Preparation method of dielectric film with ultrahigh dielectric constant

A technology of dielectric film and dielectric constant, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as not being able to meet process requirements, achieve low equivalent gate oxide thickness, ultra-high dielectric constant, reduce Lattice Distortion Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

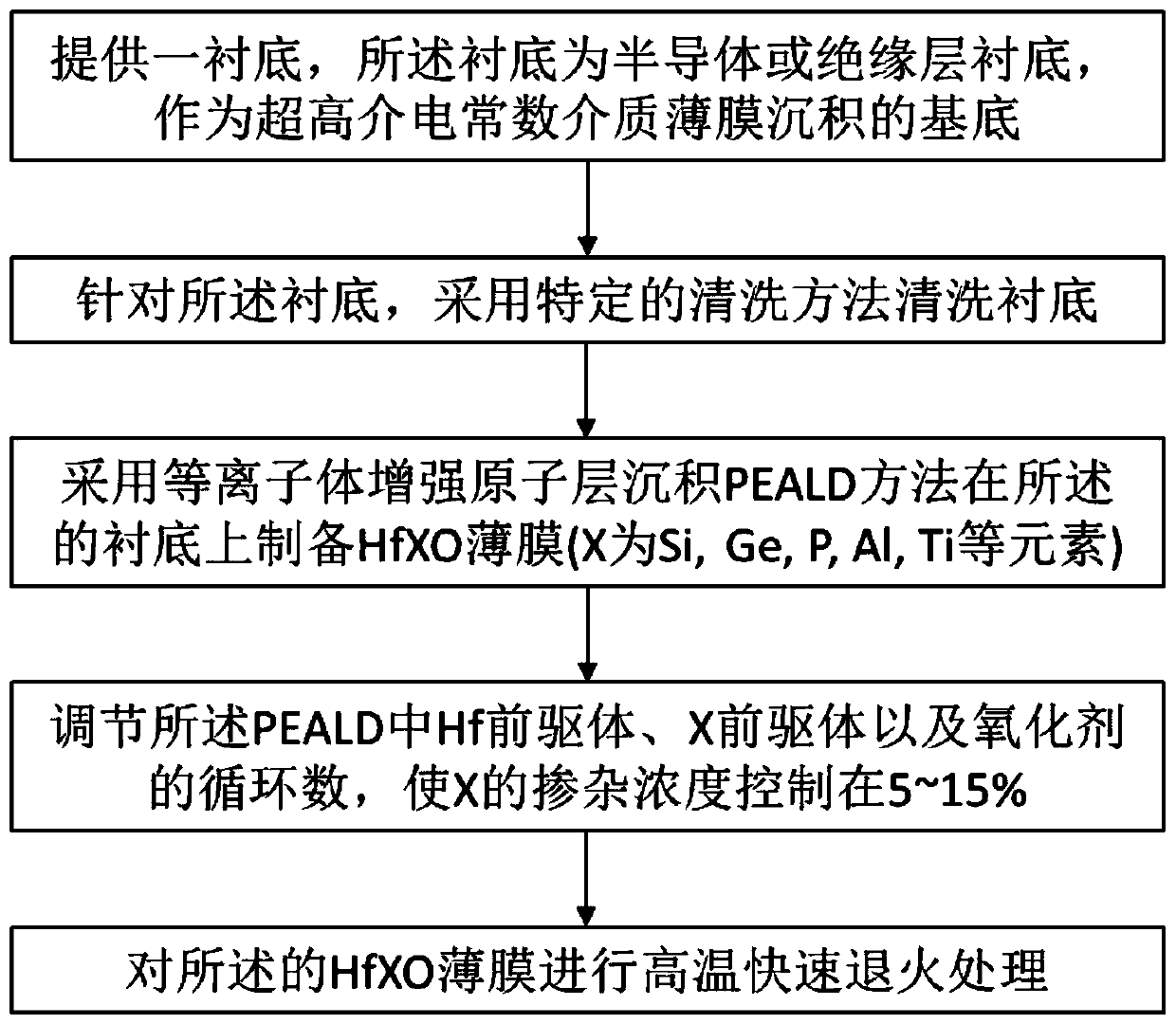

[0027] The specific implementation of a method for preparing an ultra-high dielectric constant dielectric film provided by the present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 Its main steps are as follows:

[0028] Select a substrate, and here we choose the most common Si wafer substrate as an example. In this example, first use NH with a volume ratio of 1:1:5 3 ·H 2 O, H 2 o 2 、H 2O mixed solution to clean the Si substrate, the cleaning time is 10min, and then use the volume ratio of 1% HF aqueous solution to clean the Si substrate, the cleaning time is 30s; finally use the volume ratio of 1:1:6 HCl, h 2 o 2 、H 2 O solution was used to clean the Si substrate, and the cleaning time was 10 min.

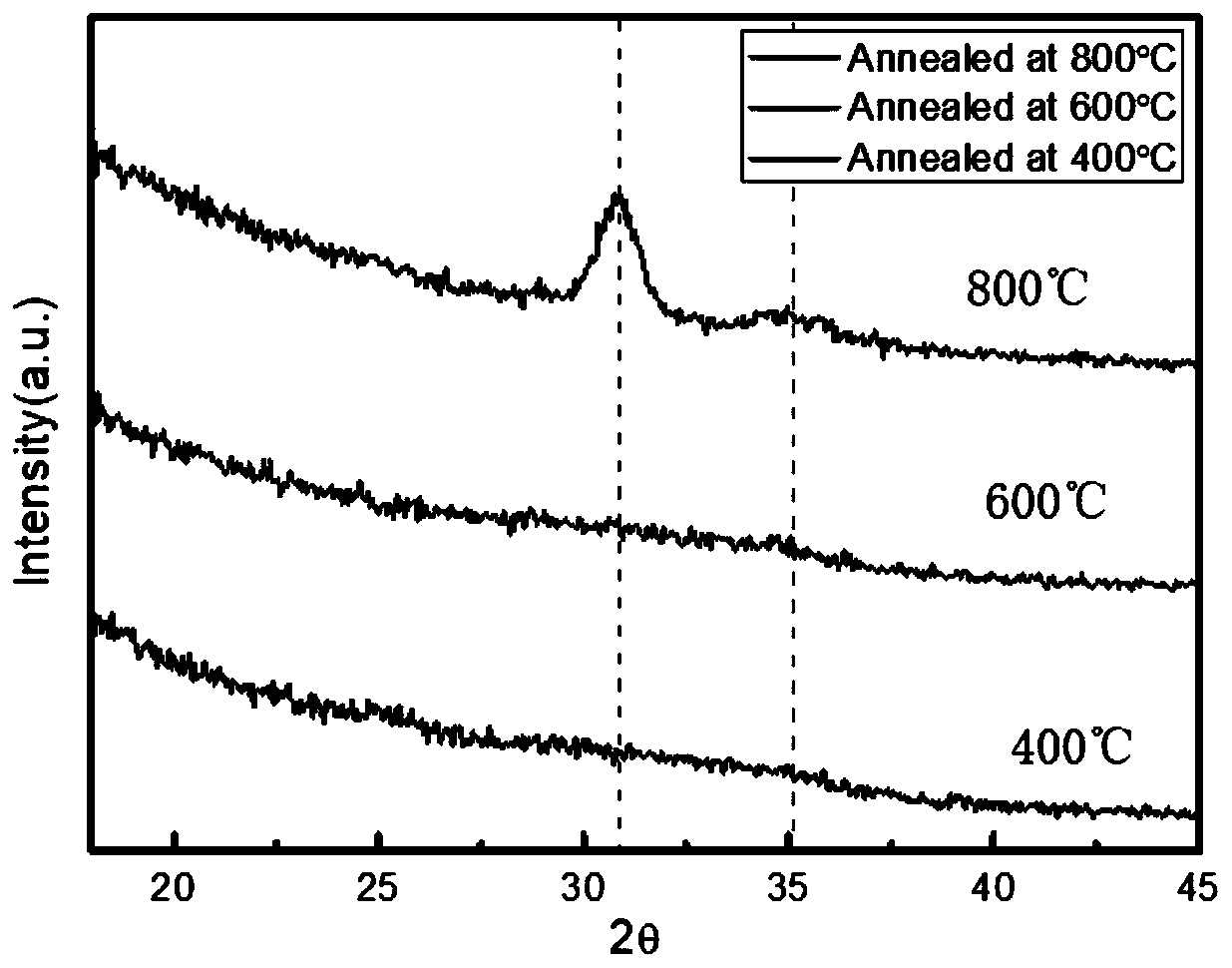

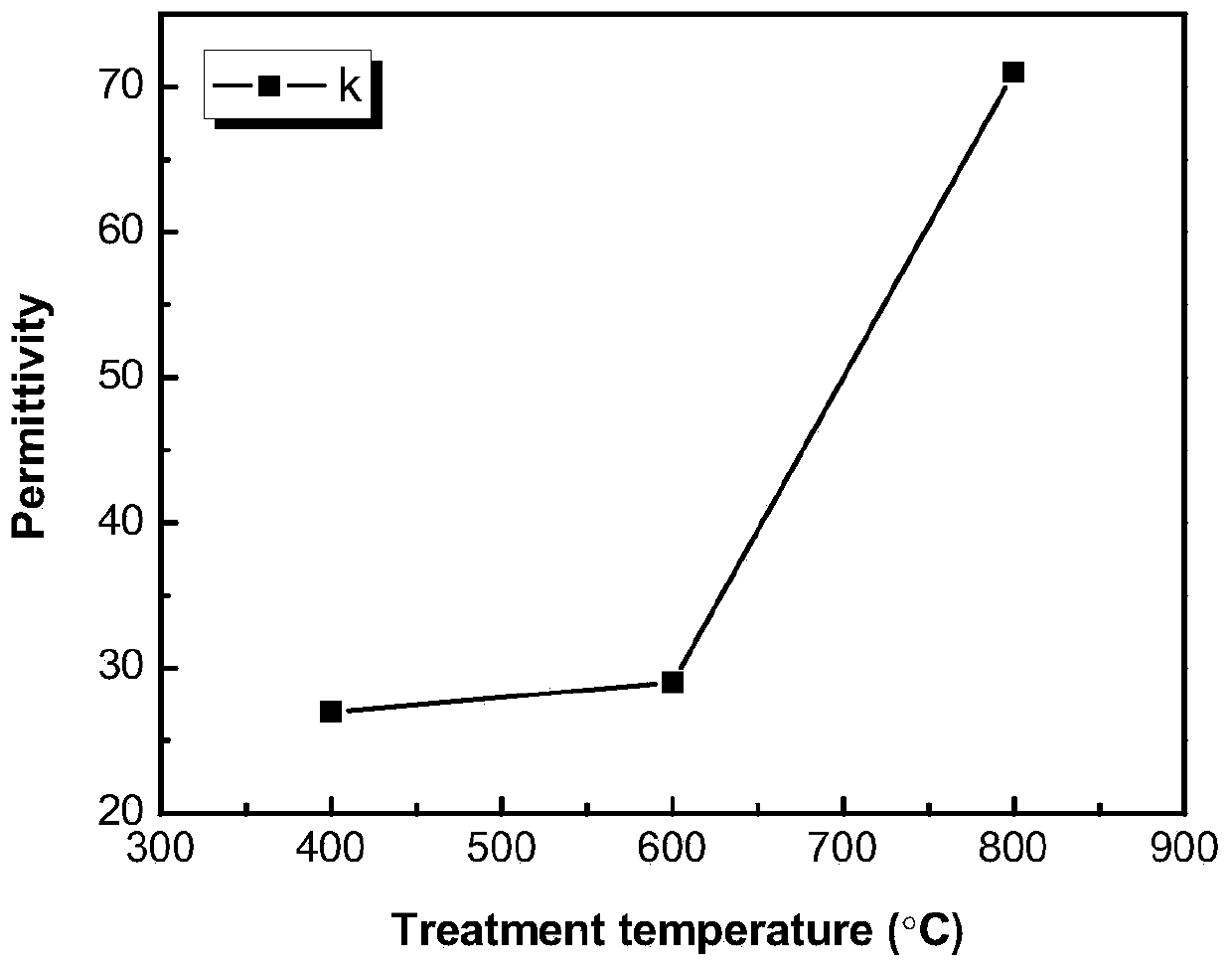

[0029] The cleaned substrate is further placed in the reaction chamber of plasma enhanced atomic layer deposition PEALD, and a nanometer-thick HfXO film is deposited on the surface of the substrate (X is Si, Ge, P, Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com