Black alumina ceramic and preparation method thereof

A technology of black alumina and alumina porcelain, applied in fibrous fillers and other directions, can solve problems such as being unsuitable for industrial production, harmful to human body and environment, and flammable ethyl orthosilicate, achieving stable crystal phase and low cost , the effect of low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

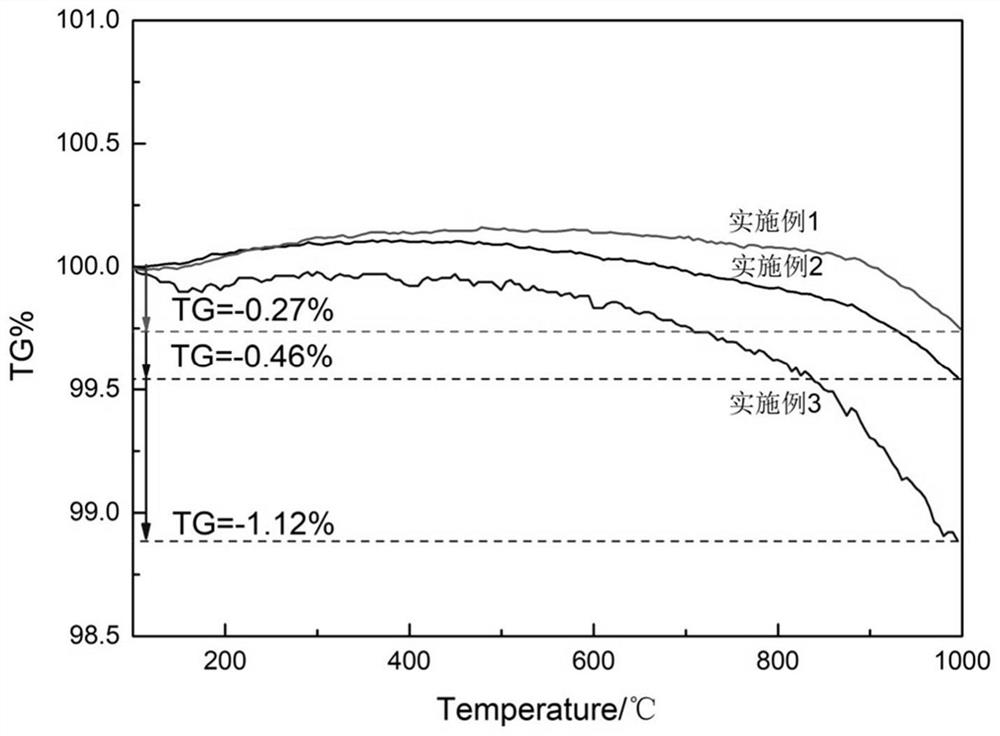

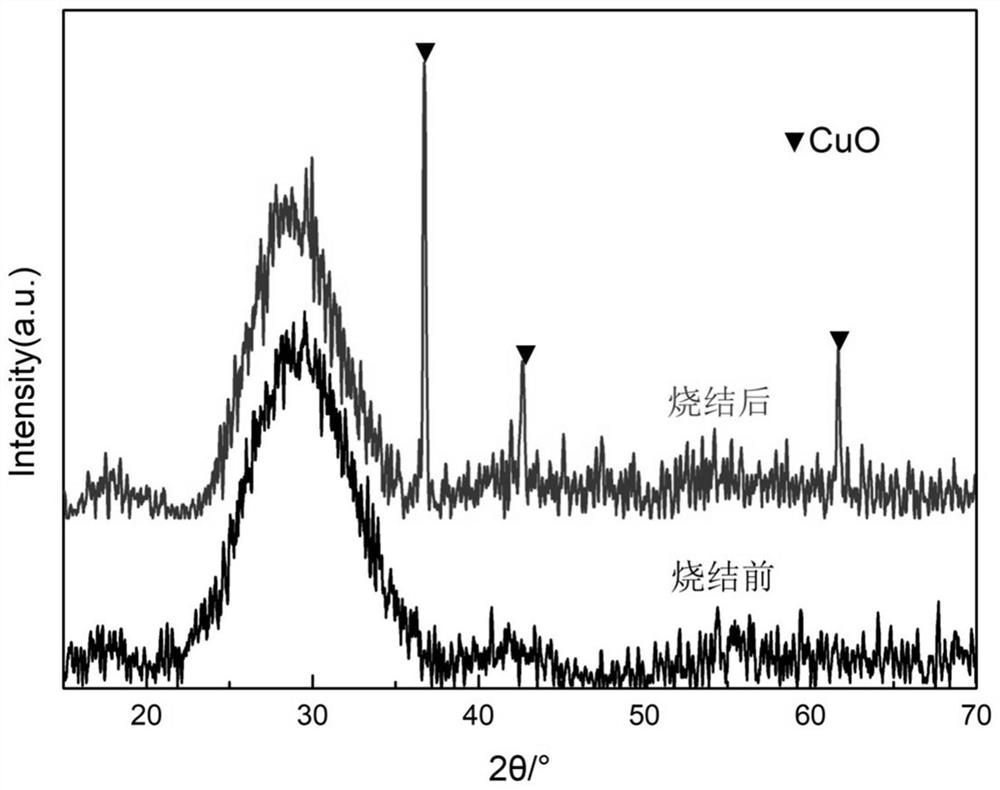

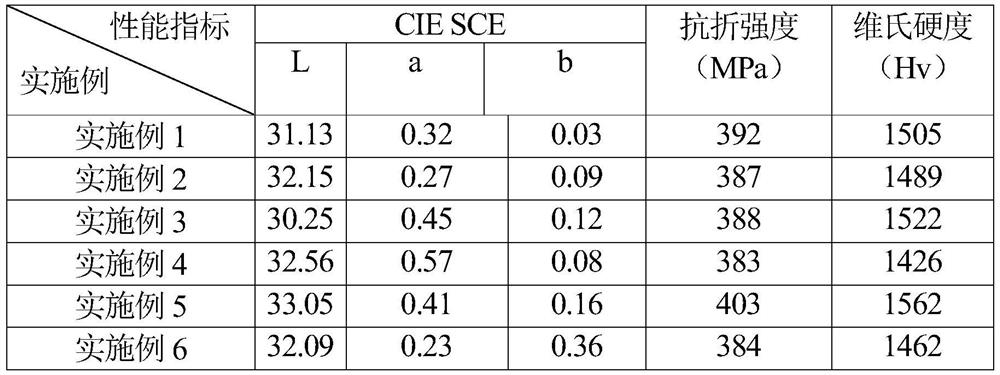

[0024] The invention provides a kind of preparation method of black alumina ceramics, specifically comprises the following steps:

[0025]1) According to the mass fraction, 4-6% of diboron trioxide, 13-15% of silicon dioxide, 55-59% of bismuth trioxide, 0.5-2% of manganese dioxide, 16-19% of oxide Copper, 0.8-1.5% of ditungsten trioxide, 1-1.5% of antimony trioxide and 0.8-2% of germanium dioxide are uniformly mixed to obtain a mixture;

[0026] 2) Add the mixture into the preheated bisque crucible in the silicon carbon rod resistance furnace. The preheating temperature of the crucible is 800-900°C, and cover it; then raise the temperature to 950-1100°C, and keep it warm for 20-30 minutes. Pour the molten liquid into distilled water at room temperature for water quenching;

[0027] 3) fish out the water-quenched material, and dry to obtain black pellets;

[0028] 4) Weigh 43-55% black granules, 1-5% calcined kaolin, 0.5-1% titanium dioxide, and 43-55% distilled water accordi...

Embodiment 1

[0035] 1) Take 5.4% diboron trioxide, 14.7% silicon dioxide, 56.5% bismuth trioxide, 1% manganese dioxide, 17.9% copper oxide, 1.4% ditungsten trioxide, 1.8% of antimony trioxide and 1.3% of germanium dioxide are uniformly mixed to obtain a mixture;

[0036] 2) Add the mixture into the preheated bisque crucible in the silicon carbon rod resistance furnace. The preheating temperature of the crucible is 850°C, and cover it; then raise the temperature to 1000°C, keep it warm for 30 minutes, and pour the molten liquid into it Water quenching in distilled water at room temperature;

[0037] 3) fish out the water-quenched material, and dry to obtain black pellets;

[0038] 4) Weigh 48.2% black granular material, 3.5% calcined kaolin, 0.7% titanium dioxide and 47.6% distilled water according to the mass fraction, put them into a ball mill jar and mill for 12 hours, pass through a 300-mesh standard sieve to obtain black slurry ;

[0039] 5) Dip the cleaned 99% alumina porcelain int...

Embodiment 2

[0044] 1) Take 4.9% diboron trioxide, 14.5% silicon dioxide, 58.4% bismuth trioxide, 2% manganese dioxide, 17.6% copper oxide, 1.5% ditungsten trioxide, 1% antimony trioxide and 1.3% germanium dioxide are uniformly mixed to obtain a mixture;

[0045] 2) Add the mixture into the preheated bisque crucible in the silicon carbon rod resistance furnace. The preheating temperature of the crucible is 830°C, and cover it; then raise the temperature to 1080°C, keep it warm for 25 minutes, and pour the molten liquid into it Water quenching in water at room temperature;

[0046] 3) fish out the water-quenched material, and dry to obtain black pellets;

[0047] 4) Weigh 46.2% black granular material, 3.2% calcined kaolin, 1% titanium dioxide and 49.6% distilled water according to the mass fraction, put them into a ball mill jar and mill for 18 hours, pass through a 300-mesh standard sieve to obtain a black slurry ;

[0048] 5) Dip the cleaned 99% alumina porcelain into the black slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com