Preparation method for hydrogen storage alloy material

A technology for hydrogen storage alloys and raw materials, applied in hydrogen separation, using solid contact hydrogen separation, etc., can solve the problems of volatilization, difficult to avoid Mg, unable to meet battery performance requirements, etc., to reduce the number of cycles, reduce the pressure of hydrogen absorption and release, The effect of improving corrosion resistance and easy activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

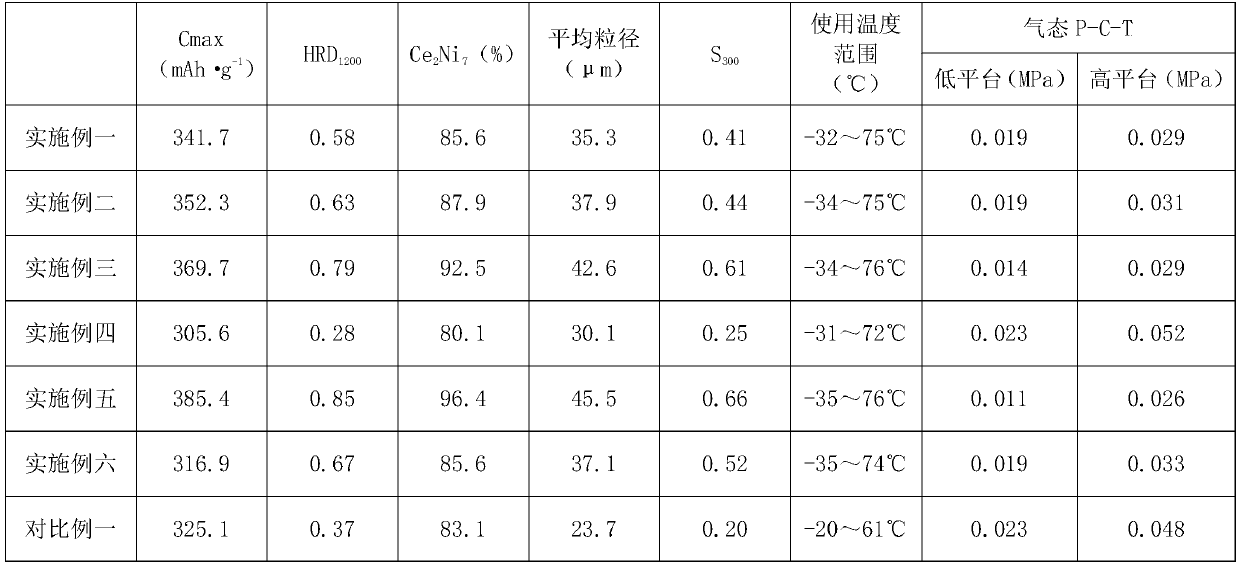

Embodiment 1

[0031] (1) Get the raw materials according to the following mass fractions: lanthanum (purity 99.8%) 17.44% (calculation, the same below), yttrium (purity 99.9%) 5.90%, samarium (purity 99.9%) 9.41%, nickel (purity 99.0%) %) 62.99%, manganese (purity 99.9%) 3.51%, cerium (purity 99.6%) 0.75%;

[0032] (2) Put the measured raw materials into the high-frequency melting furnace with argon protection in sequence according to the feeding order of yttrium, lanthanum, cerium, manganese, samarium and nickel (argon purity ≥ 99.999%);

[0033] (3) Heat up to 120°C and keep the temperature constant for 10 minutes to remove the moisture in the material;

[0034] (4) Continue to heat up to 800°C and keep the temperature constant for 5 minutes to remove low-boiling volatiles;

[0035] (5) Continue to heat up to 1650°C and keep the temperature constant for 10 minutes to fully melt the raw materials to obtain a melt;

[0036] (6) After the melt is cooled to room temperature, it is quickly t...

Embodiment 2

[0040] (1) The raw materials are taken according to the following mass fractions: lanthanum (purity 99.8%) 16.78% (calculation, the same below), yttrium (purity 99.9%) 6.24%, samarium (purity 99.9%) 10.19%, nickel (purity 99.0%) %) 61.15%, manganese (purity 99.9%) 3.84%, cerium (purity 99.6%) 1.80%;

[0041] (2) Put the measured raw materials into the high-frequency melting furnace with argon protection in sequence according to the feeding order of yttrium, lanthanum, cerium, manganese, samarium and nickel (argon purity ≥ 99.999%);

[0042] (3) be heated up to 130 ℃, constant temperature 12min, to remove the moisture in the material;

[0043] (4) Continue to heat up to 820°C and keep the temperature constant for 7 minutes to remove low-boiling volatiles;

[0044] (5) Continue to heat up to 1680°C and keep the temperature constant for 12 minutes to fully melt the raw materials to obtain a melt;

[0045] (6) After the melt is cooled to room temperature, it is quickly transferr...

Embodiment 3

[0049] (1) Get raw materials according to the following mass fractions: lanthanum (purity 99.8%) 15.31% (calculated in hundreds, the same below), yttrium (purity 99.9%) 7.60%, samarium (purity 99.9%) 11.40%, nickel (purity 99.0%) %) 57.55%, manganese (purity 99.9%) 4.34%, cerium (purity 99.6%) 3.80%;

[0050] (2) Put the measured raw materials into the high-frequency melting furnace with argon protection in sequence according to the feeding order of yttrium, lanthanum, cerium, manganese, samarium and nickel (argon purity ≥ 99.999%);

[0051] (3) Heat up to 120°C and keep the temperature constant for 10 minutes to remove the moisture in the material;

[0052] (4) Continue to heat up to 800°C and keep the temperature constant for 5 minutes to remove low-boiling volatiles;

[0053] (5) Continue to heat up to 1650°C and keep the temperature constant for 10 minutes to fully melt the raw materials to obtain a melt;

[0054] (6) After the melt is cooled to room temperature, it is q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com