Patents

Literature

33results about How to "Diffusion strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

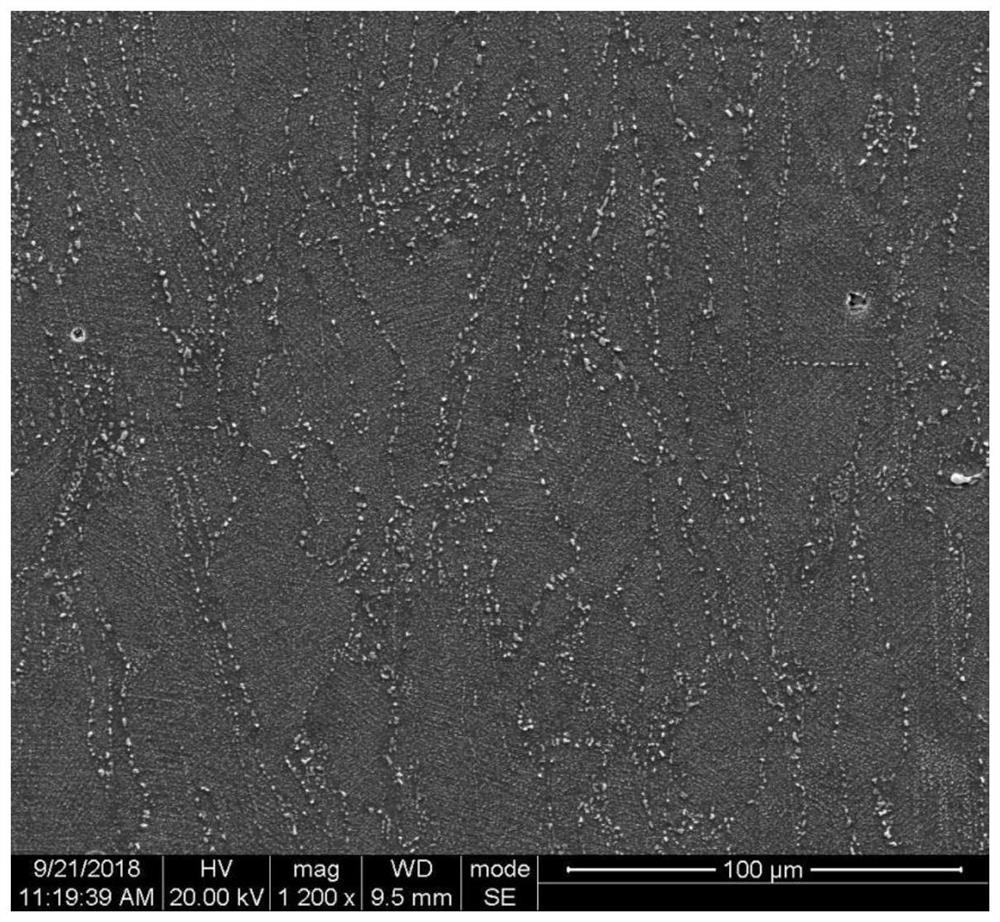

Preparation method for convex-hull-shaped abrasion-resistant nickel-plated coating reinforced through hard particles

InactiveCN105177677ADiffusion strengtheningImprove wear resistanceElectrolytic coatingsThermal treatmentElectroplating

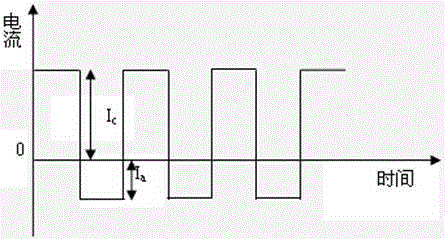

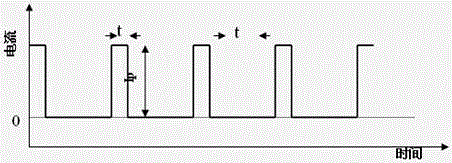

The invention discloses a preparation method for a convex-hull-shaped abrasion-resistant nickel-plated coating reinforced through hard particles. The preparation method comprises the following steps that substrate materials to be deposited are prepared, electroplate liquid of the hard particles is prepared, electro-deposition and thermal treatment are conducted, and the nickel composite coating which is of a convex-hull-shaped structure and contains the hard particles is prepared under the condition of chemical electroplating. According to the preparation method for the convex-hull-shaped abrasion-resistant nickel-plated coating reinforced through the hard particles, the technique of composite electroplating is adopted, a convex-hull-shaped structured surface is obtained by controlling pulse electroplating conditions, and the surface of the coating is fine and uniform; due to the fact that the hard particles have the function of dispersion strengthening, and the surface appearance of the composite coating is in a convex-hull shape, so that compared with a traditional nickel-plated coating, the composite coating is better in abrasion resistance.

Owner:SUZHOU SHANGKANG NEW MATERIAL SCI & TECH CO LTD

Micro-nanoparticle reinforced high-indium copper-based active solder and preparation method thereof

ActiveCN110640351ALower melting temperatureDiffusion strengtheningWelding/cutting media/materialsSoldering mediaMicro nanoIndium

The invention relates to a micro-nanoparticle reinforced high-indium copper-based active solder. The active solder comprises the following raw materials of, in parts by weight, 85 - 95 parts of base component, 2.5 - 9 parts of active component, 0.1 - 1 part of micro-component and 2 - 5 parts of micro-nano reinforced particles. A preparation method of the micro-nanoparticle reinforced high-indium copper-based active solder comprises the following steps of weighing and preparing the materials, high-frequency induction melting an intermediate alloy, vacuum smelting a solder, and conventional processing the solder into a filamentous or ribbon-shaped active solder. According to the micro-nanoparticle reinforced high-indium copper-based active solder, the formula is reasonable in design and highin cost performance; the basic component comprises the following components of, in parts by weight, 5 - 15 parts of indium, 3 - 8 parts of tin, 1 - 3 parts of manganese, 1 - 5 parts of phosphorus, 0.5 - 3 parts of antimony, 0.5 - 5 parts of silicon, 0.5 - 5 parts of germanium and the balance copper, through a method of replacing the tin with the indium and the phosphorus compositely, not only isthe melting temperature of the copper-based active solder reduced, but also the plasticity of the solder is improved and the processability of the solder is improved; and by adding the micro-nanoparticles, the strength of the solder and a soldered joint is improved.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Erosion-resistant copper alloy utilized in ocean working condition and preparation method thereof

The invention relates to the field of ocean engineering, and particularly discloses an erosion-resistant copper alloy utilized in an ocean working condition and a preparation method thereof. The copper alloy comprises the following elements by mass percent: 7% to 10% of Ni, 5% to 10.5% of Al, 0.15% to 1% of Fe, 0.5% to 1.5% of Mn, 0.15% to 1% of Ti, 0.05% to 0.15% of P, 0.2% to 0.6% of Mg and 0.005% to 0.01% of B, and the balance being copper. The preparation method comprises the steps of sequentially adding electrolytic copper, a covering agent, a CnMn intermediate alloy, a CuCo intermediate alloy, CuFe intermediate alloy, electrolytic nickel, pure chromium, electrolytic aluminium, pure silicon and the covering agent; and then, carrying out phosphor copper deoxidation, stirring slag salvaging, temperature increasing and discharging. The preparation method has the advantages that cost is low and efficiency is high, the copper alloy material has performance like sandy seawater erosion corrosion resistance, ocean organism corrosion resistance and seawater high-speed flow corrosion resistance, and the requirement of ocean engineering on corrosion-resistant and abrasion-resistant materials can be met.

Owner:HENAN UNIV OF SCI & TECH

Novel magnesium alloy composite material preparation method

The invention relates to a novel magnesium alloy composite material preparation method. The novel magnesium alloy composite material preparation method is characterized in that a novel magnesium alloy composite material is prepared through the steps that aluminum, zinc, manganese, neodymium, cerium and magnesium are proportionally mixed, nickel coated nano-SiC particles are added into a magnesium alloy melt, an electromagnetic field is applied at the same time, the nickel coated nano-SiC particles are evenly scattered in the melt through electromagnetism simulated microgravity, an electric field is applied to a casting ingot after pouring to refine grains, and finally the novel magnesium alloy composite material is subject to equal channel angular pressing. The neodymium element in the novel magnesium alloy composite material has the dispersion strengthening effect, and formed metallic compounds can prevent grain boundary sliding; the cerium element can improve the alloy structure and refine the grains; a microgravity field enables the nickel coated nano-SiC particles to be evenly scattered in the melt; the electric field can increase the degree of supercooling of the melt, nucleation barriers are reduced, and the grains are refined; and the equal channel angular pressing can further refine the grains, and the synthetic mechanical property of the composite material is improved.

Owner:CHANGZHOU UNIV +1

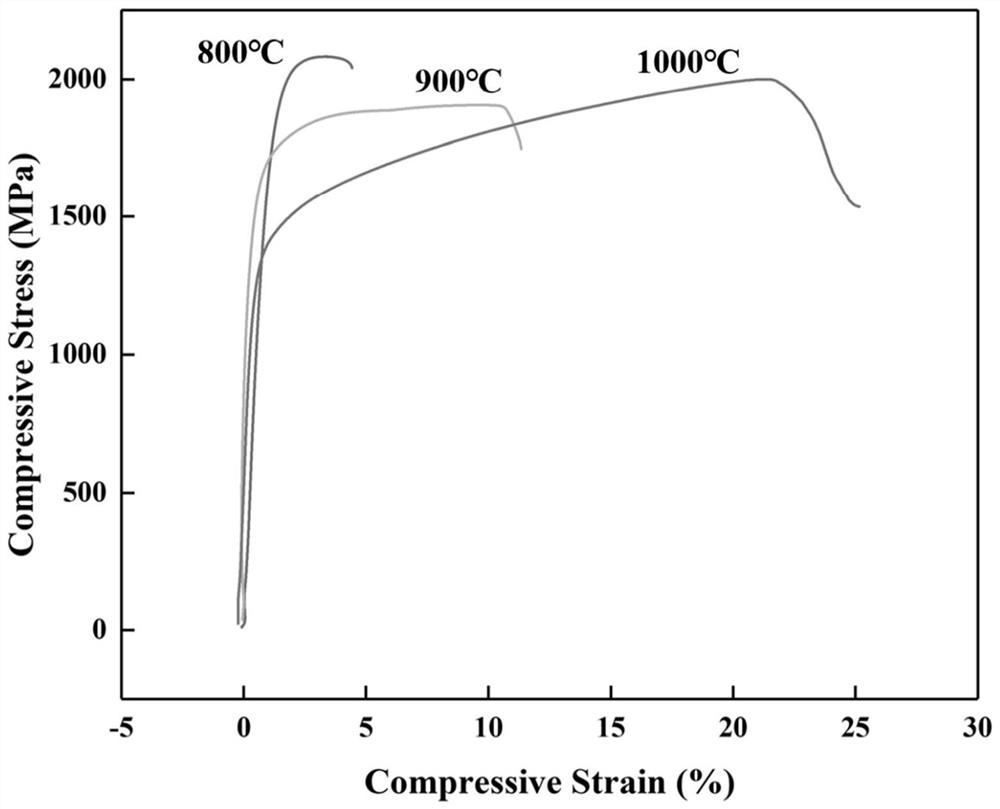

Preparation method of carbide reinforced high-entropy alloy composite material

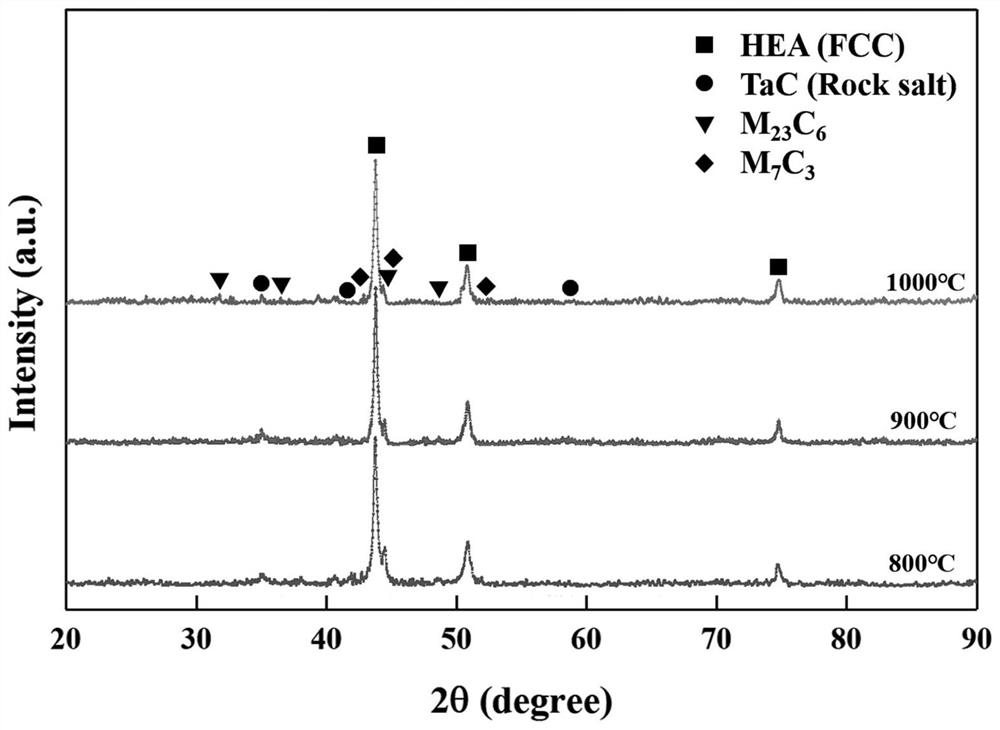

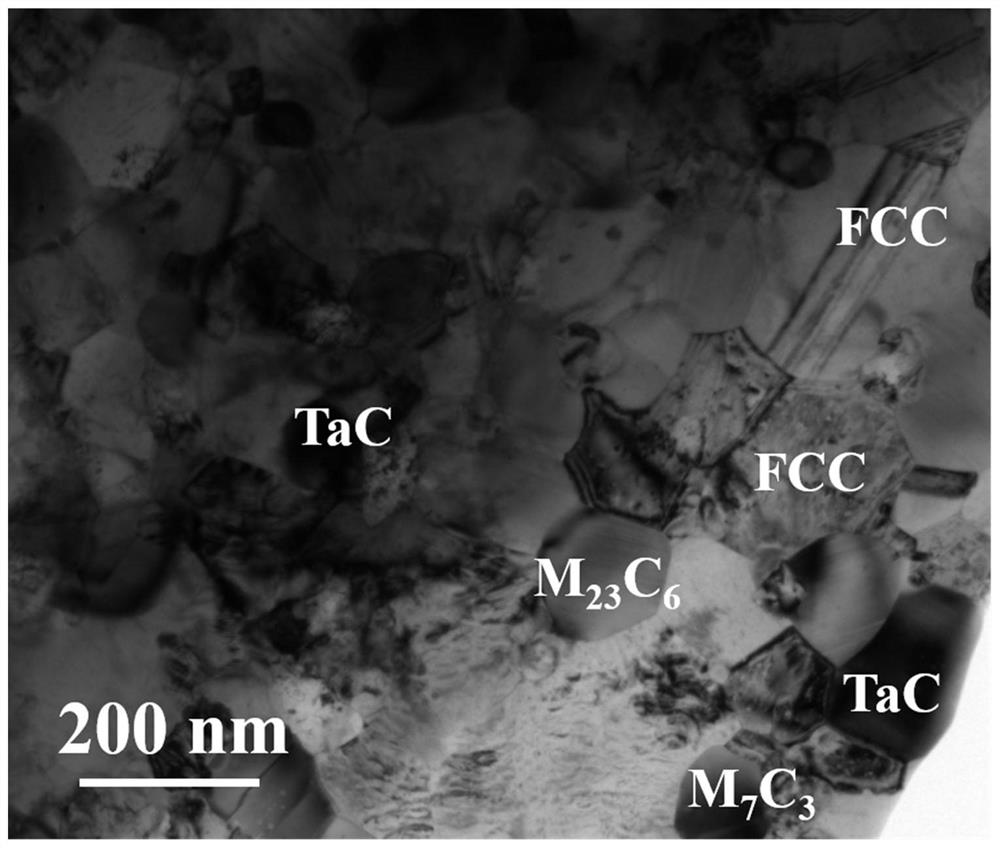

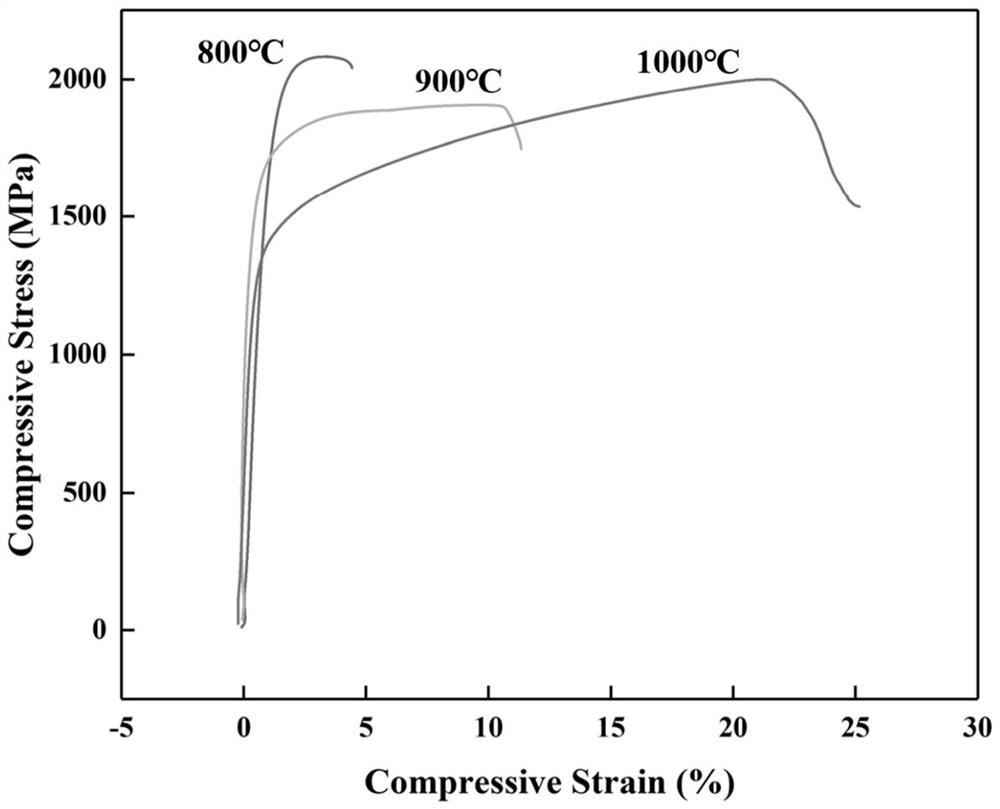

ActiveCN113337746AAchieve preparationIt has the effect of precipitation strengtheningHigh entropy alloysHydrocotyle bowlesioides

The invention relates to a scheme for preparing a carbide reinforced high-entropy alloy composite material (HEC) by adopting mechanical alloying (MA) and spark plasma sintering (SPS), in particular to a method for preparing a high-entropy compound by introducing carbide into a high-entropy alloy in two manners at the same time. The method comprises the steps that (1) a hydrocarbon additive is introduced into the high-entropy alloy in a manner of generating the carbide through a mechanical alloying reaction to prepare an in-situ high-entropy alloy composite material called HECin for short; and (2) carbide particles are added into the high-entropy alloy to prepare an ex-situ high-entropy alloy composite material called HECex for short. The method is explained in detail by taking preparation of the FeCoNiCrMn high-entropy alloy composite material as a typical case. The preparation method comprises the following steps that FeCoNiCrMn / C powder, namely, HECin powder, is prepared from five kinds of metal powder of Fe, Co, Ni, Cr and Mn and a ball milling control agent C7H16 through mechanical alloying; then TaC powder and TiC powder are added and mixed to obtain FeCoNiCrMn / C / TaC / TiC powder, namely, HECex powder; and finally, the FeCoNiCrMn high-entropy alloy composite material (HEC) is obtained through spark plasma sintering.

Owner:SHANGHAI UNIV

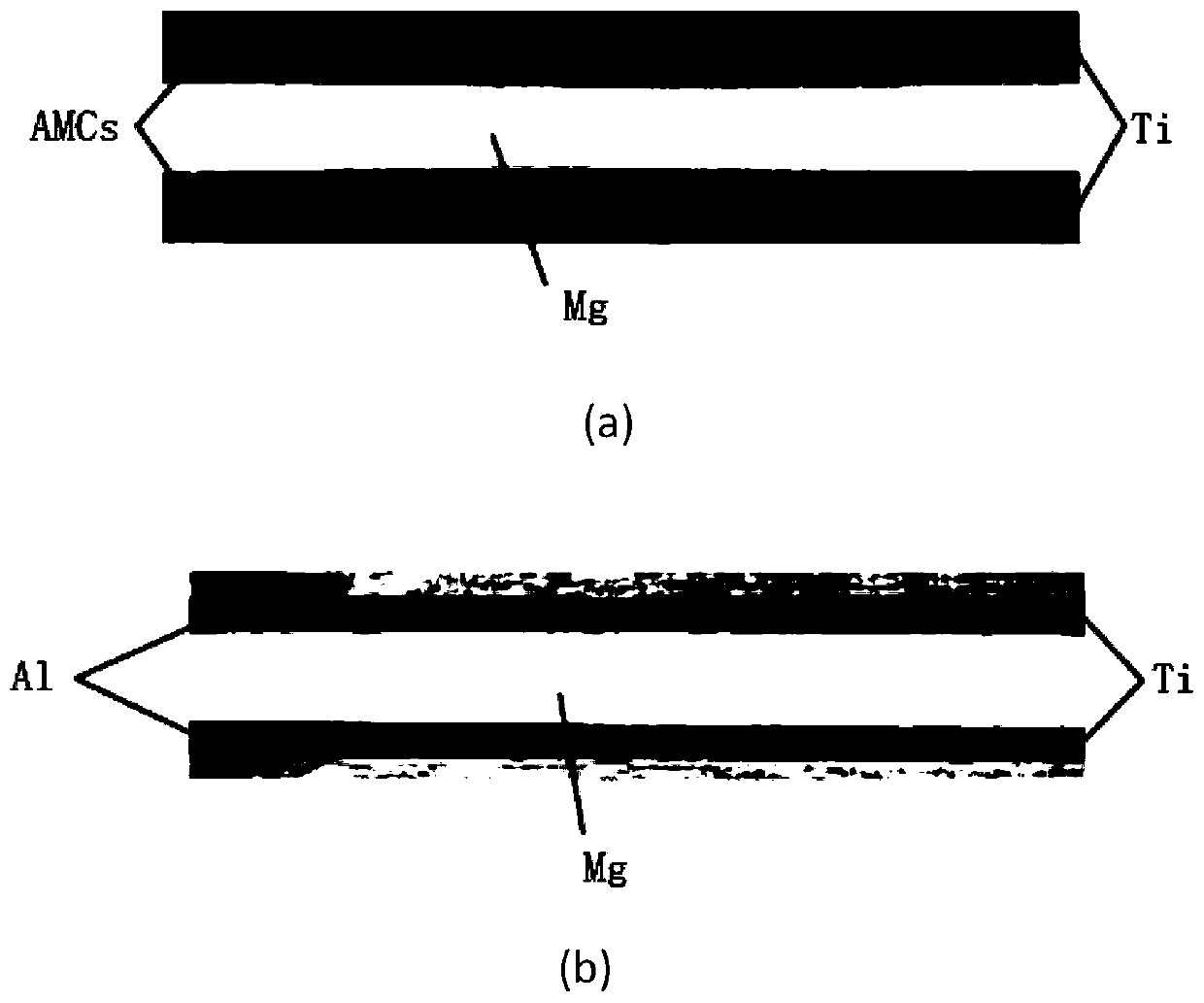

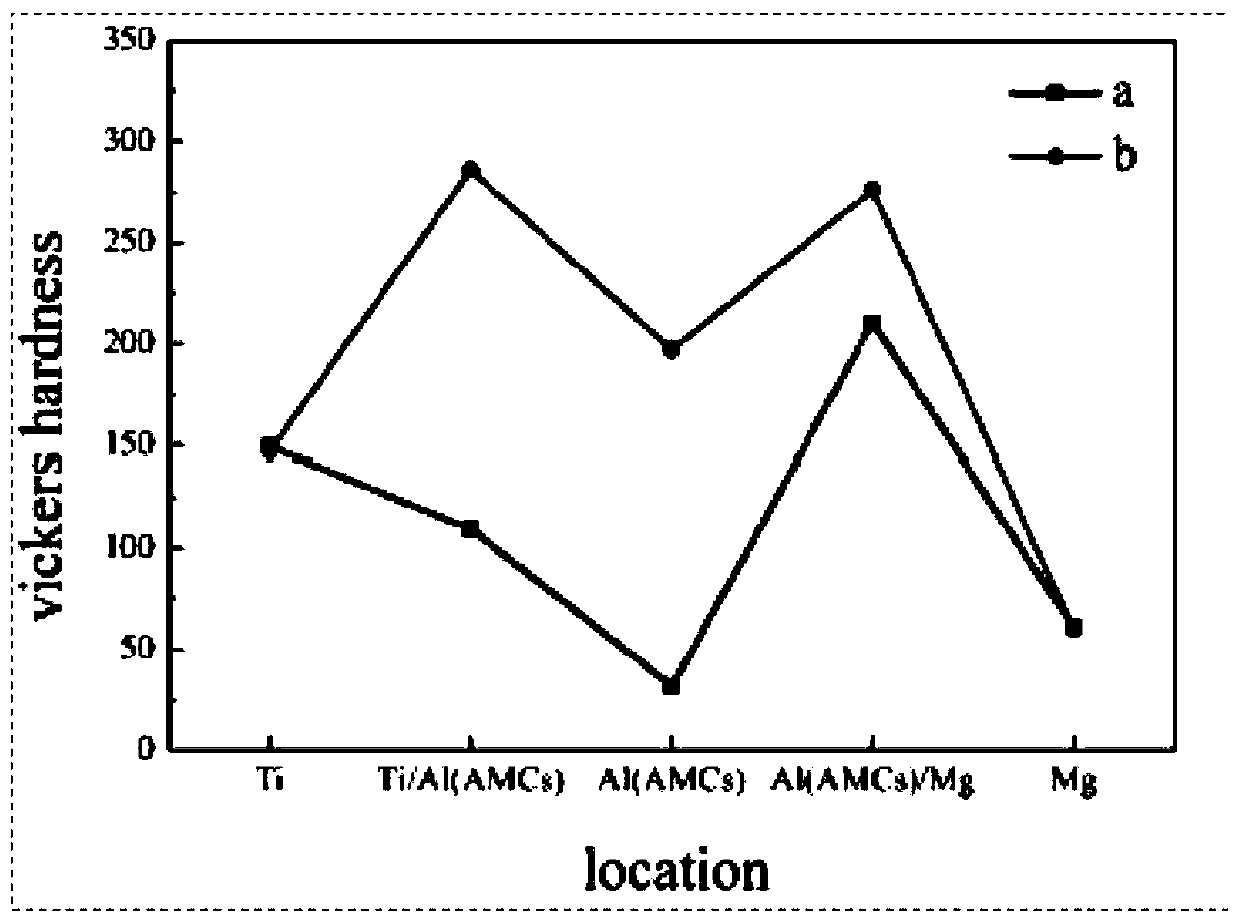

Method for improving performance of Mg/Ti connecting interface

ActiveCN110227734AImprove performanceGrain refinementLaminationLamination apparatusTitaniumToughness

The invention discloses a method for introducing a SiCp enhanced phase by designing a composite material intermediate layer so as to improve an Mg / Ti layer, and relates to a preparation method for improving "titanium / aluminum-based composite material / magnesium / aluminum-based composite material / titanium layer materials of the performance of an Mg / Ti interface. The method comprises the following steps that the SiCp reinforced aluminum-based composite material with uniformly distributed particles is prepared by adopting a semi-solid stirring casting method, hot rolling is performed to obtain an aluminum-based composite material component plate, hot rolling is performed on the aluminum-based composite material component plate by using titanium aluminum-based composite material magnesium aluminum-based composite material, and hot pressing and annealing are performed on laminated plates which are stacked in sequence. The method is simple in process, low in cost and stable and controllable inplate quality; and on one hand, a dispersion strengthening effect and a fine grain strengthening effect are generated on the metal of the component layer, so that the deformation between titanium andaluminum is more harmonious, and on the other hand, the strength and toughness of the interface area are improved, and the comprehensive performance of a composite board is remarkably improved.

Owner:TAIYUAN UNIV OF TECH

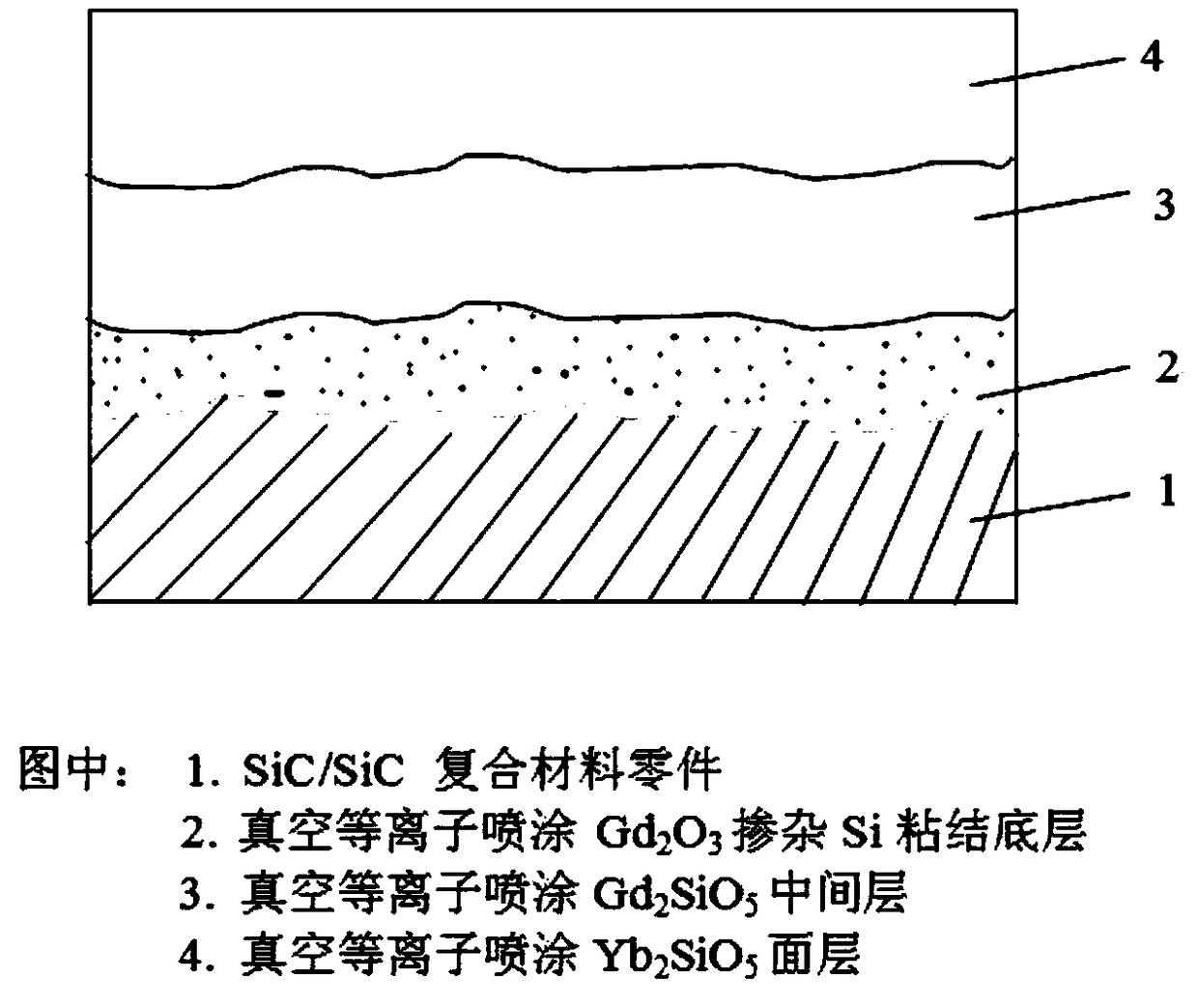

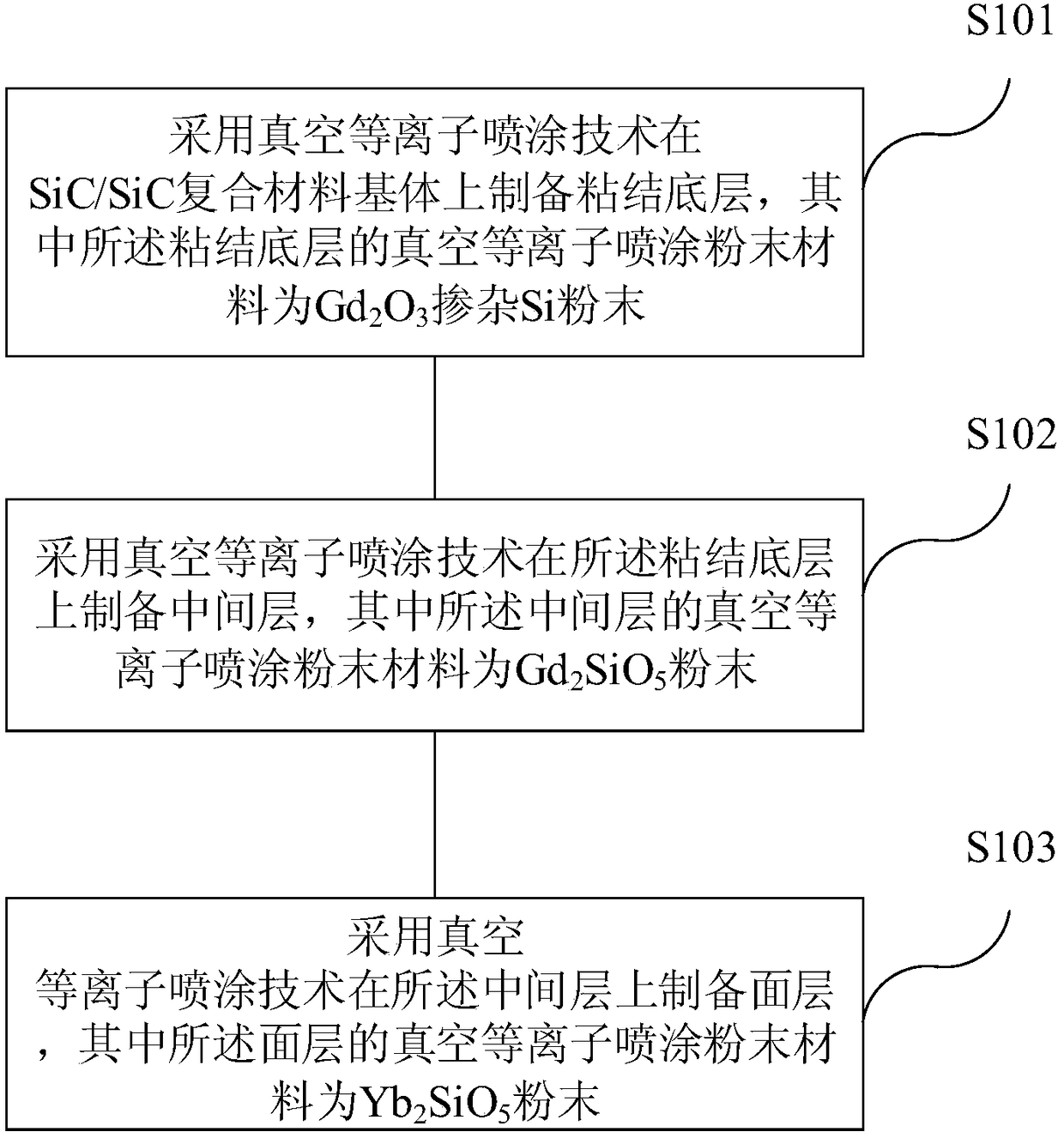

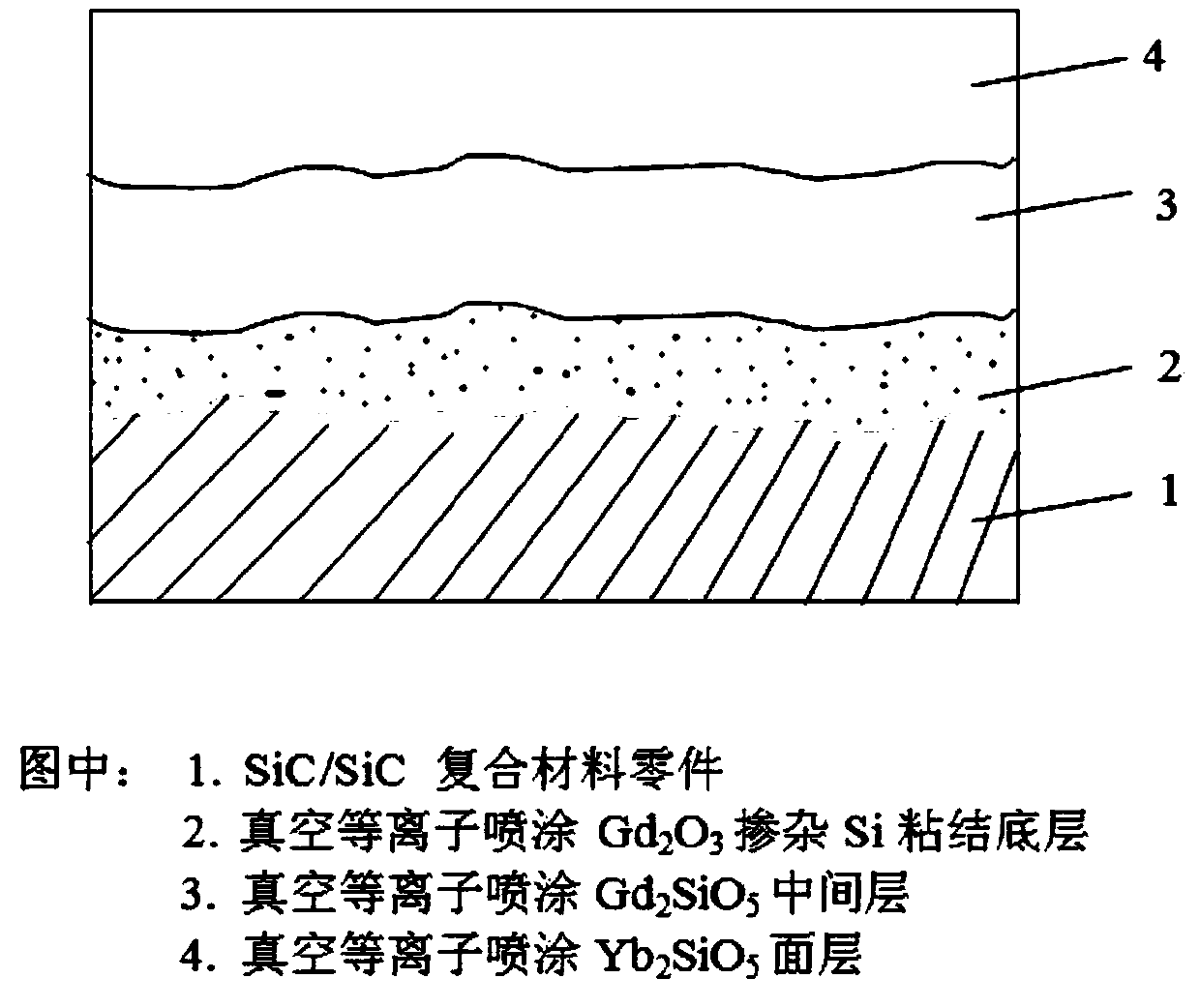

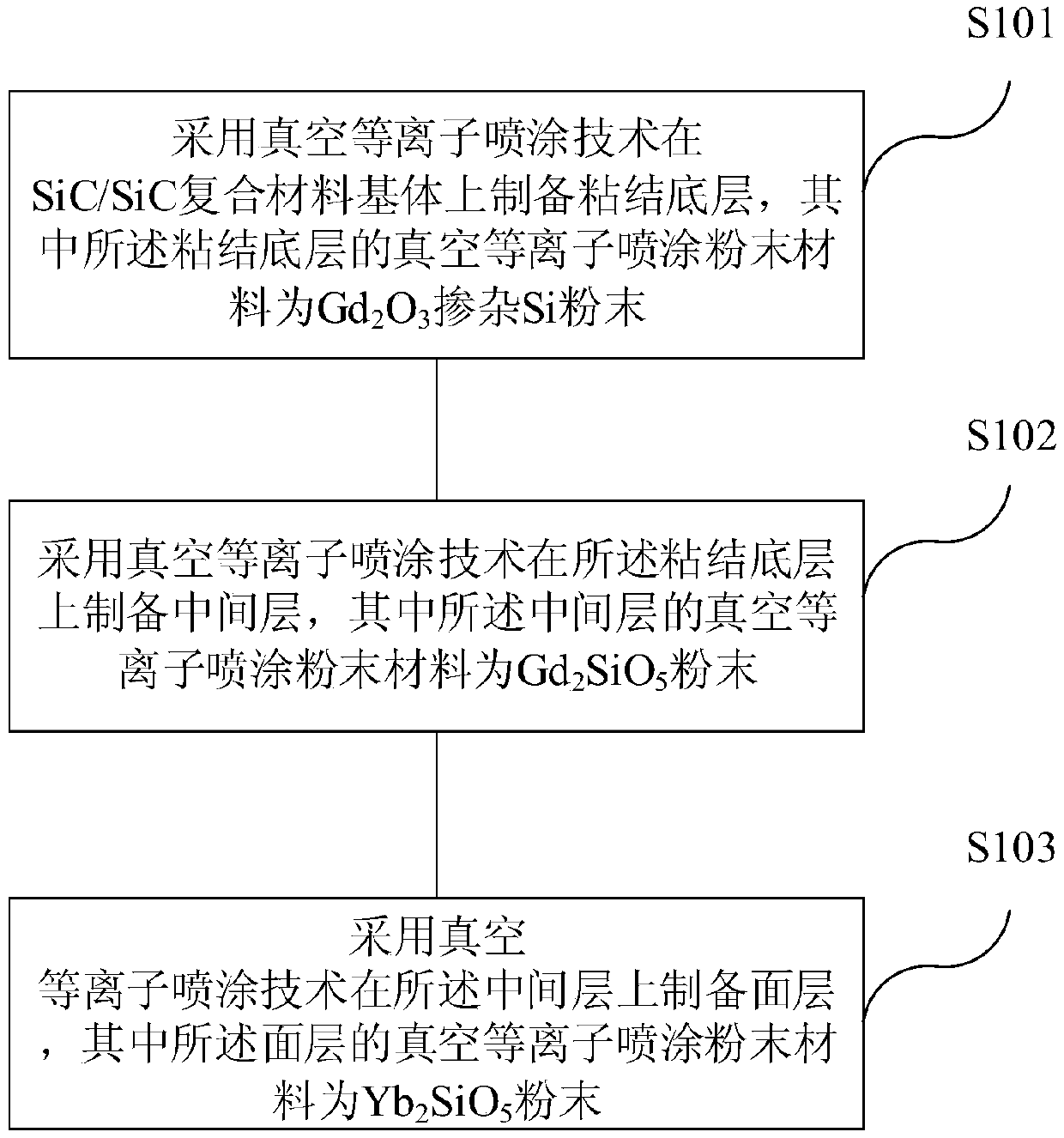

High-temperature environment barrier coating layer structure and preparation method thereof

ActiveCN108950463AExtend working lifeImprove use reliabilityMolten spray coatingSurface layerDecomposition

The invention provides a high-temperature environment barrier coating layer structure and a preparation method thereof. The structure comprises a Gd2O3 doped Si bonding bottom layer, a Gd2SiO5 middlelayer and a Yb2SiO5 surface layer laminated on the surface of a SiC / SiC composite material basal body in sequence. An environment barrier coating layer is of a three-layer structure of vacuum plasma spraying gadolinium oxide doped Si bonding bottom layer+vacuum plasma spraying gadolinium silicate middle layer+vacuum plasma spraying ytterbium silicate surface layer. A Gd2SiO5 coating layer and a Yb2SiO5 coating layer are prepared by adopting a vacuum plasma spraying process; components of the coating layers are maintained well; the material component loss and the silicate decomposition are hardly generated; the phase composition is stable; and the thermal shock resistance of the coating layers is excellent. The physical performance matchability of all the layers is excellent to effectivelyrelieve the thermal stress of the coating layers; the working temperature can reach 1400 DEG C; and the thermal shock resistance, the thermal circulation resistance and the service life of the environment barrier coating layer are greatly improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Low-voltage apparatus electrical contact material and preparation method thereof

InactiveCN103700518AReduce focused ablationDiffusion strengtheningContactsLow voltageHeat conducting

The invention discloses a low-voltage apparatus electrical contact material and a preparation method thereof. The preparation method is characterized in that nano-diamond and an aqueous solution of Ce3<+> cerium salt are uniformly mixed into a precursor by ultrasonic wave; the precursor is dried for 4h at the temperature of 90-100 DEC G, is loaded in a porcelain crucible, and is roasted for 1-2h under the temperature of 600-850 DEG C in a vacuum sintering furnace; a roasted product is smashed by a ball mill or a jet mill; after a wetting agent is added into and mixed with the smashed product, the mixed product and copper tungsten alloy powder are added into and uniformly mixed in a three-dimensional blender mixer in proportion; the mixed product is added into a mold for hot press molding and is sintered for 1.5-4h in the vacuum sintering furnace with the temperature of 1000 DEG C. The low-voltage apparatus electrical contact material has the advantages that the electrical contact material contains the nano-diamond, the dispersion strengthening function is realized, and the super-strong hardness and the wear-resisting property are realized; the diamond is super-strong in heat-conducting property, the surface temperature can be reduced, and the fusion welding and the electric ablation are resisted; the diamond is covered by cerium oxide, the electron work function is lower, the movement of an electric arc is dispersed, and the concentrated ablation on the contact material by the electric arc is reduced; the cost is greatly reduced as copper replaces silver.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

3D printed cobalt-chromium alloy for dental porcelain repair and preparation method thereof

ActiveCN112159907AHigh bonding strengthHigh sphericityAdditive manufacturing apparatusArtificial teethStress relief3d printed

The invention provides a 3D printed cobalt-chromium alloy for dental porcelain repair and a preparation method thereof, and belongs to the field of dental porcelain repair. A Ta element is added, so that the thermal expansion coefficient is reduced, the metal ceramic bonding strength is improved, the surface active energy is reduced, solid solution strengthening is caused, and the strength is improved; the content of a Cr element is increased, the content of a Co element is reduced, the content of a hcp phase is increased, metal and ceramic bonding is facilitated, after the content of the Co element is reduced, combination of Cr-W, Cr-Mo, Cr-Si and W-Mo is improved, and the strength of the alloy is improved; vacuum stress relief annealing is adopted, and residual stress is completely eliminated, so that microstructure phase change caused by the residual stress in the service process of a cobalt-chromium restoration is avoided, and micro-cracks are prevented from being formed on a metal-ceramic bonding interface; and solid solution and aging are adopted, the composition of a cobalt-chromium alloy phase and precipitation of a second phase are adjusted, so that the alloy has good mechanical properties, meanwhile, the hcp phase is further improved, and the metal-ceramic bonding strength is improved.

Owner:CHENGDU KENINGDA MATERIALS

Method for enhancing service life of cold-stamping mould of automobile by composite coating

The invention provides a method for enhancing the service life of a cold-stamping mould of an automobile by a composite coating. The method is characterized by comprising the following steps: firstly,carrying out polishing treatment on the surface of a cast iron mould; afterwards, precipitating the composite coating on the surface of the cast iron mould by chemical reduction, wherein a basal bodyof the composite coating is Ni-p alloy, 5-20% of spherical particle with nano level size is evenly distributed in an alloy layer, and the spherical particle is nano level artificial diamond or fullerene granules; and then, carrying out polishing treatment on the surface of the cast iron mould. The invention adopts the flexible grinding and polishing of the surface of the mould until a mirror faceis smooth, so that the service life of the mould can be enhanced, the smoothness degree of a stamping workpiece is enhanced, and the napping phenomenon of the surface of the workpiece is reduced. Thecomposite coating is precipitated by chemical reduction, the wear resistance of the mould is increased, the stamping frequency of the cast iron mould reaches 8-10 ten thousand times, and the phenomena of tension fracture, napping and scratch formed on the surface of the stamping workpiece are avoided.

Owner:湖北吉隆表面工程有限公司

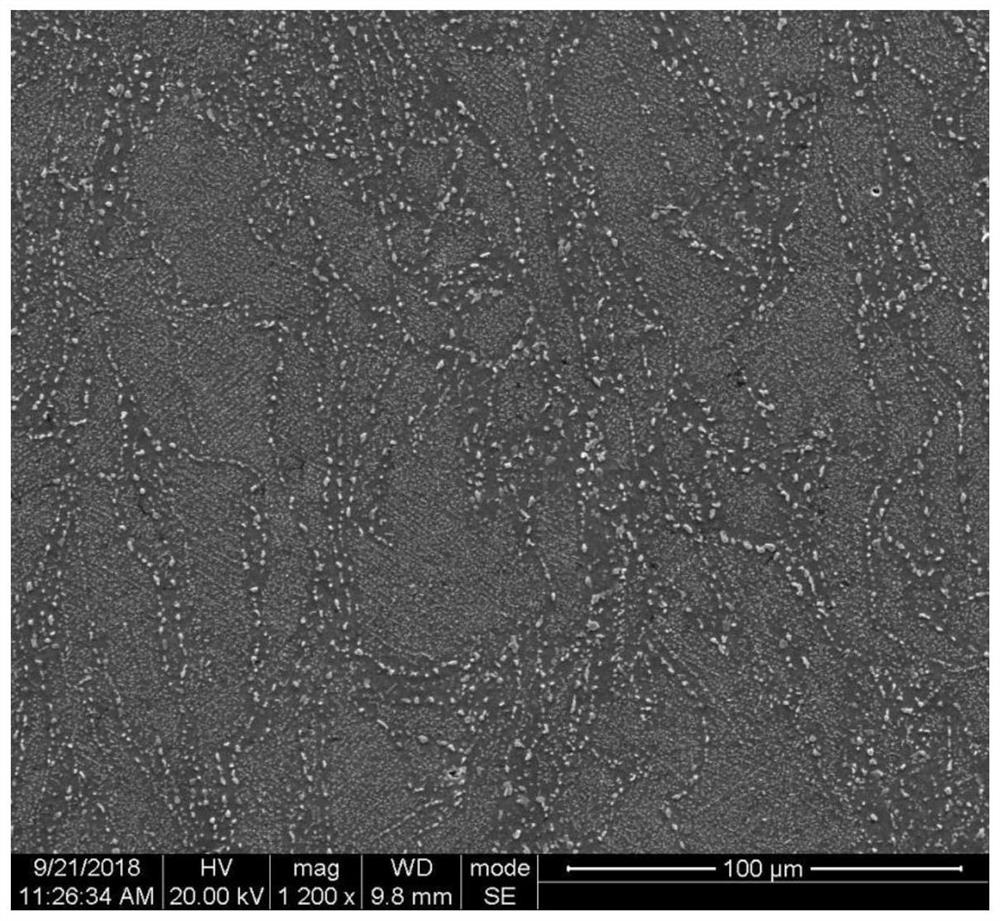

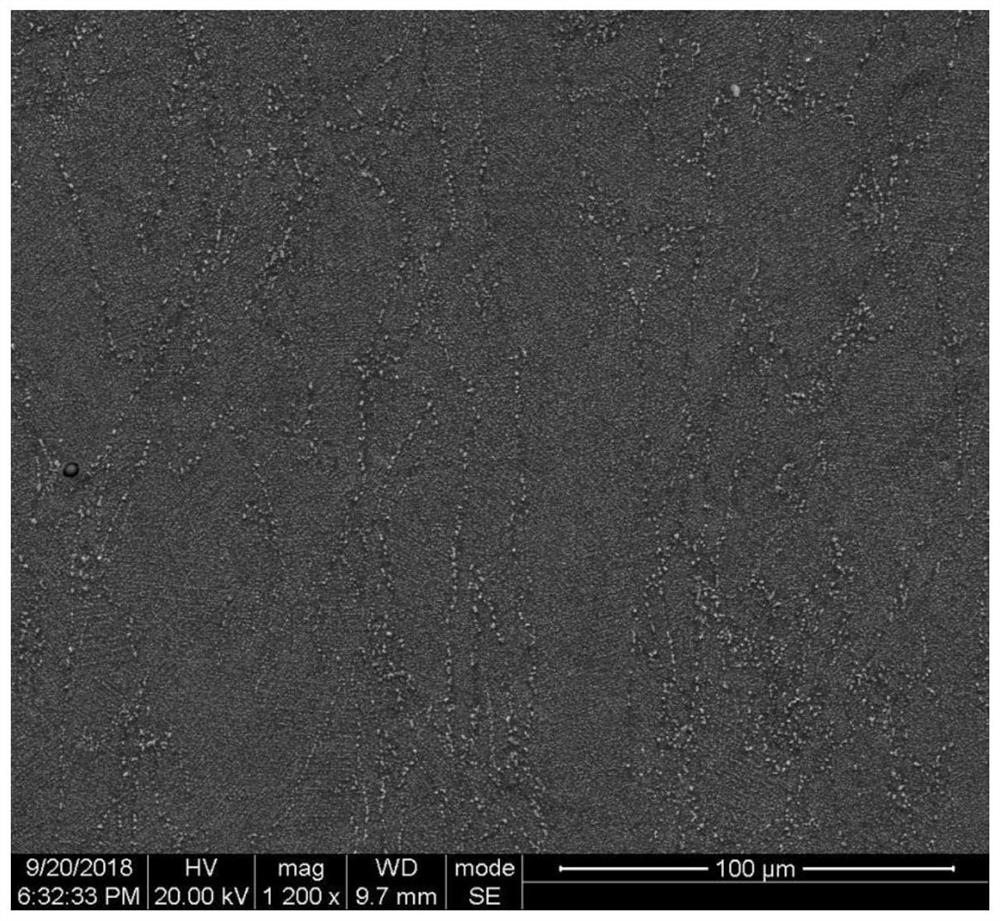

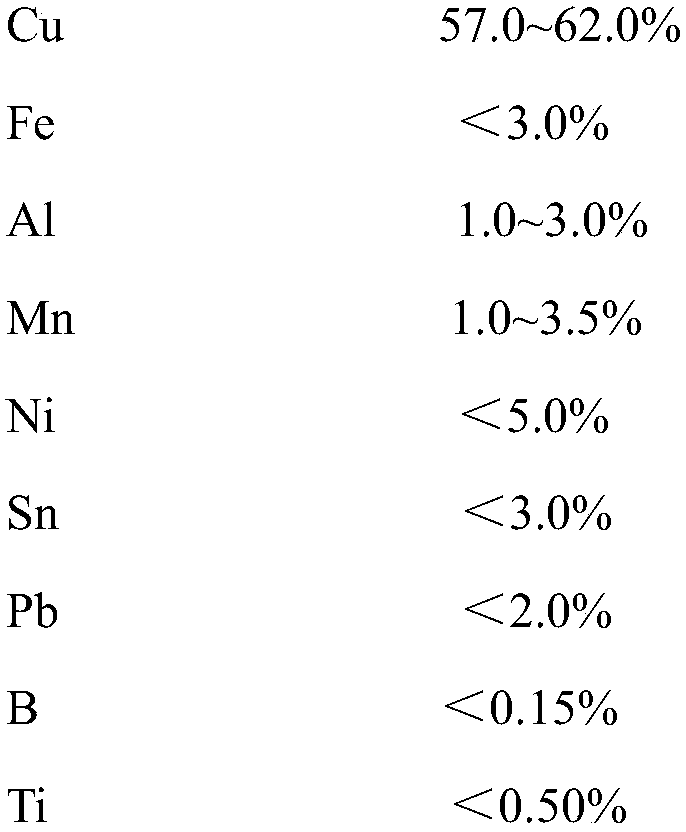

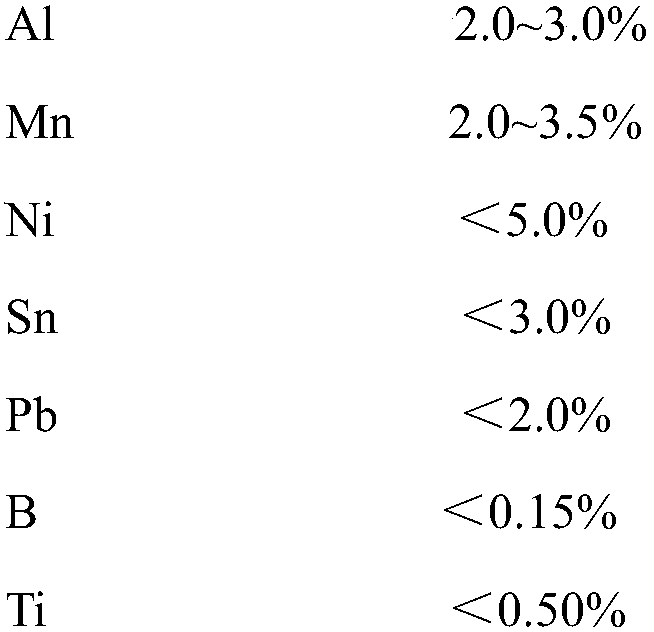

Complex copper alloy material and manufacturing method thereof

With the development of social economy, technological innovation is changing with each passing day, and performance requirements of oil-free bearings are getting higher and higher. The present invention provides a copper alloy material with high strength, wear resistance and corrosion resistance and a manufacturing method thereof. The chemical composition of the copper alloy material of the present invention includes: 57.0-62.0% of Cu, less than 3.0% of Fe, 1.0-3.0% of Al, 1.0-3.5% of Mn, less than 5.0% of Ni, less than 3.0% of Sn, less than 2.0% of Pb, less than 0.15% of B and less than 0.50%of Ti, with the balance being Zn. The manufacturing method includes compounding, melting, gas removing refining, modification, horizontal continuous casting, performance testing and machining. A production process is simple and components are easily controlled. Production through horizontal continuous casting or centrifugal casting is performed so that large-scale production can be achieved easily and social and economic benefit is good.

Owner:重庆聚洋无油轴承有限公司

Seawater-erosion-resistant machining copper alloy and preparation method thereof

The invention relates to the fields of oceanographic engineering and offshore equipment, and particularly discloses seawater-erosion-resistant machining copper alloy and a preparation method thereof. The copper alloy is composed of, by mass, 0.5-5% of nickel, 2-5% of aluminum, 1-2.5% of magnesium, 0.05-0.15% of phosphorus, 0.15-0.85% of chromium, 0.01-0.02% of tin and the balance copper. During preparation, a medium-frequency iron-core-free induction furnace is adopted, roasting and preheating are conducted to make raw materials be in dark red, and a furnace pipe is formed; the temperature is increased; electrolytic copper, a covering agent, pure chromium, electrolytic nickel, electrolytic aluminum, pure magnesium, pure tin, a covering agent and alloy CuP are sequentially added; stirring and slag salvage are conducted, the temperature is increased, and alloy is discharged out of the furnace and smelted in the atmospheric environment; and annealing is conducted. The preparation method is low in cost and high in product hardness, and the prepared copper alloy has the properties such as seawater-high-flow-rate-erosion resistance and erosion corrosion resistance, and can be used as a structural material, making contact with seawater, such as propellers of oceanographic engineering, pipes for oceanographic engineering pipelines and valve bodies.

Owner:HENAN UNIV OF SCI & TECH

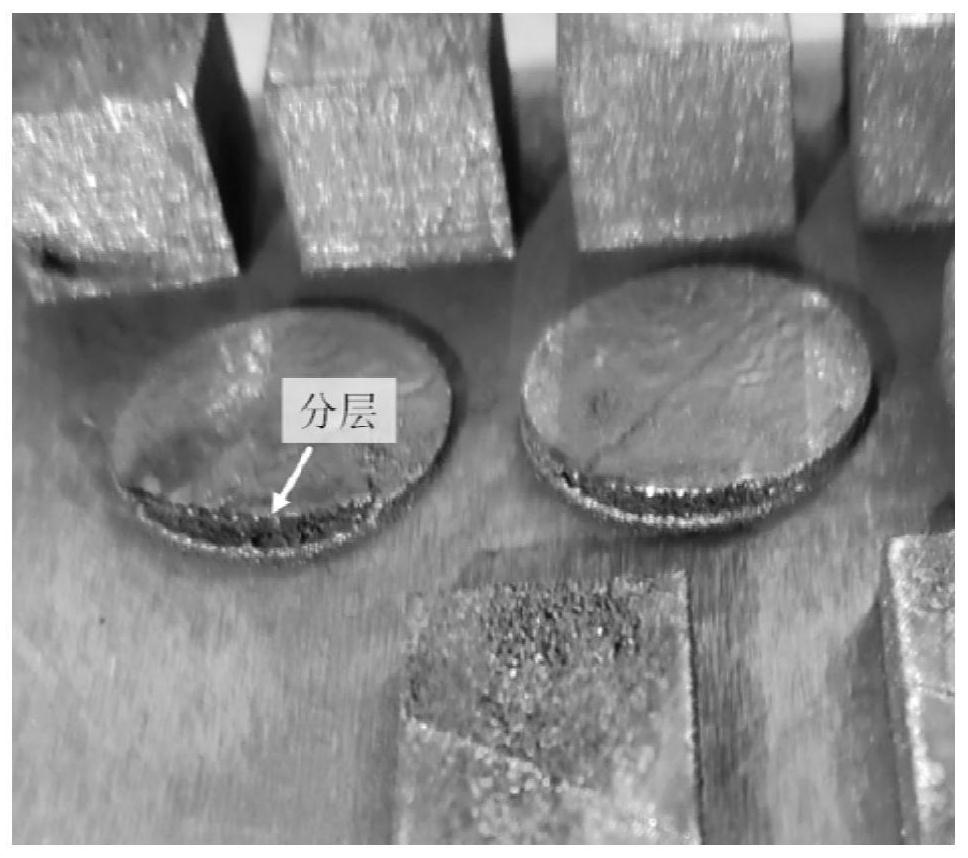

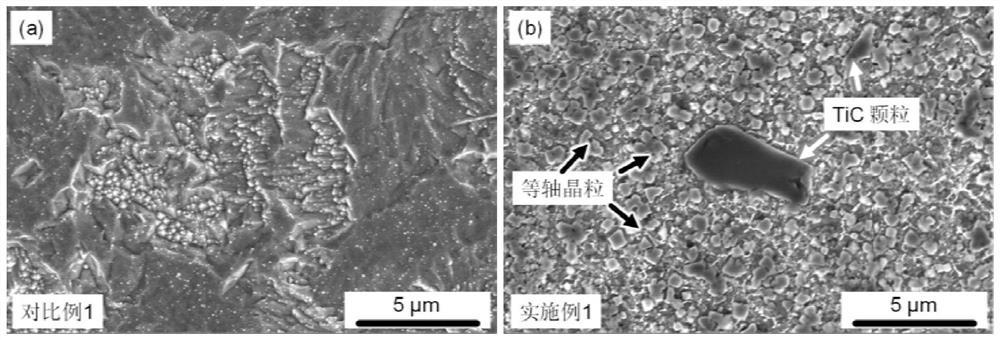

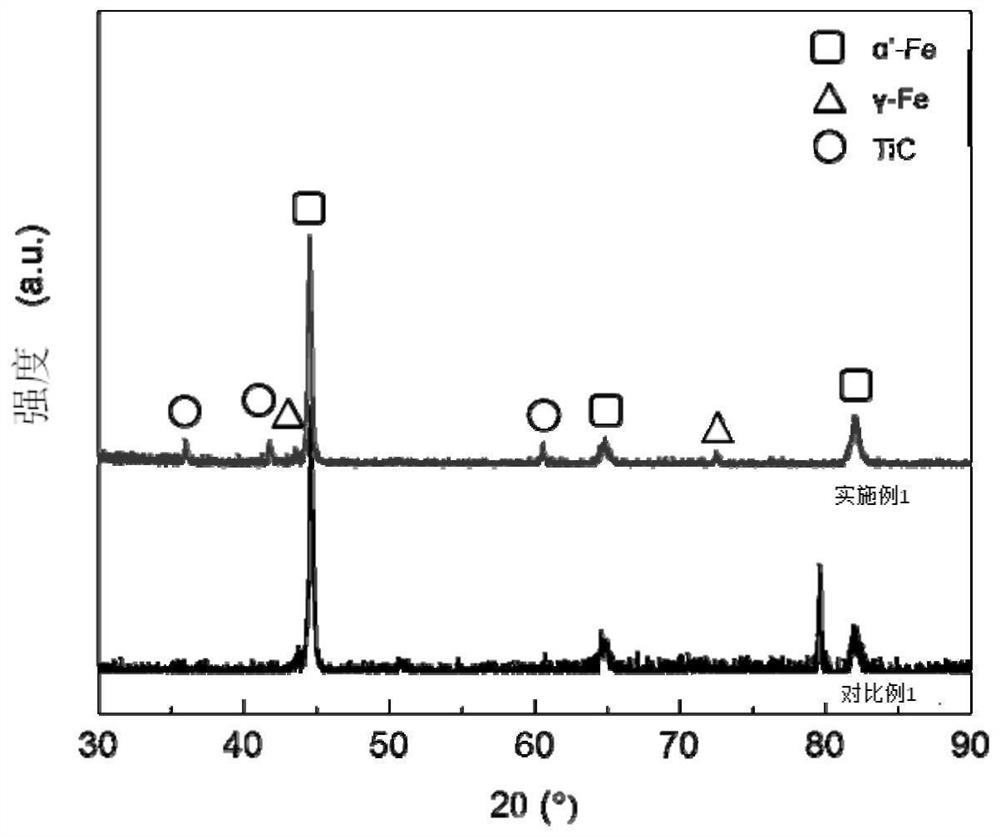

Iron-based ceramic composite material and preparation method and application thereof

InactiveCN113584382AGuaranteed toughnessGuaranteed toughness of prepared compositesAdditive manufacturing apparatusIncreasing energy efficiencyCeramic compositeMetallic materials

The invention discloses an iron-based ceramic composite material and a preparation method and application thereof, and belongs to the technical field of metal materials. The iron-based ceramic composite material comprises the following components in percentage by weight: less than or equal to 0.05% of C, 10.00%-25.00% of Cr, 7.00%-12.00% of Ni, 0.50%-3.00% of Mo, 0.80%-3.20% of Al, less than or equal to 0.60% of Mn, less than or equal to 1.00% of Si, 5.00%-15.00% of TiC, and the balance of Fe. The iron-based ceramic composite material prepared from the components has good strength, hardness and wear resistance, and has a good application prospect.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of silver base electric contact material and preparation method thereof

The invention relates to a silver-based electrical contact material and a preparation method thereof. The silver-based electrical contact material is characterized in that the material is formed by diamond-cerium oxide nuclear shell compound particles and silver. And the material is prepared by using the method comprising the following steps that: the diamond-cerium oxide nuclear shell compound particles and the silver are added into a blender mixer based on a proportion; a wetting agent is added and mixing is carried out for an uniform effect, and granulation is carried out by using a granulating machine; and a mixed material after the granulation is added into a die to carry out thermo-compression formation and nitrogen or argon filling is carried out in a vacuum sintering furnace under the temperature of 800 to 950 DEG C to protect sintering for 1 to 4 hours. According to the invention, the advantages are as follows: on the basis of granulation, particles with largely different densities are mixed uniformly; and each small particle has the identical components. The diamond-cerium oxide particles after the granulation are distributed uniformly in the electrical contact, so that the molded electrical contact material components are distributed uniformly; and thus the surface temperature is effectively reduced and the fusion welding and electrical ablation can be prevented.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Ultralow-carbon low-cobalt martensitic steel and preparation method thereof

PendingCN114480943AHigh strengthGrain refinementTransportation and packagingMetal-working apparatusSolvent debindingHeat treating

The preparation method comprises the following steps that low-cobalt martensitic steel stainless steel powder and a binder are subjected to mixing and granulation, feed is obtained, the feed is injected into a mold, an injection green body is obtained, solvent degreasing is conducted to obtain a dissolvable blank, warm isostatic pressing treatment is conducted to obtain a pressed green body, and the pressed green body is subjected to heat treatment to obtain the ultra-low-carbon low-cobalt martensitic steel with the ultra-low-carbon low-cobalt martensitic steel with the ultra-low-carbon low-cobalt martensitic steel. According to the preparation method, two times of degreasing are adopted, after the injection blank is obtained through injection molding, a solvent is adopted for degreasing to remove part of the binder, and then the ultra-low-carbon and low-cobalt martensitic steel is obtained through sintering in a vacuum environment, so that the ultra-low-carbon and low-cobalt martensitic steel is obtained. According to the ultra-low-carbon low-cobalt martensitic steel and the preparation method thereof, the low-carbon low-cobalt martensitic steel is subjected to temperature isostatic pressing treatment under the set technological parameter condition to obtain a green body, the inventor finds that the density of the green body can be greatly improved, and the ultra-low-carbon low-cobalt martensitic steel has high density, fine grains and excellent mechanical properties.

Owner:湖南英捷高科技有限责任公司

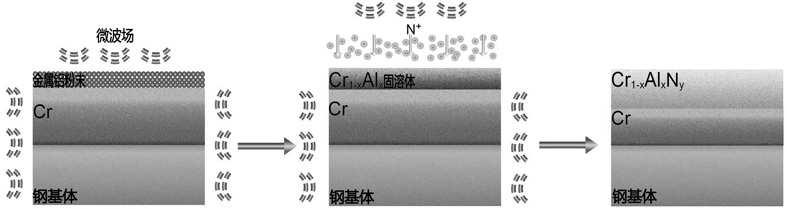

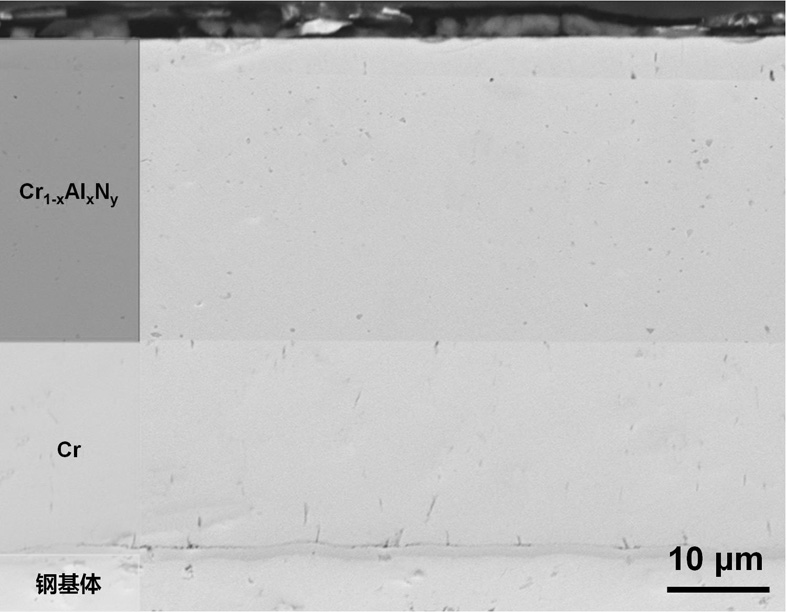

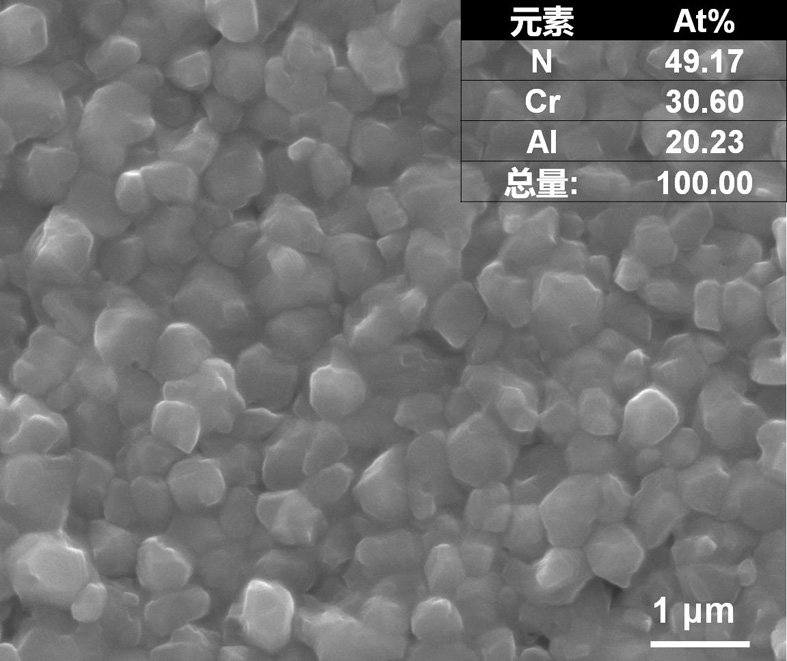

Ternary nitride coating prepared by microwave plasma chemical vapor deposition and method thereof

ActiveCN114686803AHigh hardnessImprove wear resistanceSolid state diffusion coatingPhysical chemistrySolid solution

The invention provides a ternary nitride coating prepared through microwave plasma chemical vapor deposition and a method, and belongs to the technical field of coating preparation. The invention discloses a ternary nitride coating for microwave plasma chemical vapor deposition. The molecular form of the ternary nitride coating is M < 1-x > DxNy. The invention discloses a method for preparing a ternary nitride coating through microwave plasma chemical vapor deposition. The method comprises the following steps: (1) cleaning and pretreating a substrate; (2) performing microwave plasma chemical vapor deposition for the first time to form a solid solution and / or an intermetallic compound on the surface of the metal matrix; and (3) performing microwave plasma chemical vapor deposition for the second time, and beginning to deposit the ternary nitride coating. Trace solid solutions or intermetallic compounds are evenly distributed in the ternary nitride coating, the effects of dispersion strengthening and coating performance enhancing are achieved, and the coating shows the better high-temperature service characteristic; the method provided by the invention has higher deposition efficiency, and a thicker ternary nitride coating can be obtained.

Owner:WUHAN UNIV OF TECH

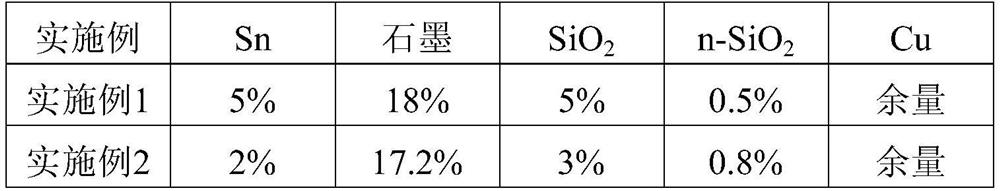

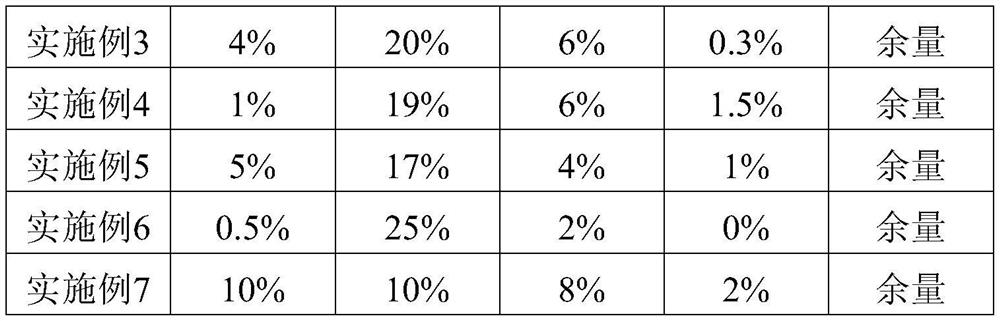

A kind of copper-based silicon dioxide composite material and preparation method thereof

ActiveCN109930021BImprove mechanical propertiesImprove wear resistanceOxide compositeMetallic materials

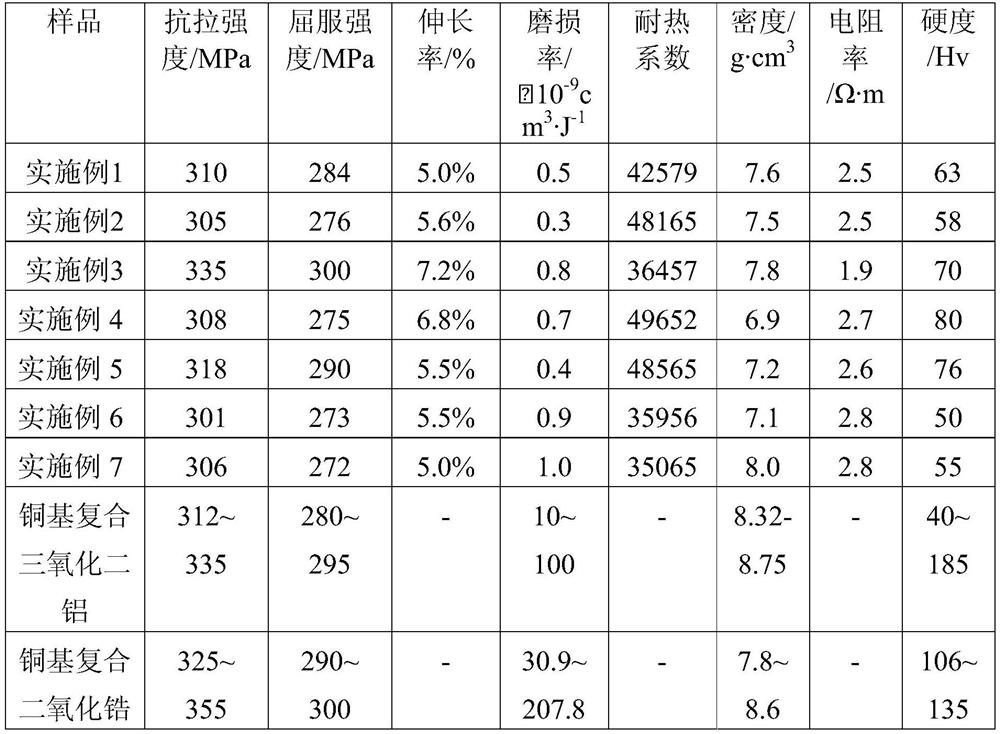

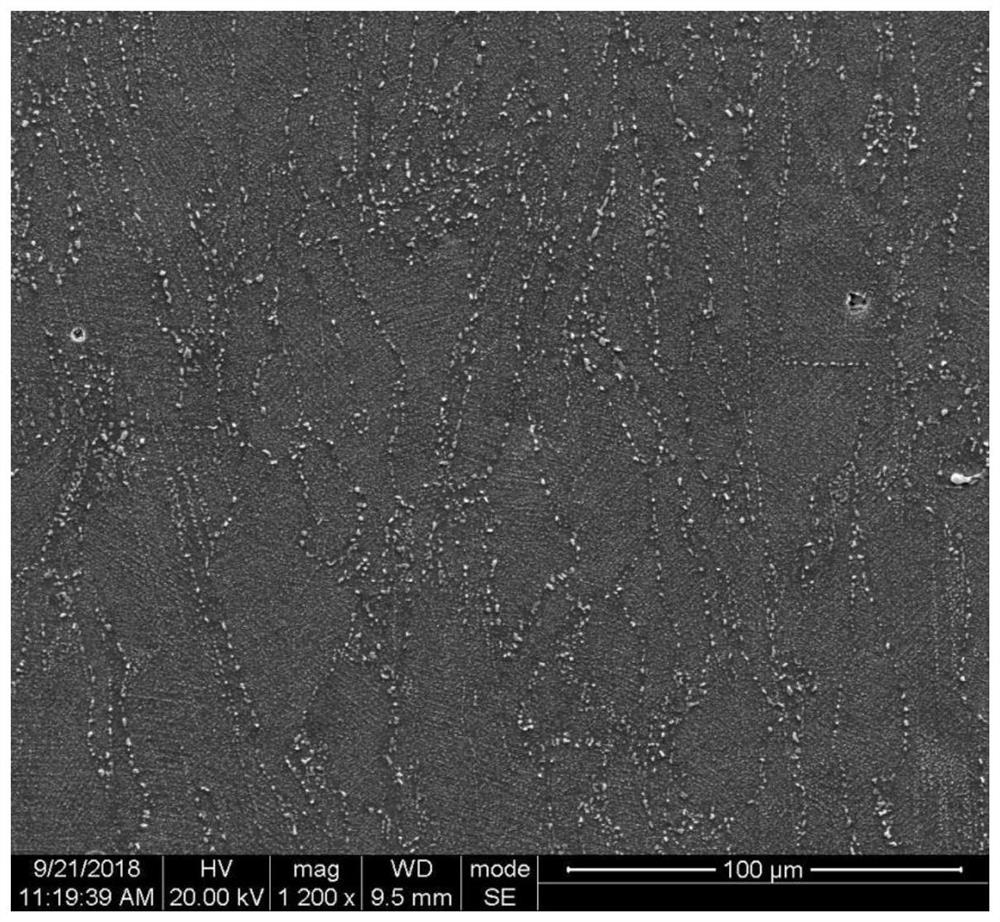

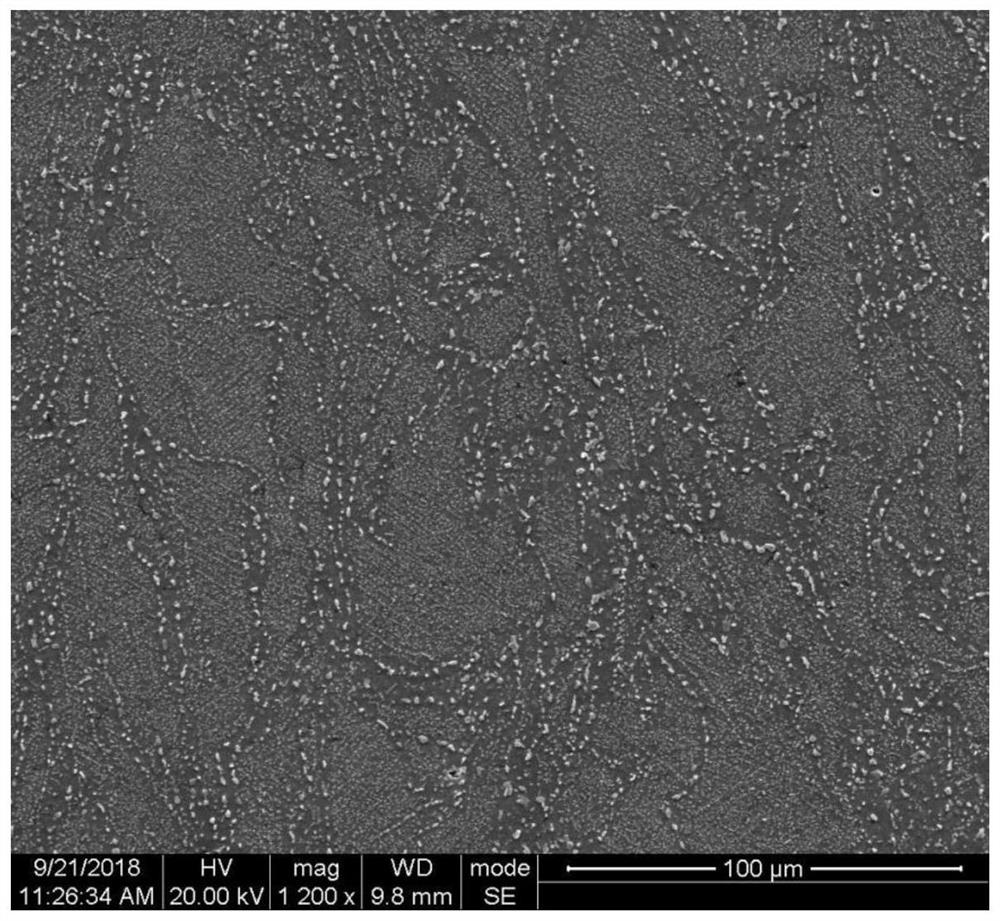

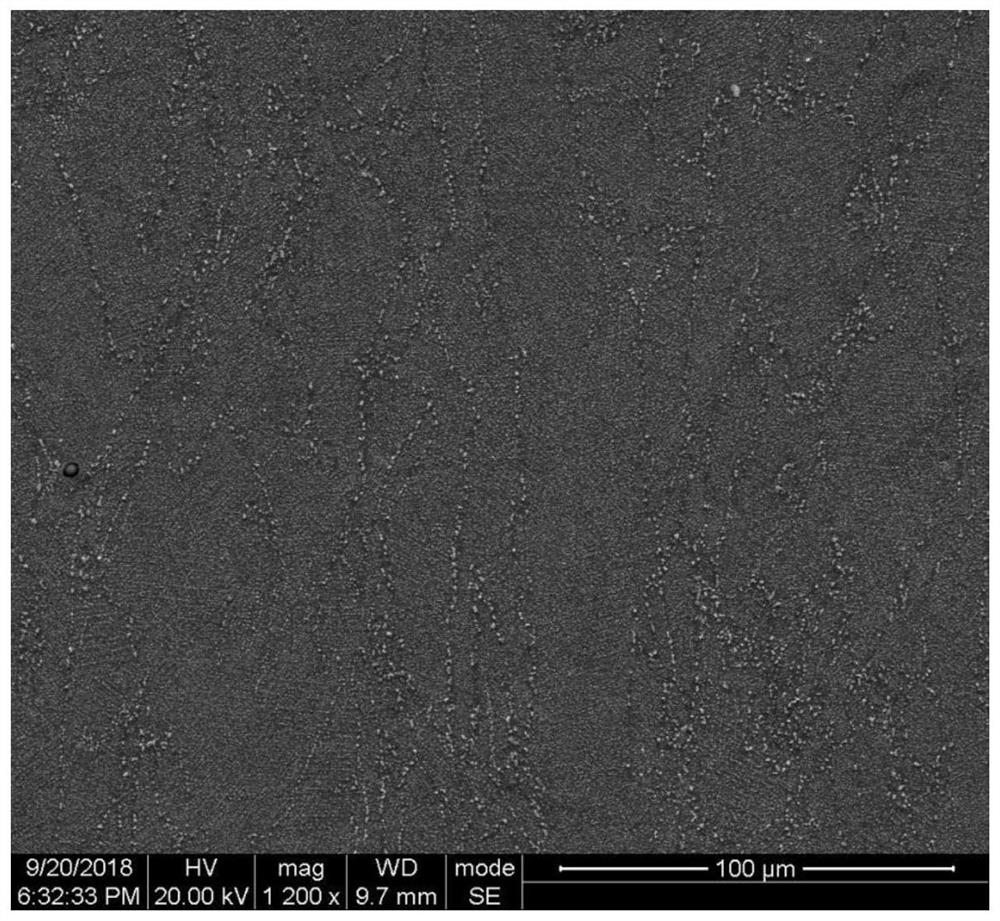

The invention relates to a copper-based silicon dioxide composite material and a preparation method thereof and belongs to the technical field of metal materials and preparation thereof. The compositematerial is prepared from the following components in percent by mass: 0.5-10% of tin, 10-25% of graphite, 2-8% of silicon dioxide, 0-2% of nano silicon dioxide and the balance copper. The preparation method comprises the following steps: proportioning; ball milling; mixing; cold pressure forming; pressurized sintering; and obtaining a product. The tensile strength of the copper-based composite material prepared by the preparation method is higher than 300 MPa, the yield strength is equivalent to that of a copper-based aluminum oxide composite material, the wear rate is smaller than 1*10<-9>cm<3> / J, the heat-resistant coefficient is higher than 35000, and the heat resistance and the wear resistance are better than those of the copper-based aluminum oxide composite material. A wear-resistant part prepared by the material can meet the demand of a product or equipment working normally for a long time in a relatively high temperature condition.

Owner:GRIMAT ENG INST CO LTD

A kind of 3D printing cobalt-chromium alloy for dental porcelain restoration and preparation method thereof

ActiveCN112159907BHigh strengthHigh melting pointAdditive manufacturing apparatusArtificial teethStress reliefCobalt chromium alloy

The invention provides a 3D printed cobalt-chromium alloy for dental porcelain restoration and a preparation method thereof, belonging to the field of dental porcelain restoration. The present invention adds Ta element, reduces thermal expansion coefficient, improves metal-ceramic bonding strength, reduces surface active energy, causes solid solution strengthening, improves strength; increases Cr element content, reduces Co element content, increases hcp phase content, is beneficial to metal-ceramic bonding, After the Co element is reduced, the combination of Cr-W, Cr-Mo, Cr-Si, W-Mo is improved, and the strength of the alloy is improved; the vacuum stress relief annealing is used to completely eliminate the residual stress, so that the cobalt-chromium restoration will not be used during service. The microstructure phase transformation will be caused by the residual stress, causing the formation of microcracks at the metal-ceramic bonding interface; solid solution and aging are used to adjust the phase composition of the cobalt-chromium alloy and the precipitation of the second phase, so that the alloy has good mechanical properties, and at the same time The hcp phase is further improved to improve the bonding strength of gold and porcelain.

Owner:CHENGDU KENINGDA MATERIALS

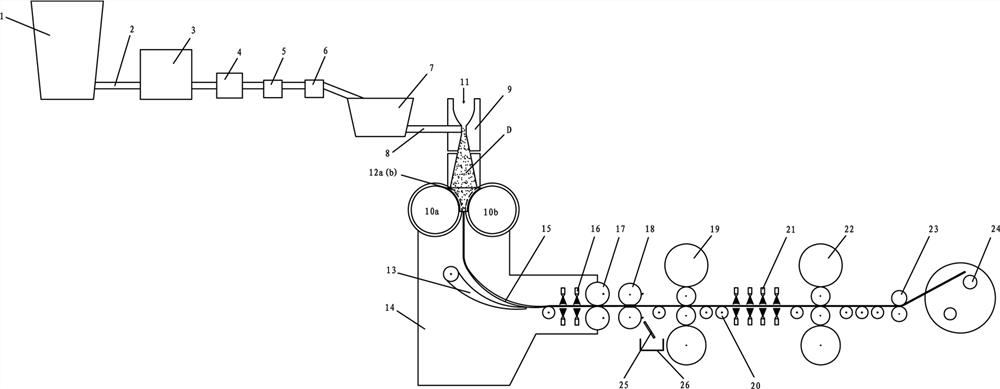

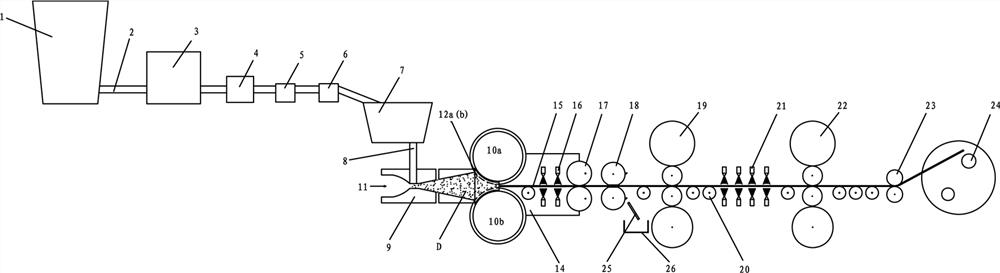

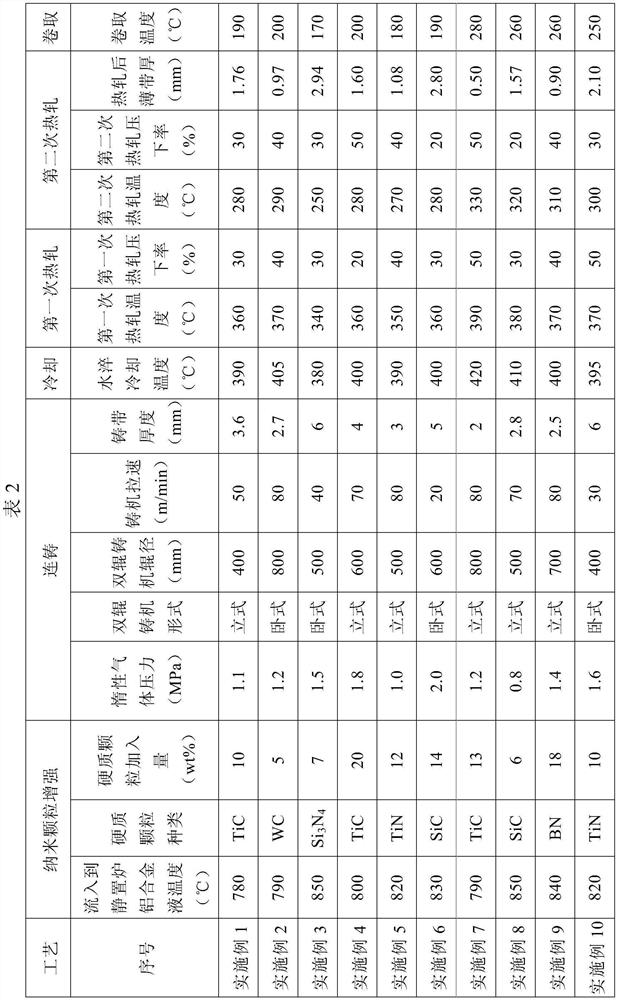

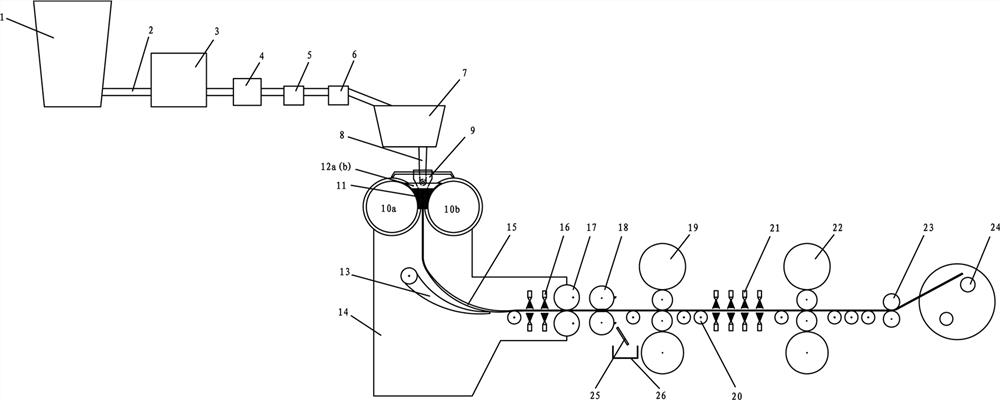

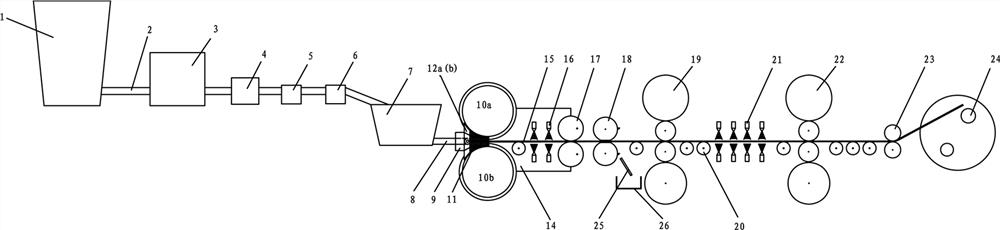

Preparation method of novel 7XXX aluminum alloy thin strip with high performance through jet casting and rolling

The invention relates to a preparation method of a novel 7XXX aluminum alloy thin strip with high performance by jet casting, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) spray deposition and continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip cast and rolled through the spray deposition combined double-roller thin strip cast rolling technology has the advantages that the strength is improved by 25% or above, and the ductility is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

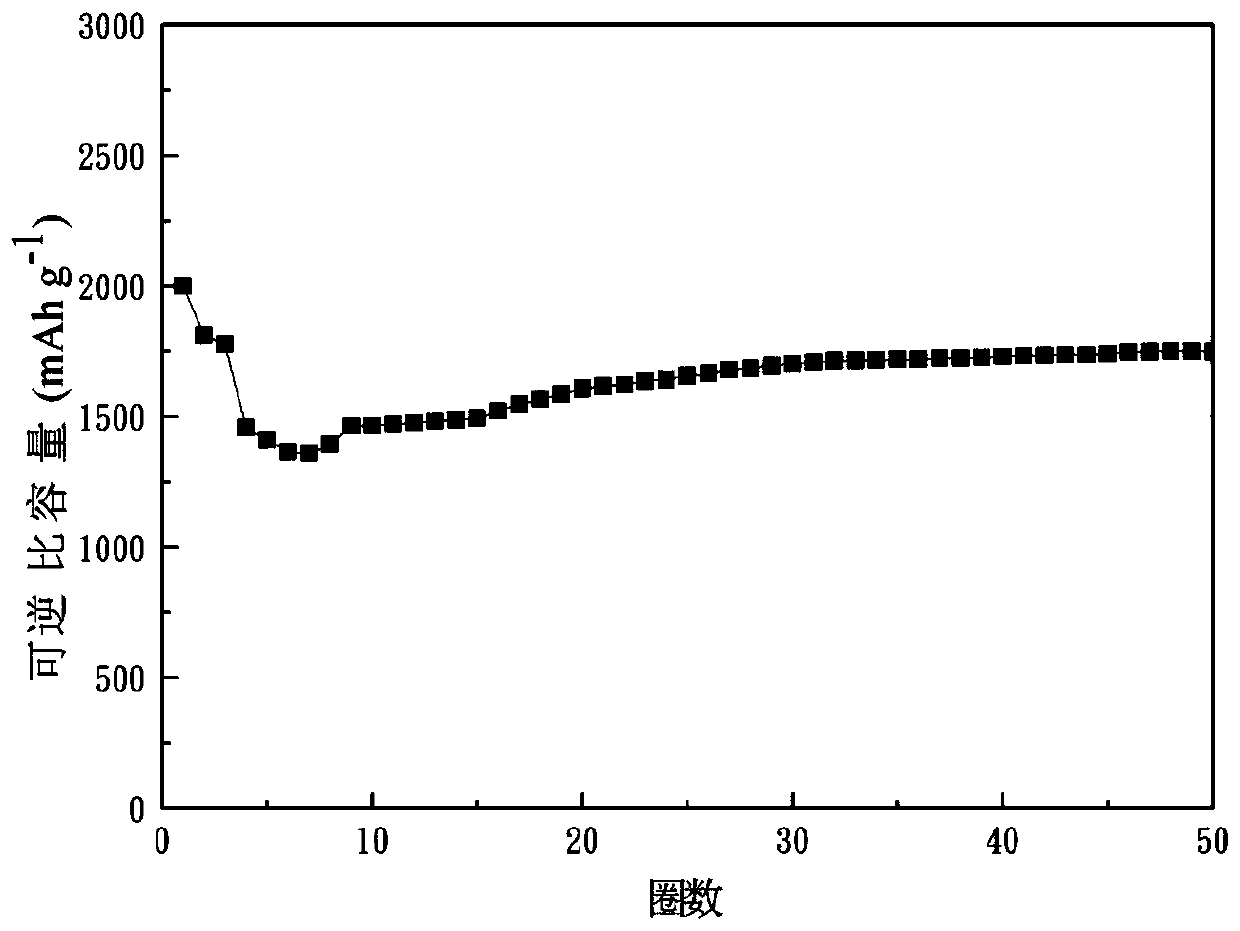

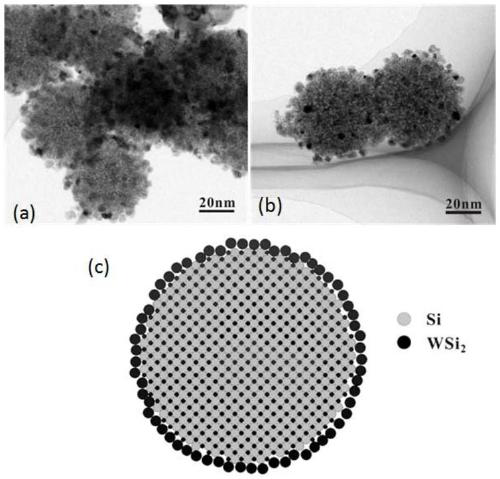

Dispersedly distributed metal silicide/nano-silicon composite material and preparation method thereof

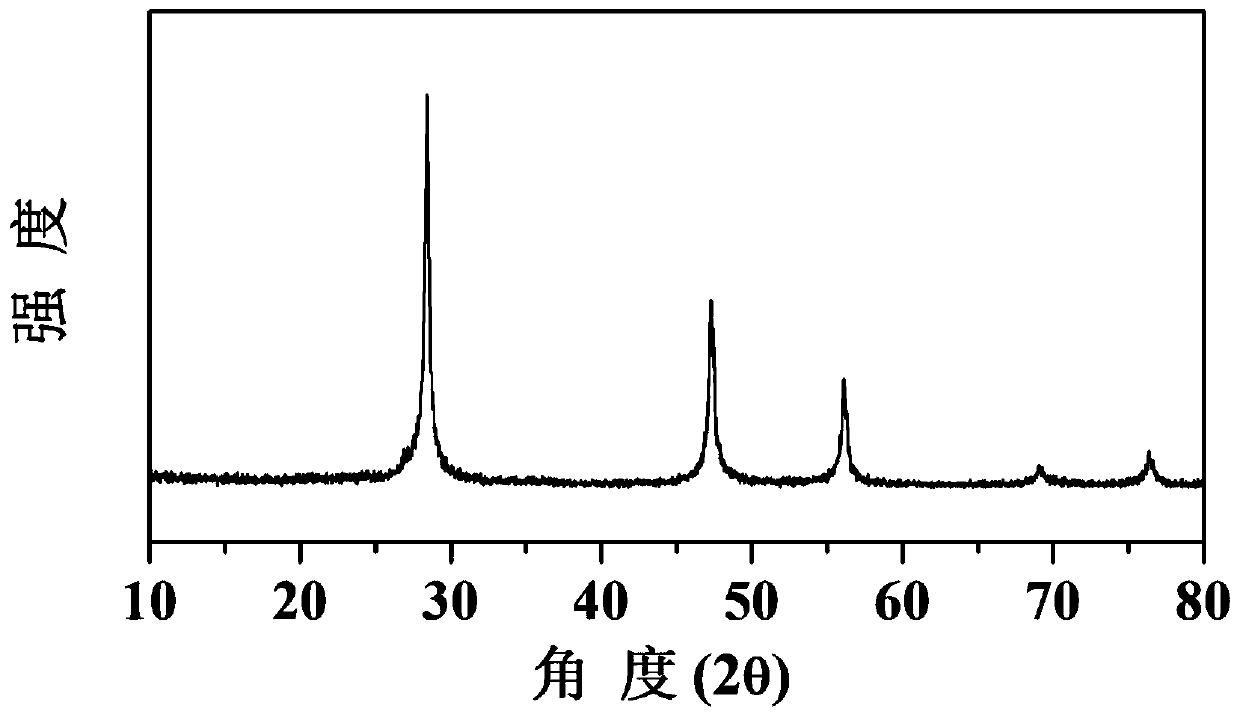

ActiveCN111082020ADiffusion strengtheningExcellent cycle performanceMaterial nanotechnologyCell electrodesNano siliconMetal silicide

The invention discloses a dispersedly distributed metal silicide / nano-silicon composite material and a preparation method thereof. The dispersedly distributed metal silicide / nano-silicon composite material is composed of metal silicide and nano-silicon particles, wherein part of the metal silicide is dispersedly distributed inside the nano-silicon, and the other part of the metal silicide coats the surfaces of the nano-silicon particles; and the mass percentage of the metal silicide in the composite material is 0.89%-16.45%, and the balance is silicon. According to the dispersedly distributedmetal silicide / nano-silicon composite material, specific metal silicide with a dispersion strengthening effect intervenes into the nano-silicon particles, is dispersedly distributed, and forms a metalsilicide coating layer on the surfaces of the nano-silicon particles. When the dispersedly distributed metal silicide / nano-silicon composite material is applied to a lithium ion battery negative electrode material, the cycle performance and the stability performance are far superior to those of an existing nano-silicon negative electrode material.

Owner:湖南宸宇富基新能源科技有限公司

Method for enhancing service life of cold-stamping mould of automobile by composite coating

Owner:湖北吉隆表面工程有限公司

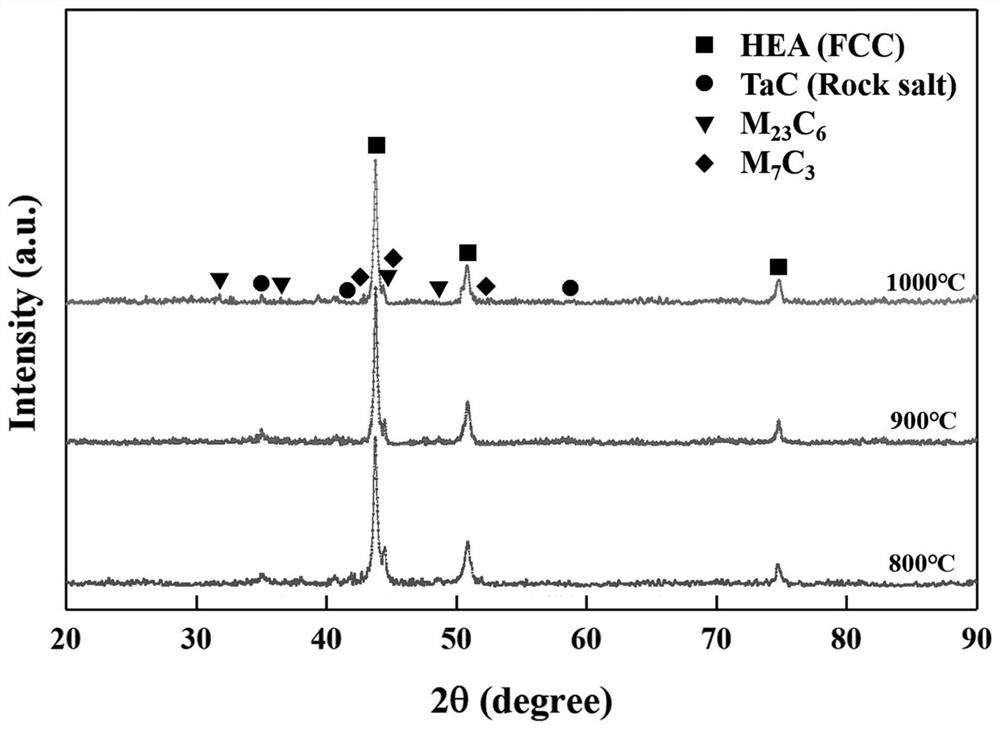

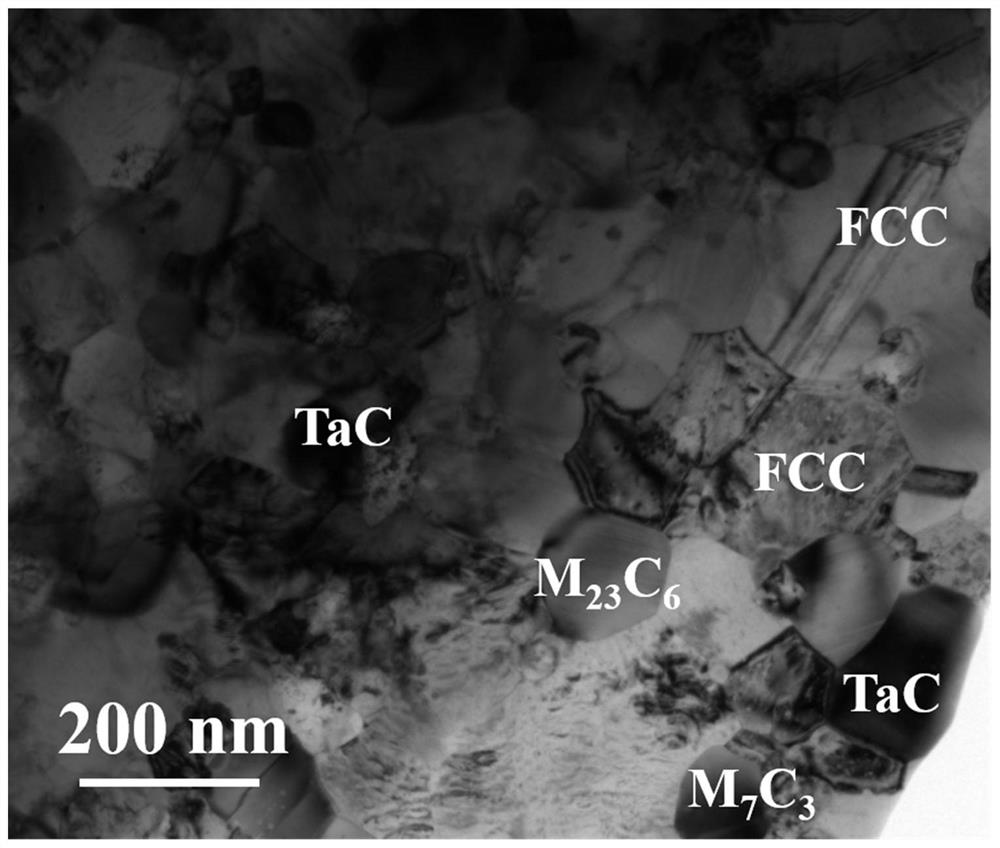

A kind of preparation method of carbide reinforced high entropy alloy composite material

ActiveCN113337746BAchieve preparationIt has the effect of precipitation strengtheningHigh entropy alloysHydrocotyle bowlesioides

This application relates to a scheme for preparing carbide-reinforced high-entropy alloy composites (HEC) by mechanical alloying (MA) and spark plasma sintering (SPS). The method for preparing high-entropy compounds from entropy alloys: (1) Introducing hydrocarbon additives into high-entropy alloys to form carbides through mechanical alloying reactions to prepare in-situ high-entropy alloy composites, referred to as HEC in ; (2) Adding carbide particles to high-entropy alloys to prepare ex-situ high-entropy alloy composites, referred to as HEC ex . This patent takes the preparation of FeCoNiCrMn high-entropy alloy composite material as a typical case to describe in detail. The preparation method is as follows: Fe, Co, Ni, Cr, Mn five metal powders and ball milling control agent C 7 h 16 Preparation of FeCoNiCrMn / C powder by mechanical alloying, i.e. HEC in powder. Then add TaC, TiC powder and mix to obtain FeCoNiCrMn / C / TaC / TiC powder, namely HEC ex powder. Finally, FeCoNiCrMn high-entropy alloy composite (HEC) was obtained by spark plasma sintering.

Owner:SHANGHAI UNIV

A high-temperature environment barrier coating structure and preparation method thereof

ActiveCN108950463BImprove thermal shock resistanceImprove physicsMolten spray coatingInter layerGadolinium oxide

The invention provides a high-temperature environment barrier coating layer structure and a preparation method thereof. The structure comprises a Gd2O3 doped Si bonding bottom layer, a Gd2SiO5 middlelayer and a Yb2SiO5 surface layer laminated on the surface of a SiC / SiC composite material basal body in sequence. An environment barrier coating layer is of a three-layer structure of vacuum plasma spraying gadolinium oxide doped Si bonding bottom layer+vacuum plasma spraying gadolinium silicate middle layer+vacuum plasma spraying ytterbium silicate surface layer. A Gd2SiO5 coating layer and a Yb2SiO5 coating layer are prepared by adopting a vacuum plasma spraying process; components of the coating layers are maintained well; the material component loss and the silicate decomposition are hardly generated; the phase composition is stable; and the thermal shock resistance of the coating layers is excellent. The physical performance matchability of all the layers is excellent to effectivelyrelieve the thermal stress of the coating layers; the working temperature can reach 1400 DEG C; and the thermal shock resistance, the thermal circulation resistance and the service life of the environment barrier coating layer are greatly improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Processed copper alloy for seawater erosion resistance and preparation method thereof

The invention relates to the fields of oceanographic engineering and offshore equipment, and particularly discloses seawater-erosion-resistant machining copper alloy and a preparation method thereof. The copper alloy is composed of, by mass, 0.5-5% of nickel, 2-5% of aluminum, 1-2.5% of magnesium, 0.05-0.15% of phosphorus, 0.15-0.85% of chromium, 0.01-0.02% of tin and the balance copper. During preparation, a medium-frequency iron-core-free induction furnace is adopted, roasting and preheating are conducted to make raw materials be in dark red, and a furnace pipe is formed; the temperature is increased; electrolytic copper, a covering agent, pure chromium, electrolytic nickel, electrolytic aluminum, pure magnesium, pure tin, a covering agent and alloy CuP are sequentially added; stirring and slag salvage are conducted, the temperature is increased, and alloy is discharged out of the furnace and smelted in the atmospheric environment; and annealing is conducted. The preparation method is low in cost and high in product hardness, and the prepared copper alloy has the properties such as seawater-high-flow-rate-erosion resistance and erosion corrosion resistance, and can be used as a structural material, making contact with seawater, such as propellers of oceanographic engineering, pipes for oceanographic engineering pipelines and valve bodies.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of a novel magnesium alloy composite material

Owner:CHANGZHOU UNIV +1

A kind of erosion-resistant copper alloy for marine working conditions and its preparation method

The invention relates to the field of ocean engineering, and particularly discloses an erosion-resistant copper alloy utilized in an ocean working condition and a preparation method thereof. The copper alloy comprises the following elements by mass percent: 7% to 10% of Ni, 5% to 10.5% of Al, 0.15% to 1% of Fe, 0.5% to 1.5% of Mn, 0.15% to 1% of Ti, 0.05% to 0.15% of P, 0.2% to 0.6% of Mg and 0.005% to 0.01% of B, and the balance being copper. The preparation method comprises the steps of sequentially adding electrolytic copper, a covering agent, a CnMn intermediate alloy, a CuCo intermediate alloy, CuFe intermediate alloy, electrolytic nickel, pure chromium, electrolytic aluminium, pure silicon and the covering agent; and then, carrying out phosphor copper deoxidation, stirring slag salvaging, temperature increasing and discharging. The preparation method has the advantages that cost is low and efficiency is high, the copper alloy material has performance like sandy seawater erosion corrosion resistance, ocean organism corrosion resistance and seawater high-speed flow corrosion resistance, and the requirement of ocean engineering on corrosion-resistant and abrasion-resistant materials can be met.

Owner:HENAN UNIV OF SCI & TECH

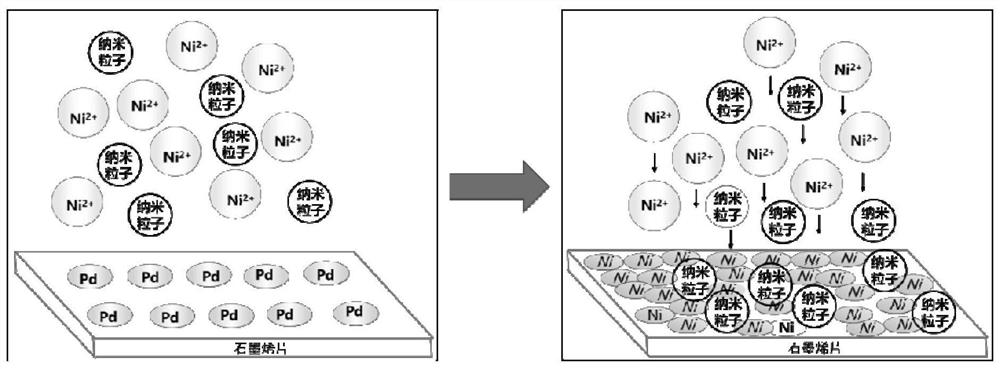

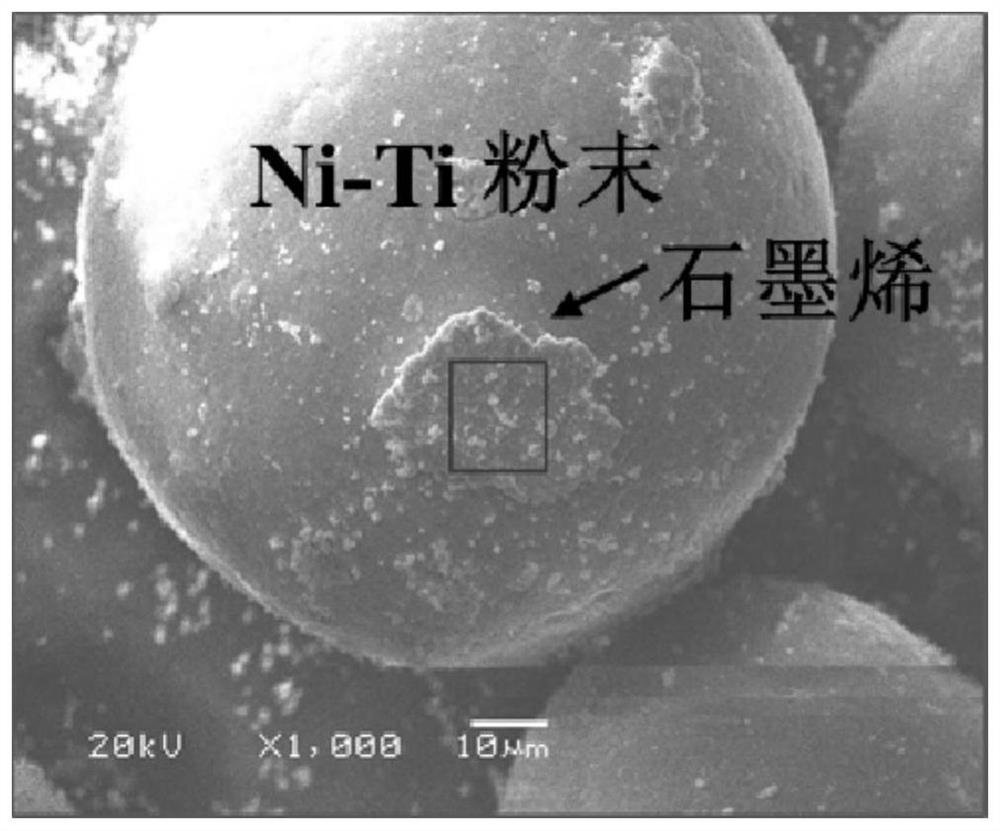

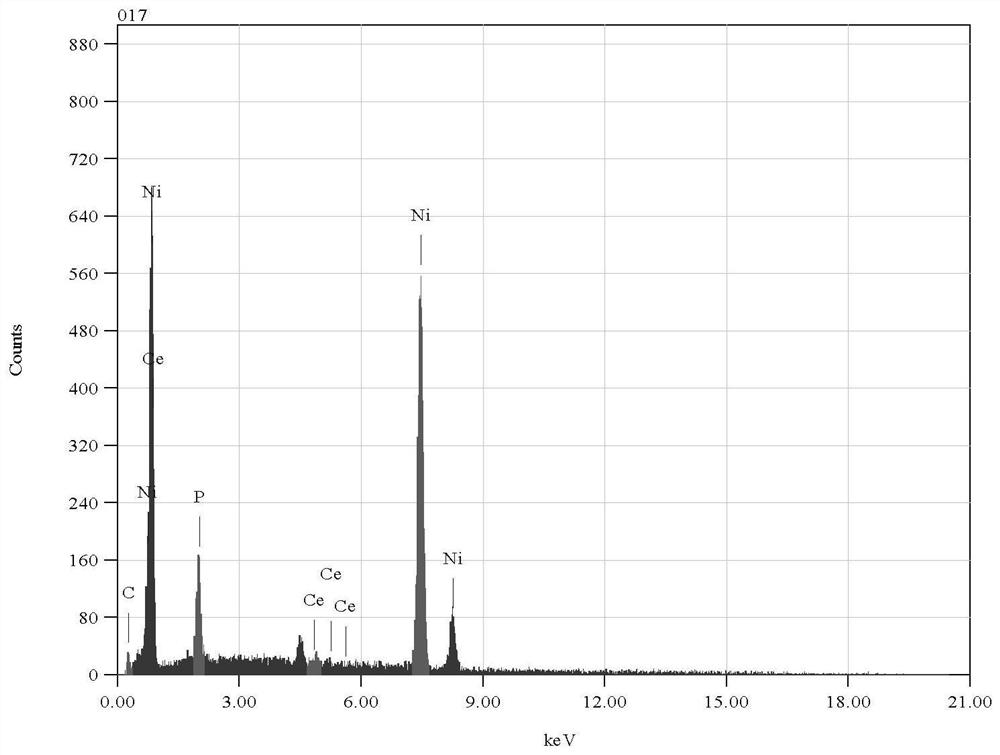

Reinforcing phase-reinforced composite powder with functional layers for fusion technology, method of preparation and application thereof

ActiveCN110918978BImprove antioxidant capacityEvenly dispersedMolten spray coatingTransportation and packagingNickel saltAlloy

A composite powder reinforced with a functional layer for fusion technology and its preparation method and application. The invention belongs to the field of composite materials. It solves the problem that the existing nanoparticle powder mixing method is prone to agglomeration and reduces its nucleation effect. The problem. The reinforcing phase reinforced composite powder with functional layer in the present invention is composed of 96wt.%-98wt.% metal base powder as matrix powder, and 4wt.%-2wt.% graphene material with functional layer as doping phase. The preparation method of the reinforcing phase with a functional layer: adding non-metallic nanoparticles into a mixed solution containing nickel salt to obtain a reaction solution, adding the reinforcing phase treated with palladium chloride into the reaction solution for reaction. In the invention, nanoparticles are introduced into the alloy powder through the medium action of the reinforcing phase, and the non-metallic nanoparticles have good compatibility with the alloy powder, and can be uniformly dispersed in the alloy powder.

Owner:HARBIN ENG UNIV

5-series aluminum alloy plate for upper cover of automobile power battery pack and preparation method of 5-series aluminum alloy plate

ActiveCN114752828AImprovement ingredientsIncrease contentCell component detailsPower batteryAluminium alloy

The invention relates to a 5-series aluminum alloy plate for an upper cover of an automobile power battery pack and a preparation method of the 5-series aluminum alloy plate, and belongs to the technical field of aluminum alloy production. The aluminum alloy is prepared from the following element components in percentage by weight: 0 to 0.10 percent of Si, 0 to 0.20 percent of Fe, 0.15 to 0.25 percent of Cu, 0.35 to 0.45 percent of Mn, 4.50 to 5.00 percent of Mg, 0.05 to 0.15 percent of V, less than or equal to 0.05 percent of single impurities, less than or equal to 0.10 percent of total impurities and the balance of Al, wherein the requirements of alkali metal are as follows: Na is less than or equal to 10ppm, Ca is less than or equal to 8ppm, and Li is less than or equal to 15ppm, and the prominent problem of surface quality defects of a TYPE B-type Luders strip easily occurring in the application of the existing 5 aluminum alloy to the upper cover of the automobile power battery pack is solved through the process steps of casting, saw milling, homogenization, hot rolling, cold rolling and complete recrystallization annealing.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

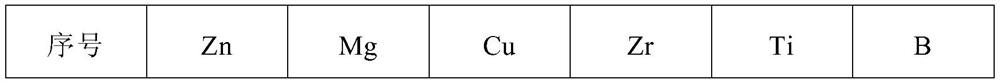

Novel particle-reinforced 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107760AImprove mechanical propertiesHigh strengthMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a novel particle-reinforced 7XXX aluminum alloy ribbon and a preparation method thereof, the aluminum alloy ribbon comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, the content of a total impurity is less than or equal to 0.2%, and the microstructure of the aluminum alloy ribbon is a fine isometric crystal matrix structure and dispersively distributed hard particles. Compared with an existing 7XXX aluminum alloy, the strength of the prepared 7XXX aluminum alloy thin strip is improved by 25% or above, and the ductility is improved by 35% or above by adopting the nanoparticle reinforcement and double-roller thin strip continuous casting technology; compared with a steel plate, the weight is reduced by 50% or more. The material can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and can provide a wide space for aerospace high reinforcement, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com