High-entropy zirconate inorganic fiber and preparation method thereof

A technology of inorganic fiber and zirconate, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve the problems of lack of preparation experience and no high-entropy oxide fiber, etc., and achieve the effect of simple process, stable and reliable sol, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

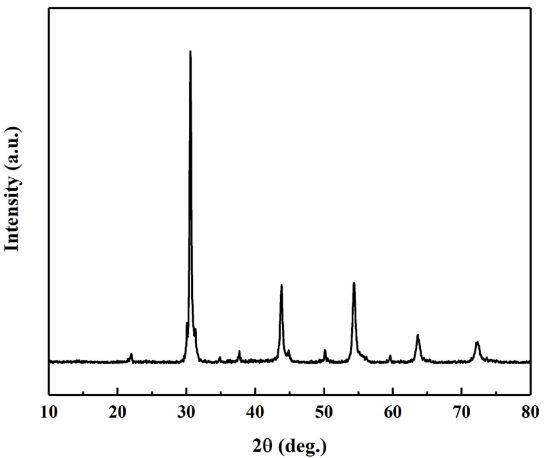

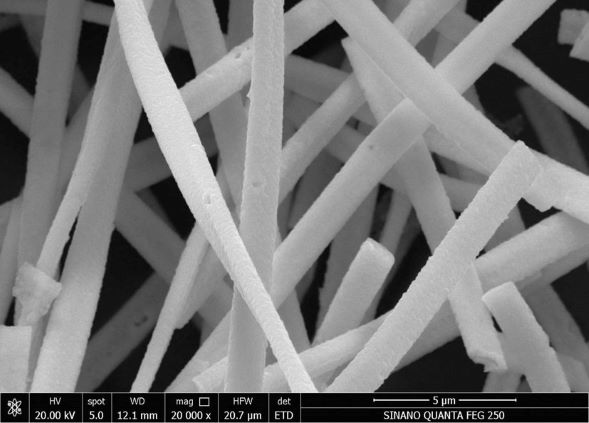

[0031] A method for preparing high-entropy zirconate inorganic fibers, comprising the steps of:

[0032] (a) Preparation of high-entropy zirconate fiber precursor sol

[0033] The solid raw material basic zirconium carbonate, calcium acetate, strontium acetate, and barium acetate are added to the water with a mass ratio of solid:water=1:1 according to the element molar ratio Zr:Ca:Sr:Ba=3:1:1:1, and Under the condition of heating and stirring at 60°C, add the molar ratio Zr:CH 3 COOH = 1: 2 glacial acetic acid, dissolved to obtain a high-entropy zirconate sol; adding polyethylene oxide with a mass fraction of 1% to the high-entropy zirconate sol, fully dissolved to obtain a high-entropy zirconate fiber precursor Sol;

[0034] (b) Preparation of high-entropy zirconate precursor fibers by electrospinning

[0035] The high-entropy zirconate fiber precursor sol in step (a) is obtained by electrospinning the high-entropy zirconate precursor fiber, wherein the electrospinning pro...

Embodiment 2

[0039] As described in Example 1, the difference is that the calcium acetate in step (a) is replaced by calcium hydroxide, adding the molar ratio Zr:CH 3 COOH = 1:3 glacial acetic acid.

Embodiment 3

[0041] As described in Example 1, the difference is that calcium acetate is replaced by calcium oxide in step (a), and the molar ratio Zr:CH is added. 3 COOH = 1:3 glacial acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com