High-stability perovskite solar cell based on oxalic acid passivation and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as dislocation defects, perovskite decomposition and phase transition, impurity defects, etc., to reduce non-radiative recombination, photoelectric Improvement of chemical performance and improvement of humidity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

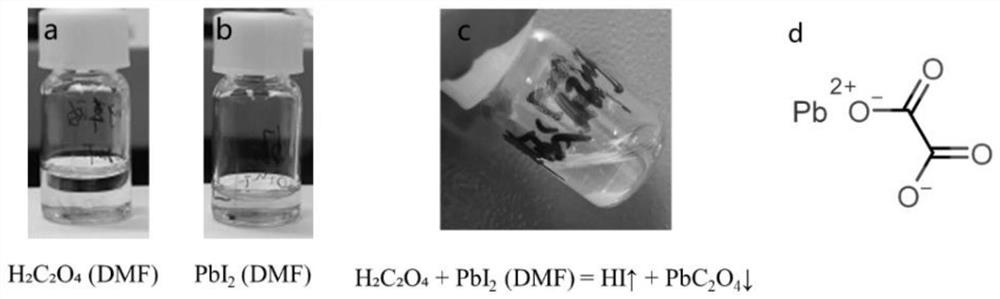

[0040] Embodiment 1 A kind based on H 2 C 2 o 4 Processed perovskite solar cells

[0041] The battery is composed of ITO conductive base layer, SnO 2 Electron transport layer, FA system perovskite light absorption layer, Spiro-OMeTAD hole transport layer and Au electrode, the FA system perovskite light absorption layer is formed by H 2 C 2 o 4 Treated perovskite light absorbing layer. Its preparation method is as follows:

[0042] (1) Select the ITO (180nm) conductive glass with a square resistance of 20Ω, a transmittance of 85%, and a size of 1.5cm×1.5cm as the substrate. The ITO conductive substrate is ultrasonically passed through deionized water, acetone, and absolute ethanol in sequence. After processing for 15 minutes, dry it with nitrogen gas for later use;

[0043] (2) Preparation of the electron transport layer: SnO with a mass percent concentration of 15% 2 Colloid aqueous solution diluted to 3.75% SnO 2 Precursor solution, then use a pipette gun to pipette...

Embodiment 2

[0047] Embodiment 2 A kind of based on H 2 C 2 o 4 Processed perovskite solar cells

[0048] Except step (3), the preparation method of all the other steps is the same as embodiment 1.

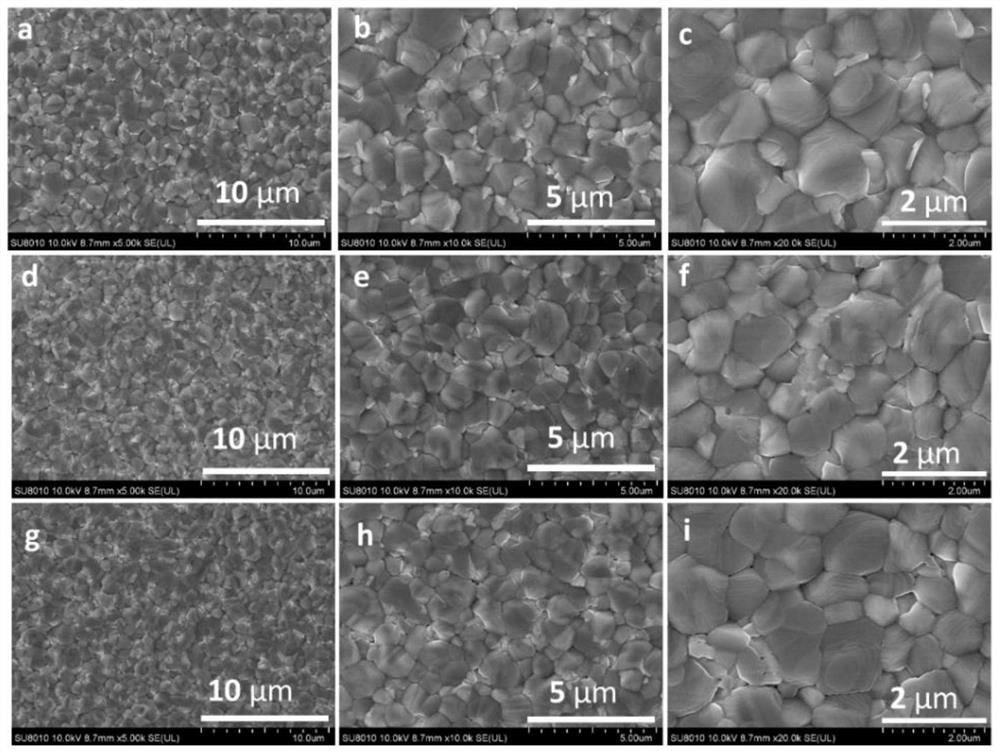

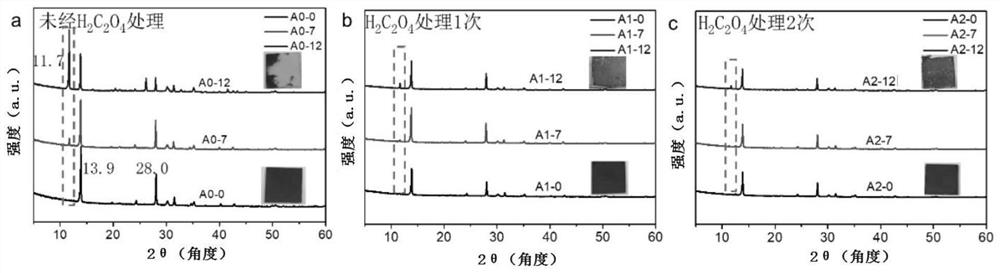

[0049] The step (3) of the present embodiment is specifically: the 0.1mg H 2 C 2 o 4 Dissolve the powder in 1mL of anhydrous ether as an anti-solvent; mix 1.4mmol of FAI and 1.4mmol of PbI 2 , 0.28 mmol of FACl was dissolved in 1 mL of a mixed solvent of DMF and DMSO with a volume ratio of 8:1 to prepare a perovskite precursor solution, and stirred and dissolved at room temperature until clear. Then pipette the SnO 2 Add 40 μL of perovskite precursor solution dropwise on the dense layer, spin coating speed is 5000rmp, time is 30s, drop 0.1mg / mL dissolved H 2 C 2 o 4 1mL of diethyl ether anti-solvent, after the spin coating, the film was annealed on a hot stage at 150°C for 10min to obtain a perovskite film, the surface morphology of which was as follows figure 2 As shown in g-i, it...

Embodiment 3

[0050] Embodiment 3 A kind of based on H 2 C 2 o 4 Processed perovskite solar cells

[0051] Except step (3), the preparation method of all the other steps is the same as embodiment 1.

[0052] The step (3) of the present embodiment is specifically: the FAI of 1.4mmol, the PbI of 1.4mmol 2, 0.28 mmol of FACl was dissolved in 1 mL of a mixed solvent of DMF and DMSO with a volume ratio of 8:1 to prepare a perovskite precursor solution, and stirred and dissolved at room temperature until clear. Then pipette the SnO 2 Add 40 μL of perovskite precursor solution dropwise on the dense layer, spin-coat at a speed of 5000 rpm for 30 s, and then place the spin-coated perovskite film in a place where 20 mgH 2 C 2 o 4 on a solid heating platform, and cover the two with a transparent glass cover, then preliminarily anneal at 100°C for 10 minutes, and then anneal on a heating platform at 150°C for 10 minutes to obtain H 2 C 2 o 4 Treated perovskite light absorbing layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com