5-series aluminum alloy plate for upper cover of automobile power battery pack and preparation method of 5-series aluminum alloy plate

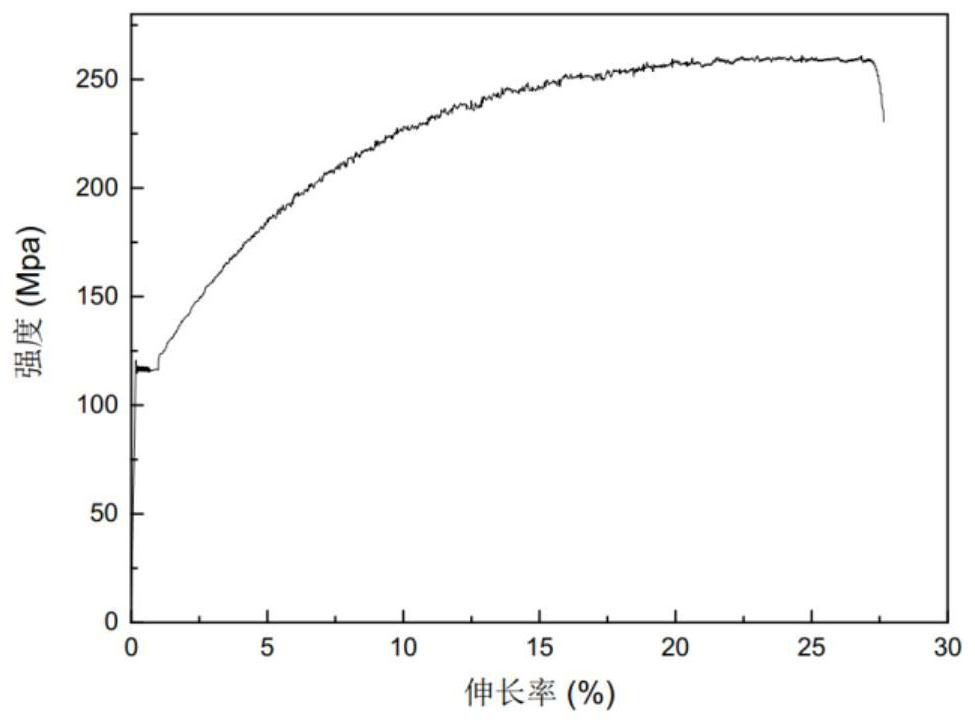

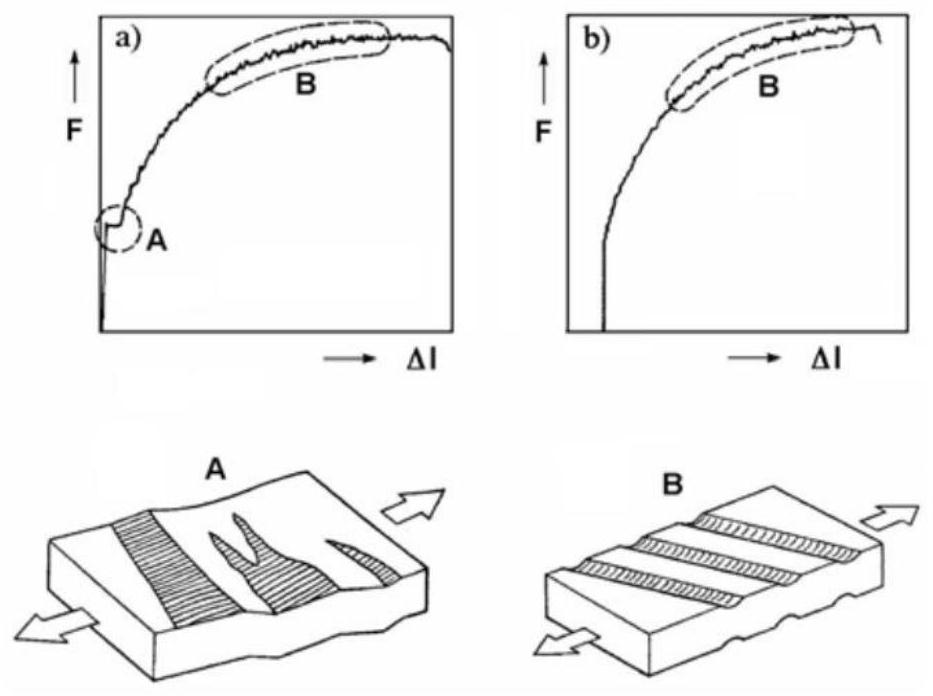

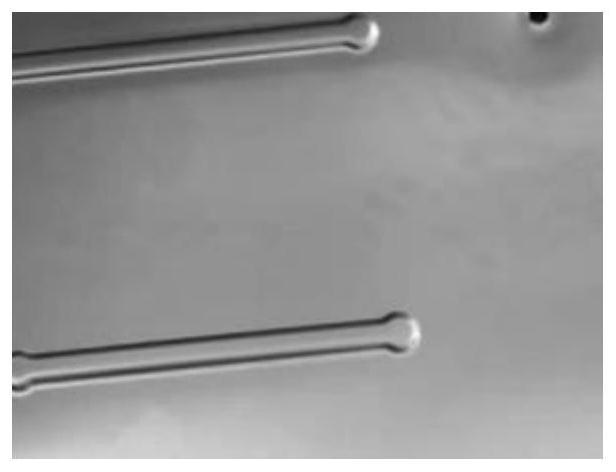

A technology for automotive power batteries and aluminum alloy plates, applied to battery pack components, circuits, electrical components, etc., can solve problems such as surface quality defects of Luders strips, achieve surface quality improvement, improve process routes and parameters, and optimize Effect of Alloy Composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A 5-series aluminum alloy plate for the upper cover of an automobile power battery pack is prepared by the following element components according to weight percentage: Si: 0-0.10%, Fe: 0-0.20%, Cu: 0.15-0.25%, Mn: 0.35-0.45%, Mg: 4.50-5.00%, V: 0.05-0.15%, single impurity ≤ 0.05%, total impurities ≤ 0.10%, the balance is Al; among them, the requirements for alkali metals: Na ≤ 10ppm, Ca ≤ 8ppm, Li≤15ppm. And specifically adopt the element content in Table 1 to carry out the proportioning.

[0039] and includes the following steps:

[0040] S1. Casting: using recycled aluminum, industrial pure aluminum, industrial pure Mg, industrial pure Zn, master alloy Al-Si, master alloy Al-Cu, master alloy Al-Fe, master alloy Al-Mn and or master alloy Al-V Proportion according to the weight percentage in Table 1; put the prepared aluminum alloy raw materials into a holding furnace with a temperature of 700-760 ° C, and turn on electromagnetic stirring to melt; adjust the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com