Method for stabilizing anatase phase nano titanium oxide and cubic phase nano zirconium oxide

A technology of nano-titanium oxide and nano-zirconium oxide, applied in the direction of titanium oxide/hydroxide, zirconium oxide, titanium dioxide, etc., can solve the problems of unreported and high stabilizer, achieve simple operation, inhibit growth, inhibit specific surface area the effect of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

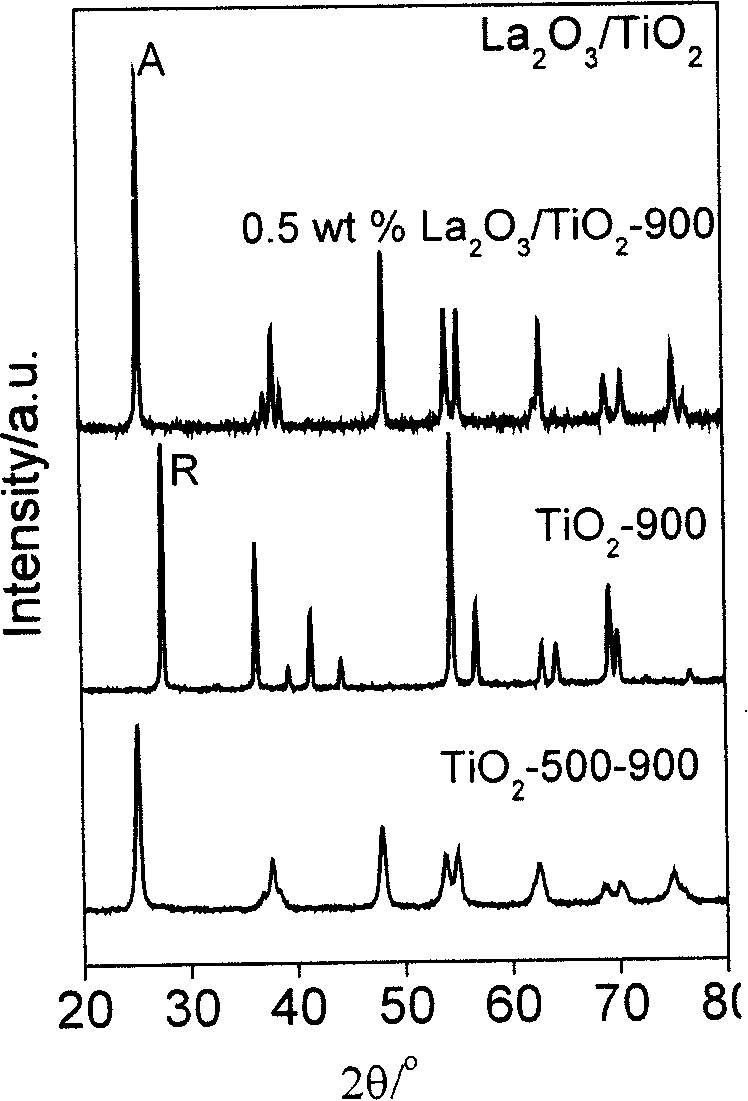

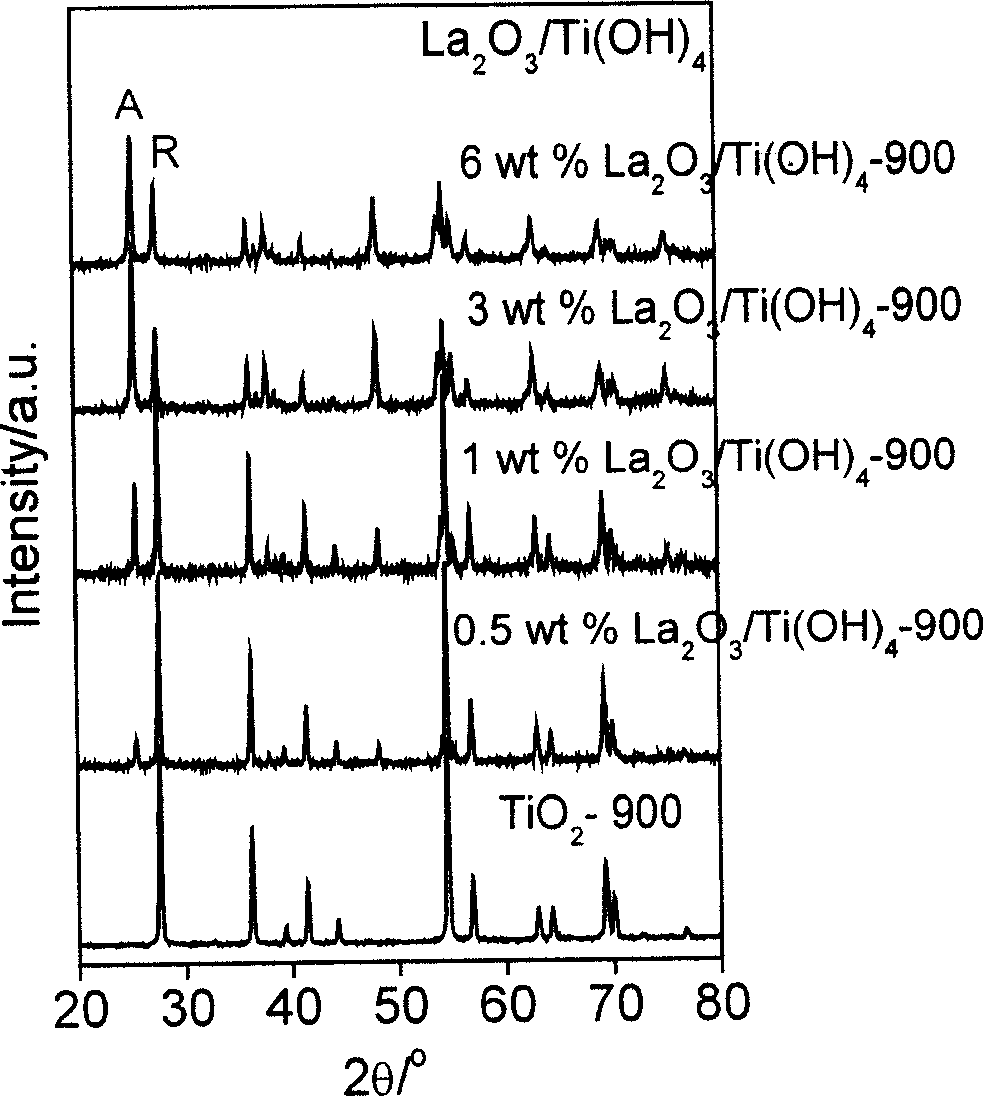

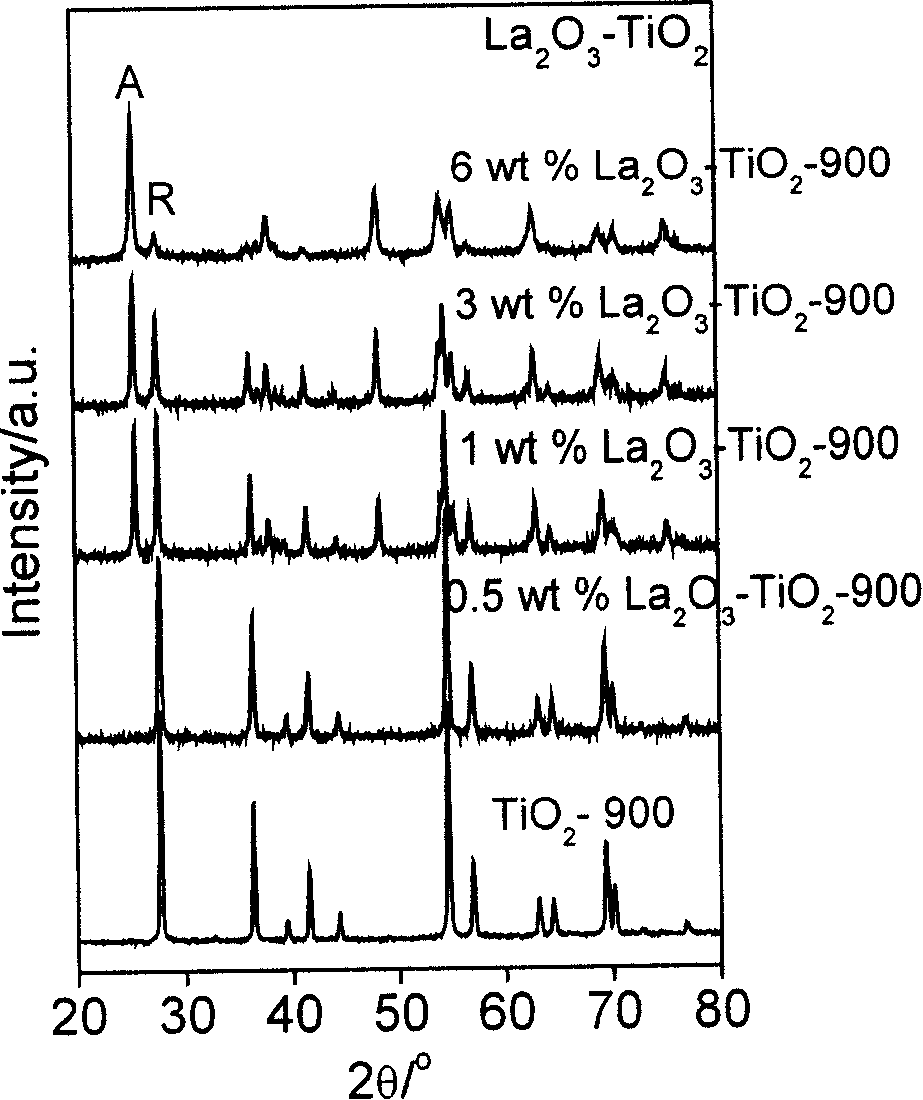

[0036] As an illustrative example, the titanium oxide carrier can be prepared as follows: add 100 ml of absolute ethanol and 20 ml of tetrabutyl titanate into a 500 ml beaker, and mix well. Ammonia water was added dropwise to the above mixed solution until the pH was about 9, and the precipitate was aged at room temperature for 12 hours. The precipitate was filtered and washed twice with deionized water and absolute ethanol respectively, then dried at 100°C, and then calcined at 500°C to obtain a titanium oxide carrier, marked as TiO 2 -500. The La(NO 3 ) 3 The solution was dropped onto the titania support (the added La(NO 3 ) 3 to La 2 o 3 Count, La 2 o 3 The amount is La 2 o 3 in TiO 23% of the dispersion of the upper single layer, that is, 0.5wt% of titanium oxide), stir evenly, and let it stand for 4 hours; then dry it in a water bath, stir vigorously during it; then put it in an oven and keep it at 120°C overnight; finally bake it at 900°C . The samples prepa...

Embodiment 2

[0047] As an illustrative example, a zirconia support can be prepared as follows: zirconium nitrate (Zr(NO 3 ) 2 ) into a 0.4M solution, and then slowly drop the solution into the concentrated ammonia solution. The pH of the solution was then adjusted to around 13 with 2M NaOH. After aging for 12 hours, the precipitate was filtered and washed thoroughly with distilled water until the pH of the filtrate was 7. The precipitate was dried at 110°C for about 12 hours, then calcined at 400°C for 4 hours as a zirconia support, and labeled as ZrO 2 -400. Similarly, La(NO 3 ) 3 The solution was dropped onto the zirconia support (the added La(NO 3 ) 3 to La 2 o 3 Count, La 2 o 3 Quantity is La 2 o 3 in ZrO 2 0.3% of the dispersion of the upper single layer, which is 0.1wt% of zirconia), stir evenly, and let it stand for 4 hours; then dry it in a water bath, stir vigorously during it; then put it in an oven and keep it at 110°C overnight; then bake it at 900°C , the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com