Reinforcing phase-reinforced composite powder with functional layers for fusion technology, method of preparation and application thereof

A technology of composite powder and reinforcing phase, which is applied in coating, melt spraying, transportation and packaging, etc. It can solve the problems of reduced nucleation effect and easy agglomeration, and achieves good load transfer, improved oxidation resistance and hardness and the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

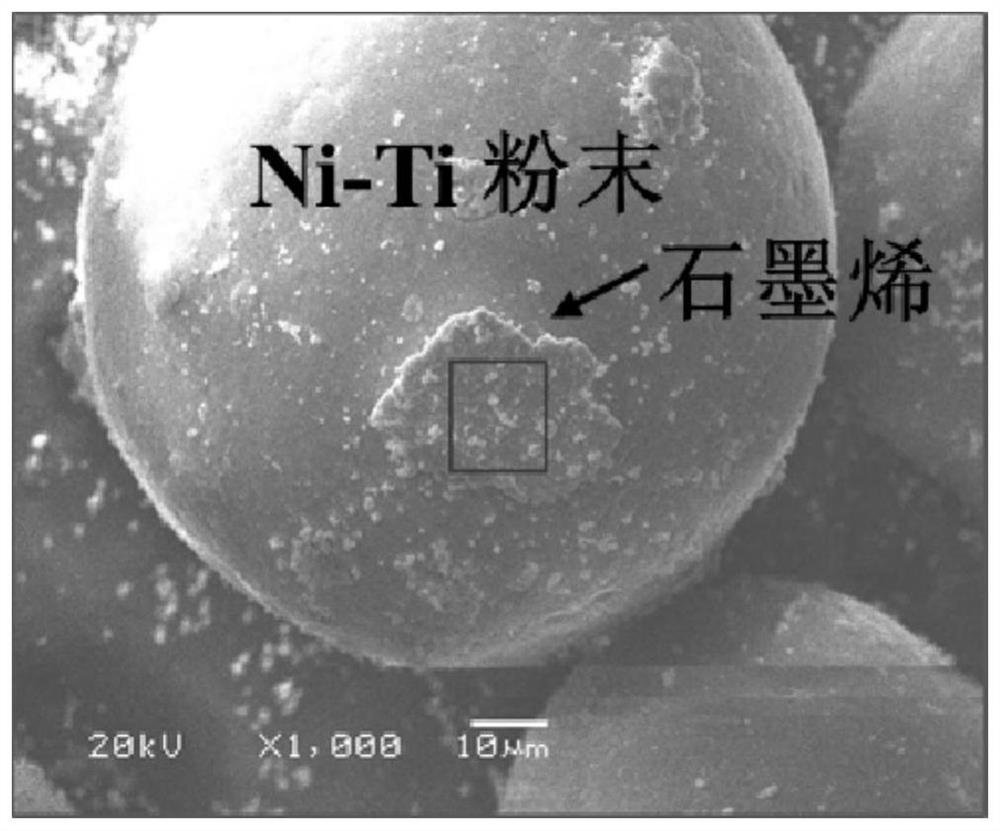

specific Embodiment approach 1

[0033] Specific implementation mode 1: This embodiment is used in the fusion technology to strengthen the composite powder with the reinforcing phase of the functional layer, which is made of 96wt.% ~ 98wt.% metal-based powder as the matrix powder, and 4wt.% ~ 2wt.% has a functional layer structure The reinforced phase is composed of a doped phase, wherein the reinforced phase is a graphene nanosheet or a graphene oxide sheet with a sheet diameter of micron;

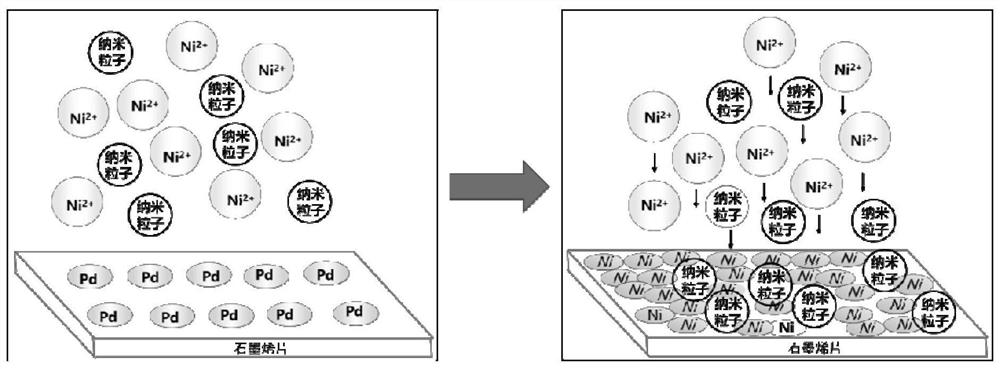

[0034] The preparation method of the reinforcing phase with a functional layer structure is realized according to the following steps:

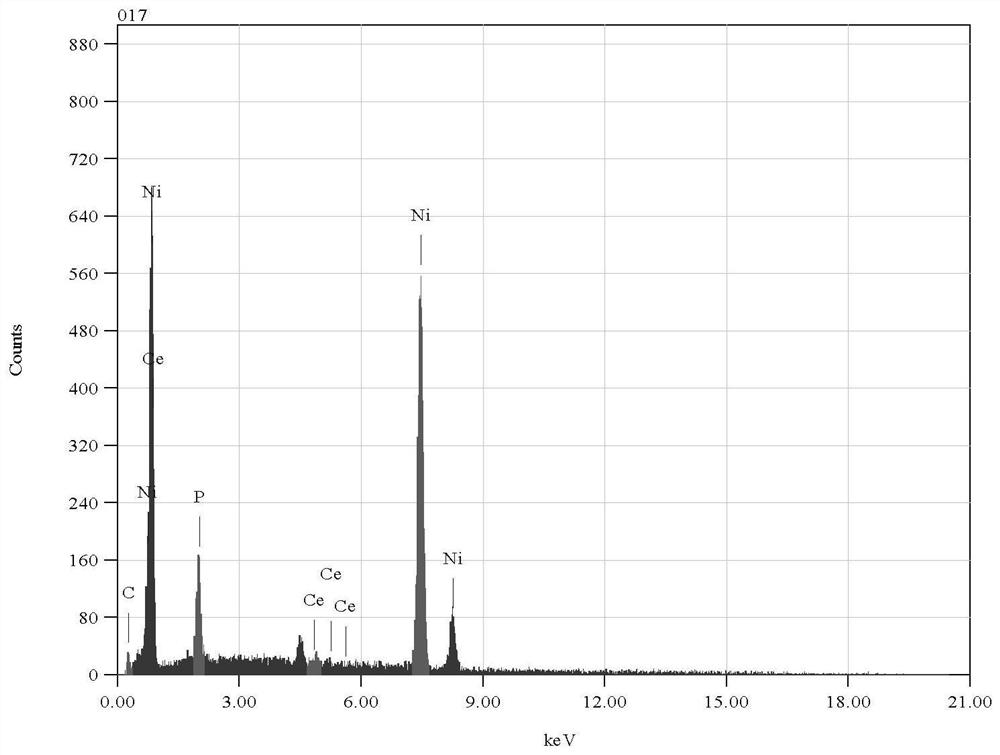

[0035] Add non-metallic nanoparticles into the mixed solution containing nickel salt, ultrasonically disperse evenly to obtain a reaction solution, add the reinforcing phase treated with palladium chloride into the reaction solution, stir the reaction ultrasonically, and obtain a functional compound after washing and drying. Reinforcement phase of layer structure;

[0036] The reaction...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment differs from Embodiment 1 in that the metal-based powder is a spherical metal-based powder with a particle size of 100-300 mesh.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the metal-based powder is titanium-based alloy powder, nickel-based alloy powder, cobalt-based alloy powder, iron-based alloy powder, copper-based alloy powder, One or mixed powder of aluminum-based alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com