Silica-encapsulated ultra-fine bismuth vanadomolybdate yellow pigment and preparation method thereof

A technology for wrapping bismuth molybdate vanadate yellow and bismuth molybdate vanadate yellow is applied in the field of inorganic pigments, which can solve the problems of inability to apply temperature resistance requirements, difficult to meet use requirements, and insufficiently dense protective films, and achieves easy control of influencing factors, Conducive to promotion and application, the effect of fine pigment particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

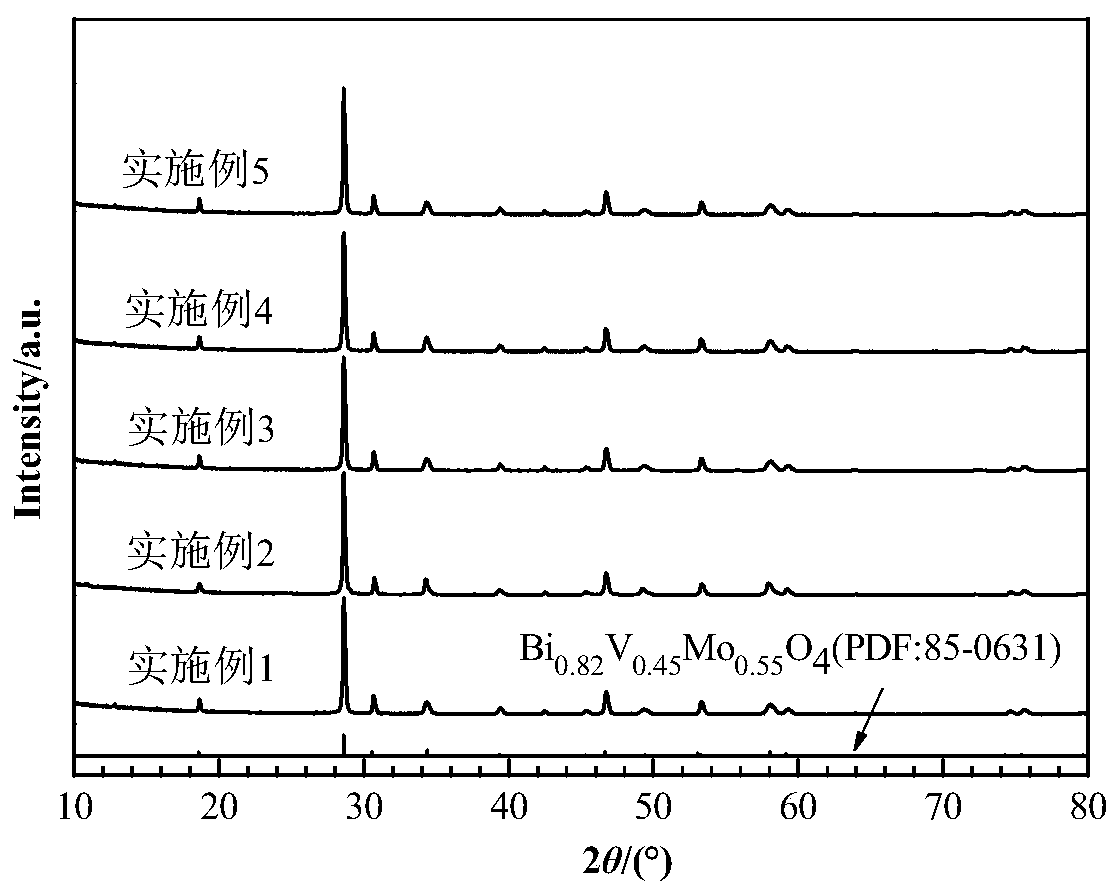

Embodiment 1

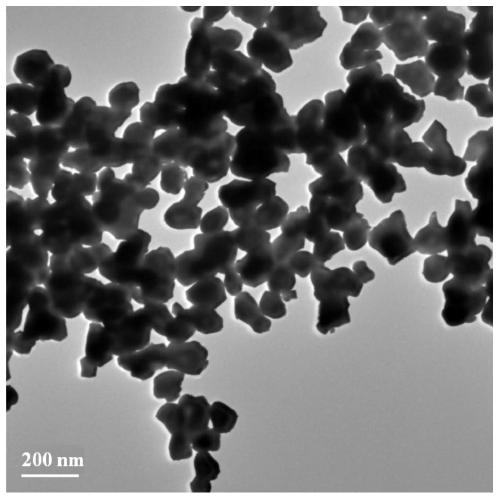

[0033] The preparation method of the present embodiment a kind of superfine silicon dioxide encapsulation type bismuth molybdenum vanadate yellow pigment, its steps are as follows:

[0034] (1) Preparation of Ultrafine Bismuth Molybdovanadate Yellow Pigment Filter Cake

[0035] (1-1) 9.70g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100 mL of nitric acid solution with a concentration of 2.0 mol / L, and after adding 0.60 g of dispersant polyvinylpyrrolidone and stirring to dissolve, liquid A was obtained;

[0036] (1-2) 9.76g ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] and 1.48g sodium metavanadate (NaVO 3 ) was dissolved in 100 mL of sodium hydroxide solution with a concentration of 2.0 mol / L to obtain liquid B;

[0037] (1-3) Mix the above liquid A and liquid B at room temperature, adjust the pH value of the system to 6.0 with sodium hydroxide solution, and react for 2.0 h under the conditions of stirring and water bath temperature of 70 °C. After suction filtration, fir...

Embodiment 2

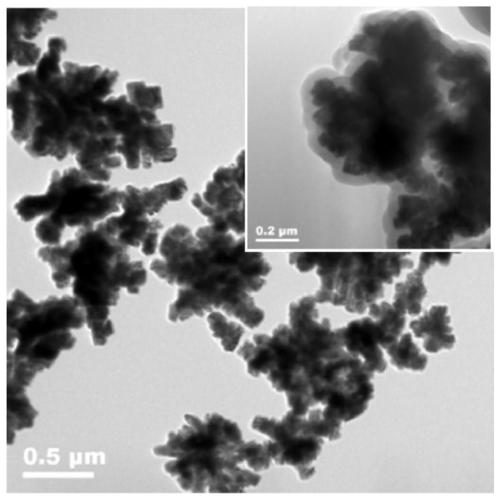

[0043] The preparation method of the present embodiment a kind of superfine silicon dioxide encapsulation type bismuth molybdenum vanadate yellow pigment, its steps are as follows:

[0044] (1) Preparation of Ultrafine Bismuth Molybdovanadate Yellow Pigment Filter Cake

[0045] (1-1) 7.30g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100 mL of nitric acid solution with a concentration of 1.5 mol / L, and after adding 0.45 g of dispersant polyvinyl alcohol and stirring to dissolve, liquid A was obtained;

[0046] (1-2) 10.0g disodium molybdate (Na 2 MoO 4 2H 2 O) and 1.06g ammonium metavanadate (NH 4 VO 3 ) was dissolved in 100 mL of sodium hydroxide solution with a concentration of 1.5 mol / L to obtain liquid B;

[0047] (1-3) Mix the above liquid A and liquid B at room temperature, adjust the pH value of the system to 6.5 with sodium hydroxide solution, and react for 2.0 h under the conditions of stirring and water bath temperature of 70 ° C, after suction filtration, first use ...

Embodiment 3

[0053] The preparation method of a kind of superfine silicon dioxide encapsulation type bismuth molybdenum vanadate yellow pigment of this embodiment, differs from embodiment one in that:

[0054] In the step (1-2), the source of vanadium is ammonium metavanadate (NH 4 VO 3 ), the dosage is 1.42g;

[0055] The temperature of the water bath in the step (1-3) is 65°C;

[0056] In step (2-1), the consumption of tetraethyl orthosilicate is 12.4 g, the consumption of concentrated ammonia water is 10.5 mL, and the consumption of distilled water is 210 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com