Borophene nanosheet and preparation method thereof

A technology of nanosheets and boronene, which is applied in the field of boronene nanosheets and its preparation, can solve the problems that the product concentration is only a few milligrams per milliliter, the output of large-scale preparation has not been reached, and the process of boronene nanosheets is difficult. Ease of industrial scale-up production, easy batch preparation, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the boron nanosheets comprises the following steps:

[0037] The first is through liquid phase intercalation. In the present invention, the liquid phase intercalation is completed in two steps. First, the surface of the boron powder is infiltrated into the interlayer through a solvent similar to the surface energy of the boron powder. The second step is to use concentrated acid for intercalation. Different from the previous liquid-phase exfoliation, the present invention uses a two-step intercalation method. In the first step, a solvent with good wettability with boron powder is used to open the edge of the layer, and in the second step, the interlayer gap is further expanded by acid intercalation. The two-step intercalation method solves the problem that the interlayer spacing of the solvent with good wettability is small and the solvent molecules are easy to come out, and at the same time avoids the defect that the surface of the boron powder ...

Embodiment 1

[0046] A preparation method of boron nanosheets, the steps are as follows:

[0047] The first step is to add a certain amount of boron powder into the ethanol / DMP mixed solvent to prepare a dispersion liquid, and then use a 500W power ultrasonic instrument to carry out ultrasonication in a water bath, keeping the temperature not exceeding 30°C to obtain an ultrasonic mixture;

[0048] In the second step, the product obtained by filtering the ultrasonic mixture is added to concentrated acid to form a concentrated acid suspension, and then ultrasonicated in a 500W ultrasonic instrument, and then centrifuged and dried to obtain the intercalation product;

[0049] In the third step, the intercalation product is expanded by temperature programming to obtain expanded boron powder;

[0050] In the fourth step, the expanded boron powder is subjected to liquid phase exfoliation to obtain boronene nanosheets. The specific process parameters are shown in Table 1.

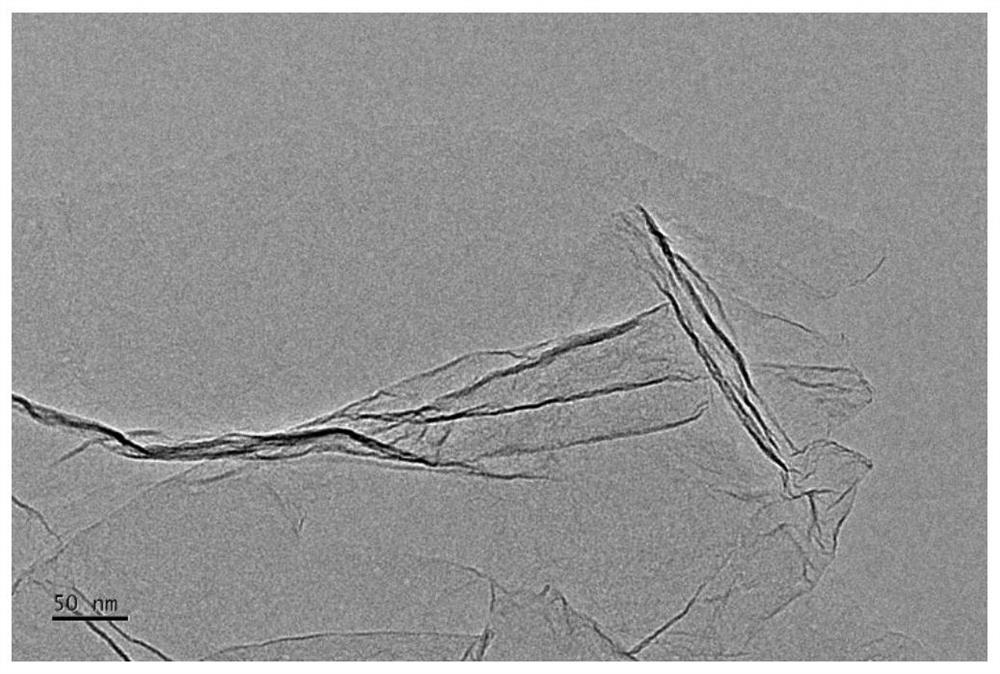

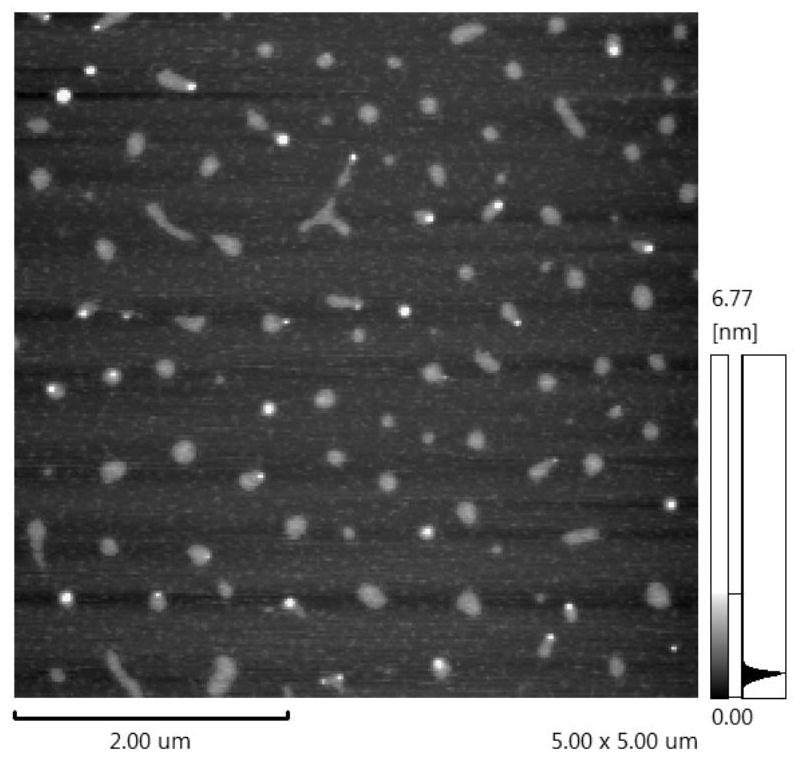

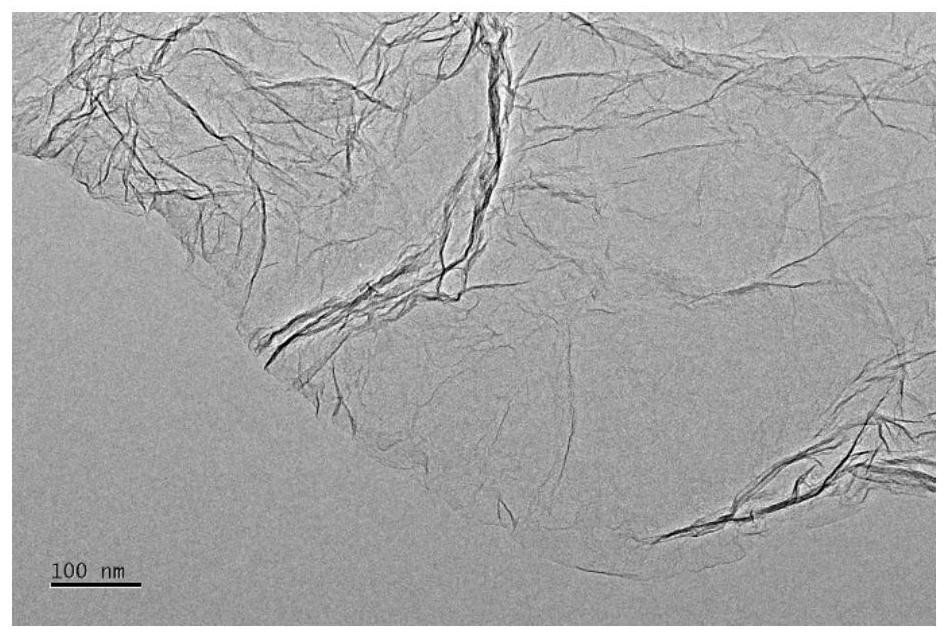

[0051] Characterizat...

Embodiment 2

[0053] A preparation method of boron nanosheets, the steps are as follows:

[0054] The first step is to add a certain amount of boron powder into the mixed solvent of isopropanol / DMF to prepare a dispersion liquid, and then use a 500W power ultrasonic instrument to carry out ultrasonication in a water bath, keeping the temperature not exceeding 30°C to obtain an ultrasonic mixture;

[0055] In the second step, the product obtained by filtering the ultrasonic mixture is added to concentrated acid to form a concentrated acid suspension, and then ultrasonicated in a 500W ultrasonic instrument, and then centrifuged and dried to obtain the intercalation product;

[0056] In the third step, the intercalation product is expanded by temperature programming to obtain expanded boron powder;

[0057] In the fourth step, the expanded boron powder is subjected to liquid phase exfoliation to obtain boronene nanosheets. The specific process parameters are shown in Table 1.

[0058] Charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com