Ternary nitride coating prepared by microwave plasma chemical vapor deposition and method thereof

A technology of chemical vapor deposition and microwave plasma, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of high preparation temperature, large coating particles, difficulty in introducing various metal elements, etc. Achieve excellent high-temperature service characteristics, uniform grain size, and good homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

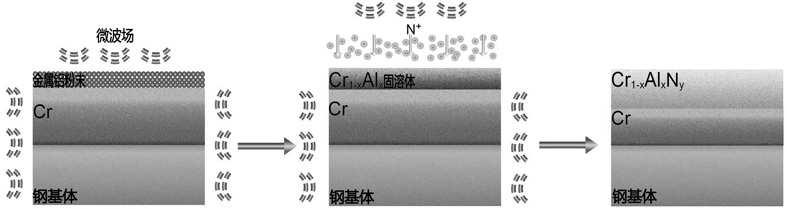

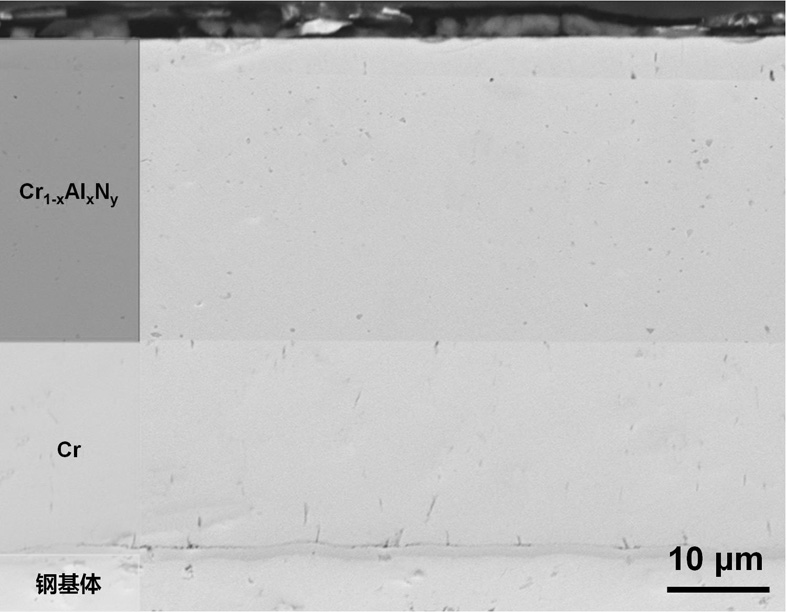

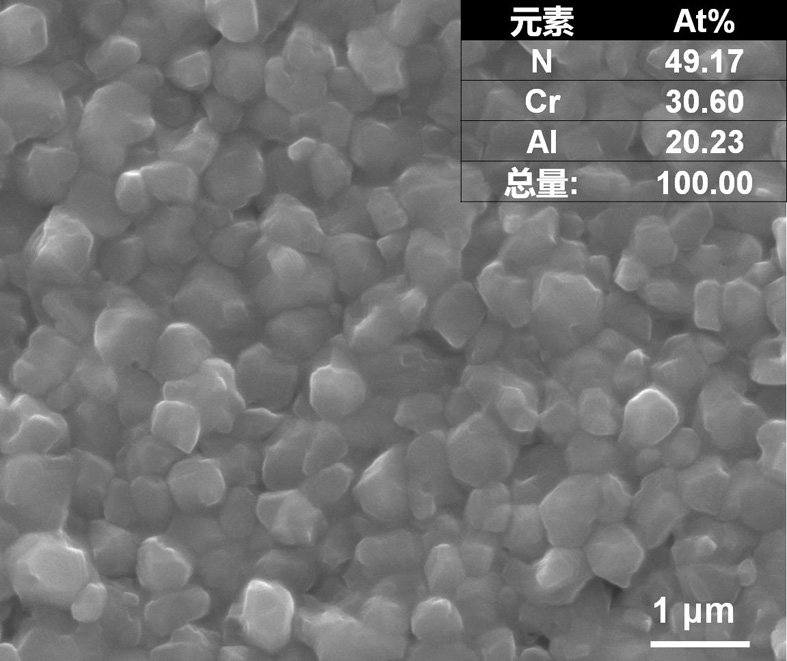

[0028] A ternary nitride coating prepared by microwave plasma chemical vapor deposition, the molecular form of the ternary nitride coating is M 1-x D x N y , wherein M is Cr, the D is Al, and solid solution and or intermetallic compound are distributed in the ternary nitride coating.

[0029] A method for preparing a ternary nitride coating by microwave plasma chemical vapor deposition, wherein the ternary nitride coating is the aforementioned ternary nitride coating, comprising the following steps;

[0030] (1) Matrix cleaning: The metal matrix was cleaned in amino acid type surfactant, soaked in acetone solution, and then ultrasonically oscillated in absolute ethanol for 2 times for 15 minutes each time to remove surface impurities and oil stains, and then at 45 ℃ drying under nitrogen atmosphere;

[0031] (2) Pretreatment: Place 20 μm thick aluminum powder on the metal substrate treated in step (1), and then put the whole into the microwave plasma chemical vapor depositi...

Embodiment 2

[0038] A ternary nitride coating prepared by microwave plasma chemical vapor deposition, the molecular form of the ternary nitride coating is M 1-x D x N y , wherein M is Ti, the D is Al, and solid solution and or intermetallic compounds are distributed in the ternary nitride coating.

[0039] A method for preparing a ternary nitride coating by microwave plasma chemical vapor deposition, wherein the ternary nitride coating is the aforementioned ternary nitride coating, comprising the following steps;

[0040] (1) Matrix cleaning: The metal matrix was cleaned in amino acid type surfactant, soaked in acetone solution, and then ultrasonically oscillated in absolute ethanol for 2 times for 15 minutes each time to remove surface impurities and oil stains, and then at 45 ℃ drying under nitrogen atmosphere;

[0041] (2) Pretreatment: place 5 μm thick metal aluminum powder on the metal substrate treated in step (1), and then put the whole into the microwave plasma chemical vapor de...

Embodiment 3

[0048] A ternary nitride coating prepared by microwave plasma chemical vapor deposition, the molecular form of the ternary nitride coating is M 1-x D x N y , wherein M is Ti, the D is Cu, and solid solution and or intermetallic compounds are distributed in the ternary nitride coating.

[0049] A method for preparing a ternary nitride coating by microwave plasma chemical vapor deposition, wherein the ternary nitride coating is the aforementioned ternary nitride coating, comprising the following steps;

[0050] (1) Matrix cleaning: The metal matrix was cleaned in amino acid type surfactant, soaked in acetone solution, and then ultrasonically oscillated in absolute ethanol for 2 times for 15 minutes each time to remove surface impurities and oil stains, and then at 45 ℃ drying under nitrogen atmosphere;

[0051] (2) Pretreatment: Place a copper sheet with a thickness of 2 mm on the titanium alloy substrate treated in step (1), and then put it into the microwave plasma chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com