Steel plate with low welding crack sensitivity and manufacturing method thereof

A technology with low welding cracks and welding cracks, applied in the field of metallurgical manufacturing, can solve the problems of high cost, increase the production cost of steel enterprises, affect the delivery time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

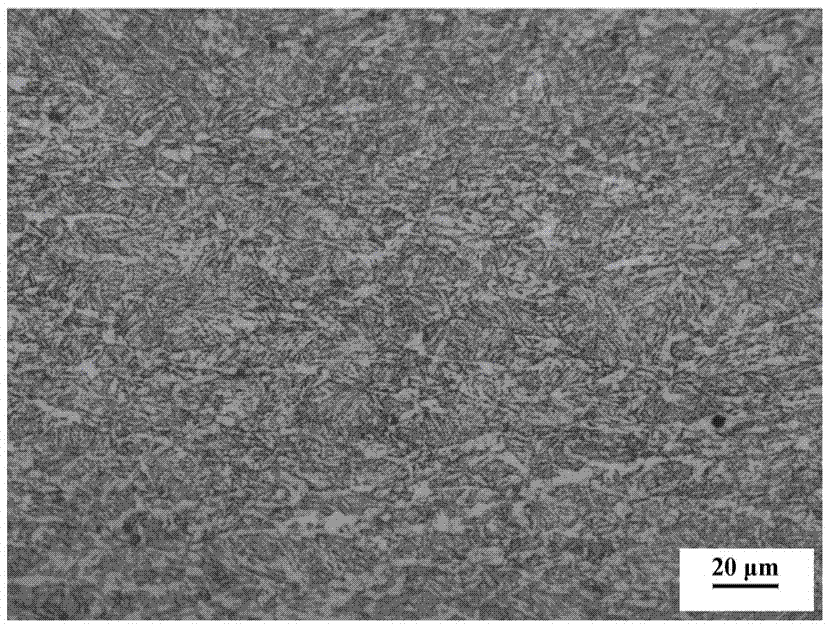

Embodiment 1

[0034] Smelt according to the chemical composition shown in Table 1, and cast into continuous casting slabs, the center porosity of the continuous casting slab is C0.5, the center segregation is 0.5, the heating temperature is 1280 °C, and the first stage is rolled until the thickness of the rolled piece is 48mm. , on the roller table to be warmed to 920℃ , followed by the second stage of rolling, the final rolling temperature is 780 ℃, and the thickness of the finished steel plate is 16mm. After rolling and relaxing for 24 seconds, the steel plate enters the rapid cooling device and is cooled to 300°C at a rate of 25°C / s, straightened after exiting the water, and cooled on the cooling bed.

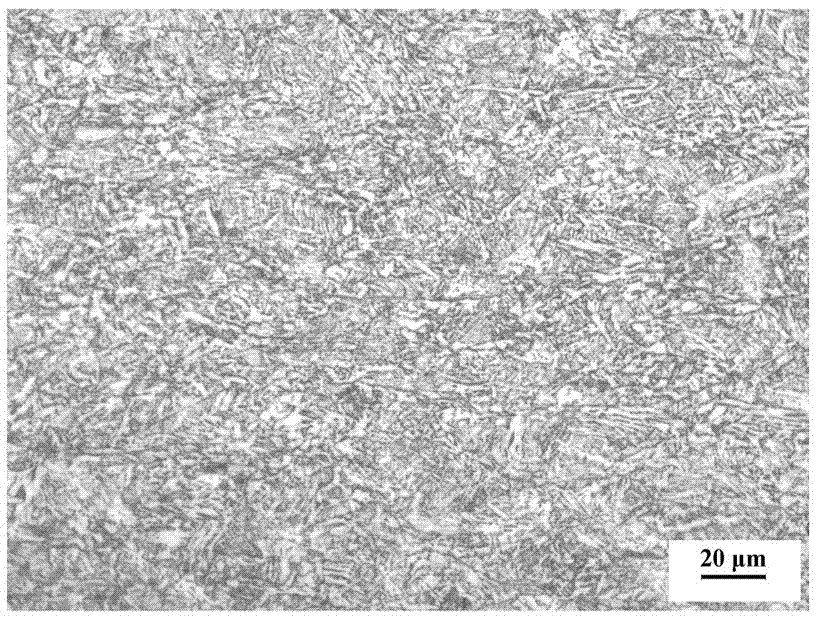

Embodiment 2

[0036] Smelted according to the chemical composition shown in Table 1, and cast into continuous casting slabs, the center of the continuous casting slabs is loose C1, the center segregation is grade 1, the heating temperature is 1280 ° C, and the first stage is rolled until the thickness of the rolled piece is 80mm. Wait until the temperature reaches 890°C on the roller table, and then carry out the second-stage rolling, the final rolling temperature is 820°C, and the thickness of the finished steel plate is 30mm. After rolling and relaxing for 28 seconds, the steel plate enters the rapid cooling device and is cooled to 320°C at a rate of 22°C / s, straightened after exiting the water, and cooled on the cooling bed.

Embodiment 3

[0038] Smelted according to the chemical composition shown in Table 1, and cast into continuous casting slabs, the center of the continuous casting slabs is loose B1, the center segregation is grade 1, the heating temperature is 1270°C, and the first stage is rolled until the thickness of the rolled piece is 100mm. Wait until the temperature reaches 870°C on the roller table, and then carry out the second-stage rolling. The final rolling temperature is 810°C, and the thickness of the finished steel plate is 36mm. After rolling and relaxing for 32 seconds, the steel plate enters the rapid cooling device and is cooled to 320°C at a rate of 18°C / s, straightened after exiting the water, and cooled on the cooling bed.

[0039] The smelting composition of table 1 embodiment billet, wt%

[0040]

[0041] Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5B

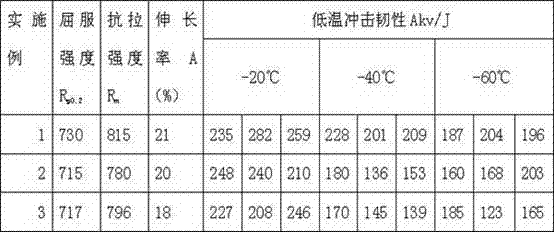

[0042] The mechanical properties of the steel plates in Examples 1-3 of the present invention are tested, and the test results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com