Rare-earth-based aerogel material with radiation shielding effect and heat insulation property as well as preparation and application of rare-earth-based aerogel material

A rare earth-based, aerogel technology, used in applications, household appliances, ceramic products, etc., can solve problems such as poor flame retardant performance and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

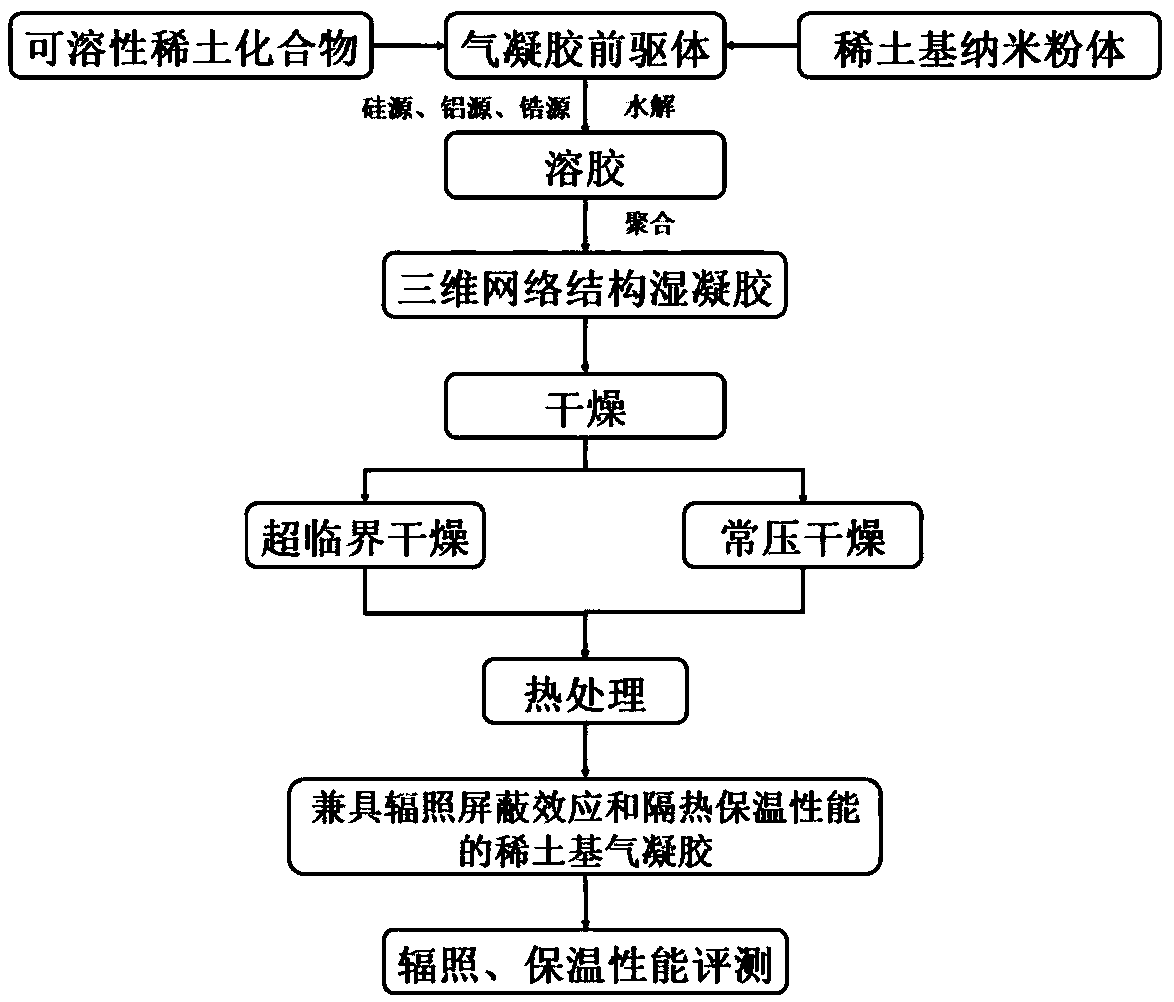

Method used

Image

Examples

Embodiment 1

[0063] This embodiment specifically prepares an airgel material composited with europium zirconate and silica airgel matrix material, and its preparation includes the following steps:

[0064] (1) Preparation of precursor mixed solution: disperse 249mg europium nitrate and 240mg zirconium nitrate (molar ratio is 1:1) into a mixed solution of 8.4mL tetraethyl orthosilicate, 17.52mL ethanol, 2.54mL water (molar ratio is 1:8:3.75);

[0065] (2) Add 200 μL of concentrated hydrochloric acid dropwise to the mixed solution prepared above under continuous stirring until the metal salt is completely dissolved;

[0066] (3) leave standstill for 24 hours to completely hydrolyze tetraethyl orthosilicate;

[0067] (4) Add 0.5M ammonia solution dropwise to the above solution under continuous stirring, and adjust to pH=5.8;

[0068] (5) Transfer the above-mentioned sol to a glass petri dish, and let it stand at room temperature until it loses fluidity, indicating that it has completely gel...

Embodiment 2

[0077] This embodiment specifically prepares an airgel material composited with europium zirconate and alumina airgel matrix material, and its preparation includes the following steps:

[0078] (1) Preparation of precursor mixed solution: mix 249mg europium nitrate, 240mg zirconium nitrate and 9.538g aluminum chloride hexahydrate with 23mL ethanol and 7.1mL water;

[0079] (2) Add 200 μL of concentrated hydrochloric acid dropwise to the mixed solution prepared above under continuous stirring until the metal salt is completely dissolved;

[0080] (3) Add network inducer propylene oxide (n (环氧丙烷) :n (Al) =9mol:1mol);

[0081] (4) Transfer the above mixed solution to a glass petri dish and let it stand until it is completely gelled;

[0082] (5) Submerge the above-mentioned gel in ethanol, and leave it in a constant temperature water bath at 60°C for 48 hours for aging;

[0083] (6) Submerge the gel after the above-mentioned aging in n-hexane, and replace the solvent several ...

Embodiment 3

[0088] This embodiment specifically prepares an airgel material composited with europium zirconate and zirconia airgel matrix material, and its preparation includes the following steps:

[0089](1) Preparation of precursor mixed solution: 762mg of europium nitrate and 11.56g of zirconyl nitrate were added to the mixed solution of 20mL ethanol / 5mL water;

[0090] (2) The above-mentioned mixed solution is continuously stirred until europium nitrate and zirconium oxynitrate are completely dissolved;

[0091] (3) Add 0.5mol network inducer propylene oxide in the above mixed solution, keep stirring and mix evenly;

[0092] (4) Transfer the above mixed solution to a glass petri dish and let it stand until it is completely gelled;

[0093] (5) Submerge the above-mentioned gel in ethanol, and leave it in a constant temperature water bath at 60°C for 48 hours for aging;

[0094] (6) Transfer the above-mentioned gel after aging to 100 mL, 10% (v / v) trimethylchlorosilane n-hexane solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com