Super-high-strength martensite aging stainless steel resistant to seawater corrosion

An ultra-high-strength, martensitic technology, applied in ultra-high-strength maraging stainless steel, the manufacture of high-toughness structural parts, and high-strength fields, it can solve the problems of low strength and poor corrosion resistance that cannot meet the reliability requirements of structural parts to achieve excellent seawater corrosion resistance, ensure strength, toughness and corrosion resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

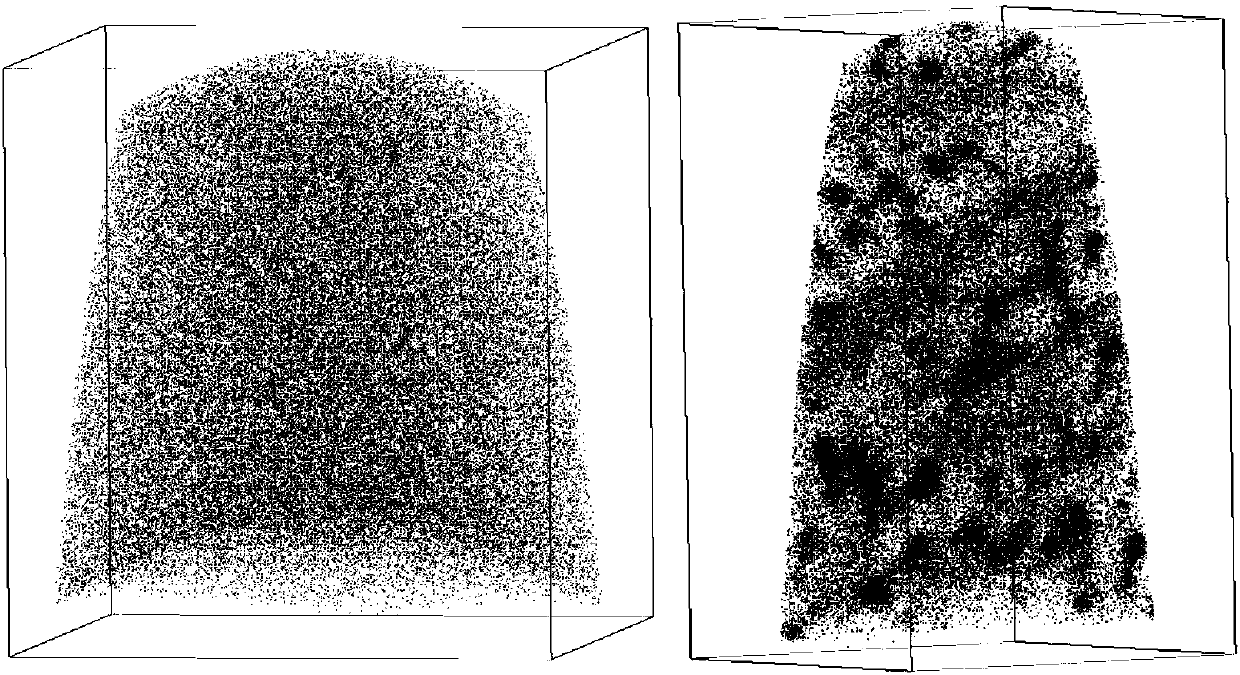

Image

Examples

Embodiment 1

[0049] According to the following nominal composition (wt.%): C: 0.02%, Cr: 13.0%, Ni: 4.5%, Co: 6.0%, Mo: 4.5%, Ti: 2.0%, Si: 0.1%, Mn: 0.1% , P: 0.01%, S: 0.01%, Fe: the balance, after batching and mixing, it is melted in a vacuum induction melting furnace, and after being cast into an ingot, heat processing and heat treatment are carried out according to the following process:

[0050] (1) Forging in the austenite single-phase region, the forging ratio is 8, and air-cooled to room temperature after forging;

[0051] (2) Hot rolling after forging, the initial rolling temperature is 1200°C, the final rolling temperature is 900°C, and the total cumulative reduction of hot rolling is 80%;

[0052] (3) Heat treatment system: solution treatment (1100°C for 1.5h, air cooling to room temperature), cryogenic treatment (-196°C for 6h in liquid nitrogen), aging treatment (480°C for 12h, air cooling).

[0053] After heat treatment, the material is processed into a 10*10*5mm sample, an...

Embodiment 2

[0056] On the basis of Example 1, the content of some alloy elements was appropriately adjusted, and the Cr / Ni equivalent ratio and the type and quantity of precipitated phases were changed to obtain better microstructure and mechanical properties than Example 1.

[0057] According to the following nominal composition (wt.%): C: 0.015%, Cr: 13.0%, Ni: 7.0%, Co: 6.0%, Mo: 4.5%, Ti: 2.7%, Si: 0.1%, Mn: 0.1% , P: 0.01%, S: 0.01%, Fe: the balance, after batching and mixing, it is melted in a vacuum induction melting furnace. The smelted ingot is subjected to thermal processing and heat treatment according to the process conditions described in Example 1.

Embodiment 3

[0060] On the basis of Example 1 and Example 2, the content of some alloying elements was further adjusted to obtain a qualified structure (full martensitic structure), and by changing the type and content of the precipitated phase, the mechanical properties were better than The novel maraging stainless steels of Example 1 and Example 2.

[0061] According to the following nominal composition (wt.%): C: 0.015%, Cr: 13.0%, Ni: 7.0%, Co: 6.0%, Mo: 4.5%, Ti: 2.1%, Si: 0.1%, Mn: 0.1% , P: 0.01%, S: 0.01%, Fe: the balance, after batching and mixing, it is melted in a vacuum induction melting furnace. The smelted ingot is subjected to thermal processing and heat treatment according to the process conditions described in Example 1.

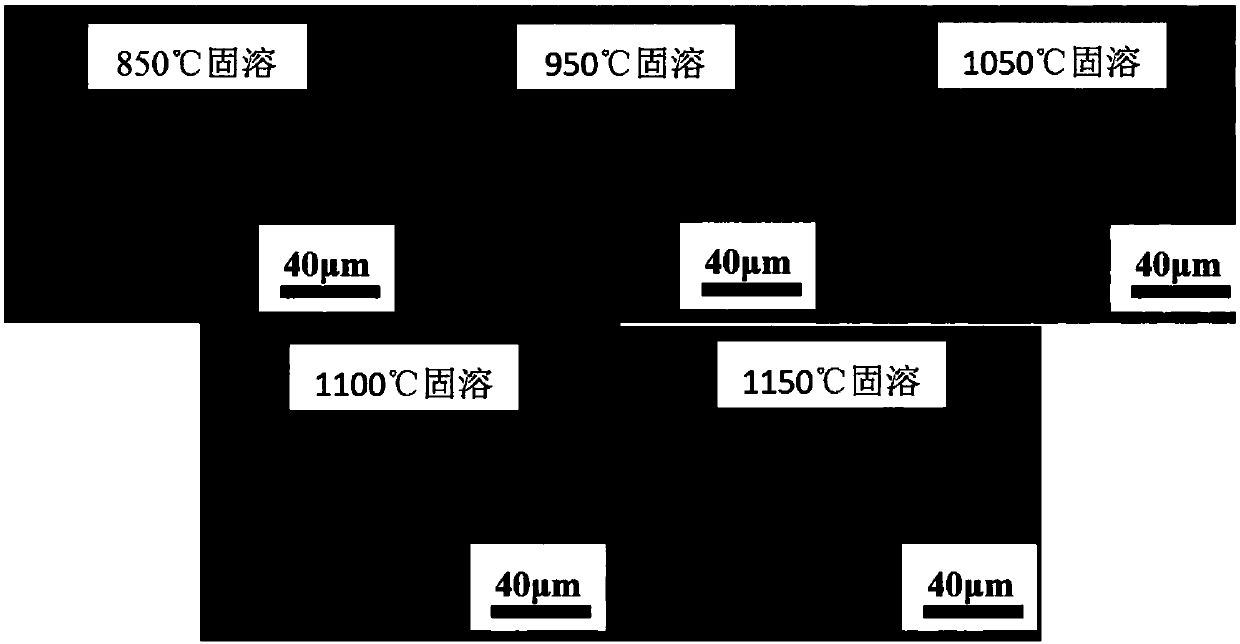

[0062] The metallographic structure of the material after heat treatment is as follows: Figure 4 As shown, a qualified full martensitic structure has been successfully obtained through the adjustment of the content of alloying elements, and the age ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pitting potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com