High-strength aluminum-plastic composite template and preparation method thereof

An aluminum-plastic composite, high-strength technology, applied in the field of building construction tooling, can solve the problems of high moisture absorption of nylon and difficulty in applying concrete formwork, etc., to improve heat insulation performance, facilitate molding and maintenance, and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment prepares a kind of modified PA resin, and the specific implementation process is as follows:

[0033] Step A1: Take a three-necked flask equipped with a stirrer and a thermometer, add 100 g of 3,5-dimethylbenzoic acid to the three-necked flask, and then add 800 mL of xylene to start stirring, and no 3,5-dimethylformaldehyde can be seen when stirring for 8 minutes. The benzoic acid has been completely dissolved, and then 90 mL of thionyl chloride was added to the three-necked flask, and the three-necked flask was heated in a water bath. When the temperature reached 50 °C, the heat preservation reaction was carried out for 3 hours. After the reaction, the alcohol lamp was used for heating until the The temperature of the reaction solution reaches 140°C, the temperature difference is allowed to float by 2°C, and high-speed stirring is performed for 5 minutes to decompose the unreacted thionyl chloride, and at the same time, a small amount of solvent x...

Embodiment 2

[0037] The present embodiment prepares a kind of modified PA resin, and the specific implementation process is as follows:

[0038] Step A1: Take a three-necked flask equipped with a stirrer and a thermometer, add 100 g of 3,5-dimethylbenzoic acid to the three-necked flask, and then add 1200 mL of xylene to start stirring, and no 3,5-dimethylformaldehyde can be seen when stirring for 7 minutes. The benzoic acid has been completely dissolved, and then 110 mL of thionyl chloride was added to the three-necked flask, and the three-necked flask was heated in a water bath. When the temperature reached 55 °C, the thermal insulation reaction was carried out for 5 h. After the reaction was completed, use an alcohol lamp to heat until The temperature of the reaction solution reaches 140°C, the temperature difference is allowed to float by 2°C, and high-speed stirring is performed for 5 minutes to decompose the unreacted thionyl chloride, and at the same time, a small amount of solvent xy...

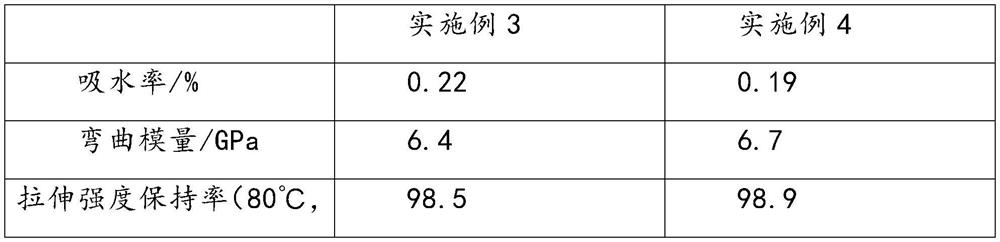

Embodiment 3

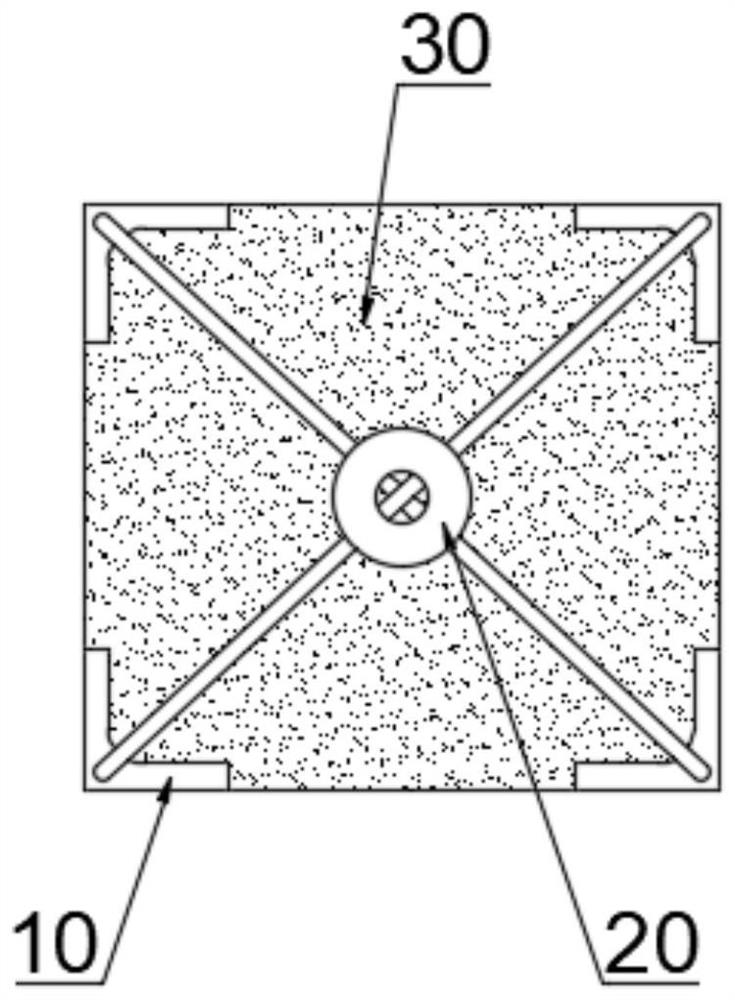

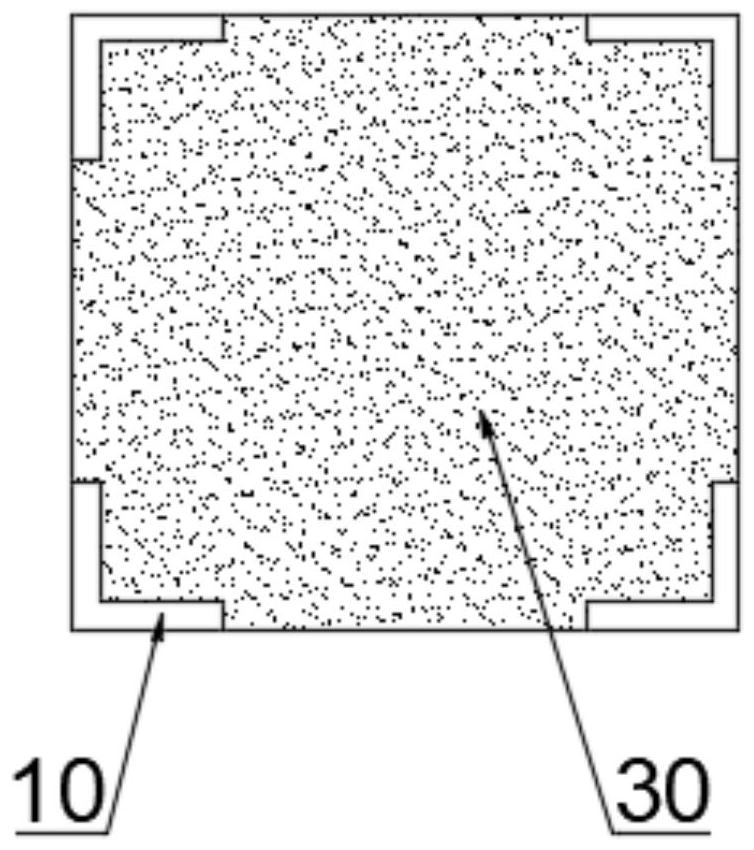

[0042] This example prepares a high-strength aluminum-plastic composite template, please refer to Figure 1-Figure 2 The specific implementation process is as follows:

[0043] Step S1: Take four groups of aluminum corner protectors 10, the aluminum corner protectors 10 are formed into a 90° plate shape, and a bottom plate is provided on the bottom surface of the aluminum corner protectors 10 to provide welding sites, and the four groups of aluminum corner protectors 10 are placed on the bottom surface of the aluminum corner protector 10. The corner of the mold is positioned, and then the aluminum bracket 20 is taken. The middle of the aluminum bracket 20 is provided with a support ring, which is used to provide a support point when the mold is closed, and the force is evenly distributed to prevent the support from cracking the template. The aluminum bracket 20 The ends of 4 groups of aluminum corner protectors 10 are welded and fixed respectively;

[0044] Step S2: Take 10kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com