A kind of high-entropy zirconate inorganic fiber and preparation method thereof

A technology of inorganic fiber and zirconate, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve the problems of no high-entropy oxide fiber and lack of preparation experience, and achieve stable and reliable sol, simple process and complete fiber shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

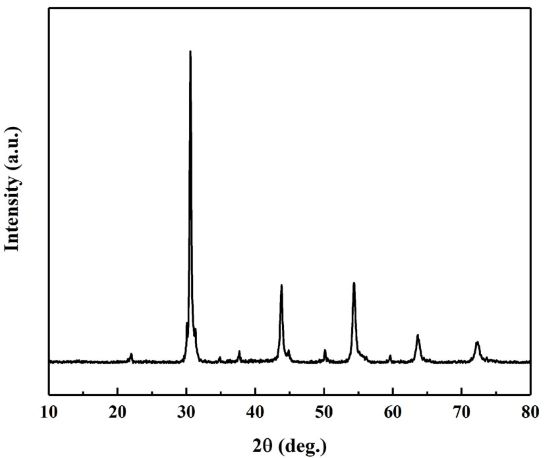

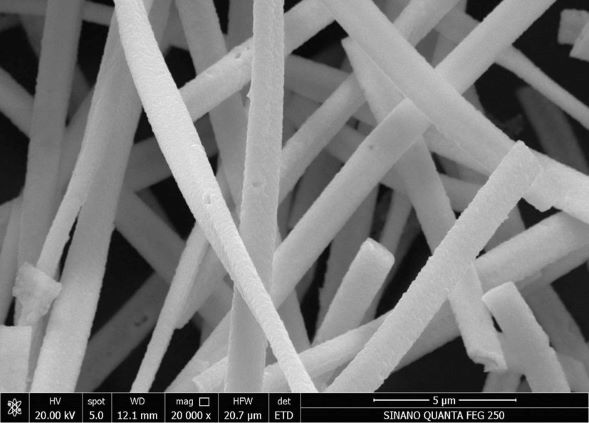

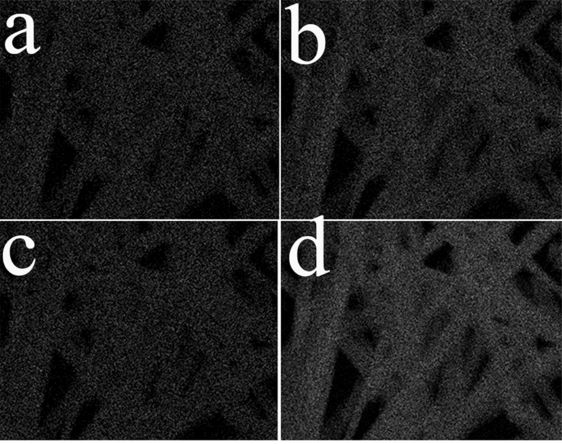

[0031] A preparation method of high-entropy zirconate inorganic fiber, comprising the following steps:

[0032] (a) Preparation of high-entropy zirconate fiber precursor sol

[0033] The solid raw material basic zirconium carbonate, calcium acetate, strontium acetate and barium acetate are added to the water of mass ratio solid: water=1:1 according to the element mol ratio Zr:Ca:Sr:Ba=3:1:1:1, and Under the condition of heating and stirring at 60 °C, the molar ratio Zr:CH was added. 3 The glacial acetic acid with COOH=1: 2 was dissolved to obtain a high-entropy zirconate sol; polyethylene oxide with a mass fraction of 1% was added to the high-entropy zirconate sol, and the high-entropy zirconate fiber precursor was fully dissolved. sol;

[0034] (b) Preparation of high-entropy zirconate precursor fibers by electrospinning

[0035] The high-entropy zirconate fiber precursor sol of step (a) is electrospinned to obtain high-entropy zirconate precursor fibers, wherein the elect...

Embodiment 2

[0039] As described in Example 1, the difference is that the calcium acetate in step (a) is replaced with calcium hydroxide, and the mol ratio Zr:CH is added. 3 COOH = 1:3 glacial acetic acid.

Embodiment 3

[0041] As described in Example 1, the difference is that in step (a), calcium acetate is replaced with calcium oxide, and the molar ratio Zr:CH is added. 3 COOH = 1:3 glacial acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com