Method for improving oxidation resistance of active Ti/2B nano powder material

A nano-powder and anti-oxidation technology, which is applied in the field of improving the oxidation resistance of active Ti/2B nano-powder materials, can solve problems such as safety hazards, activity loss, etc., to prevent agglomeration, improve oxidation resistance, and improve the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

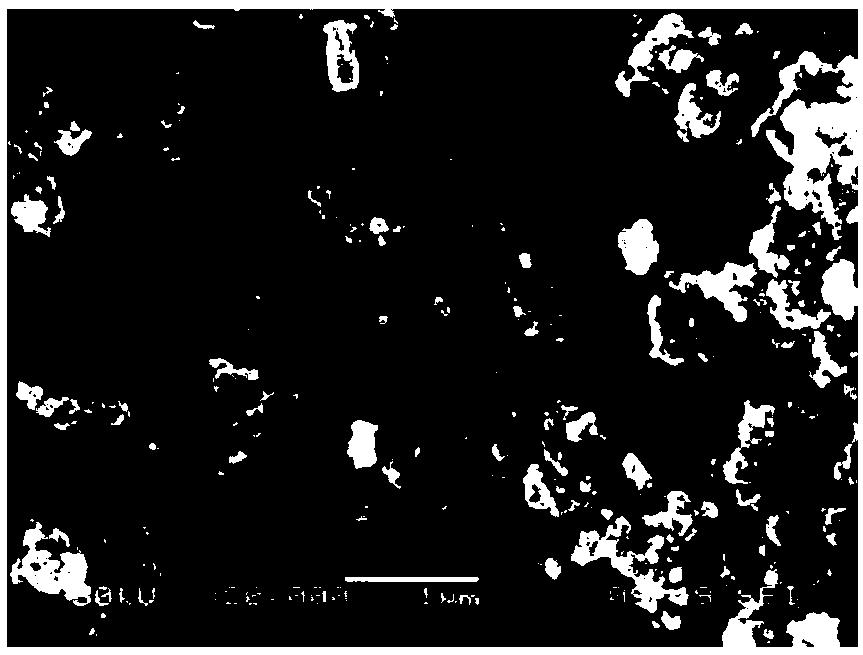

Image

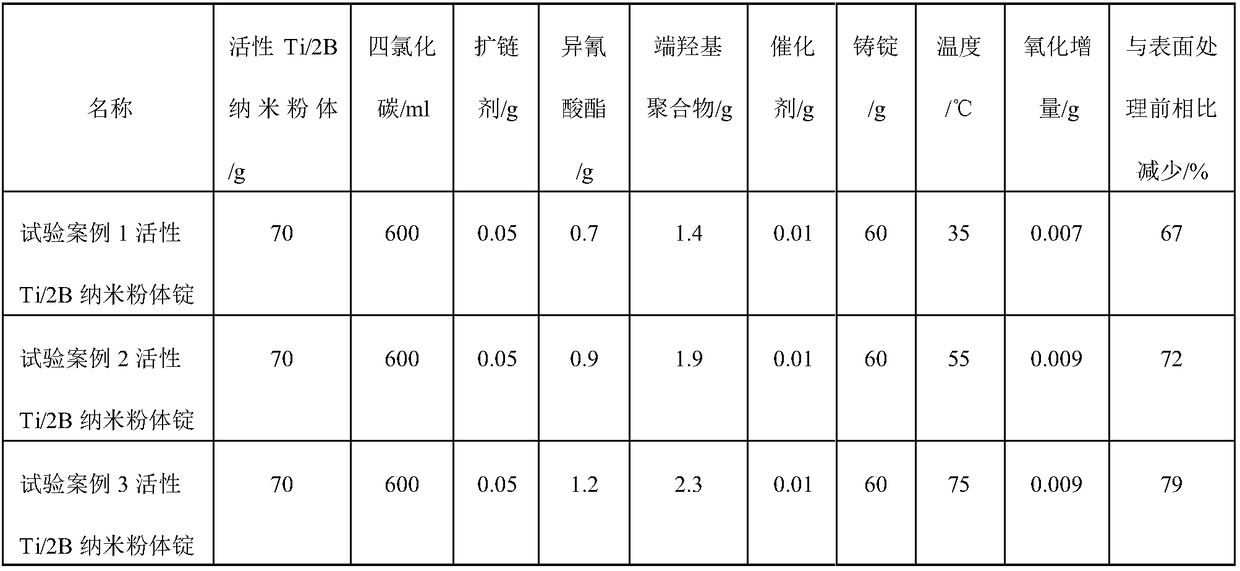

Examples

Embodiment 1

[0030] A method for improving the oxidation resistance of active Ti / 2B nano powder material, the specific steps are as follows:

[0031] (1) Preparation of active Ti / 2B nanopowder

[0032] (1) Synthesis of elemental boron powder

[0033] Pass boron trichloride and magnesium powder through a 200-mesh sieve, weigh 350g of boron trichloride and 180g of magnesium powder, mix for 10 minutes, heat to 700°C, continue the reaction for 1 hour, rinse with 30% hydrochloric acid after cooling down, and then rinse with distilled water Rinse, filter and dry to obtain the product for use.

[0034] Add 95g of KBF 4 and 75g of KHF 2 Put the mixture into the above product, heat to 900°C for 1 hour, rinse with 30% hydrochloric acid after cooling down, then rinse with distilled water, filter and dry to obtain 28g of elemental boron powder.

[0035] (2) Preparation of nano boron powder

[0036] Under low temperature (lower than 20°C), drying, and under the protection of argon, pass the obtain...

Embodiment 2

[0046] A method for improving the oxidation resistance of active Ti / 2B nano powder material, the specific steps are as follows:

[0047] (1) Preparation of active Ti / 2B nanopowder

[0048] (1) Synthesis of elemental boron powder

[0049] After diboron trioxide and magnesium powder pass through 80 mesh sieve, weigh 100g of diboron trioxide and 180g of magnesium powder, mix for 10min, heat to 700°C, continue to react for 1h, rinse with 40% hydrochloric acid after cooling down, and then Rinse with distilled water, filter and dry to obtain the product for use.

[0050] Add 95g of KBF 4 and 75g of KHF 2 Put the mixture into the above product, heat to 900°C for 1 hour, rinse with 40% hydrochloric acid after cooling down, then rinse with distilled water, filter and dry to obtain 30g elemental boron powder.

[0051] (2) Preparation of nano boron powder

[0052] Under low temperature (less than 20°C), drying, and under the protection of argon, pass the elemental boron powder obtai...

Embodiment 3

[0062] A method for improving the oxidation resistance of active Ti / 2B nano powder material, the specific steps are as follows:

[0063] (1) Synthesis of elemental boron powder

[0064] Pass the diboron trioxide and magnesium powder through a 100-mesh sieve, weigh 100g of diboron trioxide and 180g of magnesium powder, mix for 10min, heat to 600°C, continue the reaction for 1h, rinse with 45% hydrochloric acid after cooling down, and then use distilled water Rinse, filter and dry.

[0065] Add 95g of KBF 4 and 75g of KHF 2 The mixture was heated to 800° C. for 1 hour, rinsed with 45% hydrochloric acid after cooling down, and then rinsed with distilled water, filtered and dried to obtain 27.5 g of elemental boron powder.

[0066] (2) Preparation of nano boron powder

[0067] Under low temperature (lower than 20°C), drying, and under the protection of argon, pass the obtained elemental boron powder through a 30-mesh sieve, use a high-energy nano-mill, adopt dry ball milling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com