Preparation method of PAM (Polyacrylamide) enhancement nano-hydroxyapatite biological composite coating

A technology of nano-hydroxyapatite and composite coating, applied in the direction of coating, can solve the problem of low bonding force between coating and coating, and achieve the effect of improving bonding strength and stable crystal phase of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

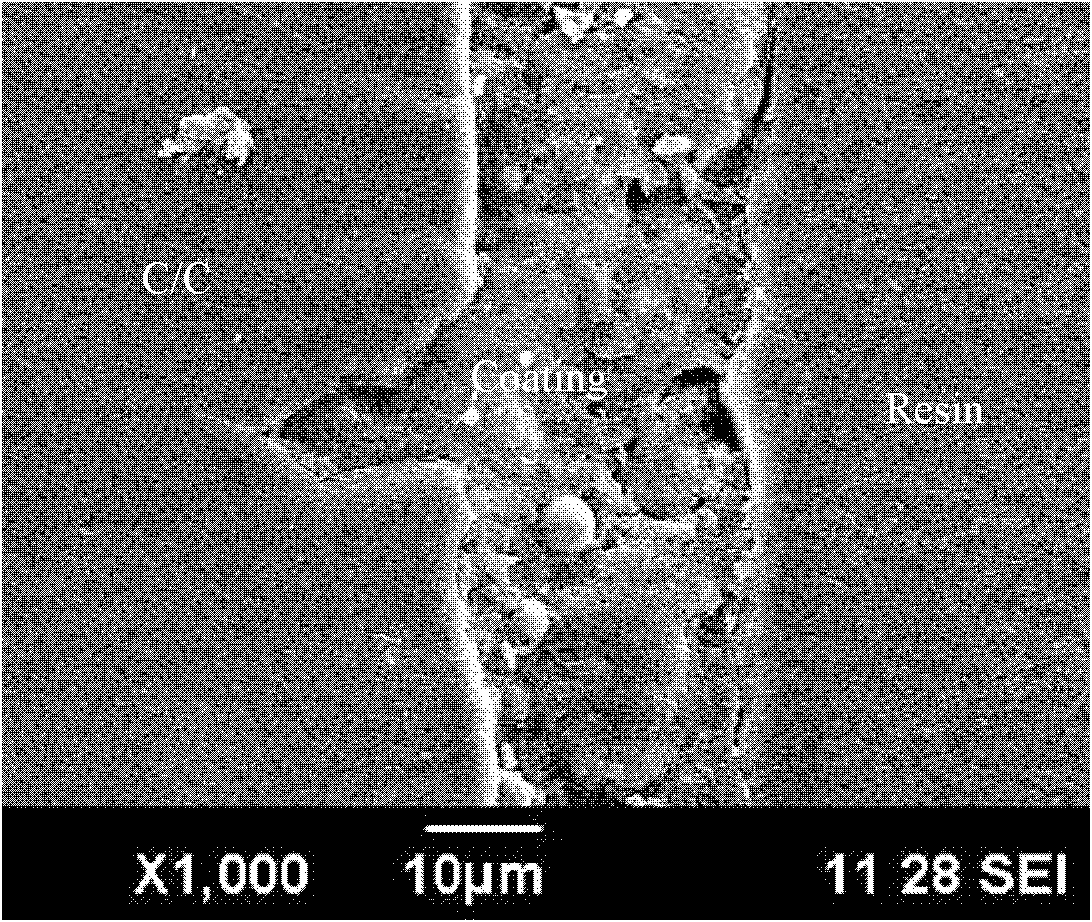

Image

Examples

Embodiment 1

[0017] Example 1: 1) Preparation of nano-hydroxyapatite powder First, analytically pure Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of calcium to phosphorus of 1:1.57, then add distilled water to dissolve Ca 2+ Solution A with an ion concentration of 0.04mol / L; secondly, according to Ca(NO 3 ) 2 4H 2 O:(NH 2 ) 2 HPO 4 =1:5 mass ratio, add urea powder to solution A and stir to make a mixed solution; finally, under magnetic stirring, put the generation head of the multi-frequency sonochemical generator into the above mixed solution at 100-300w Sonochemical synthesis was performed at 40°C for 1.5 hours under ultrasonic power, and then heated to 70°C for 2 hours, then the upper liquid was filtered off, and then washed with distilled water and then with absolute ethanol. Vacuum drying to obtain nano-hydroxyapatite powder; 2) take nano-hydroxyapatite powder and disperse it in analytically pure isopropanol to make a solution with a concentration...

Embodiment 2

[0018] Example 2: 1) Preparation of nano-hydroxyapatite powder First, analytically pure Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the calcium-phosphorus molar ratio of 1:1.67, then add distilled water to dissolve Ca 2+ Solution A with an ion concentration of 0.08mol / L; secondly, according to Ca(NO 3 ) 2 4H 2 O:(NH 2 ) 2 HPO 4=1:6 mass ratio, add urea powder to solution A and stir to make a mixed solution; finally, under magnetic stirring, put the generation head of the multi-frequency acoustic chemical generator into the above mixed solution at 100-300w Sonochemical synthesis was performed at 40°C for 1.5 hours under ultrasonic power, and then heated to 70°C for 2 hours, then the upper liquid was filtered off, and then washed with distilled water and then with absolute ethanol. Vacuum drying to obtain nano-hydroxyapatite powder; 2) take nano-hydroxyapatite powder and disperse it in analytically pure isopropanol to make a solution with a concentration o...

Embodiment 3

[0019] Example 3: 1) Preparation of nano-hydroxyapatite powder First, analytically pure Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of calcium to phosphorus of 1:1.77, then add distilled water to dissolve Ca 2+ Solution A with an ion concentration of 0.12mol / L; secondly, according to Ca(NO 3 ) 2 4H 2 O:(NH 2 ) 2 HPO 4 =1:7 mass ratio, add urea powder to solution A and stir to make a mixed solution; finally, under magnetic stirring, put the generation head of the multi-frequency acoustic chemical generator into the above mixed solution at 100-300w Sonochemical synthesis was performed at 40°C for 1.5 hours under ultrasonic power, and then heated to 70°C for 2 hours, then the upper liquid was filtered off, and then washed with distilled water and then with absolute ethanol. Vacuum drying to obtain nano-hydroxyapatite powder; 2) take nano-hydroxyapatite powder and disperse it in analytically pure isopropanol to make a solution with a concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com