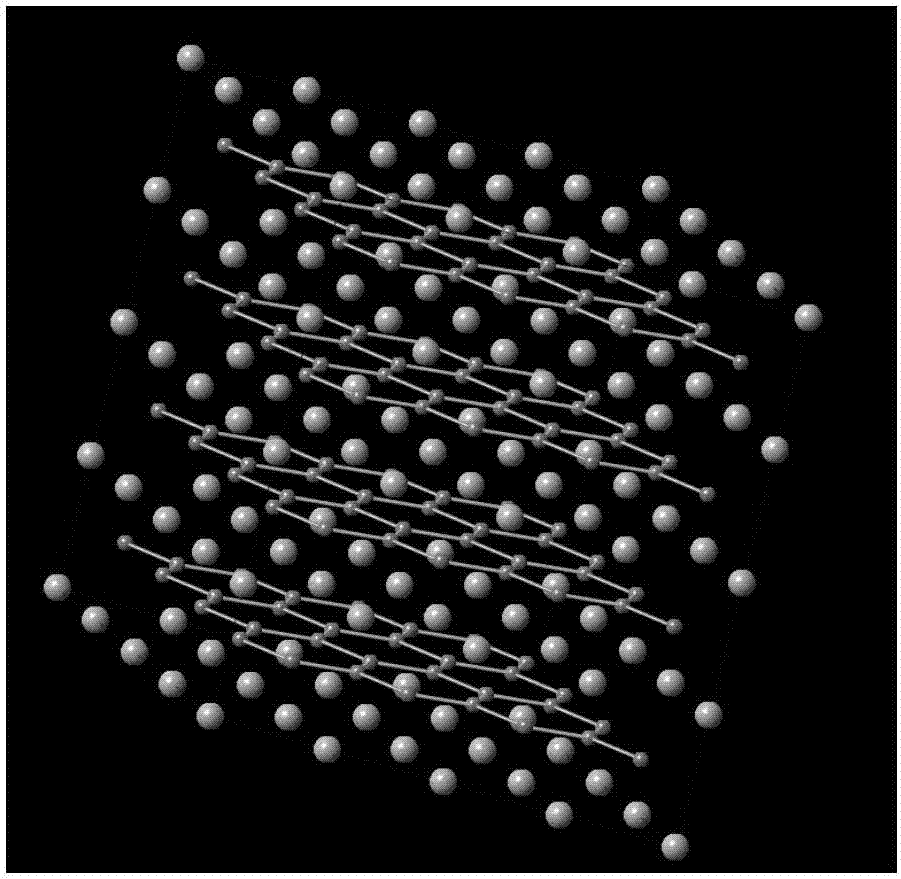

Method for preparing layered boron material through liquid phase method

A liquid phase method and layered technology, which is applied in the field of rapid preparation of boron materials by liquid phase method at room temperature and pressure, achieving the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

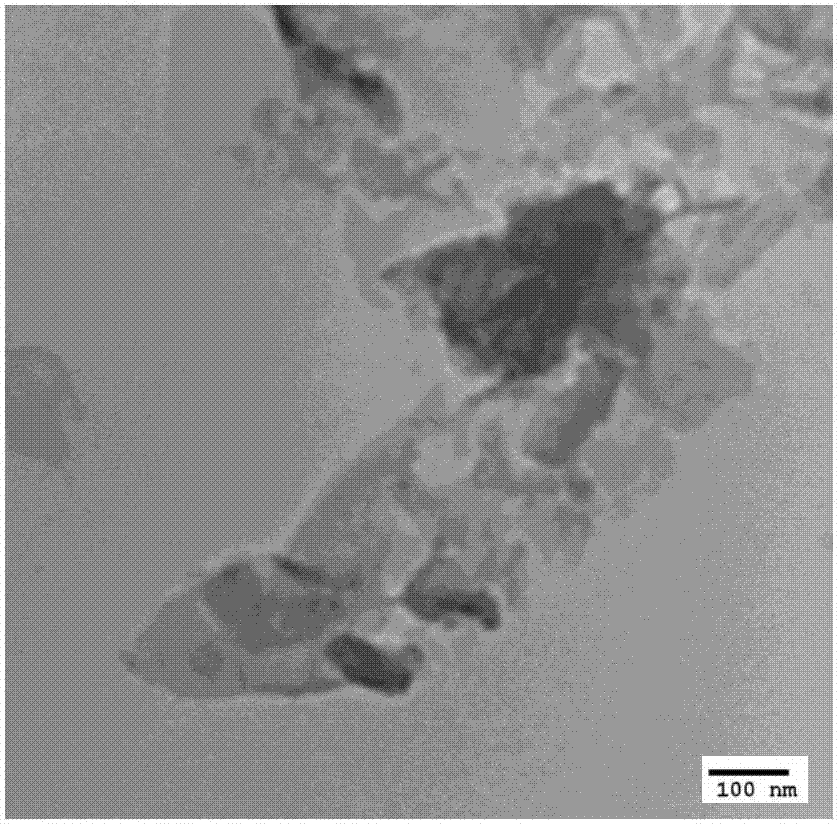

Image

Examples

Embodiment 1

[0026] Add 0.2 grams of magnesium boride powder into 10 milliliters of deionized water (reaction solvent), stir magnetically for 10 minutes, then add 10% dilute hydrochloric acid to wash and remove the magnesium hydroxide generated by the reaction, continue washing and drying to obtain the target The product layered boron material.

Embodiment 2

[0028] Except that the reaction temperature is increased to 120° C., the others are the same as in Example 1.

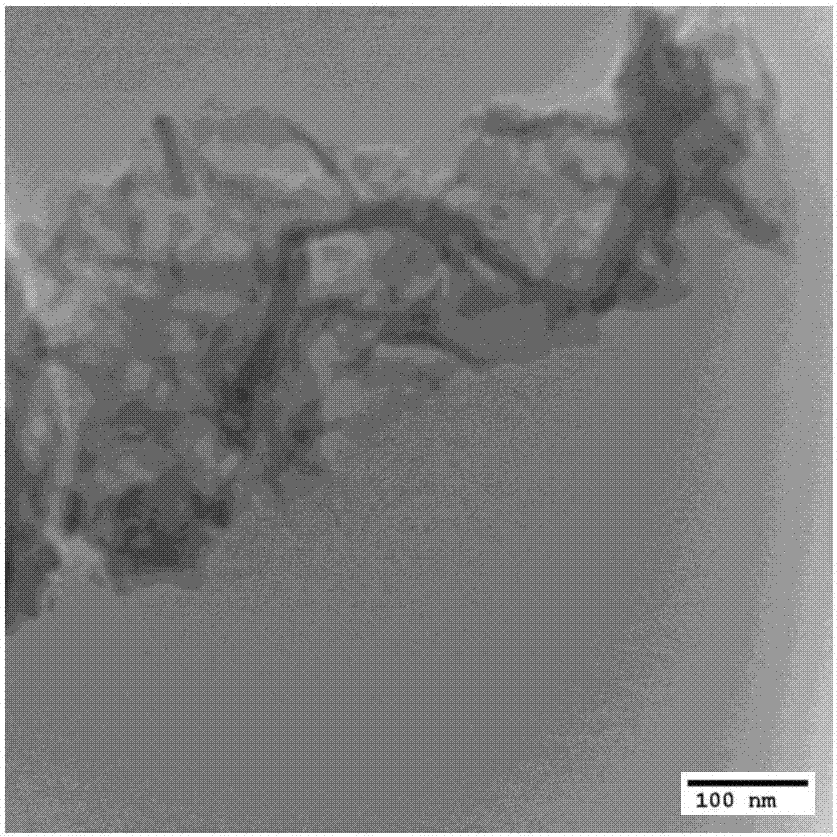

Embodiment 3

[0030] Except using the dilute hydrochloric acid of pH=1 as reaction solvent, other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com