Method for preparing Hap-PAM biological gradient compound coating by impulse hydrothermal electrophoretic polymerization method

A composite coating and gradient technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve problems such as insufficient binding force, and achieve the effect of ensuring biocompatibility and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

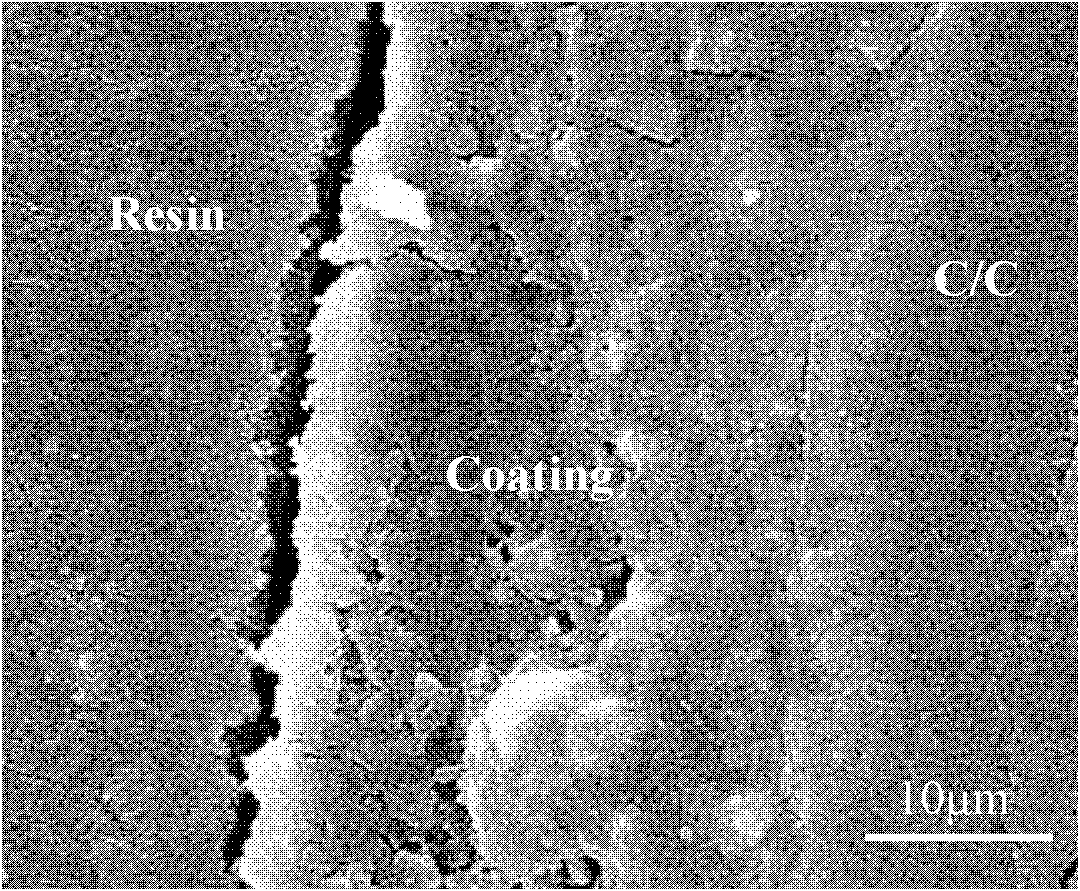

[0016] Example 1: Step 1: Dissolve 3.5g of analytically pure acrylamide monomer in water to make acrylamide aqueous solution with a concentration of 35g / L, then add 0.035g of analytically pure sodium sulfite and 0.035g of ammonium persulfate initiator respectively Fully dissolve in acrylamide aqueous solution, seal and store in a dark place to obtain solution A; Step 2: Take 3.0g of hydroxyapatite with an average particle size of 10-50nm and disperse it in 150ml of isopropanol, and then add 0.6g / L of iodine, ultrasonically dispersed for 12 hours, and aged for 8 hours to obtain B solution; Step 3: using a density of 1.8g / cm 3 The 3D C / C composite material is cut into 10mm×10mm×2mm thin slices, polished and irradiated with ultraviolet light for 20min, cleaned in distilled water, ultrasonically cleaned with absolute ethanol, dried with hot air, and fixed on the electrodeposition device and place it in the A solution by DC electrodeposition at room temperature at 80V for 5s, then ...

Embodiment 2

[0017] Example 2: Step 1: Dissolve 5g of analytically pure acrylamide monomer in water to make acrylamide aqueous solution with a concentration of 50g / L, then add 0.050g of analytically pure sodium sulfite and 0.050g of ammonium persulfate initiator to propylene respectively Fully dissolved in the amide aqueous solution, sealed and stored in a dark place to obtain solution A; Step 2: Take 2.5g of hydroxyapatite with an average particle size of 10-50nm and disperse it in 150ml of isopropanol, and then add 1.0g / L of Iodine, ultrasonically dispersed for 8 hours, and aged for 15 hours to obtain B solution; Step 3: Use a density of 1.8g / cm 3 The 3D C / C composite material is cut into 10mm×10mm×2mm thin slices, polished and irradiated with ultraviolet light for 30 minutes, cleaned in distilled water, ultrasonically cleaned with absolute ethanol, dried with hot air, and fixed on the electrodeposition device and put it in the A solution, take it out after depositing at 100V for 3s at r...

Embodiment 3

[0018] Example 3: Step 1: Dissolve 6g of analytically pure acrylamide monomer in water to make acrylamide aqueous solution with a concentration of 60g / L, then add 0.060g of analytically pure sodium sulfite and 0.060g of ammonium persulfate initiator to propylene respectively Fully dissolved in the amide aqueous solution, sealed and stored in a dark place to obtain solution A; Step 2: Take 2.0g of hydroxyapatite with an average particle size of 10-50nm and disperse it in 150ml of isopropanol, and then add 0.8g / L of Iodine, ultrasonically dispersed for 5 hours, and aged for 20 hours to obtain B solution; Step 3: Use a density of 1.8g / cm 3The 3D C / C composite material is cut into 10mm×10mm×2mm thin slices, polished and irradiated with ultraviolet light for 40min, cleaned in distilled water, ultrasonically cleaned with absolute ethanol, dried with hot air, and fixed on the electrodeposition device and place it in the A solution by direct current electrodeposition at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com