the reaction raw materials, wherein x=0.025~0.200; Perform high-energy ball milling; 3) Densification: The powder obtained by high-energy ball milling is subjected to spark plasma sintering or hot-pressing sintering to obtain high-density, high-performance cubic phase Cu 3 Sb 3 bulk thermoelectric material. Cu according to the present invention 3 Sb 1‑ x A x S 3 Thermoelectric materials are high-purity cubic phase products with high density, stable thermodynamic performance, excellent thermoelectric performance, abundant and cheap raw material sources, and good feasibility and repeatability of the preparation process.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com