Iron-based ceramic composite material and preparation method and application thereof

A ceramic composite material, iron-based technology, applied in the field of metal materials, can solve problems such as underdevelopment, and achieve the effect of improving comprehensive mechanical properties and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

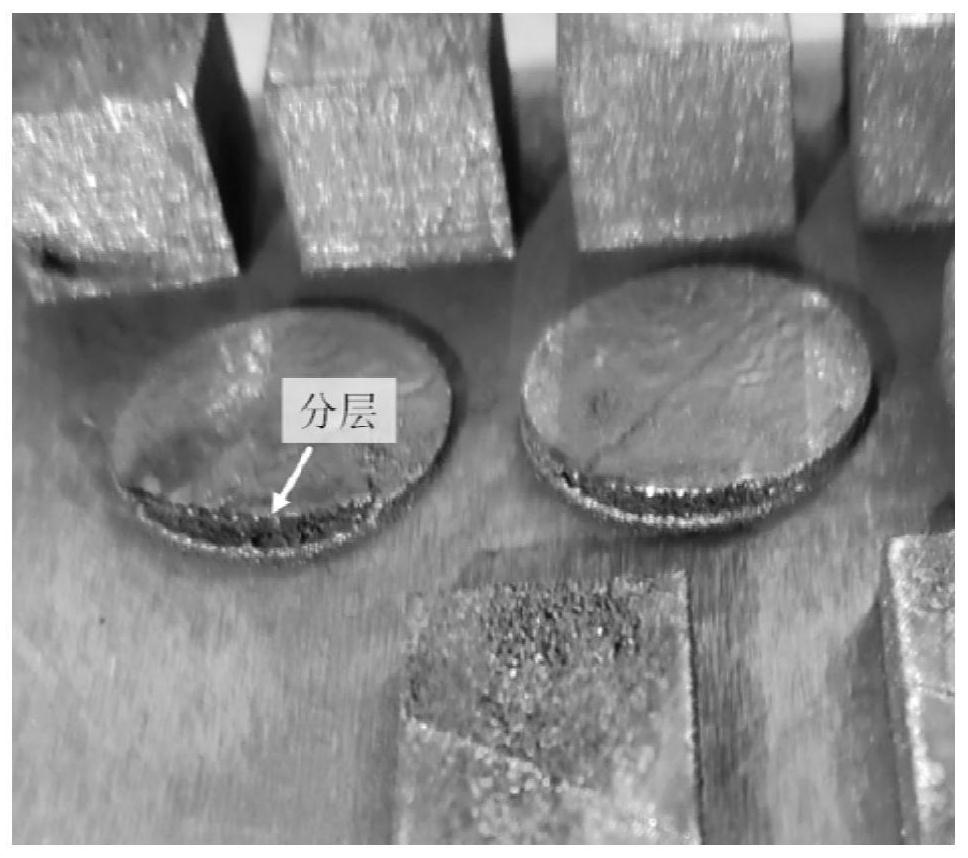

Examples

Embodiment 1~3

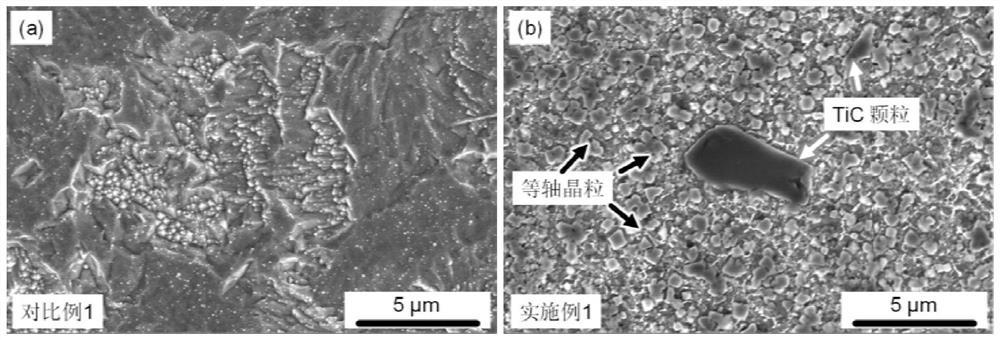

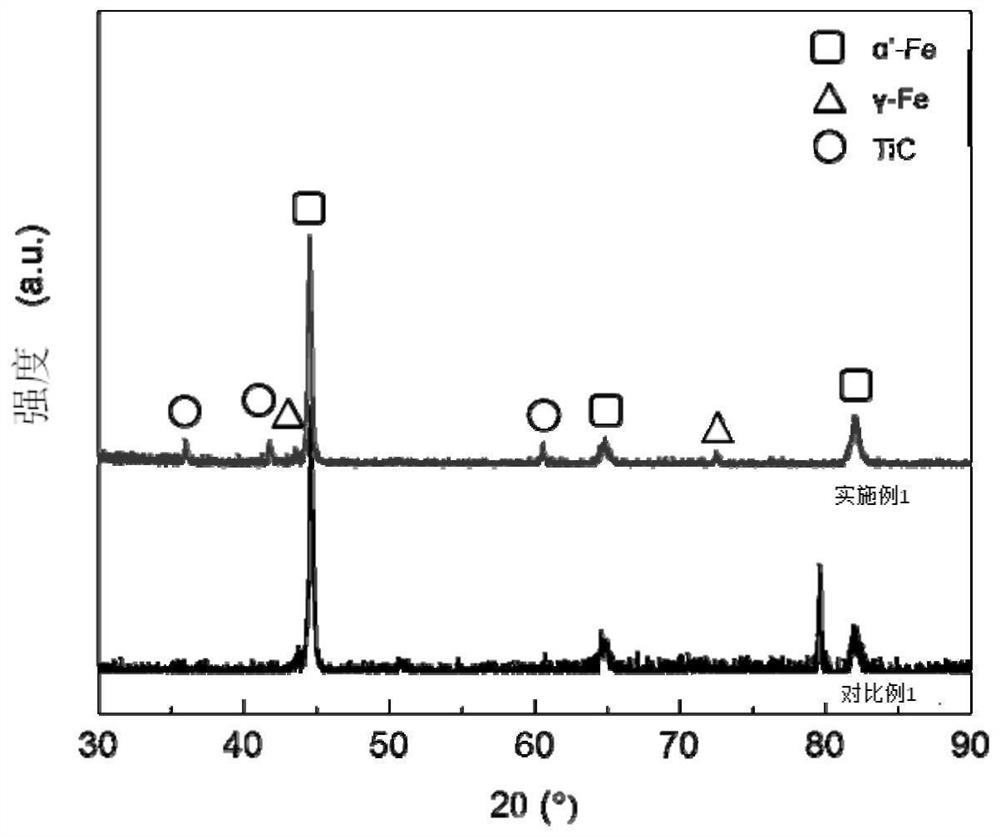

[0029] The embodiment of the iron-based ceramic composite material of the present invention, the composition of the iron-based ceramic composite material described in this embodiment is shown in Table 1, and the preparation method is as follows:

[0030] (1) Weigh raw materials by weight percentage, wherein, the particle diameter of TiC is 1~4 μ m, and purity is 99.9wt%, and the purity of Cr, Ni, Mo, Al, Fe is ≥99.00wt.%; In purity is 99.99vol. The ball milling is carried out under the protective atmosphere of argon, the ball milling tank is a stainless steel tank, and the balls are ZrO 2 , the ball milling speed is 500r / min, the ball milling time is 20h, and the mass ratio of balls to raw materials is 6:1;

[0031] (2) Heat the ball-milled particles to 1500°C in a vacuum environment, obtain a molten alloy after smelting for 80 minutes, and then use nitrogen with a purity of 99.99vol.% for spray granulation to collect spherical alloys with a particle size range of 12 to 75 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com