Method for preparing boron nano material through arc discharge

An arc discharge and nanomaterial technology, applied in the field of arc discharge preparation of boron nanomaterials, can solve the problems of low preparation efficiency, poor product purity, low yield, etc., and achieve the effects of simple process, high product purity, and large production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing boron nanomaterials by arc discharge in this embodiment comprises the following steps:

[0020] (1) Prepare powder mixture: mix boron powder and tungsten powder in a volume ratio of 4:1 to obtain a powder mixture;

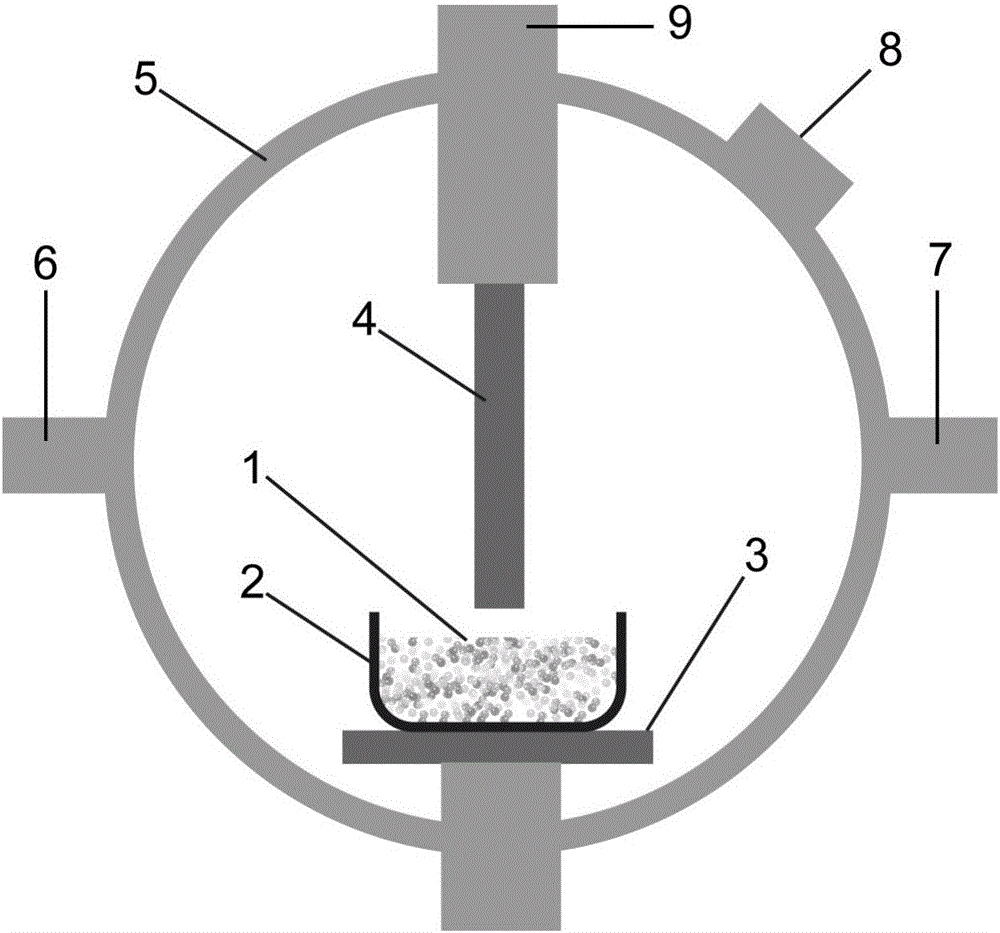

[0021] (2) Install a pure tungsten cathode and a mixed anode in the reaction chamber of the arc discharge device, and the mixed anode and the pure tungsten cathode are all connected to a power supply; the powder mixture prepared in step (1) is packed into a tungsten crucible, and the Hybrid electrodes made by machine compaction;

[0022] (3) evacuate the reaction chamber so that the air pressure in the reaction chamber is lower than 0.0001Pa, and then feed argon gas;

[0023] (4) Turn on the power supply for arc discharge, first adjust the initial current to 10 amperes, then adjust the distance between the pure tungsten cathode and the mixed anode, so that when the distance between the pure tungsten cathode and the mixed anode is 8mm,...

Embodiment 2

[0027] A method for preparing boron nanomaterials by arc discharge in this embodiment comprises the following steps:

[0028] (1) Prepare the powder mixture: mix boron powder and tungsten powder in a volume ratio of 1:1 to obtain a powder mixture;

[0029] (2) Install a pure tungsten cathode and a mixed anode in the reaction chamber of the arc discharge device, and the mixed anode and the pure tungsten cathode are all connected to a power supply; the powder mixture prepared in step (1) is packed into a tungsten crucible, and the Hybrid electrodes made by machine compaction;

[0030] (3) evacuate the reaction chamber so that the air pressure in the reaction chamber is lower than 0.0001Pa, and then feed argon gas;

[0031] (4) Turn on the power supply for arc discharge, first adjust the initial current to 10 amperes, then adjust the distance between the pure tungsten cathode and the mixed anode, so that when the distance between the pure tungsten cathode and the mixed anode is ...

Embodiment 3

[0034] A method for preparing boron nanomaterials by arc discharge in this embodiment comprises the following steps:

[0035] (1) Prepare the powder mixture: mix boron powder and tungsten powder at a volume ratio of 10:1 to obtain a powder mixture;

[0036] (2) Install a pure tungsten cathode and a mixed anode in the reaction chamber of the arc discharge device, and the mixed anode and the pure tungsten cathode are all connected to a power supply; the powder mixture prepared in step (1) is packed into a tungsten crucible, and the Hybrid electrodes made by machine compaction;

[0037] (3) evacuate the reaction chamber so that the air pressure in the reaction chamber is lower than 0.0001Pa, and then feed argon gas;

[0038] (4) Turn on the power supply for arc discharge, first adjust the initial current to 10 amperes, then adjust the distance between the pure tungsten cathode and the mixed anode, so that when the distance between the pure tungsten cathode and the mixed anode is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com