Boron quantum dot, and stabilizing treatment method and application thereof

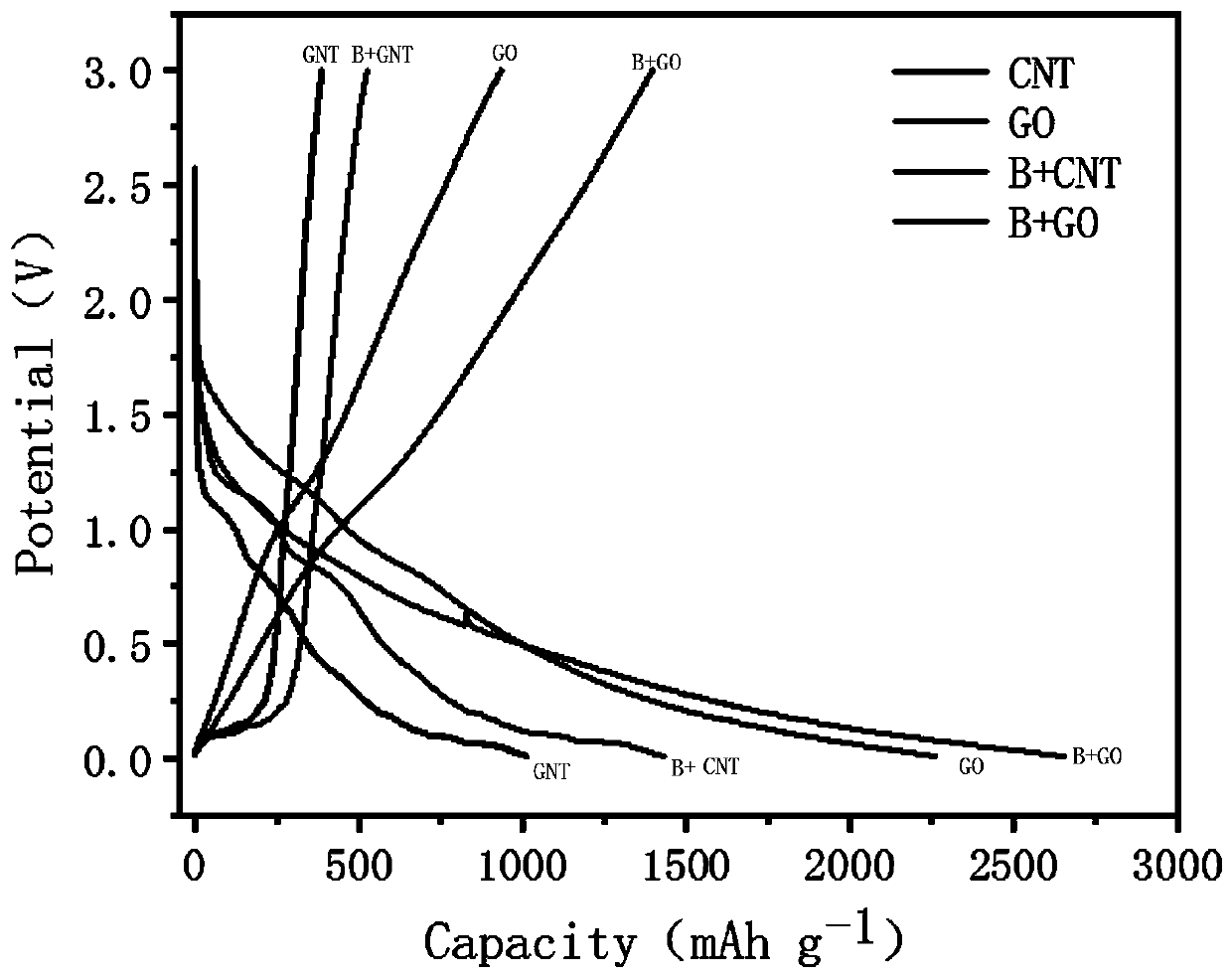

A stabilized treatment, quantum dot technology, applied in chemical instruments and methods, boron/boride, boron, etc., can solve the problem that boron quantum dots are difficult to exist stably, and achieve the effect of improving lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

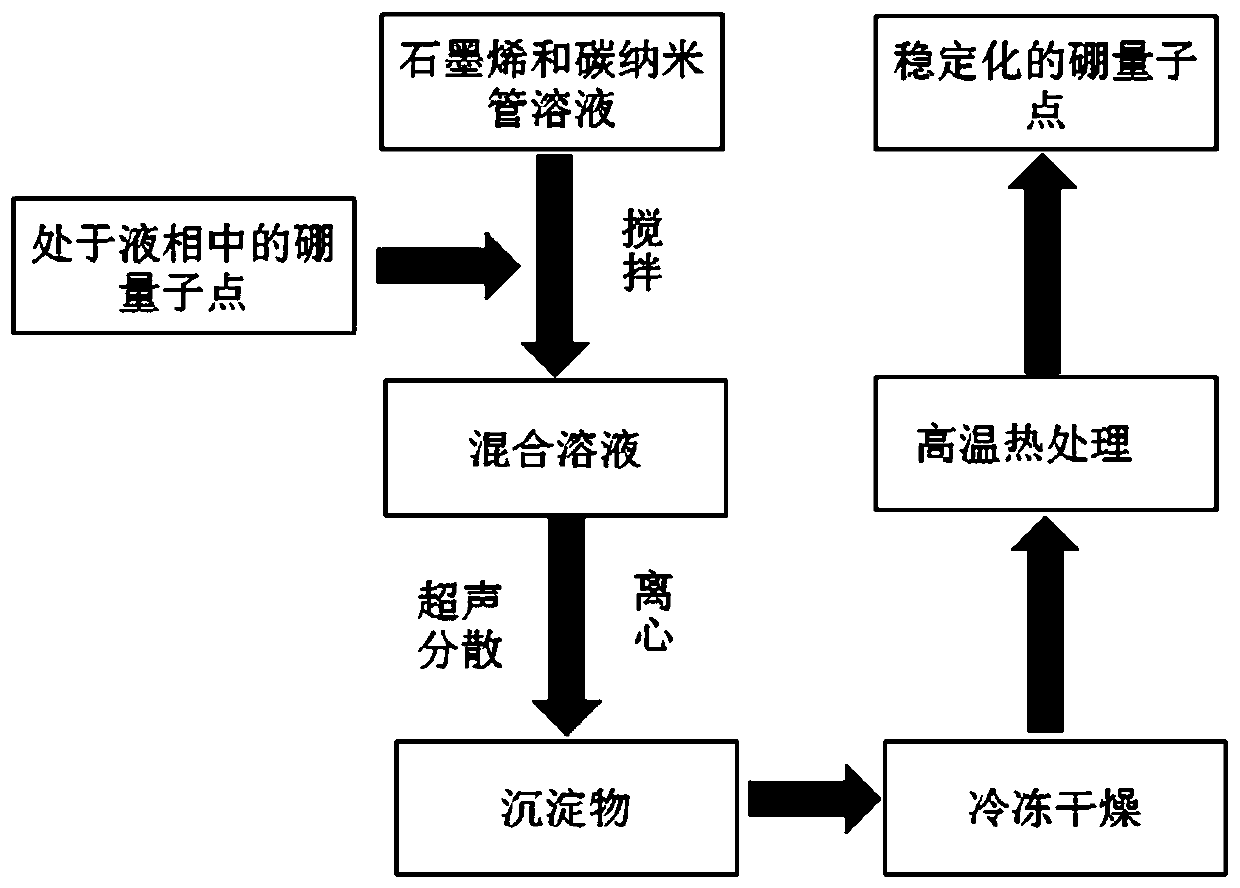

[0028] (1) Add the boron quantum dot solution with a concentration of 15 mg / mL dispersed in the liquid phase to the carbon nanotube and graphene solution with a concentration of 5-15 mg / mL;

[0029] (2) The solution in step (1) was stirred, ultrasonically broken, and then centrifuged at a centrifugal rate of 8000rpm for 20min to obtain a precipitate;

[0030] (3) freeze-dry the precipitate in step (2), the freeze-drying temperature is -52°C, and the duration is 10h, to prepare a composite boron quantum dot sample;

[0031] (4) Treat the freeze-dried sample in step (3) at high temperature in an inert environment, the maximum temperature is 500°C, and keep it warm for 2 hours, so that the boron quantum dots can stably exist in the carbon nanotubes and graphene.

[0032] Wherein the flow chart of above-mentioned boron quantum dot stabilization is as follows figure 1 As shown, the boron quantum dot solution in the liquid phase is added to the carbon nanotube and graphene solutio...

Embodiment 2

[0034] (1) Add the boron quantum dot solution with a concentration of 50 mg / mL dispersed in the liquid phase to the graphitized carboxyl multi-walled carbon nanotube solution with a concentration of 15 mg / mL;

[0035] (2) The solution in step (1) was stirred, ultrasonically dispersed, and then centrifuged at a centrifugal rate of 10,000 rpm for 40 minutes to obtain a precipitate;

[0036] (3) freeze-dry the precipitate in step (2), the freeze-drying temperature is -48°C, and the duration is 24h, to prepare a composite boron quantum dot sample;

[0037] (4) The freeze-dried sample in step (3) is subjected to high temperature treatment in an inert environment, the maximum temperature is 1000° C., and the temperature is kept for 5 hours, so that the boron quantum dots can stably exist in the graphitized multi-walled carbon nanotubes.

Embodiment 3

[0039] (1) Add the boron quantum dot solution with a concentration of 30 mg / mL dispersed in the liquid phase to the graphitized carboxyl multi-walled carbon nanotube solution with a concentration of 10 mg / mL;

[0040] (2) The solution in step (1) was stirred, ultrasonically dispersed, and then centrifuged at a centrifugal rate of 9000rpm for 30min to obtain a precipitate;

[0041] (3) Freeze-dry the precipitate in step (2), the freeze-drying temperature is -50°C, and the duration is 18 hours, to prepare a composite boron quantum dot sample;

[0042] (4) The freeze-dried sample in step (3) is subjected to high temperature treatment in an inert environment, the maximum temperature is 800° C., and the temperature is kept for 3 hours, so that the boron quantum dots are stably present in the graphitized multi-walled carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com