Method for preparing high-purity alpha-aluminium oxide by means of waste activated aluminium oxide

An activated alumina, high-purity technology, applied in the field of waste resource reuse, can solve the problems of low recycling rate of waste alumina, unreasonable treatment methods, ecological environment pollution, etc. The effect of low surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0029] Following embodiments 1~4 are all carried out by following operations:

[0030] 1) Source of raw material: The raw material comes from the hydrogen peroxide production plant A: the invalid waste activated alumina in the regeneration bed of the hydrogenation solution and the clay bed in the production of hydrogen peroxide, with an average particle size of 2mm.

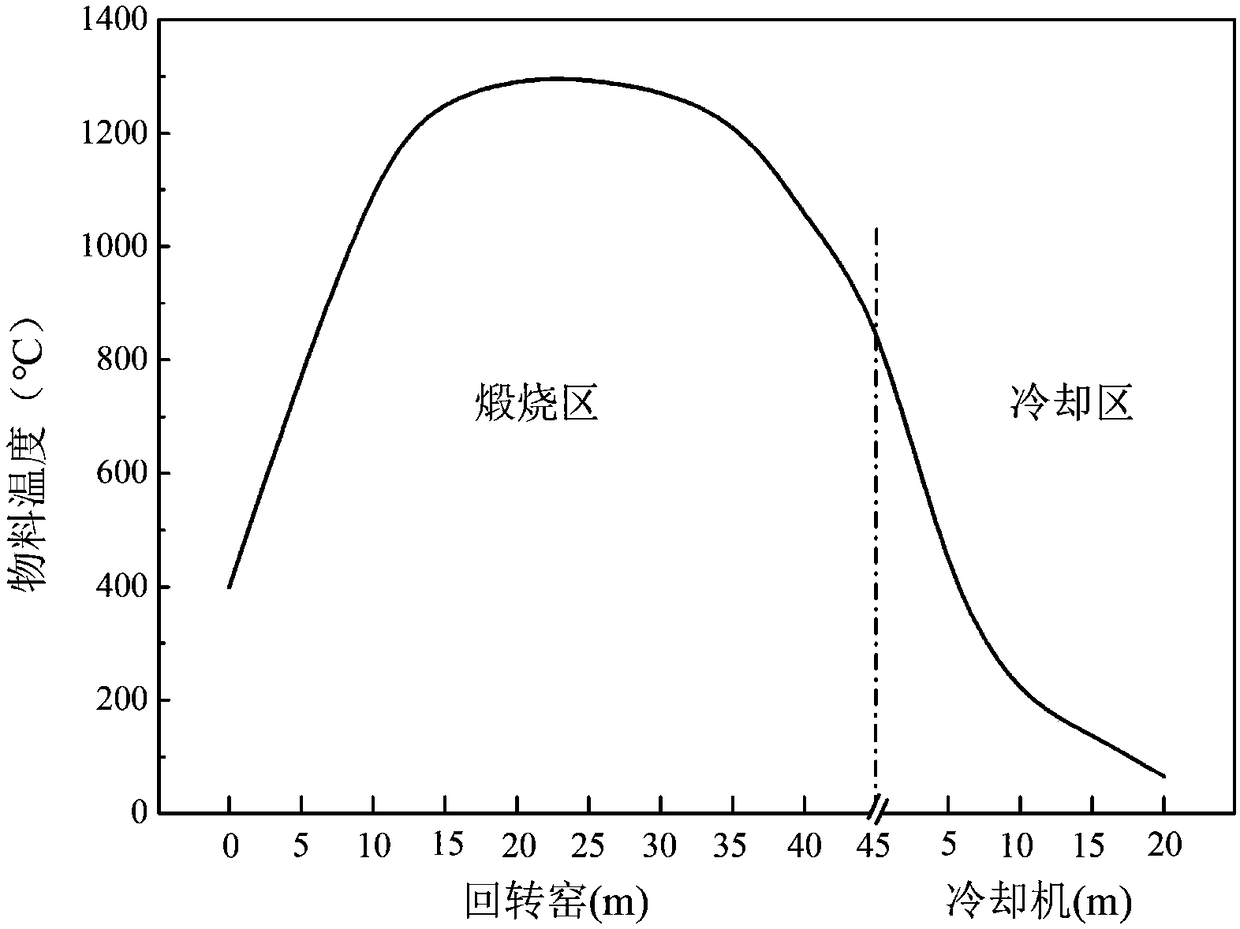

[0031] 2) Equipment: straight cylinder rotary kiln, cylinder diameter 2200mm, cylinder length 45000mm, slope 3%, speed 2r / min; cooling machine adopts single cylinder cooling machine, the specification is preferred The rotating speed is 6r / min, and the residence time is 30min.

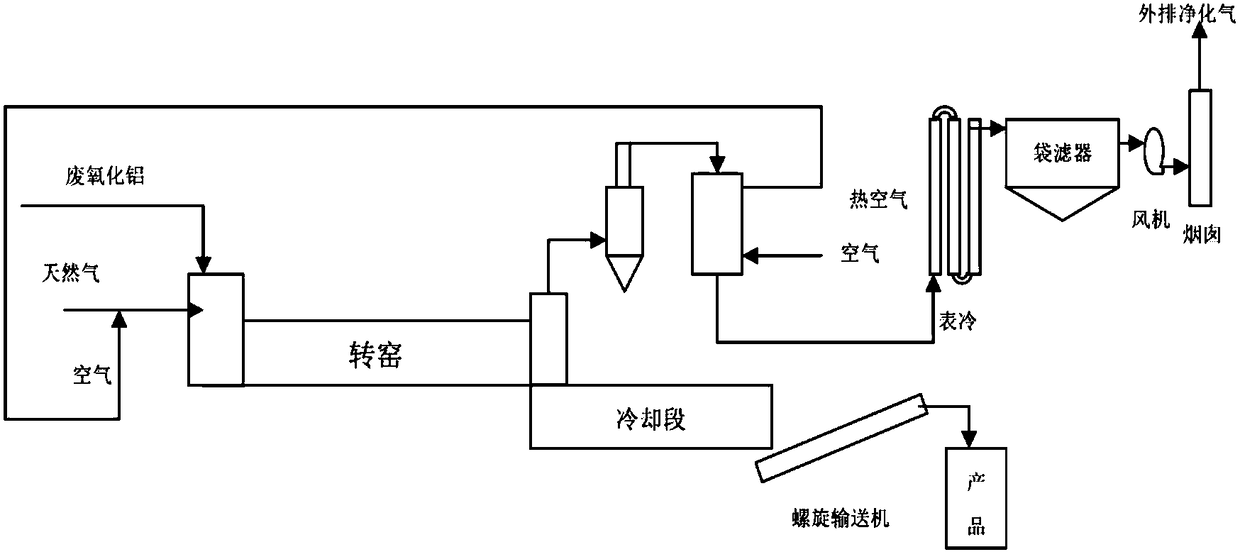

[0032] 3) Calcination treatment process: the raw materials enter the rotary kiln preheating tower through the elevator for drying, and the rotary kiln drives the materials into the reaction zone of the kiln body, and undergoes chemical and physical processes such as drying, preheating, calcination, and cooling in sequence. High purity α-...

Embodiment 1

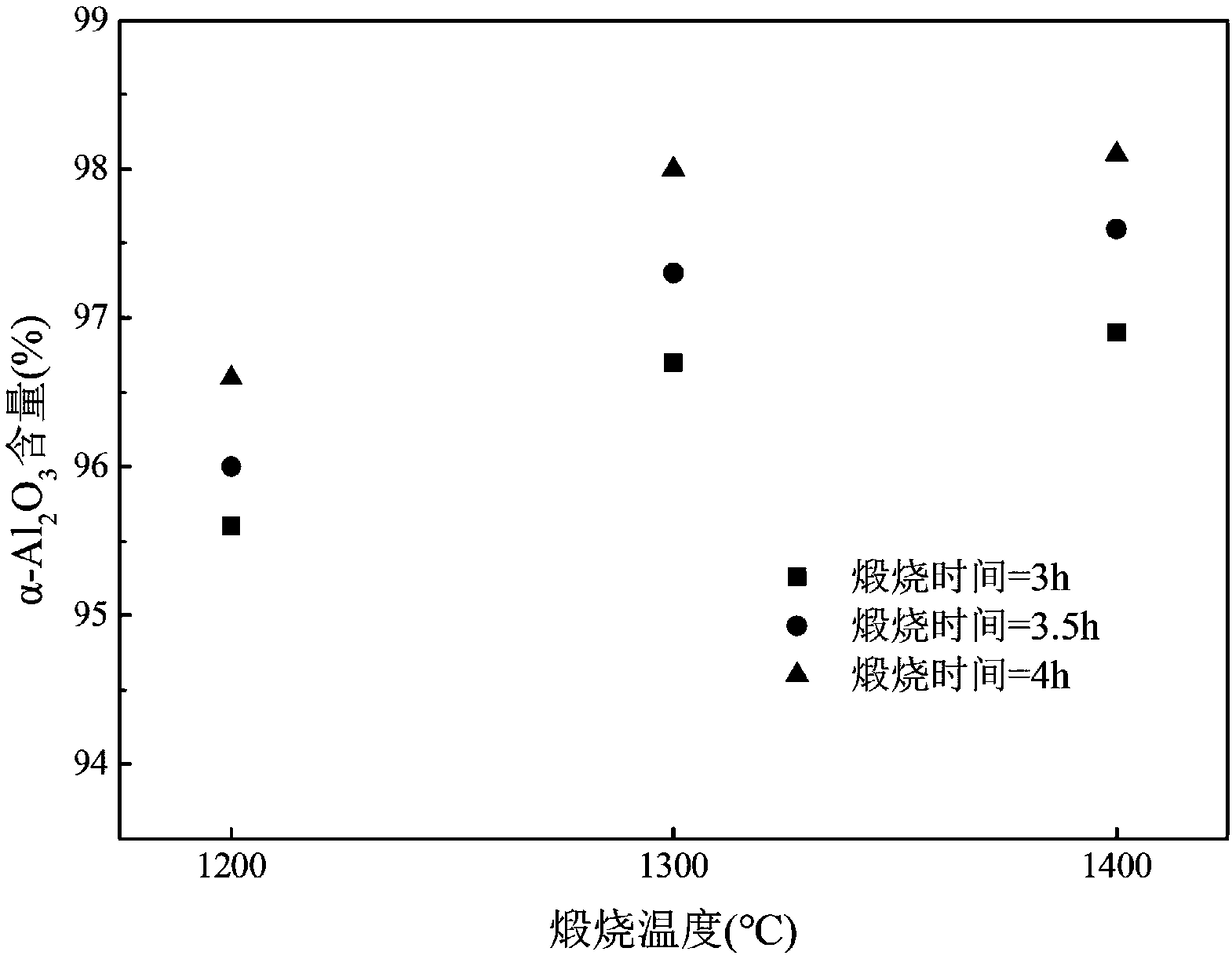

[0034] By adding 2% (w / w) α-Al 2 o 3 The seed powder makes the moisture content in the raw material 10%, the total organic matter content 6%, and the alumina content 81%. The material is heated to 1300 ℃ at a rate of 95 ℃ / m in the rotary kiln, and the holding time of the high temperature section is 2 hours. The total residence time is 4h; the inlet pressure of the rotary kiln is 3Pa, the flue gas temperature is 360°C, the outlet pressure of the rotary kiln is -31Pa, the flue gas temperature is 560°C, and the material enters the cooler to cool down at a rate of up to 90°C / m. Discharge.

Embodiment 2

[0036] By adding 2.5% (w / w) α-Al 2 o 3 The seed crystal powder makes the moisture content in the raw material 8%, the total organic matter content is 5%, and the alumina content is 84%. The residence time is 4h; the inlet pressure of the rotary kiln is 5Pa, the flue gas temperature is 340°C, the outlet pressure of the rotary kiln is -32Pa, the flue gas temperature is 540°C, the material enters the cooler and cools at a rate of up to 90°C / m, material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com