Preparation method of carbide reinforced high-entropy alloy composite material

A high-entropy alloy and composite material technology is applied in the field of preparation of carbide-reinforced high-entropy alloy composite materials. And the effect of wear resistance, high yield strength, high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

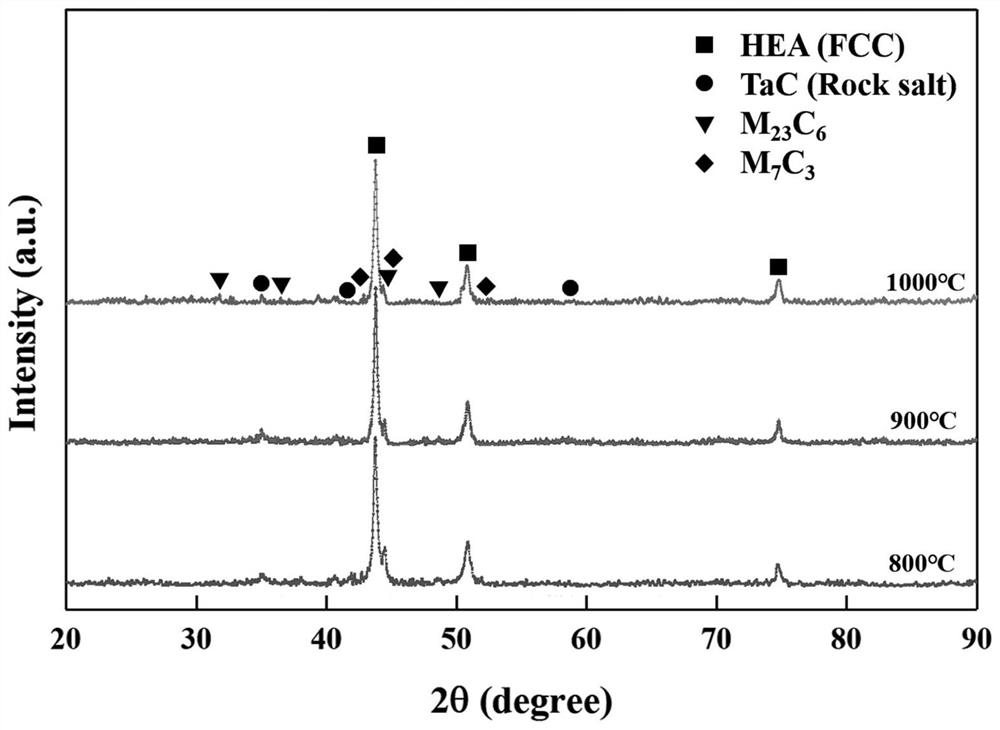

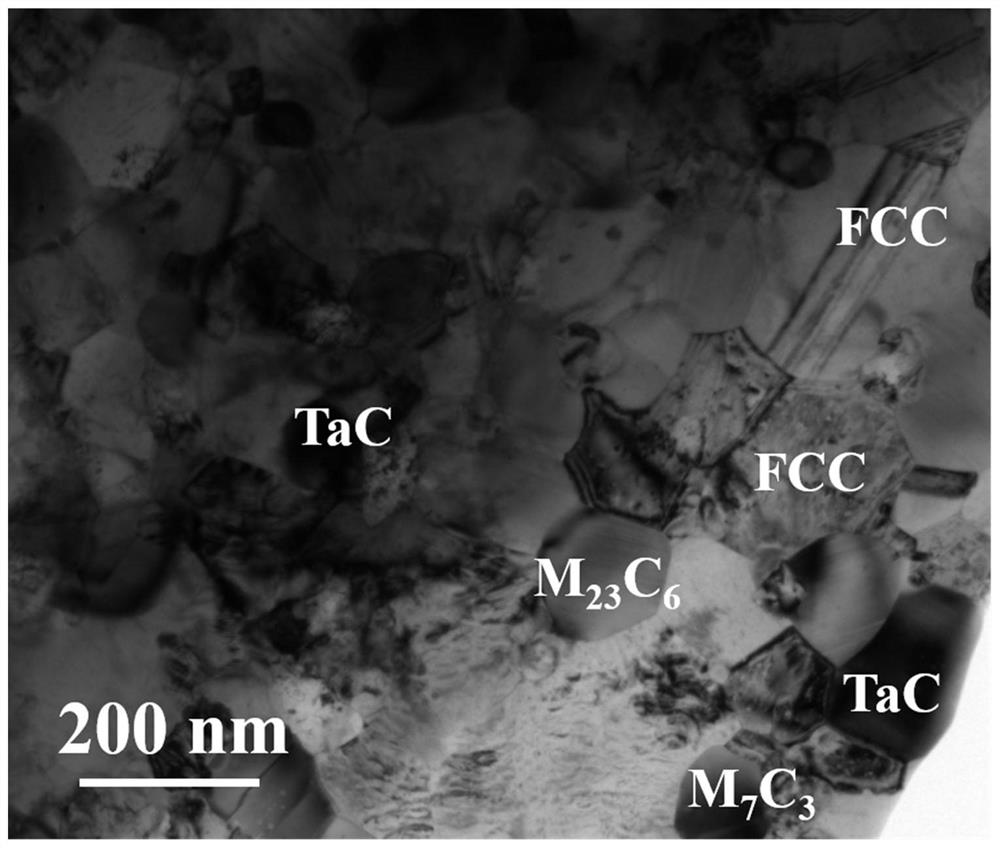

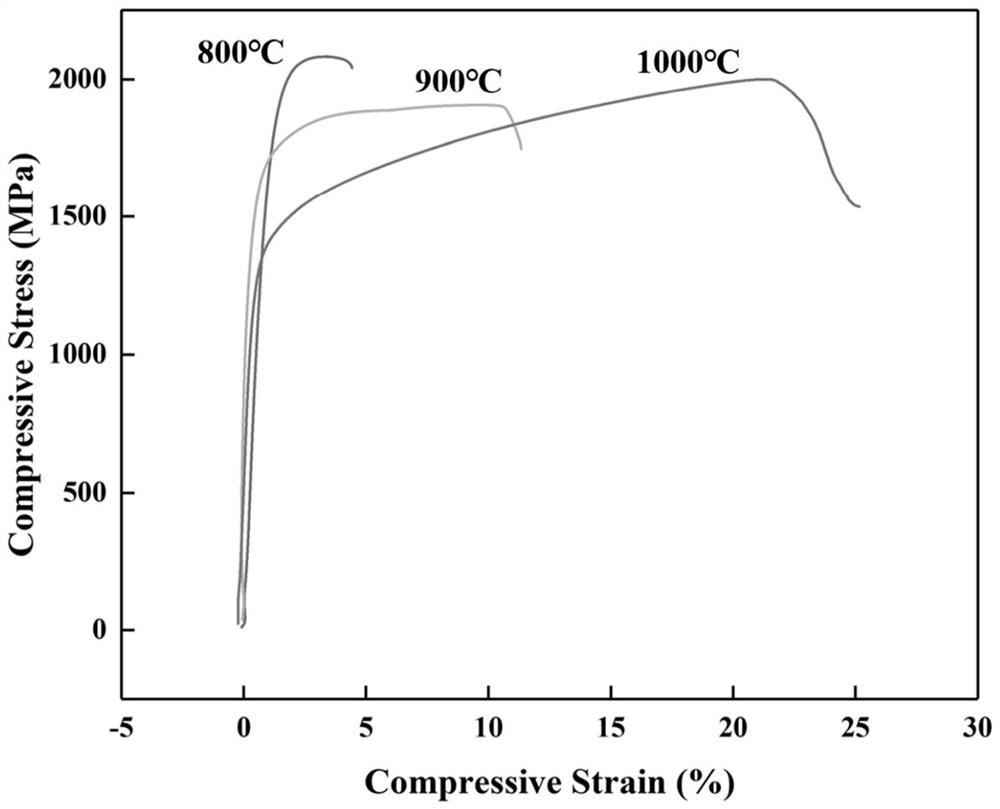

Embodiment approach 1

[0029] a.HEC in Preparation of powder

[0030] Under argon as protective gas atmosphere, 99.5wt% HEA (FeCoNiCrMn): 0.5wt% C (C 7 Hide 16 ) 1500mL of a stainless steel ball mill jar, add diameters of 5mm, 10mm and 15mm latter three stainless steel balls in a stainless steel tank closure body, the weight ratio of three kinds of balls 5: 8: 8, and ball milled HEC in Powder mass ratio was 15: 1, to milling speed 400r / min, 40h after milling to give FeCoNiCrMn / C powder, i.e. HEC in powder.

[0031] b.HEC ex Preparation of powder

[0032] The 95wt% HEC in : 5wt% ceramic carbide (TaC and TiC molar ratio of 1: 1) was placed in a stainless steel ball mill jar 1500mL added diameters of 5mm, the latter three stainless steel balls of 15mm and 10mm stainless steel cans closure three ball weight ratio of 5: 8: 8, and ball milled HEC ex Powder mass ratio was 15: obtain FeCoNiCrMn / C / TaC / TiC powders, the next step is the spark plasma sintering SPS after 1, ball speed is set to 400r / min,...

Embodiment approach 2

[0037] a.hec in Powder preparation

[0038] 99.5 wt% HEA (FECONICRMN): 0.5 wt% C (C) was 99.5 wt% Hea: 0.5% C (C) at a atmosphere of argon 7 Hide 16 Placed in 1500 ml of stainless steel ball grinding, the addition of three stainless steel grinding balls of 5mm, 10 mm, and 15 mm, respectively, and the weight ratio of three balls is 5: 8: 8, grinding ball and HEC. in The mass ratio of the powder is 15: 1, the ball mill is set to 400r / min, and the ball mill is worn for 40 h to get FECONICRMN / C powder, ie HEC in powder.

[0039] B.hec ex Powder preparation

[0040] 95WT% HEC in The 5 wt% ceramic carbide (Tac and TiC molar ratio was 1: 1) placed in 1500 ml of stainless steel ball grinding, the addition of three stainless steel grinding balls of 5mm, 10mm and 15mm, respectively, respectively, three kinds of stainless steel cans, three The weight ratio of the ball is 5: 8: 8, grinding ball and HEC ex The mass ratio of the powder is 15: 1, the ball mill is set to 400r / min, and the b...

Embodiment approach 3

[0045] a.hec in Powder preparation

[0046] 99.5 wt% HEA (FECONICRMN): 0.5 wt% C (C) was 99.5 wt% Hea: 0.5% C (C) at an atmosphere of argon to protect gas. 7 Hide 16 Placed in 1500 ml of stainless steel ball grinding, the addition of three stainless steel grinding balls of 5mm, 10 mm, and 15 mm, respectively, and the weight ratio of three balls is 5: 8: 8, grinding ball and HEC. in The mass ratio of the powder is 15: 1, the ball mill is set to 400r / min, and the ball mill is worn for 40 h to get FECONICRMN / C powder, ie HEC in powder.

[0047] B.hec ex Powder preparation

[0048] 95WT% HEC in The 5 wt% ceramic carbide (Tac and TiC molar ratio was 1: 1) placed in 1500 ml of stainless steel ball grinding, the addition of three stainless steel grinding balls of 5mm, 10mm and 15mm, respectively, respectively, three kinds of stainless steel cans, three The weight ratio of the ball is 5: 8: 8, grinding ball and HEC ex The mass ratio of the powder is 15: 1, the ball mill is set to 400r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com